Advertisement

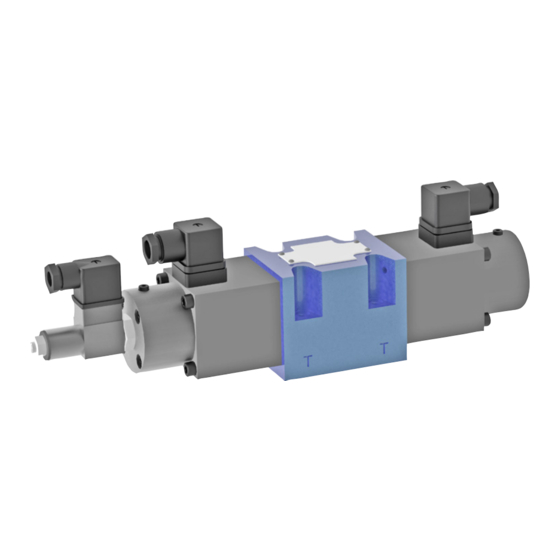

Proportional valve USEB 10

NS 10 | p

35 MPa | Q

max

max

DATA SHEET - OPERATION MANUAL

APPLICATION

Proportional directional valve type USEB10... is used to control

the direction and speed of movement of an actuator. Flow rate

of hydraulic oil directed to the actuator is adjusted by change of

electric current supplying the solenoid coil.

a

a

5

5

DESCRIPTION OF OPERATION

The proportional directional valve type USEB 10 sonsists of the housing

1, solenoids 2 and 4,inductive offset detector 3, spool 5, springs 6 and 7.

Electric regulator (30 RE ...) can be included with thevalve. The regulator is

applied to control proportionalsolenoids and receive the signals from offset

detector.The proportional solenoid 2 or 4 pushes the spool fromits neutral

position. The neutral position is held by thesprings 6 and 7. The inductive

offset detector hasdouble stroke. Its range allows to measure the offsetof

the spool from neutral position to the right or left.The offset of the spool

TECHNICAL DATA

hydraulic fluid

required fluid cleanliness class

nominal fluid viscosity

viscosity range

fluid temperature range (in the tank)

ambient temperature range

max. working pressure

hysteresis

repeatability

sensitivity

hydr. zero shif t

working position

assembly and operation requirements at: www.operating-conditions.ponar.pl

USEB10 | Data Sheet - Operation Manual

64 dm

/min | WK 420 560

3

2

7

2

7

mineral oil ISO 4406 class 20/18/15

37 mm

/s w temperature 55 °C

2

2,8 ÷ 380 mm

/s

2

rec: 40 ÷ 55°C; max.: -20 ÷ 70 °C

-20 ÷ 50 °C

35 MPa (ports P, A, B); 21 MPa (port T)

<1%

<1%

≤ 0,5% of nominal signal

0,2%/ °C

any position

USEB10 - 3X/E - 32

USEB10 - 3X/E - 32

T

A

P

B

T

T

A

P

B

T

1

3

6

1

3

6

5 is transmitted electrically asinitial data. It is held in the signal sent by the

electronicregulator in form of current with certain intensity that ischanged

by the solenoid 2 or 4 into force pushing thespool 5 against spring 6 or 7.

Simultaneously the offsetdetector 3 determines actual position of the

spool and inform of electrical signals sends as feedback to theelectronic

regulator. The both signals: initial data andactual value are compared in

the electronic regulator,which sends a new signal correcting the position of

thespool 5 in order to adjust it in conforming with the initialsignal

with 2 solenoids

weight

with 1 solenoids

nom. power of the solenoid

22,5 W

10 Ω (for cold solenoid 20 °C )

coil resistance

14 Ω (for max heated solenoid)

inductive switch stroke

± 4,5 mm linear

linearity tolerance

1%

coil I

coil II

resistance of sensor coil

coil III

for valve with

2 solenoids

electronic controllers

for valve with

1 solenoid

1/6

b

b

4

4

7,65 kg

5,65 kg

56 Ω

56 Ω

112 Ω

32RE21 acc. to WK 495 774

32RE11 acc. to WK 495 772

WK 420 560 | 05.2021

Advertisement

Table of Contents

Summary of Contents for Ponar Wadowice USEB 10

- Page 1 USEB10 - 3X/E - 32 DESCRIPTION OF OPERATION The proportional directional valve type USEB 10 sonsists of the housing 5 is transmitted electrically asinitial data. It is held in the signal sent by the 1, solenoids 2 and 4,inductive offset detector 3, spool 5, springs 6 and 7.

- Page 2 SCHEMATY HYDRAULIC DIAGRAMS symbole graficzne rozdzielaczy 3-położeniowych graphical symbols of 3-position spool valves symbole graficzne suwaków położenia robocze i położenia robocze versions USEB10 wersje USEB6 ... positions: working and interim working pośrednie E, E1, E2 NOTES: for spools E1 i W1 flows are: P →...

- Page 3 OVERALL AND CONNECTION DIMENSIONS 11 - 4 counterbores 6,6 - 4 holes 11 - 4 counterbores 6,6 - 4 holes 69,5 69,5 10,5 10,5 18,5 70,5 18,5 70,5 solenoid on a side solenoid on b side connector on a side - type ISO 4400 (DIN 43650) connector on b side - type ISO 4400 (DIN 43650) manual override 18, 5...

- Page 4 CHARAKTERYSTYKI ν measured at viscosity of hydraulic fluid = 41 mm /s and temperature t = 50 °C ® ® ® ® version USAB10... 16 ...; f P A / B T or P B / A shift of spool [%] ®...

- Page 5 4 pcs/set delivered on separate order G 534/01 - threaded connection G ¾ tightening torque of the screws M = 15 Nm. CONTACT PONAR Wadowice S.A. tel. +48 33 488 21 00 ul. Wojska Polskiego 29 www.ponar-wadowice.pl 34-100 Wadowice USEB10 | Data Sheet - Operation Manual...

- Page 6 CONTACT PONAR Wadowice S.A. tel. +48 33 488 21 00 ul. Wojska Polskiego 29 www.ponar-wadowice.pl 34-100 Wadowice USEB10 | Data Sheet - Operation Manual WK 420 560 | 05.2021...

Need help?

Do you have a question about the USEB 10 and is the answer not in the manual?

Questions and answers