Table of Contents

Advertisement

Advertisement

Chapters

Table of Contents

Summary of Contents for Shanghai Diesel Engine E Series

- Page 2 E 系列柴油机 使用保养说明书 Operation and Maintenance Manual E Series Diesel Engine 上海柴油机股份有限公司 Shanghai Diesel Engine Co., Ltd. 2012 年 8 月 August of 2012...

- Page 3 告诫 为降低人员受伤和财产损失的可能性,降低柴油机性能恶化及柴油机早期磨损或 损坏的可能性,请务必认真遵守本手册中所给出的安全须知和操作规范,尤其是操作 警告和注意事项。 本手册中给出的警告部分内容是必须严格遵循,否则会引起烧伤、截肢、致残、 窒息、其他人身伤害或死亡的可能;注意部分内容是提醒操作者必须按正确的方法操 作,以避免柴油机零部件损坏或柴油机性能恶化。这些“警告”和“注意”并不周全, 上海柴油机股份有限公司不可能,也不能给出违反这些安全须知和操作规范而产生的 所有潜在的危险后果。 未经上海柴油机股份有限公司书面许可,不得复制本出版物的任何部分,也不得 将其存储在检索系统中或以任何形式(无论是电子方式、机械方式还是复印方式)传 递。 产品报修、技术咨询、投诉与建议 产品报修、技术咨询、投诉与建议,请与上柴“易+人”呼叫中心联系,365×24 小时为您提供快捷、专业、真情的服务。全国免费服务热线 400-820-5656。 产品报修,请务必提供如下信息: 柴油机型号 柴油机订货号 柴油机机号 设备采购日期 较详细的故障描述 联系人地址与电话...

-

Page 4: Table Of Contents

目录 1 引言..............................1 1.1 致用户和操作者........................1 1.2 用户反映产品质量情况须知....................1 1.3 产品售后服务承诺........................1 1.4 安全须知........................... 1 1.5 柴油机使用注意事项....................... 2 2 柴油机概况............................3 2.1 柴油机外形..........................3 2.2 柴油机型号识别........................7 2.3 柴油机铭牌..........................7 2.4 柴油机技术规格........................8 3 柴油机使用............................10 3.1 燃油............................10 3.2 机油............................ -

Page 6: 致用户和操作者

E 系列柴油机使用保养说明书 1 引言 1.1 致用户和操作者 感谢您选择使用上海柴油机股份有限公司的柴油机产品! E 系列柴油机分为 10L 和 12L 两种排量,是我公司新开发的六缸大功率四气门柴油机。E 系列柴油机动力强 劲、油耗低,排放符合国家相关法规标准,是中高端汽车和工业设备等的理想配套动力。 本手册主要叙述该系列柴油机基本型的技术规格、使用操作和保养注意事项,以帮助用户熟悉本产品并正确 使用和保养本产品。用户在柴油机使用前应认真阅读本手册中的有关内容和要求。由于产品性能和结构在不断改 进,本手册中所列技术规格和图例说明与您在使用中的实物可能略有不同,我公司在今后再版时会不断予以补充 完善,不再专门通知用户,谨请注意。在本产品的使用保养中,如有任何疑问请随时联系上柴“易+人”呼叫中心 (400-820-5656) ,以获得技术咨询或技术指导。 上海柴油机股份有限公司(上柴公司)的产品采用最新技术和高质量零部件。维修保养时,建议使用上柴公 司品牌的服务备件。上柴公司授权的维修站遍布全国各地,提供维修服务和备件供应,维修人员经过专业培训。 1.2 用户反映产品质量情况须知 为便于我公司了解和分析产品质量问题及其产生故障的原因,及时改进产品质量,更好地为用户服务,谨请 用户在反映产品质量时说明下列事项: 1)发生故障的时间和地点; 2)柴油机出厂编号(机号) 、型号、订货号、发货日期、收货者确切地址; 3)柴油机使用条件、工作累计时间(小时数或公里数) 、工作状态(功率、转速) 、使用的燃油和机油牌号; 4)被驱动设备的特性(型号、消耗功率、结构特点等) ; 5)故障现象描述; 6)要求赔偿或检修的零件或部件,应随同损坏过程记录或说明寄到或带到本公司,以便进行分析。如用户发现问 题较多或问题特别严重时,应保持现场,并及时告知,我公司派员共同分析之。 对柴油机质量问题的处理按照质量保修手册有关规定。 1.3 产品售后服务承诺 为做好产品售后的服务工作,减小因产品出现质量问题给用户造成损失,上柴公司建立了... -

Page 7: 柴油机使用注意事项

E 系列柴油机使用保养说明书 柴油机上。 ●在起动刚修复的柴油机时,要作好切断空气供给的准备。一旦在柴油机起动后发生飞车现象时,立即断气停止 柴油机。 ●不得利用风扇部位盘动柴油机曲轴,否则会造成严重的人身伤害或风扇叶片损坏。 ●柴油机排气系统温度较高,不可用手触摸排气管等高温零部件。 ●在拆卸或松开任何管路、固定接头、接口或有关零部件之前,要先释放这些零部件所属系统的压力,如空气系 统、冷却系统、润滑系统或燃油系统中的压力。不可用手检查泄漏。高压高温燃油或润滑油会伤害人体。 ●当柴油机长期停车不用时或在维修时,应拆除柴油机与蓄电池的连接导线,以防止柴油机意外起动。 ●使用过的柴油机机油可能含有致癌成分,且能引起再生毒性。要避免吸入机油蒸汽或长时间与其接触。用适当 的、安全的、可靠的方法处理废油。 ●为防止窒息或冻伤,在拆除空调致冷剂(氟利昂)管路时,一定要穿戴防护衣并且必须在通风良好的环境中进 行。为保护环境,致冷系统必须使用专门的设备进行倒空或灌装,以防止氟利昂扩散到大气中。应回收和循环使 用致冷剂。 1.5 柴油机使用注意事项 ●认真阅读本手册,严格遵守本手册中规定的操作步骤及保养规程。 ●应严格遵守本手册规定,进行日常维护和四级保养,并做好定期保养记录。 ●应按本手册规定,使用恰当的燃油、润滑油和冷却液。 ●对新机或大修后的柴油机,使用前须经 60 小时磨合运行。磨合要求见 3.7 节。 ●不允许在不带空气滤清器情况下运行柴油机,以免柴油机发生早期磨损。 ●柴油机的冷却系统在任何气候下都应采用规定的冷却液。 ●在加注机油时,不同规格的润滑油不得混用。 ●起动柴油机前,应做好“起动前的准备”工作,切记柴油机必须空载起动。 ●起动柴油机前,必须检查冷却液、机油、燃油是否足够。禁止燃油箱内柴油很少的情况下运行柴油机,应及时 补充燃油箱内柴油,否则,容易造成喷油泵损坏。 ●柴油机运行时,应经常观察其运行状态和所有仪表的显示值。如遇紧急情况应采取紧急停车措施,防止因缺水 过热或机油压力过低而导致柴油机运动件咬合。 ●检查胶带张力及其它驱动装置时,柴油机应处于停车状态。 ●如调温器失灵应及时更换,不得随意拆除不用。 ●禁止私自拆下喷油泵上的铅封进行调整,否则极易引柴油机损坏、动力不足等故障。... -

Page 8: 柴油机概况

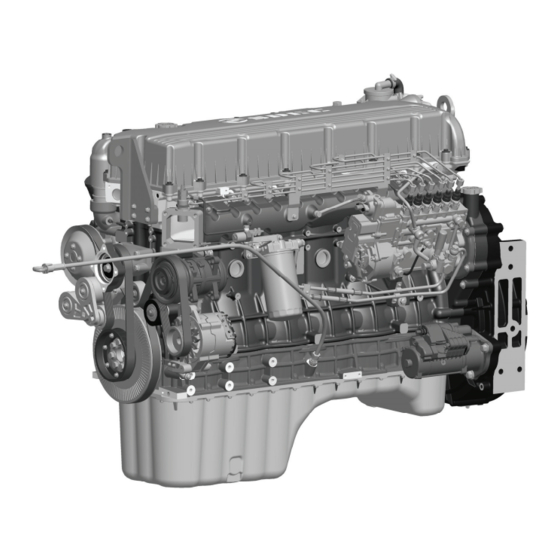

E 系列柴油机使用保养说明书 2 柴油机概况 2.1 柴油机外形 柴油机进气侧 1 油底壳 2 燃油滤清器 3 滤清器进油管 4 起动电机 5 飞轮壳 6 喷油泵 7 后吊环 8 喷油器回油管 9 喷油泵进油管 10 缸盖罩壳 11 高压油管 12 电磁阀进油管 13 燃油电磁阀 14 燃油电磁阀出油管 15 火焰预热塞 16 前吊环 17 进气管 18 机油尺... - Page 9 E 系列柴油机使用保养说明书 柴油机排气侧 1 机油滤清器 2 增压器回油管 3 油底壳放油螺塞 4 机油冷却器 5 放水螺塞 6 水泵组件 7 加油盖 8 增压器进油管 9 涡轮增压器 10 总回水管 11 排气管及隔热罩 12 空压机出水管 13 油气分离器 14 油气分离器出气管 15 油气分离器回油管 16 空压泵 17 空压机进水管...

- Page 10 E 系列柴油机使用保养说明书 柴油机前端 1 水温传感器 2 水泵胶带轮 3 张紧轮 4 风扇胶带轮 5 张紧轮 6 减震器部件 7 惰轮 8 空调压缩机胶带轮...

- Page 11 E 系列柴油机使用保养说明书 柴油机后端 1 飞轮...

-

Page 12: 柴油机型号识别

E 系列柴油机使用保养说明书 2.2 柴油机型号识别 柴油机型号表示下列含义: □ □ □ 排放标准:如 3 代表国Ⅲ 用途:Q—汽车;G—工程机械;D—发电 柴油机功率(马力) 系列 柴油机排量(L) 上柴动力 例:SC10E380Q3 代表上柴 E 系列 10 升四气门 380 马力国Ⅲ车用柴油机柴油机 2.3 柴油机铭牌 柴油机铭牌标明了您所购买的柴油机主要技术数据和信息:型号、订货号、机号、出厂日期、标定功率、标 定转速,是用户购买维修零件和我公司进行售后技术服务的主要依据。希望用户将这些信息和数据记录到您的柴 油机或所配设备的工作日志中。在日后联系维修和反映质量问题时,及时提供这些信息,有助于正确解决您所反 映的问题。请保护好标牌不受损坏。铭牌位于柴油机气缸盖罩壳侧面(进气侧) 。 注意:未经我公司许可,用户不得随意更换柴油机铭牌! -

Page 13: 柴油机技术规格

E 系列柴油机使用保养说明书 2.4 柴油机技术规格 2.4.1 基本参数 SC10E SC12E 柴油机 10.4 11.8 活塞总排量/L 形 式 直列、四冲程、水冷 缸径/mm 行程/mm 缸 数 每缸气门数 发火次序 1-5-3-6-2-4 (从自由端数起) 曲轴旋转方向 逆时针 (面向飞轮端) 起动方式 电起动 进气方式 增压中冷 燃油系统 机械式燃油喷射泵 1000 1090 净重/kg 1360 长/mm 外形尺寸 宽/mm (基本型) 1130 1155 高/mm... - Page 14 E 系列柴油机使用保养说明书 2.4.2 主要技术参数 SC10E SC12E 柴油机 润滑系统 机油压力/kPa 怠速时允许最低 标定转速时允许最低 标定转速时允许最高 油底壳容量/L 35-29 41-33 (油尺“高”-“低”) 系统总容量/L * 冷却系统 23.2 冷却液容量/L 进排气系统 允许最大进气阻力/kPa 7.2(新滤芯) 7.2(新滤芯) (标定工况,干式空气滤清器) 最大允许的排气阻力/kPa ** (涡轮出口压力) (标定工况) 电器系统 最小推荐的蓄电池容量/Ah *** 24V 系统: -18°C 蓄电池冷起动电流/CCA 起动电机 电压/V 功率/kW 发电机...

-

Page 15: 柴油机使用

E 系列柴油机使用保养说明书 3 柴油机使用 正确使用柴油机,不仅能保持柴油机工作正常、性能良好,而且会延长柴油机的寿命、降低使用成本。按本 章节的要求采用正确的燃油、机油和冷却液,采用正确的操作步骤。 3.1 燃油 柴油机使用的柴油应根据环境温度来确定牌号。在冬季气温低的环境下,应使用低凝固点的柴油,夏季则反 之。本柴油机采用的燃油规格应符合 GB 19147-2009 标准规定,燃油牌号使用地区按 GB 19147-2009 标准推荐。 用户也可按下表推荐来选用:例如,环境温度为-27℃时,应选用-35 号柴油。 柴油牌号与适用最低气温的关系 柴油牌号 0 号 -10 号 -20 号 -35 号 十六烷值 ≥49 ≥49 ≥46 ≥45 凝固点(℃) ≤0 ≤-5 4℃以上 -5℃以上 -14℃以上 -29℃以上 适用最低气温(柴油机工作环境温度... -

Page 16: 柴油机起动

E 系列柴油机使用保养说明书 3.4 柴油机起动 在使用柴油机之前,应根据具体的使用环境和条件,选用适当规格的机油、燃油和冷却液。起动前应做好如 下工作: •对柴油机及起动系统作一次环视检查,发现问题,及时解决。 •检查机油压力表、温度压力表、警示灯、以及其他仪表是否处于正常状态。 •检查空滤器保养指示器是否出现红色柱塞。 △注意:绝不允许不带空滤器起动柴油机(船用柴油机除外) ,以防柴油机早期磨损。 •检查燃油粗滤器保养指示器是否变红色。 •检查机油油面高度是否在规定的范围内。 •检查冷却液液面高度是否在规定的范围内。 •检查电解液液面高度是否在规定的范围内。 •如果柴油机已有多日停止工作,或者刚刚更换过燃油滤清器,燃油系统内可能有空气。必要时对燃油系统泵油排 气,具体操作见 4.3 节中燃油系统泵油排气。 •检查电起动线路是否处于正常状态。 •所有安全防护装置必须安装就位。 •检查油门踏板动作是否灵活。 3.4.1 常规起动步骤 •使柴油机与传动装置脱离或将变速箱置于空挡位置。 •机械操纵装置等处于运转位置。 •插入电钥匙,将开关从 OFF 位置转到 ON 位置,接通电子控制器和其他电器。 •待进气预热器指示灯熄灭后将开关从 ON 位置转到 START 位置。如有进气预热,指示灯亮;如没有进气预热,指 示灯不亮。对车用柴油机,起动时需要踏油门。 △注意:为防止损坏起动电机,起动时间不得超过 15 秒,两次起动之间应间隔 2 分钟。 每次起动时间一般为... -

Page 17: 柴油机运行

E 系列柴油机使用保养说明书 子控制器控制。 电子控制器根据环境温度决定是否启动进气加热。进气加热分为 2 个阶段:起动前的进气预热和起动后的进 气加热。在预热过程中一般不允许起动柴油机,若起动则预热停止,待预热完成后方可起动。 •起动前先插入电钥匙并从 OFF 位置转到 ON 位置,接通预热辅助装置电路,此时指示灯亮,进气预热开始;进气 预热结束,预热灯闪烁,告知柴油机可以起动。 •待预热灯熄灭后,将电钥匙从 ON 位置转到 START 位置起动柴油机。起动成功后,开关自动回位到 ON 位置。 •起动后的进气加热(第 2 阶段加热)开始,时间由电子控制器控制,期间预热灯不亮。 起动后的其他事项按按 3.4.1 节“常规起动步骤”规定。 注:若指示灯开始闪烁后 30S 未进行起动操作或起动不成功,电子控制器将自动切断预热回路、电磁阀回路 和指示灯回路,进入延时保护。若再要起动,需将电钥匙退回到 OFF 位置,停留 5 秒后重复上述过程。 3.4.3 长时间停车或更换机油后的起动 每当更换机油后或停车时间大于 30 天时,起动柴油机前,必须先检查机油液面是否在油尺刻线范围之内,并 给燃油系统泵油排气,具体操作见第 4.3 节,然后按常规起动或低温起动程序起动柴油机。 3.5 柴油机运行... -

Page 18: 新柴油机或大修后柴油机的磨合

E 系列柴油机使用保养说明书 柴油机如需停用一段时间,需要做好保存工作,具体见第 6 章柴油机停运后保存。 3.6.2 紧急停车 在紧急或特殊情况下,为避免柴油机发生严重事故可采取紧急停车。此时用手拨动紧急停车手柄,即可达到 目的。 3.7 新柴油机或大修后柴油机的磨合 新的或大修后的柴油机,在正式使用前须经 60 小时或约 2000 公里的磨合并更换机油后,方可投入全负荷使 用,以改善柴油机各运动部件的工作状况,提高柴油机的运行可靠性和延长使用寿命。磨合应视柴油机用途和拖 载方式的不同,考虑具体磨合方案。原则上随着磨合时间的增加分阶段逐步提高柴油机的转速和负载。在整个磨 合期内负荷应是标定功率的 50~80%,转速应不大于标定转速的 80%。 柴油机在磨合期及磨合后的正常工作期,均不宜长时间处于怠速运行或低负荷运行。柴油机怠速连续运行时 间一般不宜超过 5 分钟,以避免因积碳而引起早期磨损或影响柴油机性能。... -

Page 19: 柴油机保养

E 系列柴油机使用保养说明书 4 柴油机保养 4.1 柴油机保养计划 下表给出了本系列柴油机保养周期及保养内容。用户应根据本表规定进行定期保养。若柴油机经常在环境温 度低于-18℃或高于 38℃情况下运行,或者在多尘环境或频繁停车情况下运行,须适当缩短保养周期。 每 10000 公里 每 20000 公里 每 40000 公里 每 80000 公里 日常 或每 250 小时 或每 500 小时 或每 1000 小时 每 2000 小时 保养内容 保养 或每 3 个月 或每 6 个月 或每... -

Page 20: 柴油机保养记录

E 系列柴油机使用保养说明书 4.2 柴油机保养记录 用户应做好定期保养记录。用户可参考下面提供的“保养记录”格式,编制自己的保养记录本。 保养记录 柴油机编号________________________柴油机型号/订货号________________________ 用户名称__________________________设备名称/编号____________________________ 公里(小时) 日期 或 实际里程 保养内容 保养者 备注 时间间隔... -

Page 21: 柴油机保养内容及方法

E 系列柴油机使用保养说明书 4.3 柴油机保养内容及方法 检查柴油机外围 每天在柴油机起动前进行柴油机外围检查,内容如下: •检查柴油机及散热器上有无揩布、废电线、管夹、螺钉等杂物堆积,保持柴油机清洁、整齐。 •检查燃油系统、冷却系统、润滑系统各处接头、密封面有无泄漏。 •检查风扇连接和安全护罩是否安全可靠到位。 •检查附件紧固情况。 •检查电气线路接头是否松动,导线是否完好。 •检查传动胶带是否完好。 检查燃油箱 每天检查燃油箱油面。 检查空气滤清器保养指示器 按钮 每天检查空气滤清器上的保养指示器,如果检视窗 口显示红色,表示空滤器进气阻力超过规定值,需 要更换滤芯。滤芯更换后,必须按下保养指示器端 部上的按钮,使其复位。 △注意:更换空气滤清器滤芯后,确保空气滤清器两端面可靠密封,不得漏气。 △注意:绝不允许不带空气滤清器情况下起动柴油机。否则极易造成柴油机早期磨损。 检查燃油粗滤器保养指示器 每天检查燃油粗滤器保养指示器。当粗滤器杂质累 保养指示器 计已达到一定程度,造成输油泵泵油困难,此时滤 清器上的保养指示器显示红色,提醒用户需要更换 燃油粗滤器。如果粗滤器使用 250 小时后,指示器 未出现红色,根据保养规定,也必须更换。燃油粗 滤器也是旋入式的,更换步骤与燃油精滤器,参见 燃油精滤更换。 燃油粗滤器 检查机油油面 应每天在柴油机起动前或停车状态时 (停车后至少 15 分钟)检查机油油面,以使机油有充分的时间流回油 底壳。机油油面高度应在油尺上的下刻线(低油位) 和上刻线(高油位)之间。如果机油量不足,应添加... - Page 22 E 系列柴油机使用保养说明书 检查冷却液液面 ▲警告:柴油机工作时,其冷却液温度较高且有压力,容易引起烫伤。待柴油机停车并且冷却液温度下降至 50℃以下,慢慢旋松压力盖释放压力后才能进行冷却液液面检查或添加。 ▲警告:冷却液中的防锈剂含碱,应避免其与皮肤和眼睛接触,以防伤害。 车用柴油机 每天在柴油机起动前或停车状态检查膨胀水箱内冷却 液液面高度。冷却液液面应保持在刻线上限(MAX) 膨胀水箱 和下限(MIN)液面之间,必要时添加,添加至接近上 刻线。 非车用柴油机 (1)在柴油机起动前或停车后冷却液温度下降至 50℃以下后,慢慢旋开散热器或膨胀水箱上的冷却液加液盖以 释放压力。 (2)从加液口或液面检查口检查冷却液液面高度,应在上下刻线内或满足车辆或设备制造商的规定。 (3)必要时添加。添加至接近上刻线或满足车辆或设备制造商的规定。 △注意:添加冷却液时应慢慢注入,以防产生气阻。 检查电解液液面 (1)每天卸下加液盖,查看电解液液面。卸下加液 盖,电解液液面应在加注口底部。如果液面不足, 应按要求补充。 (2)装上加液盖。 检查传动胶带 每天目视检查传动胶带。检查胶带是否有纵横交叉 的裂纹。沿胶带宽度方向的横向裂纹是允许的。但 不允许出现纵向(沿胶带长度方向)和横向贯穿的裂 纹。若胶带磨损或出现材料剥落也应予更换。 检查冷却风扇 每天用肉眼检查风扇有无裂纹等缺陷。应确保风扇安装可靠。必要时应拧紧紧固螺栓,或更换损坏的风扇。 ▲警告:风扇叶片损坏会造成伤人的严重事故。绝不允许拖拉和撬动风扇,更不能借风扇转动柴油机曲轴。...

- Page 23 E 系列柴油机使用保养说明书 检查进气系统 检查进气胶管是否有裂缝或穿孔,夹箍是否松动。如有发现进气胶管失效应予以更换,发现夹箍松动应拧紧 夹箍螺钉,确保进气系统不漏气。 更换机油和机油滤清器 ▲警告:在更换机油和机油滤清器时要注意安全,与热机油和柴油机表面接触会引起皮肤烫伤。 (1) 待柴油机运转至冷却液温度达到 60°C 时停车, 拆下油底壳放油螺塞,报废垫片,放尽机油。 注:某些配套油底壳有 2 个放油螺塞,一个在大油 池底部,一个在小油池侧面。 放油螺塞 △注意:不要在柴油机冷态时泄放机油。因为在冷态时,悬浮在机油中的杂质颗粒已沉积到油底壳底部并粘 附在油底壳内部表面上,不能随机油一起排出。机油温热时杂质颗粒悬浮在机油中,此时泄放机油,杂质颗粒易 排出。 (2)清洁放油螺塞安装面,更换新垫片,安装放油螺塞,拧紧螺塞至 80 N·m。 (3)清洁机油滤清器外表面,用工具拆下机油滤清器并报废。 (4)清洁滤清器座密封面,不得有旧的 O 型密封圈残留。 (5)安装新的机油滤清器前,对 SC12E 柴油机,应从 滤清器周边 8 个小孔注入清洁的机油,注满滤清器内 腔,油面离螺纹孔下端 3-15mm。并在密封圈密封表面 上涂一薄层干净的机油,用以形成润滑膜。 △注意:不得从滤清器中心的孔注入机油。 对 SC10E 柴油机,只需在密封圈密封表面上涂一薄层 干净的机油,用以形成润滑膜。因滤清器是横置的,...

- Page 24 E 系列柴油机使用保养说明书 (7)打开加油口盖,用清洁的机油注入柴油机至接 近油尺上刻线(高油面记号) 。 加油口 加油口 缸盖罩盖 本柴油机系统机油容量 40 L(SC10E) 45 L(SC12E) 后齿轮室 (8)起动柴油机并怠速运转,检查机油滤清器和放油螺塞是否漏油。 (9)停车,约等 5 分钟让机油有充分的时间流回油底壳,然后检查机油液面高度。如需添加,添加至接近油尺上 刻线(高油面记号) 。 (10)安装加油口盖,手感拧紧即可。 注:若装有转子滤清器,在更换机油滤清器时需同时更换转子滤清器转子。其更换方法如下: (1)停机,确保转子滤清器在操作前完全停止运行。 转子盖 (2)待柴油机冷却到手感不烫时,用工具松开转子滤清 器罩盖下方的 2 个锁紧螺栓,将滤清器罩盖移开。注意 螺栓 检查罩盖 O 型密封圈,如有损坏须立即更换。 (3) 沿着转子滤清器的立轴向上抬起转子, 把转子内部的 油放掉。然后把转子沿立轴垂直向上进行拆卸。拆卸时应 注意不要损伤转子的轴承。 (4) 将全新的转子装入中心轴, 并检查转子能否自由转动。 (5)装上...

- Page 25 E 系列柴油机使用保养说明书 (4)手旋动滤清器直到密封圈接触到安装面,然后拧紧至 40-50 N·m。 燃油系统泵油排气 柴油机更换燃油滤清器(精滤、粗滤)后或已有多日停止工作,空气会进入燃油系统,需要按以下步骤排气: (1)松开燃油粗滤器上的排气螺栓。 (2)反复按输油泵上手揿泵进行泵油排气,直到从放气 螺栓 螺栓处流出的柴油中没有气泡为止。 手揿泵 (3)拧紧放气螺栓。 △注意:没有及时加燃油,导致空气进入燃油系统,或者其它因素导致燃油系统有空气,均需要排除空气。 燃油粗滤器放水 粗滤器有油水分离功能。当粗滤器上水储存罐中的水位 达到一定高度时,水位传感器将信号提供给装在驾驶室 的水位指示灯,提醒驾驶员及时排水。旋松放水阀门, 排除水和沉淀物,直到清洁的燃油流出为止,然后再关 紧阀门。不要用力拧紧,手感紧即可。 放水阀 检查空气滤清器滤芯 检查空滤器滤芯是否破损。检查前先清洁滤芯。 ▲警告:在使用压缩空气时,应做好防护。压缩空气最高压力应不超过 205 kPa。不要用硬物碰撞 或敲击的办法来清洁滤芯。清洁后应检查滤芯。不得使用有褶纹、密封垫或密封圈损坏的滤芯。 (1)用压缩空气沿着褶纹长度方向吹洗内部。 (2)用压缩空气沿着滤芯褶纹长度方向吹洗外 部,再沿着滤芯褶纹长度方向吹洗内部。...

- Page 26 E 系列柴油机使用保养说明书 (3)在清洁后的滤芯内放置检查灯进行检查。根据 透光情况来判断滤芯是否有破洞或撕裂。如有则更 换新的滤芯。 检查中冷器 用肉眼检查中冷器进出气室是否有裂缝、穿孔或其他损坏,检查进出气管是否有裂缝、脱焊及其他损坏。如 有,应予以更换。 调整气门间隙 新柴油机和大修后投入使用的柴油机,在首保时,进行第一次气门间隙检查,以便及时调整和纠正间隙的初 期变化。在其后的正常运转期间,按保养计划检查和调整。 气门间隙检查在柴油机停止运转并冷却至 60℃以下后进行。 (1)拧松气缸盖罩壳紧固螺栓,拆下罩壳。 (2)用盘车工具转动曲轴,使柴油机处于第 1 缸活塞压 缩上止点位置。 注:当指针对正减振器 0 位刻线,并且凸轮轴齿轮缺口朝 上时,为第 1 缸活塞压缩上止点。 凸轮轴齿轮缺口 (3)用塞片检查第 1、 第 2 和第 4 缸进气门间隙, 第 1、 第 3 和 5 缸排气门间隙。 注:用间隙塞片检查间隙时,塞片在气门桥杆顶面与摇 臂之间移动时手感有点阻力,即为正确的气门间隙。...

- Page 27 E 系列柴油机使用保养说明书 (5)拧紧调节螺母至 40 N·m,复查该气门间隙,间隙数值不应有变化。 气门间隙: 进气门……………………0.40±0.08 mm 排气门……………………0.65±0.08 mm (6)在减振器做上标志,然后旋转曲轴一周(360°) ,以同样的步骤调整其余的进排气门间隙。 (7)安装气缸盖罩壳,检查罩壳密封条是否完好,如有破损,则更换新的。将罩壳螺栓拧紧至 18 Nm。 检查胶带张紧轮 (1)顺时针旋转张紧轮,拆下传动胶带。转动张紧轮 带轮,检查张紧轮是否有卡滞或径向/轴向窜动,以此来 确定张紧轮轴承表面是否划伤或磨损;摆动张紧轮张 臂,检查其弹簧工作性能是否良好。 (2)安装传动胶带,然后目测和调整,确保胶带中心 处于各胶带轮中央。 检查风扇轴承 顺时针旋转胶带张紧轮,拆下传动胶带。手动转动风扇 皮带轮检查转动轴轴承是否有异常。转动风扇时不得有 振动和过大的轴向窜动现象。 检查增压器 目视检查增压器涡轮叶片和压缩机叶片是否损坏或有裂纹,手指轻压叶片,叶片是否会与涡轮壳或压气机壳 接触,增压器转轴转动是否不灵活自如。如发现上述问题,需要更换增压器。 检查减振器 检查减振器是否有减振液(硅油)泄漏、减振器表面是否塌陷;检查减振器厚度以确定减振器是否变形。如 发生上述问题,需要更换减振器。 检查空气压缩机 ▲警告:空气系统内的空气有一定的压力。在拆卸空气压缩机上零部件前,必须先释放空气系统内的压力, 以免人员受伤。 检查空气压缩机出气管 检查管路及管接头的积碳情况,视积碳程度的轻重分别 采取清洗或更换的措施。...

- Page 28 E 系列柴油机使用保养说明书 检查空气压缩机进气卸载阀 仔细检查卸载阀是否积炭, 若严重积炭,应清除并清洗干净。并应检查空压机缸头 和进、排阀部件,必要时更换有关部件。 更换冷却液 为确保柴油机冷却液的冷却和防蚀效果,必须每 80000 公里、或每 2000 小时、或每 2 年(先到为准)更换冷 却液。更换冷却液时须清洗冷却系统。 ▲警告:在工作温度下,柴油机冷却液温度较高且有压力。蒸汽能引起人身伤害。只有在柴油机停止工作后, 待冷却液温度降至 50℃以下,才可慢慢拧开散热器上压力盖释放压力。 ▲警告:冷却液内防锈剂含碱,应避免皮肤和眼睛与其接触,以防人身伤害。 (1)待柴油机停车冷却液温度下降至 50℃以下,慢慢旋松散热器上压力盖以释放压力,卸下压力盖。旋开散热 器的放水阀,放净冷却系统中所有冷却液。 (2)拧松并拆下柴油机上的放水螺塞,放尽冷却系统 中所有冷却液。 放水螺塞 (3)下列步骤清洗冷却系统 (a)装上并拧紧所有放水阀和放水螺塞,从散热器加水口处将碳酸钠水溶液(或在市场上能买到的碳酸钠与 水的混合物)加入冷却系统。 △注意:每 23 L 水用 0.5 kg 碳酸钠混合。不得用含腐蚀剂的清洗剂,否则会损坏铝制零件。 △注意:在灌注清洗液过程中必须将冷却水腔中空气排出,且慢慢注入,以防止产生气阻,清洗液需加至散 热器加水口底面,等待 3-5 分钟,让空气充分排出。 (b)起动柴油机,等清洗液温度升到 80℃以上后运转 5 分钟,然后停车并放尽冷却系统中的清洗液。 △注意:冷却系统清洗整个过程中,不安装散热器加水压力盖,并在不加水盖的情况下运行柴油机。...

- Page 29 E 系列柴油机使用保养说明书 本柴油机冷却液容量 22 L(SC10E) 23.2 L(SC12E) △注意:表中容积值仅指本柴油机系统容积。实际添加量以整车数据或设备数据为准。 △注意:加注冷却液时,须慢慢注入,以防止产生气阻,冷却液需加至散热器加水口底面或符合车辆或设备 制造商的要求,等待 3-5 分钟,让空气充分排出。 (6)安装压力盖,起动柴油机,直至水温到达 80℃,然后停车检查冷却系统是否泄漏。 (7)停车后待冷却液温度降至 50℃以下,打开散热器加水口压力盖,复查冷却液液面,如有必要,再补注适量 冷却液。...

-

Page 30: 柴油机故障排除指南

E 系列柴油机使用保养说明书 5 柴油机故障排除指南 5.1 故障排除指南 下表列出了柴油机使用中一些简单典型的失效故障模式、可能原因及故障排除步骤。柴油机在运行中若出现 其中任何一个征兆,用户都应采取适当方法予以排除,否则有可能酿成柴油机的大的事故。用户可按照可能原因 的排列顺序(即查找步骤)查找原因,自行排除简单的故障,复杂故障需要联系上柴“易+人”呼叫中心 (400-820-5656) ,以获得技术指导或专业的维修服务。 序号 故障模式 序号 故障模式 发电机不充电或充电不足 柴油机敲缸 起动系统故障 柴油机噪声过大 柴油机不能起动或起动困难 柴油机冒黑烟 柴油机能起动,但不能保持运转 柴油机冒白烟 柴油机在低转速下易熄火 柴油机冒蓝烟 柴油机发火不良或转速不稳定 燃油消耗量过高 柴油机功率不足 冷却液温度高于正常情况—柴油机逐步过热 负荷情况下不能达到额定转速 冷却液温度高于正常情况—柴油机突然过热 柴油机工作粗暴或缺火 冷却液温度低于正常情况 柴油机意外停机或减速时熄火 冷却液污染 柴油机加速性能差 机油压力过高 柴油机无法停机 机油压力过低 柴油机怠速时运行粗暴 机油污染... - Page 31 E 系列柴油机使用保养说明书 故障模式 3:柴油机不能起动或起动困难 可能原因 排除方法 起动方法错误 参看车辆或设备使用说明书 起动时间约2-3秒 属于正常情况,不用调整 驱动装置合上 脱开驱动装置 起动速度太低(最低起动速度 100 转/分) 检查蓄电池电压, 检查起动电机接头是否松动或腐蚀 燃油箱内燃油不足 添加燃油 燃油系统中有空气 检查泄漏源,必要时拧紧燃油接头、油管夹箍,或更 换燃油接头、油管,然后给燃油系统泵油排气 燃油低压管路接头松动 检查燃油低压管路,拧紧所有低压管路接头 燃油滤清器或燃油吸油管堵塞 更换燃油滤清器或燃油吸油管 天冷燃油结蜡 根据使用环境,选择本手册规定的适合燃油 燃油泵中没有燃油 检查输油泵,必要时,联系上柴“易+人”呼叫中心 进气系统阻力超过规定值 检查进气系统,必要时更换空滤器滤芯 排气系统阻力不符合要求 检查排气系统 曲轴旋转受阻 柴油机盘车, 检查曲轴受阻情况, 必要时联系上柴 “易 +人”呼叫中心 喷油泵静态供油提前角不正确...

- Page 32 E 系列柴油机使用保养说明书 故障模式 6:柴油机发火不良或转速不稳定 可能的原因 排除方法 燃油箱中燃油偏少 添加燃油 燃油系统内进入空气 检查泄漏源,必要时拧紧燃油接头、油管夹箍,或更 换燃油接头、油管,然后给燃油系统泵油排气 燃油压力低 检查油箱内是否有油, 检查油箱至输油泵之间油管有 无漏油、严重变型、弯曲或有脏污引起阻塞,管内是 否有气泡。必要时,联系上柴“易+人”呼叫中心 高压油管接头处漏油 拧紧接头,如果接头螺纹已损坏,应更换相关零件 喷油泵供油提前角不正确 按 5.2 节给出的步骤检查并调整喷油泵供油提前角 气门间隙不正确 检查并调整气门间隙 联系上柴“易+人”呼叫中心 故障模式 7:柴油机功率不足 可能的原因 排除方法 询问驾驶员或操作者 获得所有与问题相关的信息 超载运行 减少载荷至许用范围 车辆或柴油机在超过规定的高原上行驶或运行 在规定的高原上行驶或运行,随着海拔升高,功率会 相应变小 柴油机驱动系统若已更换,与柴油机不匹配 检查驱动系统齿轮传动与柴油机是否匹配 机油油位超过规定值 检查并调整至规定的油位范围内 油门踏板没有到底...

- Page 33 E 系列柴油机使用保养说明书 故障模式 8:负荷情况下不能达到额定转速 可能的原因 排除方法 负荷过大 降低车辆或设备负荷或换成低档 车辆驱动系统更改,导致其与柴油机不匹配 检查驱动系统与柴油机匹配情况 转速表故障或转速传感器故障 检查转速表和转速传感器,必要时更换 燃油进油阻力大 检查燃油滤清器及燃油吸油管路, 必要时更换滤清器 增压器故障 检查增压器,必要时联系上柴“易+人”呼叫中心 进气系统泄漏 检查进气管、中冷器及其管路连接是否松动、泄漏 进气系统阻力超过规定值 检查进气系统阻力,必要时更换空滤器滤芯 燃油规格不符使用要求或油品差 使用本手册规定的燃油, 用临时油箱盛放品质好的燃 油开车验证 联系上柴“易+人”呼叫中心 故障模式 9:柴油机工作粗暴或缺火 可能的原因 排除方法 仅发生在怠速时 参见故障诊断“冷却液温度低于正常情况” 柴油机运行温度低 参见故障诊断“冷却液温度低于正常情况” 气门调整错误 调整气门间隙 联系上柴“易+人”呼叫中心 故障模式 10:柴油机意外停机或减速时熄火 可能的原因 排除方法...

- Page 34 E 系列柴油机使用保养说明书 故障模式 12:柴油机无法停机 可能的原因 排除方法 柴油机吸入油雾 检查柴油机进气管,隔离油雾源 外部供电电压 检查并确认没有外部电压电路连接到车辆或设备的 电源电路上 增压器机油密封不良,漏油 检查压气机出气口、空气接管是否有机油痕迹 联系上柴“易+人”呼叫中心 故障模式 13:柴油机怠速时工作粗暴 可能的原因 排除方法 柴油机温度过低 让柴油机升温 怠速负荷过大(大于50马力) 降低怠速负荷 中冷器或中冷器管路有泄漏 检查中冷器及管路 进气管漏气 检查进气管 柴油机支撑问题 检查柴油机支架和缓冲垫 发电机故障 临时断开发电机,测试柴油机 气门间隙不对 调整气门间隙 联系上柴“易+人”呼叫中心 故障模式 14:柴油机怠速不稳、游车 可能的原因 排除方法 燃油系统中有空气 检查低压管路,排除泄漏源,必要时拧紧或更换接头 和低压油管,然后给燃油系统泵油排气 联系上柴“易+人”呼叫中心...

- Page 35 E 系列柴油机使用保养说明书 故障模式 17:柴油机噪声过大 可能的原因 排除方法 传动胶带张力不足或负荷过大 检查张紧轮工作情况,必要时更换;检查各带轮是否 转动自如 进气和排气泄漏 检查进排系统泄漏情况,拧紧已松动的零部件,必要 时更换相关零部件 增压器噪声 检查叶轮和涡轮是否与壳体相碰 喷油泵供油提前角不正确 按5.2节给出的步骤检查并调整喷油泵供油提前角 气门间隙太大 检查并调整气门间隙 联系上柴“易+人”呼叫中心 故障模式 18:柴油机冒黑烟 可能的原因 排除方法 柴油机过载 使用低速排挡或减低设备负荷 进气系统阻力超过规定 检查进气系统阻力,必要时更换空滤器滤芯 喷油泵供油提前角不正确 按5.2节给出的步骤检查并调整喷油泵供油提前角 进气门或排气门间隙错误 调整气门间隙 燃油不符合使用要求或油品差 使用本手册规定的燃油, 用临时油箱盛放品质好的燃 油开车验证 联系上柴“易+人”呼叫中心 故障模式 19:柴油机冒白烟 可能的原因 排除方法 柴油机处于冷态...

- Page 36 E 系列柴油机使用保养说明书 故障模式 21:燃油消耗量过高 可能的原因 排除方法 驾驶员的操作技术 检查驾驶员换挡、减速和怠速操作 里程表显示错误 调整里程表 驱动系统与柴油机匹配不正确 检查车辆齿轮,确认柴油机及驱动系统零件无误 燃油泄漏 检查燃油系统的管路密封性,如有松动则拧紧 进气或排气阻力过大 检查进排气系统,特别是空滤器、排气消声器,必要 时联系上柴“易+人”呼叫中心 机油油位过高 检查机油油面,调整机油油量 喷油泵供油提前角不正确 按5.2节给出的步骤检查并调整喷油泵供油提前角 进气或排气门密封不良 检查并调整气门间隙 燃油品质差 使用本手册规定的燃油, 用临时油箱盛放品质好的燃 油开车验证 联系上柴“易+人”呼叫中心 故障模式 22:冷却液温度高于正常情况—柴油机逐步过热 可能的原因 排除方法 柴油机过载运行 减少负载运行 冷却液液位过低 检查冷却液液面和泄漏情况,排除泄漏,添加冷却液 至规定范围 机油油面过高或过低 检查机油油面,调整至规定范围 散热器叶片堵塞或损坏 检查散热器叶片,必要时修理或更换...

- Page 37 E 系列柴油机使用保养说明书 故障模式 24:冷却液温度低于正常情况 可能的原因 排除方法 散热器百叶窗卡死在最大开度 检查百叶窗,必要时更换 流过散热器的冷风过多 目视检查风扇和风扇离合器(如配置)运行情况,必 要时联系联系上柴“易+人”呼叫中心 柴油机在低温环境下工作 采取提高进气温度措施 冷却液温度表故障或温度传感器故障 检查温度表和传感器,必要时更换 联系上柴“易+人”呼叫中心 故障模式 25:冷却液污染 可能的原因 排除方法 冷却介质选用不当 选用本手册规定的冷却液 冷却液更换周期太长 按更换周期要求更换冷却液 联系上柴“易+人”呼叫中心 故障模式 26:机油压力过高 可能的原因 排除方法 柴油机运转温度过低,机油黏度大 参见故障诊断“冷却液温度低压于正常情况” 机油压力表故障或压力传感器故障 检查压力表和传感器,必要时更换 润滑油规格不符合要求 更换成本手册规定的润滑油,并更换机油滤清器 联系上柴“易+人”呼叫中心 故障模式 27:机油压力过低 可能的原因 排除方法 机油油面过低...

- Page 38 E 系列柴油机使用保养说明书 故障模式 29:机油消耗量过高 可能的原因 排除方法 怠速时间过长 缩短怠速时间 机油油面过高 检查机油油面,必要时调整 柴油机外部漏油 检查柴油机外部的管路、密封垫片、油封等是否有泄 漏,更换损坏的零部件 增压器机油泄漏到进气或排气系统 检查压气机出气口、空气接管是否有机油痕迹 曲轴箱内压力将机油压到油气分离器 检查油气分离器周围是否有机油痕迹, 必要时联系上 柴“易+人”呼叫中心 空气压缩机泵油 检查空气压缩机出气口是否有机油痕迹, 必要时更换 空气压缩机 油品规格不符合要求 检查机油规格。采用正确规格的机油,并更换机油和 机油滤清器 联系上柴“易+人”呼叫中心...

-

Page 39: 喷油泵静态供油提前角检查和调整

E 系列柴油机使用保养说明书 5.2 喷油泵静态供油提前角检查和调整 要排除与喷油泵静态供油提前角有关的故障,需要按下面步骤检查和调整静态供油提前角。 在检查和调整喷油泵静态供油提前角时,规定曲轴转向以面对飞轮端逆时针方向为柴油机工作转向,以确保 消除齿轮系统的齿侧间隙。 检查和调整喷油泵供油提前角前需确定第 1 缸活塞压缩上止点。 确定第 1 缸活塞压缩上止点(方法 1) (1)拧松气缸盖罩壳紧固螺栓,拆下罩壳。 (2)盘车使柴油机处于第 1 缸活塞压缩上止点位置。 注:当指针对正减振器 0 位刻线,并且凸轮轴齿轮缺口朝上 时,为第 1 缸活塞压缩上止点。 凸轮轴齿轮缺口 注:此方法用于实际喷油泵静态供油提前角与规格值相差较大情况。 确定第 1 缸活塞压缩上止点(方法 2)即确定理论静态供油提前角 (1)拆下飞轮壳观察监视窗盖板。 (2) 逆时针转动曲轴, 使飞轮壳上的指针对准飞轮上 0 刻线。 (3)从喷油泵调速器壳体上拆下定时销安装螺塞,取出定时 销,反向将定时销插入凸轮轴定时齿或定时槽。如不能插入, 小幅度转角来回盘动曲轴,边盘边插;如还是不能插入,须 再逆时针转动 360°CA,插入定时销。定时销插入说明喷油泵 正时销... - Page 40 E 系列柴油机使用保养说明书 应的刻线角度,该角度就是当前实际喷油泵静态供油提前角。如该角度与规定的静态供油提前角(见柴油机铭牌) 不符合,则需要进行调整。记录当前提前角与规格提前角差值,负值为偏小,正值为偏大。 调整静态供油提前角 (1)拆除飞轮壳上油泵齿轮拆装小盖板(喷油泵齿 凸轮轴齿轮螺母 拔模工具 轮拆装窗口)。 观察窗口 (2)拆下喷油泵齿轮紧固螺母。 △注意:拆除时要小心,紧固螺母和弹簧垫圈不可掉 入齿轮室内。 (3) 小幅度慢慢顺时针或逆时针转动曲轴, 使齿轮上 2 个拆卸螺孔与飞轮壳上 2 个用于安装齿轮拆卸工具 的螺栓孔对齐,用工具将齿轮拉离喷油泵凸轮轴。 (4)根据提前角检查结果进行调整。如提前角偏小 2°CA,则指针对应刻线增加 2°CA,即曲轴顺时针转过 2° CA,反之相反。 (5)安装齿轮,使喷油泵齿轮与凸轮轴齿轮啮合。 (6)安装齿轮紧固螺母,拧紧油泵齿轮紧固螺母至 250-300 N·m。 (7)复查喷油泵静态供油提前角。如不符合,再重新调整,直至正确为止。 (8)拧紧高压油管螺母,拧紧力矩 25-33 N·m。 (9)安装喷油泵齿轮拆装小盖板,检查 O 形密封圈,如损坏,需更换。 (10)安装监视窗盖板。 (11)将调速器手柄置于正常位置。 (12)如果之前拆卸气缸盖罩壳,需要重新安装,检查罩壳密封带,如有损坏,需更换。罩壳螺栓拧紧力矩为 18 N·m。...

-

Page 41: 柴油机停运后保存

E 系列柴油机使用保养说明书 6 柴油机停运后保存 柴油机如需停用一段时间(最长至 6 个月) ,需要做好清洁工作和必要的油封措施,防止生锈。 △注意:附件驱动带轮表面需采取一定防锈措施。... - Page 42 Warnings and cautions in this manual are not complete since Shanghai Diesel Engine Co., Ltd. (SDEC) has no possibility and is not able to foresee all potential risks resulted from failure to follow the safety cautions and operation instructions.

- Page 43 Table of Contents 1 Introduction............................1 1.1 To User and Operator........................ 1 1.2 Notices for Engine Quality Feedback ..................1 1.3 Safety Instructions........................1 1.4 Engine Operation Instructions....................2 2 About the Engine ..........................3 2.1 Engine Outline Diagrams ......................3 2.2 Engine Model Name Identification ...................

-

Page 44: Introduction

Thank you for purchasing a diesel product of Shanghai Diesel Engine Co., Ltd! The E series diesel engine, available in two displacements of 10L and 12L, is a large-power four-valve diesel engine with four or six cylinders that is newly developed by SDEC. Featuring strong power and low fuel consumption and with the emissions conforming to relevant national regulations, the E series diesel engine is a perfect power for the middle- and high-end heavy-duty vehicles and industrial equipment. -

Page 45: Engine Operation Instructions

Operation and Maintenance Manual E Series Diesel Engine your eye(s) for 15 minutes with clean water and seek for medical treatment immediately. ●Cool the engine first to avoid being hurt by the steam when filling coolant. Open the pressure cap only when the coolant is lower than 50℃, and then slowly loosen the cap to release the pressure of coolant. -

Page 46: About The Engine

Operation and Maintenance Manual E Series Diesel Engine 2 About the Engine 2.1 Engine Outline Diagrams 2.1.1 SC10E diesel engine (10L) Intake Side View 1 Oil pan 2 Fuel filter 3 Fuel filter inlet pipe 4 Starting motor 5 Flywheel housing... - Page 47 Operation and Maintenance Manual E Series Diesel Engine Exhaust Side View 1 Oil filter 2 Turbocharger oil drain pipe 3 Oil drain plug 4 Oil cooler 5 Water drain plug 6 Water pump 7 Oil filler cover 8 Turbocharger oil inlet pipe...

- Page 48 Operation and Maintenance Manual E Series Diesel Engine Front End View 1 Water temperature sensor 2 Water pump pulley 3 Multi wedge belt tensioner 4 Fan pulley 5 Drive belt tensioner 6 Vibration damper 7 Idler pulley 8 Air conditioning compressor pulley...

- Page 49 Operation and Maintenance Manual E Series Diesel Engine Rear End View 1 Flywheel...

-

Page 50: Engine Model Name Identification

Engine series Displacement /L Shang Chai Power For example: SC10E380Q3 stands for Shang Chai Power E series four-valve vehicle diesel engine of 10 liters with power of 380 PS and compliant with China Ⅲ 2.3 Diesel Engine Nameplate The diesel engine nameplate indicates the main technical data and information: model, order no., serial no., date of production, rated power and rated speed, which are the major basis for you to purchase service parts and for SDEC to conduct after-sale technical service. -

Page 51: Specifications And Parameters

Operation and Maintenance Manual E Series Diesel Engine 2.4 Specifications and Parameters 2.4.1 Specifications Engine SC10E SC12E Total piston displacement/L 10.4 11.8 Type In-line, four-stroke, water-cooled Bore/mm Stroke/mm Number of Cylinders Number of valves of each cylinder Firing order 1-5-3-6-2-4... - Page 52 Operation and Maintenance Manual E Series Diesel Engine 2.4.2 Parameters Engine SC10E SC12E Lubricating System Oil pressure/kPa @ Idle speed (minimum allowable) @ Rated speed (minimum allowable) @ Rated speed (maximum allowable) Oil pan capacity/L (Oil dipstick “high-low”) (35, 29)...

-

Page 53: Engine Operation

Operation and Maintenance Manual E Series Diesel Engine 3 Engine Operation Proper use of your engine can not only keep it in normal working order and good performance, but also can extent its service life and reduce its use cost. Adopt proper fuel, oil and coolant, as well as the correct operation steps stipulated in this section. -

Page 54: Coolant

Operation and Maintenance Manual E Series Diesel Engine 3.3 Coolant In order to ensure the normal operation and long service life of the engines, use SDEC- designated special organic coolant (anti-freezing type) for any climate. The coolant proves antifreeze, anticorrosion, good thermal conductivity, performance stability, and environmental friendliness. -

Page 55: Engine Operation

Operation and Maintenance Manual E Series Diesel Engine △Caution: Do not idle the engine for a long period of time or it can cause problems to the engine. When an engine idles, the temperature in combustion chamber is low and combustion is not complete. It can cause carbon deposit in cylinder that results in blocking of orifice of fuel injector, as well as the seizures of piston rings and valve, thus leading to engine performance deterioration. -

Page 56: Engine Shutdown

Operation and Maintenance Manual E Series Diesel Engine ●When engine overheating starts to happen that is indicated by the coolant temperature alarming, reduce engine speed or place the transmission to lower gear or take the both actions until the coolant temperature falls down into the normal range;... -

Page 57: Engine Maintenance

Operation and Maintenance Manual E Series Diesel Engine 4 Engine Maintenance 4.1 Maintenance Schedule The following table gives maintenance period and tasks. Make regular maintenance based on this table. If the engine frequently operates at the ambient temperature below -18°C or above 38°C, or in dusty environment or under a stop-and-go condition, the maintenance period should be shortened properly. -

Page 58: Maintenance Record

Operation and Maintenance Manual E Series Diesel Engine 4.3 Maintenance Record Make a regular maintenance record. You may make your own maintenance log by referring to the format of Maintenance Record below. Maintenance Record Engine Serial No. Engine Model/Order No. -

Page 59: Tasks And Methods Of Engine Maintenance

Operation and Maintenance Manual E Series Diesel Engine 4.3 Tasks and Methods of Engine Maintenance Checking engine periphery Check the periphery of the engine each time before starting: •Check if the engine is in clean state and free from useless things on it. - Page 60 Operation and Maintenance Manual E Series Diesel Engine Checking oil level Check the oil level daily before starting the engine or the engine is in stop (at least 15 minutes after being stopped) to provide enough time for oil to flow back to the oil pan. The oil level should be between the upper mark (high oil level) and lower mark (low oil level).

- Page 61 Operation and Maintenance Manual E Series Diesel Engine Checking drive belt Perform visual check on the drive belt everyday for any intersecting cracks. Transverse cracks along the width direction of the belt are acceptable, while longitudinal cracks (along the length direction) that intersect with transverse cracks are not allowed.

- Page 62 Operation and Maintenance Manual E Series Diesel Engine For the SC10E engine, only apply a light film of clean engine oil to the O-rings on the new filters to form a lubricating film. (6) Turn the filters by hand until the O-rings touch the sealed surfaces of the filter heads, and further tighten them by 45±5...

- Page 63 Operation and Maintenance Manual E Series Diesel Engine (1) Raise the spool along the axial of the filtration and drain the oil in it. Remove the spool along the axial. Be sure not to damage its bearing. (2) Install a new spool and check it for free spin.

- Page 64 Operation and Maintenance Manual E Series Diesel Engine Drain water The first stage fuel filter has a function of water and fuel separation. When water level in the water container of the first stage fuel filter reaches a certain level, the water-level sensor will send a signal to the water-level indicator light in cab, reminding the driver to drain the water timely.

- Page 65 Operation and Maintenance Manual E Series Diesel Engine and correct the initial changes of the valve clearances. Later valve clearance checking and regulating should be based on the maintenance plan if the engine operates normally. Valve clearance checking should be conducted after the engine has been stopped and the coolant temperature falls to below 60℃.

- Page 66 Operation and Maintenance Manual E Series Diesel Engine Checking belt tensioner (1) Rotate the belt tensioner clockwise, and remove the drive belt. Turn the tensioner pulley to check it for seizure or radial/axial movement, by which to determine if there is scratch or wear on the bearing surface of the tensioner pulley.

- Page 67 Operation and Maintenance Manual E Series Diesel Engine Air inlet unloader valve Carefully check unloader valve for carbon deposit. Clean and remove deposit if it is serious. Check the air compressor head, inlet and outlet for any problems and replace them or relevant parts if necessary.

- Page 68 Operation and Maintenance Manual E Series Diesel Engine (d) Start the engine and keep it running for 5 minutes after the water temperature goes up to above 80℃, then stop the engine and completely drain the clean water in the cooling system.

-

Page 69: Troubleshooting Guidelines

Operation and Maintenance Manual E Series Diesel Engine 5 Troubleshooting Guidelines 5.1 Troubleshooting Guidelines Some simple typical diesel engine fault modes, possible causes and troubleshooting steps are listed in the table below. If any one of modes occurs in engine operation, it is required to eliminate it by taking appropriate measures. Otherwise, it would lead to severe engine failure. - Page 70 Operation and Maintenance Manual E Series Diesel Engine Fault mode 3:Engine is difficult to start or will not start Possible cause Correction Refer to the operating instruction manual of the vehicle Improper starting method or the equipment for proper starting method...

- Page 71 Operation and Maintenance Manual E Series Diesel Engine Fault mode 5:Liable misfire or unsteady speed Possible cause Correction Fuel level in the fuel tank too low Add fuel Air in fuel system Check for air in the system. Tighten or replace the fuel...

- Page 72 Operation and Maintenance Manual E Series Diesel Engine Fault mode 8:Engine power output low Possible cause Correction Inquire the driver or operator Obtain all the information related to the problem Overloaded operation Reduce the load to allowed range The engine runs on the plateau beyond the Run the engine on the specified plateau.

- Page 73 Operation and Maintenance Manual E Series Diesel Engine Fault mode 10:Unexpected engine halt or misfire in deceleration Possible cause Correction Causes related to the protective system of the vehicle Contact the manufacturer of the vehicle or equipment or equipment Check for air in the system. Tighten or replace the fuel...

- Page 74 Operation and Maintenance Manual E Series Diesel Engine Fault mode 14:Rough running at idle speed Possible cause Correction Engine temperature is too low Warm up the engine The load at idle speed is too heavy (more than 50 Reduce the load at idle speed...

- Page 75 Operation and Maintenance Manual E Series Diesel Engine Fault mode 17:Excessive noise Possible cause Correction Noise from drive belt due to poor tension or heavy Check the belt drive system and ensure all pulleys load running Check the intake and exhaust systems for leakage.

- Page 76 Operation and Maintenance Manual E Series Diesel Engine Fault mode 21:Fuel consumption too much Possible cause Correction Check driver’s operation for gear shift, deceleration and Something related to driving technique idle speed Display error of the odometer Adjust or replace the odometer...

- Page 77 Operation and Maintenance Manual E Series Diesel Engine Fault mode 23:Coolant temperature above normal—sudden overheat Possible cause Correction Check coolant level and engine external for leakage, Coolant level is too low eliminating the leakage and adding the coolant to be...

- Page 78 Operation and Maintenance Manual E Series Diesel Engine Fault mode 27:Oil pressure too high Possible cause Correction The operating temperature of the engine is too low Refer to the fault mode “Coolant temperature below and the oil viscosity is high normal”...

-

Page 79: Check And Adjustment Of Static Fuel Injection Pump Timing

Operation and Maintenance Manual E Series Diesel Engine 5.2 Check and Adjustment of Static Fuel Injection Pump Timing To remove the faults related to static injection pump timing, check and adjust the static pump timing as per following steps. In order to eliminate gear backlashes, it is required to rotate the crankshaft counterclockwise viewed from the flywheel end, which is defined as the engine working rotation when checking and adjusting of the injection pump timing. - Page 80 Operation and Maintenance Manual E Series Diesel Engine Note: The method is applicable for a small difference between the actual timing and required one. (4) Take the pin out. Reinstall it with the other end in and install the plug and washer. Tighten the plug by 15 N·m.

-

Page 81: Engine Storage

Operation and Maintenance Manual E Series Diesel Engine 6 Engine Storage If the diesel engine is to be shutdown for a period of time (6 months at most), measures of cleaning and necessary oil seal should be taken for rust protection.

Need help?

Do you have a question about the E Series and is the answer not in the manual?

Questions and answers