Summary of Contents for Allice Messtechnik R&S ZND

- Page 1 Allice Messtechnik GmbH ® R&S Vector Network Analyzers User Manual (;×íÇ2) 1173955702 Version 61...

- Page 2 Allice Messtechnik GmbH ® This manual describes the R&S ZND (2 ports, 9 kHz to 4.5 GHz, unidirectional, N connectors), order no. 1328.5170K92 and its options. Hardware Options ● ® R&S ZND-B7 "High Output Power", order no. 1338.1578.02 ●...

-

Page 3: Table Of Contents

Allice Messtechnik GmbH ® Contents R&S Contents 1 Safety and regulatory information............13 Safety instructions......................13 Warning messages in the documentation..............15 Korea certification class A..................16 2 Welcome to the R&S ZND..............17 What's new in firmware version 3.40.................17 Documentation overview....................20 2.2.1... - Page 4 Allice Messtechnik GmbH ® Contents R&S Operating the instrument................... 40 3.3.1 Manual operation......................40 3.3.2 Control elements of the application window..............45 3.3.3 Working with dialogs..................... 51 3.3.4 Handling diagrams, traces, and markers..............52 3.3.5 Entering data.........................56 3.3.6 Scaling diagrams......................59 Performing measurements..................65...

- Page 5 Allice Messtechnik GmbH ® Contents R&S 4.4.3 Memory-mapped trace data transfer................143 Calibration......................... 145 4.5.1 Calibration types......................146 4.5.2 Calibration standards and calibration kits..............157 4.5.3 Calibration pool......................163 4.5.4 Calibration labels......................163 4.5.5 Automatic calibration....................164 4.5.6 Scalar power calibration....................175 4.5.7 Parallel calibration of multiple channels..............

- Page 6 Allice Messtechnik GmbH ® Contents R&S 4.7.20 External switch matrices..................... 220 4.7.21 External DLLs......................226 4.7.22 R&S ZNXSIM......................228 5 GUI reference..................232 Function Keys and Softtools................... 232 Meas softtool......................234 5.2.1 S-Params tab......................235 5.2.2 Ratios tab........................244 5.2.3 Wave tab........................247 5.2.4...

- Page 7 Allice Messtechnik GmbH ® Contents R&S Lines softtool......................316 5.6.1 Limit Test tab....................... 316 5.6.2 Ripple Test tab......................325 5.6.3 Circle Test tab......................329 5.6.4 Display Circle tab......................333 5.6.5 Horiz. Line tab......................334 Marker softtool......................335 5.7.1 Markers tab......................... 335 5.7.2...

- Page 8 Allice Messtechnik GmbH ® Contents R&S 5.11.4 Use Cal tab......................... 434 5.12 Channel Config softtool....................439 5.12.1 Channels tab....................... 440 5.12.2 Port Config tab......................443 5.12.3 Mode tab........................448 5.12.4 Pwr Cal Settings tab....................449 5.13 Offset Embed softtool....................449 5.13.1 Offset Embed dock widget..................449 5.13.2...

- Page 9 Allice Messtechnik GmbH ® Contents R&S 5.16.4 View Bar tab........................ 537 5.16.5 Touchscreen tab......................538 5.17 Setup softtool......................539 5.17.1 Setup tab........................539 5.17.2 Freq. Ref. tab......................564 5.17.3 Remote Settings tab....................565 5.17.4 External Devices tab....................568 5.17.5 External Ports tab......................574 5.18...

- Page 10 Allice Messtechnik GmbH ® Contents R&S 6.5.1 Overview of status registers..................609 6.5.2 Structure of a SCPI status register................609 6.5.3 Contents of the status registers...................611 6.5.4 Application of the status reporting system..............617 6.5.5 Reset values of the status reporting system............... 620 7 Command reference................

- Page 11 Allice Messtechnik GmbH ® Contents R&S 7.4.1 SNMP/REST commands................... 1100 7.4.2 System information commands................. 1104 7.4.3 Device tags commands..................... 1114 7.4.4 Utilization commands....................1115 7.4.5 Service date commands.................... 1118 R&S ZVR/ZVABT compatible commands.............. 1120 8 Programming examples..............1143 Basic tasks.......................1143 8.1.1 Typical stages of a remote control program..............

- Page 12 Allice Messtechnik GmbH ® Contents R&S 12.1.2 Remote operation in a LAN..................1186 12.2 System recovery......................1190 12.3 Interfaces and connectors..................1190 12.3.1 Rear panel connectors....................1190 12.3.2 LAN interface......................1192 12.3.3 GPIB interface......................1193 12.3.4 Handler I/O (universal interface)................1196 12.4 Showroom mode..................... 1204 12.5...

-

Page 13: Safety And Regulatory Information

Allice Messtechnik GmbH ® Safety and regulatory information R&S Safety instructions 1 Safety and regulatory information The product documentation helps you use the product safely and efficiently. Follow the instructions provided here and in the following chapters. Intended use The product is intended for the development, production and verification of electronic components and devices in industrial, administrative, and laboratory environments. - Page 14 Allice Messtechnik GmbH ® Safety and regulatory information R&S Safety instructions Choosing the operating site Only use the product indoors. The product casing is not waterproof. Water that enters can electrically connect the casing with live parts, which can lead to electric shock, serious personal injury or death if you touch the casing.

-

Page 15: Warning Messages In The Documentation

Allice Messtechnik GmbH ® Safety and regulatory information R&S Warning messages in the documentation ● Only connect the product to a power source with a fuse protection of maximum 20 A. ● Ensure that you can disconnect the product from the power source at any time. -

Page 16: Korea Certification Class A

Allice Messtechnik GmbH ® Safety and regulatory information R&S Korea certification class A 1.3 Korea certification class A 이 기기는 업무용(A급) 전자파 적합기기로서 판매자 또는 사용자는 이 점을 주의하시기 바라며, 가정외의 지역에서 사용하는 것을 목적으로 합니다. User Manual 1173.9557.02 ─ 61... -

Page 17: Welcome To The R&S Znd

Allice Messtechnik GmbH ® Welcome to the R&S ZND R&S What's new in firmware version 3.40 2 Welcome to the R&S ZND This manual is intended to provide you with all information that is necessary for setup, manual and remote control of the R&S ZND. - Page 18 Allice Messtechnik GmbH ® Welcome to the R&S ZND R&S What's new in firmware version 3.40 New remote control features ● Deembedding tools ISD, SFD, and EZD: – New commands CALCulate:FMODel:DIRectory, CALCulate:FMODel: DIRectory:DEFault, and CALCulate:FMODel:DIRectory:DEFault: for managing the common working directory CLEar –...

- Page 19 Allice Messtechnik GmbH ® Welcome to the R&S ZND R&S What's new in firmware version 3.40 ● For time domain traces, CALCulate<Chn>:MARKer<Mk>:FUNC:DOMAIN:USER commands did not accept values with units (and returned a misleading error mes- sage). ● Markers on traces whose value at the marker position was above or below the visi- ble range were not displayed.

-

Page 20: Documentation Overview

Allice Messtechnik GmbH ® Welcome to the R&S ZND R&S Documentation overview ● Switch matrix operation: if multiple matrix switch positions are needed, the external "Channel (Sweep)" trigger required one trigger signal per matrix position instead of one trigger signal per channel ●... -

Page 21: Getting Started Manual

Allice Messtechnik GmbH ® Welcome to the R&S ZND R&S Documentation overview 2.2.1 Getting started manual Introduces the R&S ZND and describes how to set up and start working with the prod- uct. Includes basic operations, typical measurement examples, and general informa- tion, e.g. -

Page 22: Data Sheets And Brochures

Allice Messtechnik GmbH ® Welcome to the R&S ZND R&S Documentation overview 2.2.6 Data sheets and brochures The data sheet contains the technical specifications of the R&S ZND. It also lists the firmware applications and their order numbers, and optional accessories. -

Page 23: Getting Started

Allice Messtechnik GmbH ® Getting started R&S Preparing for use 3 Getting started Note: the following chapters are identical to those in the printed R&S ZND Getting Started manual. ● Preparing for use.....................23 ● Instrument tour......................33 ● Operating the instrument..................40... -

Page 24: Setting Up The Product

Allice Messtechnik GmbH ® Getting started R&S Preparing for use Electromagnetic compatibility classes The electromagnetic compatibility (EMC) class indicates where you can operate the product. The EMC class of the product is given in the data sheet under "General data". - Page 25 Allice Messtechnik GmbH ® Getting started R&S Preparing for use Left = Stacked correctly, same dimensions Middle = Stacked correctly, different dimensions Right = Stacked incorrectly, too many products 4. NOTICE! Overheating can damage the product. Prevent overheating as follows: ●...

-

Page 26: Considerations For Test Setup

Allice Messtechnik GmbH ® Getting started R&S Preparing for use 2. Remove the R&S ZND from the rack. 3. If placing the R&S ZND on a bench top again, unmount the adapter kit from the R&S ZND. Follow the instructions provided with the adapter kit. -

Page 27: Connecting The Analyzer To The Ac Supply

Allice Messtechnik GmbH ® Getting started R&S Preparing for use During operation, if the firmware observes a serious unexpected disturbance (e.g. due to ESD), it resets all hardware components to ensure proper instrument functioning. It then restores the user settings to the state before the disturbance and indicates the foregone hardware reset by an "Hardware communication problem [...]"... -

Page 28: Standby And Ready State

Allice Messtechnik GmbH ® Getting started R&S Preparing for use To shut down the instrument 1. Press the standby toggle key. Pressing the standby toggle key causes the instrument to save all loaded recall sets, to close the VNA application, to shut down Windows ®... - Page 29 Allice Messtechnik GmbH ® Getting started R&S Preparing for use Modifications of the operating system The operating system is adapted to the network analyzer. To avoid impairment of instrument functions, only change the settings described in this manual. Existing soft- ware must be modified only with update software released by Rohde &...

-

Page 30: Minimizing The Vna Application

Allice Messtechnik GmbH ® Getting started R&S Preparing for use ment. Rohde & Schwarz does NOT recommend running anti-virus software in the background ("on-access" mode) on Windows-based instruments, due to potentially degrading instrument performance. However, Rohde & Schwarz does recommend run- ning it during non-critical hours. -

Page 31: Connecting External Accessories

Allice Messtechnik GmbH ® Getting started R&S Preparing for use 3.1.11 Connecting external accessories The analyzer's standard PC interfaces (Monitor, USB, LAN) can be used to connect various accessories: ● An external monitor expands/displays the Windows ® desktop, which is, by default, covered by the vector network analyzer (VNA) (VNA) application window in full- screen mode. - Page 32 Allice Messtechnik GmbH ® Getting started R&S Preparing for use To access Windows ® , use the button in the toolbar of the application window. 3.1.11.3 Connecting a mouse A USB mouse can be connected to any of the USB connectors. After being auto-detec- ted by the operating system, it can safely be disconnected and reconnected even dur- ing measurements.

-

Page 33: Instrument Tour

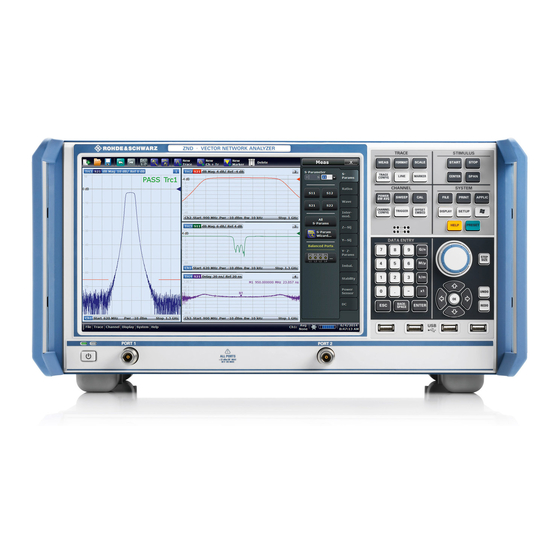

Allice Messtechnik GmbH ® Getting started R&S Instrument tour Printer configuration Use the "Printer Setup" dialog of the firmware (SYSTEM – [PRINT] > "Print...") or the ® Windows printer management to configure the printer properties and printing prefer- ences. - Page 34 Allice Messtechnik GmbH ® Getting started R&S Instrument tour Figure 3-1: Front View of R&S ZND 3.2.1.1 Touchscreen The analyzer is equipped with a 12.1'' XGA color touchscreen. The touchscreen pres- ents all measurement results, mostly in the form of diagrams. Besides, all instrument functions can be accessed and operated by tapping the control elements on the touch- screen.

- Page 35 Allice Messtechnik GmbH ® Getting started R&S Instrument tour Screen saver The screen saver function of the operating system can be used to switch off the display if the analyzer receives no command for a selectable period of time. The display is switched on again if any front panel key is pressed.

- Page 36 Allice Messtechnik GmbH ® Getting started R&S Instrument tour The SYSTEM keys provide general system settings. ● ® [FILE] provides standard Windows functions used to create, save, recall or print recall sets, to copy the active screen and to shut down the application.

- Page 37 Allice Messtechnik GmbH ® Getting started R&S Instrument tour – Confirm selections and entries made and close dialogs (equivalent to the "OK" button). – Compress or expand menus or the Help table of contents ● BACKSPACE deletes the last character before the cursor position or the selected character sequence or numeric value.

- Page 38 Allice Messtechnik GmbH ® Getting started R&S Instrument tour The standby toggle switch is located in the bottom-left corner of the front panel. The key serves two main purposes: ● Toggle between standby and ready state; see Chapter 3.1.8, "Standby and ready state",...

-

Page 39: Rear Panel

Allice Messtechnik GmbH ® Getting started R&S Instrument tour 3.2.2 Rear panel This section gives an overview of the rear panel controls and connectors of the net- work analyzer. Figure 3-2: Rear Panel R&S ZND The following connectors are available on all instruments: ●... -

Page 40: Operating The Instrument

Allice Messtechnik GmbH ® Getting started R&S Operating the instrument ● The ground connector in the lower left corner of the rear panel provides the ground of the analyzer's supply voltage. Use this connector for ESD protection; see "Pre- venting electrostatic discharge (ESD)"... - Page 41 Allice Messtechnik GmbH ® Getting started R&S Operating the instrument Figure 3-3: Function Keys Customizing the screen The contents of the screen and the size and position of many display and control ele- ments are not fixed. You can display or hide most elements. You can also drag and drop traces, info fields, and even the softtool panel to your preferred position;...

- Page 42 Allice Messtechnik GmbH ® Getting started R&S Operating the instrument left = unidirectional R&S ZND right = bidirectional R&S ZND 2. Activate the desired softtool tab, e.g. "Z←Sij". left = unidirectional R&S ZND right = bidirectional R&S ZND 3. Select a control element, e.g. "Z←S11".

- Page 43 Allice Messtechnik GmbH ® Getting started R&S Operating the instrument Using the menu bar The menu bar at the bottom of the application screen provides alternative access to all instrument functions. To repeat the measured quantity selection described above, ►...

- Page 44 Allice Messtechnik GmbH ® Getting started R&S Operating the instrument left = unidirectional R&S ZND right = bidirectional R&S ZND 2. Select "S-Parameter" to open the "Meas" > "S-Params" softtool tab. left = unidirectional R&S ZND right = bidirectional R&S ZND 3.

-

Page 45: Control Elements Of The Application Window

Allice Messtechnik GmbH ® Getting started R&S Operating the instrument left = unidirectional R&S ZND right = bidirectional R&S ZND 3.3.2 Control elements of the application window The application window of the analyzer provides all control elements for the measure- ments and contains the diagrams for the results. - Page 46 Allice Messtechnik GmbH ® Getting started R&S Operating the instrument These methods are described in more detail in the following sections. For further reference: ● Refer to Chapter 4.2.1, "Display elements of a diagram", on page 86 to obtain information about the results in the diagram.

- Page 47 Allice Messtechnik GmbH ® Getting started R&S Operating the instrument The toolbar is divided into several icon groups, separated by vertical lines. These icons represent the undo and redo actions that are also available via the menu bar items "System" > "Undo" / "Redo".

- Page 48 Allice Messtechnik GmbH ® Getting started R&S Operating the instrument Figure 3-4: Scale softtool A softtool consists of a title area with a close/re-open icon and a tabbed panel below it. The title area remains displayed when the softtool is closed, which allows you to reopen a closed softtool at any time.

- Page 49 Allice Messtechnik GmbH ® Getting started R&S Operating the instrument ● The "Display" menu provides all display settings and the functions for activating, modifying and arranging different diagrams. ● The "Application" menu gives access to applications and tools that extend the func- tionality of the analyzer firmware.

- Page 50 Allice Messtechnik GmbH ® Getting started R&S Operating the instrument 3.3.2.6 Hardkey panel The (virtual) "Hard Key" panel provides on-screen access to the function keys (plus the [UNDO] and [REDO] key) of the R&S ZND. Most of the function keys open a related softtool.

-

Page 51: Working With Dialogs

Allice Messtechnik GmbH ® Getting started R&S Operating the instrument ● the "EXT REF" symbol, if an external reference clock is used for synchronization (see "Ext Frequency" on page 565) ● the switch matrix status symbol, if a switch matrix is configured (See Chapter 4.7.20, "External switch... -

Page 52: Handling Diagrams, Traces, And Markers

Allice Messtechnik GmbH ® Getting started R&S Operating the instrument – Use the "Dialog Transparency" function to make the display elements behind the dialog visible. Note: The "Dialog Transparency" is a global setting, i.e. it applies to all dialogs. - Page 53 Allice Messtechnik GmbH ® Getting started R&S Operating the instrument 2. Select the adequate drop position, depending on whether you want to display the new trace in the existing diagram, or whether you want to add a new diagram. The highlighted area indicates the target diagram.

- Page 54 Allice Messtechnik GmbH ® Getting started R&S Operating the instrument Alternative control elements To measure a different quantity, select TRACE – [MEAS]. Drag and drop a softkey rep- resenting a measured quantity to create a trace. Or simply select another softkey to change the measured quantity of the active trace.

- Page 55 Allice Messtechnik GmbH ® Getting started R&S Operating the instrument 3.3.4.3 Deleting display elements Markers, traces, diagrams, and other display elements are most conveniently deleted using the "Delete" icon in the toolbar above the diagram area. ● To delete a single marker, drag it into vertical direction to release it from the trace and drop it onto the "Delete"...

-

Page 56: Entering Data

Allice Messtechnik GmbH ® Getting started R&S Operating the instrument Screen element Action Drag and drop... Reset / suspend "Zoom" element in additional trace line --> "Delete" icon; see Chapter 3.3.6.1, graphic zoom "Using the graphical zoom", on page 59... - Page 57 Allice Messtechnik GmbH ® Getting started R&S Operating the instrument ● Use [-] to change the sign of the value. ● (-)9 Use [G/n], [M/μ], [k/m], or [x1] to multiply the entered value with factors of 10 (-)6 , 10 (-)3 or 1 and to add the appropriate physical unit.

- Page 58 Allice Messtechnik GmbH ® Getting started R&S Operating the instrument 3. If desired, select a "Step Size" and use the cursor up/down buttons to increment/ decrement the current value. If a marker is active, you can also set the numeric value to the current marker value ("Set to Marker").

-

Page 59: Scaling Diagrams

Allice Messtechnik GmbH ® Getting started R&S Operating the instrument Figure 3-6: Windows 10 on-screen keyboard To call up the on-screen keyboard: 1. Open the SYSTEM – [APPLIC] softtool. 2. In the "External Tools" tab, select "Screen Keyboard". 3.3.6 Scaling diagrams The analyzer provides various tools for customizing the diagrams and for setting the sweep range. - Page 60 Allice Messtechnik GmbH ® Getting started R&S Operating the instrument The icon changes its background color from black to blue. ● In the active diagram area, select an appropriate rectangular area. The zoomed view shows the selected rectangle, scaled in both horizontal and verti- cal direction.

- Page 61 Allice Messtechnik GmbH ® Getting started R&S Operating the instrument Alternative settings ● The TRACE – [SCALE] > "Zoom" softtool tab allows you to define the displayed zoom range numerically. It can also be opened from the menu of the "Zoom Config" toolbar icon.

- Page 62 Allice Messtechnik GmbH ® Getting started R&S Operating the instrument ● Tap and hold (with a mouse: right-click) the "Start" or "Stop" label in the channel list and select "Start Frequency", "Stop Frequency", "Center Frequency", or "Fre- quency Span" from the context menu.

- Page 63 Allice Messtechnik GmbH ® Getting started R&S Operating the instrument 3.3.6.5 Circular diagrams The radial scale of a circular diagram ("Polar", "Smith" or "Inverted Smith") can be changed with a single linear parameter, the "Ref Value". The reference value defines the radius of the outer circumference.

- Page 64 Allice Messtechnik GmbH ® Getting started R&S Operating the instrument 2. Place "M1" to the start value of the desired sweep range and tap TRACE – [MARKER] > "Set by Marker" > "Start = Marker". 3. Place "M2" to the stop value of the desired sweep range and tap TRACE –...

-

Page 65: Performing Measurements

Allice Messtechnik GmbH ® Getting started R&S Performing measurements 3.4 Performing measurements This chapter takes you through a sample session with a R&S ZND network analyzer and describes basic operation tasks. Prerequisite The instrument is set up, connected to the mains system, and started up as described Chapter 3.1, "Preparing for... - Page 66 Allice Messtechnik GmbH ® Getting started R&S Performing measurements 1. Connect the DUT between test ports 1 and 2 of the network analyzer as shown above. 2. Use the [PRESET] key to restore a well-defined instrument state. The analyzer is now set to its default state. The default measured quantity is the transmission S-parameter S Select TRACE –...

- Page 67 Allice Messtechnik GmbH ® Getting started R&S Performing measurements 2. The stimulus signal from the analyzer port no. 2 is not needed except for some cali- bration types. By default the sweep range is set to the frequency range of the analyzer, which can be unsuitable for your DUT.

- Page 68 Allice Messtechnik GmbH ® Getting started R&S Performing measurements Due to the R&S ZND's calibration wizard, calibration is a straightforward, guided proc- ess. 1. Replace the DUT by the Through standard of your calibration kit. Make sure to dis- connect all calibration units.

- Page 69 Allice Messtechnik GmbH ® Getting started R&S Performing measurements 6. Tap"Start". 7. The calibration dock widget indicates the standard measurements that make up a "Trans Norm" calibration. Select "Through (mm)" to initiate the measurement of the connected Through stan- dard.

- Page 70 Allice Messtechnik GmbH ® Getting started R&S Performing measurements The analyzer performs a calibration sweep for the measured quantity S . The magnitude and phase of the result is displayed in two diagrams, together with the expected typical result for a Through standard. The similarity of real and expected traces indicates that the Through standard has been properly connected.

- Page 71 Allice Messtechnik GmbH ® Getting started R&S Performing measurements The group delay represents the propagation time of the wave through the DUT; it is displayed in a Cartesian diagram. The marker info field shows the frequency and group delay at the marker position.

-

Page 72: Reflection S-Parameter Measurement

Allice Messtechnik GmbH ® Getting started R&S Performing measurements 7. In the "Save" dialog: a) Select a file location ("Look in:"). b) Enter a name for the recall set file ("File name:"). c) Select "Save". The analyzer saves the active recall set, containing channel, stimulus and trace settings, to a znx file. - Page 73 Allice Messtechnik GmbH ® Getting started R&S Performing measurements ● Some of the trace formats are particularly suited for reflection measurements. For instance, you can display the measured reflection coefficient S in a Smith chart to obtain the complex input impedance at port 1.

-

Page 74: Concepts And Features

Allice Messtechnik GmbH ® Concepts and features R&S Basic concepts 4 Concepts and features The following chapter provides an overview of the analyzer's capabilities and their use. It contains a description of the basic concepts that the analyzer uses to organize, proc- ess and display measurement data. -

Page 75: Recall Sets

Allice Messtechnik GmbH ® Concepts and features R&S Basic concepts ● Cal pool data including system error correction and power correction data ● Directories for trace data, limit lines, calibration data etc. ● Color schemes and printer settings ●... - Page 76 Allice Messtechnik GmbH ® Concepts and features R&S Basic concepts 4.1.3.1 Trace settings The trace settings specify the mathematical operations used to obtain traces from the measured or stored data. They can be divided into several main groups: ●...

-

Page 77: Sweep Control

Allice Messtechnik GmbH ® Concepts and features R&S Basic concepts 4.1.3.3 Active and inactive traces and channels A window can display several diagrams simultaneously, each with a variable number of traces. One of these traces is active at each time. The active trace is highlighted in the trace list on top of the active diagram (Trc4 in the figure below): When a trace is selected in the diagram area, it becomes the active trace. - Page 78 Allice Messtechnik GmbH ® Concepts and features R&S Basic concepts After changing the channel settings or selecting another measured quantity, the ana- lyzer needs some time to initialize the new sweep. This preparation period increases with the number of points and the number of partial measurements involved. It indica- ted in the status bar: All analyzer settings can still be changed during sweep initialization.

- Page 79 Allice Messtechnik GmbH ® Concepts and features R&S Basic concepts Use the "Alternated" mode to increase the accuracy of measurements on DUTs with long level settling times (e.g. quartzes, SAW filters). To measure DUTs with short set- tling times and obtain a trace from the beginning of the sweep, use "Chopped" mode.

- Page 80 Allice Messtechnik GmbH ® Concepts and features R&S Basic concepts Ch1 Sweep End Ch2 Sweep End Ch3 Sweep End Ch1 HW Sweep Ch2 HW Sweep Ch3 HW Sweep … Ch1 Calc Ch2 Calc Ch3 Calc Ch1 Results Ch2 Results...

- Page 81 Allice Messtechnik GmbH ® Concepts and features R&S Basic concepts With unidirectional operation, the following restrictions apply: ● S12, S22 and wave quantities of the reverse direction (port 2 as source) are not available ● Other (derived) results that require driving both ports, such as Y- and Z-parameters or stability parameters, are not available ●...

-

Page 82: Data Flow

Allice Messtechnik GmbH ® Concepts and features R&S Basic concepts – For "Segmented" sweeps, the start and stop frequency in a sweep segment must not be different. So with a segmented sweep you can measure n points at frequency f... - Page 83 Allice Messtechnik GmbH ® Concepts and features R&S Basic concepts RAW WAVE Channel data flow QUANTITIES for all traces of the channel SYSTEM ERROR CORRECTION (Factory) SYSTEM POWER POWER SYST. ERR. ERROR CORRECTION CORRECTION CORRECTION CORRECTION DATA (User) DATA...

- Page 84 Allice Messtechnik GmbH ® Concepts and features R&S Basic concepts calibration on the measured wave quantities, intermediate results were transformed to the S-parameter domain. Before each de-/embedding step, the S-parameters were transformed to conductance (~ wave quantities), and vice versa afterwards.

- Page 85 Allice Messtechnik GmbH ® Concepts and features R&S Basic concepts Channel data flow for all traces AVERAGE of the channel Trace 1 Mem 1,1 Mem 1,2 Trace 2 Mem 2,1 Mem 2,2 Unformatted Trace data flow TRACE MATH for individual traces...

-

Page 86: Screen Elements

Allice Messtechnik GmbH ® Concepts and features R&S Screen elements 4.2 Screen elements This section describes manual operation of the analyzer, including trace settings, mark- ers and diagrams. For a description of the different quantities measured by the instru- ment, refer to Chapter 4.3, "Measurement... - Page 87 Allice Messtechnik GmbH ® Concepts and features R&S Screen elements 4.2.1.1 Title An optional title across the top of the diagram can be used for a brief description of the diagram contents. Select SYSTEM – [DISPLAY] > "Diagram" > "Title" to enter the diagram title and "Show Title"...

- Page 88 Allice Messtechnik GmbH ® Concepts and features R&S Screen elements The type of each trace in a diagram is indicated in the trace list: "MEM<no>" at the beginning of the trace name indicates a memory trace (with default naming), Math at the end of the trace label indicates a mathematical trace.

- Page 89 Allice Messtechnik GmbH ® Concepts and features R&S Screen elements Example: The following context menu is assigned to the measured quantity section in the trace list: A label "Cal Off" appears at the end of the trace line if the system error correction no longer applies to the trace.

- Page 90 Allice Messtechnik GmbH ® Concepts and features R&S Screen elements The most common tasks to be performed with markers can be achieved using the "Marker" menu functions: ● Determine the coordinates of a measurement point on the trace. In polar diagrams where no x-axis is displayed, markers can be used to retrieve the stimulus value of specific points.

- Page 91 Allice Messtechnik GmbH ® Concepts and features R&S Screen elements markers assigned to a trace are independent of each other and of the trace format settings. ● The active marker has a dot placed in front of the marker line.

- Page 92 Allice Messtechnik GmbH ® Concepts and features R&S Screen elements trace (the raw measurement data) and the respective target format. This must be kept in mind when interpreting the results and physical units displayed. The following table describes how a complex marker value z = x + jy is converted. It jφ(z)

- Page 93 Allice Messtechnik GmbH ® Concepts and features R&S Screen elements Marker Format Description Formula Imp Mag Magnitude of (series) impedance | = (R IMP Mag series***) Imp Mag paral- Magnitude of parallel impedance | = (R lel***) Adm Mag...

- Page 94 Allice Messtechnik GmbH ® Concepts and features R&S Screen elements Only one kind of marker coupling can be enabled. For instance it is not possible to cou- ple markers per channel and per diagram at the same time. Basic marker search functions The search functions are tools for searching measurement data according to specific criteria.

- Page 95 Allice Messtechnik GmbH ® Concepts and features R&S Screen elements The info field contains the following search results: ● "Bandwidth" is the n-dB bandwidth of the bandpass/bandstop region, where n is a selectable bandwidth factor. The bandwidth is equal to the difference between the lower and the upper band edge frequency.

- Page 96 Allice Messtechnik GmbH ® Concepts and features R&S Screen elements Each line in the channel list describes a single channel. The channel of the active trace is highlighted. The lines are divided into several sections with the following contents (from left to right): ●...

-

Page 97: Dialogs

Allice Messtechnik GmbH ® Concepts and features R&S Screen elements ● Channel list (separate context menus for channel name section, sweep range sec- tion, additional parameter section) To open a context menu associated with a display element, tap and hold the element for some seconds. - Page 98 Allice Messtechnik GmbH ® Concepts and features R&S Screen elements numeric value is incremented or decremented, or when display elements are added or removed. In most dialogs, however, it is possible to cancel an erroneous input before it takes effect.

- Page 99 Allice Messtechnik GmbH ® Concepts and features R&S Screen elements ● "Windows Explorer" opens the selected directory in the Windows Explorer. ● "File name" specifies a filename to save the current data. The analyzer adds the extension in the "Files of type" field.

-

Page 100: Trace Formats

Allice Messtechnik GmbH ® Concepts and features R&S Screen elements Figure 4-4: Multi-channel setup dialog The channel selector in the title bar and the channel-related buttons in the lower part of the dialog ("Copy to New Channel", "Copy to New Ch + Diagram" allow you to select the target channels. - Page 101 Allice Messtechnik GmbH ® Concepts and features R&S Screen elements ● The x-axis scaling depends on the sweep type of the channel to which the trace is assigned: – For sweep types "Lin Freq", "Power", "CW Mode" and "Time" it is scaled line- arly.

- Page 102 Allice Messtechnik GmbH ® Concepts and features R&S Screen elements An extended range of formats and conversion formulas is available for markers. To convert any point on a trace, create a marker and select the appropriate marker format. Marker and trace formats can be selected independently.

- Page 103 Allice Messtechnik GmbH ® Concepts and features R&S Screen elements Example: Reflection coefficients in polar diagrams If the measured quantity is a complex reflection coefficient (S etc.), then the cen- ter of the polar diagram corresponds to a perfect load Z at the input test port of the DUT (no reflection, matched input).

- Page 104 Allice Messtechnik GmbH ® Concepts and features R&S Screen elements ● Points with the same reactance produce arcs. The following example shows a Smith chart with a marker used to display the stimulus value, the complex impedance Z = R + j X and the equivalent inductance L.

- Page 105 Allice Messtechnik GmbH ® Concepts and features R&S Screen elements dinates in the normalized impedance plane and in the reflection coefficient plane are related as follows (see also: definition of matched-circuit (converted) impedances): From this equation, it is easy to relate the real and imaginary components of the com- plex resistance to the real and imaginary parts of Γ:...

- Page 106 Allice Messtechnik GmbH ® Concepts and features R&S Screen elements In a diagram, the grid lines overlaid to a "Smith" trace correspond to points of equal conductance G and susceptance B: ● Points with the same conductance are located on circles.

- Page 107 Allice Messtechnik GmbH ® Concepts and features R&S Screen elements ● The upper and lower half of the diagram correspond to negative (inductive) and positive (capacitive) susceptive components of the admittance, respectively. Example: Reflection coefficients in the inverted Smith chart If the measured quantity is a complex reflection coefficient Γ...

-

Page 108: Measurement Results

Allice Messtechnik GmbH ® Concepts and features R&S Measurement results 4.2.3.3 Measured quantities and trace formats The analyzer allows any combination of a display format and a measured quantity. The following rules can help to avoid inappropriate formats and find the format that is ide- ally suited to the measurement task. -

Page 109: S-Parameters

Allice Messtechnik GmbH ® Concepts and features R&S Measurement results 4.3.1 S-parameters S-parameters are the basic measured quantities of a network analyzer. They describe how the DUT modifies a signal that is transmitted or reflected in forward or reverse direction. -

Page 110: Reference Impedances

Allice Messtechnik GmbH ® Concepts and features R&S Measurement results Meaning of squared amplitudes The squared amplitudes of the incident and outgoing waves and of the matrix elements have a simple meaning: Table 4-3: Squared S-parameters Available incident power (= the power provided by a generator with... - Page 111 Allice Messtechnik GmbH ® Concepts and features R&S Measurement results The default values for the balanced port reference impedances are derived from the default reference impedance of the physical analyzer ports (Z = 50 Ω): ● The default value for the differential mode is Z = 100 Ω...

-

Page 112: Impedance Parameters

Allice Messtechnik GmbH ® Concepts and features R&S Measurement results ... - Page 113 Allice Messtechnik GmbH ® Concepts and features R&S Measurement results Example: For a 2-port DUT that is terminated at its output with the reference impedance Z is the input impedance (matched-circuit impedance measured in a forward reflection measurement). A converted impedance Z completely describes a one-port DUT.

- Page 114 Allice Messtechnik GmbH ® Concepts and features R&S Measurement results Table 4-5: Calculation of Converted Series Transmission Impedances Traveling Waves Power Waves Parallel transmission impedance A two-port transmission parameter Z (i ≠ j) can also describe a parallel impedance between the two ports.

- Page 115 Allice Messtechnik GmbH ® Concepts and features R&S Measurement results 4.3.3.2 Z-parameters The Z-parameters describe the impedances of a DUT with open output ports (impe- dance = 0). The analyzer provides the full set of Z-parameters including the transfer impedances (i.e.

-

Page 116: Admittance Parameters

Allice Messtechnik GmbH ® Concepts and features R&S Measurement results ● is the output impedance, defined as the ratio of the voltage V to the current I measured at port 2 (reverse measurement with open input, I = 0). -

Page 117: Wave Quantities And Ratios

Allice Messtechnik GmbH ® Concepts and features R&S Measurement results ● is the forward transfer admittance, defined as the ratio of the current I to the voltage V (forward measurement with output terminated in a short circuit, V = 0). - Page 118 Allice Messtechnik GmbH ® Concepts and features R&S Measurement results Examples for using wave quantities The wave quantities provide the power at the different receive ports of the analyzer. This is different from an S-parameter measurement, where the absolute power of a lin- ear device is canceled.

- Page 119 Allice Messtechnik GmbH ® Concepts and features R&S Measurement results Examples for using ratios A measurement of ratios is particularly suitable for the following test scenarios: ● The test setup or some of its components (e.g. active components or non-recipro- cal devices) do not allow a system error correction so that a complete S-parameter measurement is not possible.

-

Page 120: Unbalance-Balance Conversion

Allice Messtechnik GmbH ® Concepts and features R&S Measurement results The following detectors are available: ● "Normal" selects the default detector mode where each valid measurement point is displayed without modification. The analyzer then proceeds to the next sweep point. - Page 121 Allice Messtechnik GmbH ® Concepts and features R&S Measurement results Internal balance- unbalance conversion Logical Physical VNA ports VNA ports Common Differential mode mode Balanced port Physical transformer (balun) Unbalance-balance conversion avoids the disadvantages of real transformers: ● There is no need to fabricate test fixtures with integrated baluns for each type of DUT.

- Page 122 Allice Messtechnik GmbH ® Concepts and features R&S Measurement results Example: 2 physical ports: Reflection measurements on 1 balanced port Balanced port: Differential mode Log. Bal. port port Common mode 3 physical ports: Reflection and transmission measurements on 1 balanced port...

- Page 123 Allice Messtechnik GmbH ® Concepts and features R&S Measurement results Mixed mode parameters are used to distinguish the following three port modes: ● s: Single-ended (for unbalanced ports) ● d: Differential mode (for balanced ports) ● c: Common mode (for balanced ports) The notation of a general S-parameter is S , where <mout>...

- Page 124 Allice Messtechnik GmbH ® Concepts and features R&S Measurement results 2. DUT with one balanced port: Only reflection and mode conversion measurements with differential and common mode parameters. 3. DUT with one balanced and one single-ended port. 4. DUT with two balanced ports or one balanced and two single-ended ports. Both device types are fully characterized by 4x4 mixed mode S-matrices.

-

Page 125: Stability Factors

Allice Messtechnik GmbH ® Concepts and features R&S Measurement results General Definition In general, imbalance and CMRR are quantities with two numeric indices, indicating the logical output port and the logical input port of the DUT during the measurement... -

Page 126: Delay, Aperture, Electrical Length

Allice Messtechnik GmbH ® Concepts and features R&S Measurement results where denotes the complex conjugate of S. Stability factors are calculated as functions of the frequency or another stimulus parameter. -

Page 127: Operations On Traces

Allice Messtechnik GmbH ® Concepts and features R&S Operations on traces In practice, the analyzer calculates an approximation to the derivative of the phase response, taking a small frequency interval Δf and determining the corresponding phase change ΔΦ. The delay is thus computed as: ... - Page 128 Allice Messtechnik GmbH ® Concepts and features R&S Operations on traces A limit check consists of comparing the measurement results to the limit lines and dis- play a pass/fail indication. An acoustic warning and a TTL signal at the USER PORT on the rear panel (for test automation) can be generated in addition if a limit is violated.

- Page 129 Allice Messtechnik GmbH ® Concepts and features R&S Operations on traces When the sweep axis is changed from linear frequency sweep to logarithmic sweeps, straight limit lines are transformed into exponential curves. The sweep points are redis- tributed along the x-axis, so the number of failed points can change.

- Page 130 Allice Messtechnik GmbH ® Concepts and features R&S Operations on traces 4.4.1.2 Rules for ripple test definition The analyzer places few restrictions on the definition of ripple limit ranges. The following rules ensure a maximum of flexibility: ● Ranges do not have to be sorted in ascending or descending order (e.g. the "Start Stimulus"...

- Page 131 Allice Messtechnik GmbH ® Concepts and features R&S Operations on traces The limit line rules for logarithmic sweeps and segmented frequency sweeps with point-based x-axis also apply to ripple limit lines (see Chapter 4.4.1.1, "Rules for limit line definition", on page 128).

- Page 132 Allice Messtechnik GmbH ® Concepts and features R&S Operations on traces ● With a circle limit line centered on the left border of an inverted Smith diagram (Y = infinity), you can check whether the imaginary part of the admittance (Im(Y), sus- ceptance) falls below a limit.

- Page 133 Allice Messtechnik GmbH ® Concepts and features R&S Operations on traces 4.4.1.4 File format for limit lines The analyzer uses a simple ASCII format to export limit line data. By default, the limit line file has the extension *.limit and is stored in the directory shown in the "Save Limit Line"...

-

Page 134: Trace Files

Allice Messtechnik GmbH ® Concepts and features R&S Operations on traces Compatibility with other instruments The VNAs of the R&S ZNx and R&S ZVx families use the same file format. Limit line files can be interchanged without restriction. 4.4.1.5 File format for ripple limits The analyzer uses a simple ASCII format to export ripple limits. - Page 135 Allice Messtechnik GmbH ® Concepts and features R&S Operations on traces ● When exporting traces to a file, it is recommended to set the analyzer to single sweep mode (CHANNEL – [SWEEP] > "Sweep Control" > "All Channels on Hold").

- Page 136 Allice Messtechnik GmbH ® Concepts and features R&S Operations on traces # <frequency unit> <parameter> <data format> R <reference resistance> ● # indicates the beginning of the option line ● <frequency unit> can be either Hz, kHz, MHz or GHz. Default is GHz.

- Page 137 Allice Messtechnik GmbH ® Concepts and features R&S Operations on traces Timestamp The timestamp comment line reflects the time at which the Touchstone file was cre- ated. For "Version 1.1 (ZNx)" export format, it is represented as Coordinated Universal...

- Page 138 Allice Messtechnik GmbH ® Concepts and features R&S Operations on traces ● "Version 1.1" and "Version 2.0" export formats These export formats always use single-ended identifiers Sij and port numbers 1 to n in the table header. ! freq[Hz] S11[Re] S11[Im] ...

- Page 139 Allice Messtechnik GmbH ® Concepts and features R&S Operations on traces The purpose of the keywords is to give more details about the file contents in a stand- ardized way. During "Version 2.0" export, the R&S ZND writes the following keywords...

- Page 140 Allice Messtechnik GmbH ® Concepts and features R&S Operations on traces first (or only) data line of a data block is a frequency value. The complex network parameter data is formatted as pairs of values. The following general rules apply ●...

- Page 141 Allice Messtechnik GmbH ® Concepts and features R&S Operations on traces 1.000000000000000e+09 -2.375070438098596e-01 -4.533104459856211e-01 1.010000000000000e+09 -3.132740349817996e-01 -5.874596585157938e-01 1.020000000000000e+09 -3.062444919836442e-01 -4.587379501906624e-01 Conditions for Touchstone file export ● One-port Touchstone files with data from a single trace Typically, Touchstone files contain a complete set of S-parameter traces of an n- port network.

- Page 142 Allice Messtechnik GmbH ® Concepts and features R&S Operations on traces In this case, the reference impedances of the individual ports are used for the renormalization and these impedances are documented in the Renormalization information comment. If the port-specific reference impedances are different, an additional warning is added to this comment, indicating that the option line contains a non-matching reference resistance.

-

Page 143: Memory-Mapped Trace Data Transfer

Allice Messtechnik GmbH ® Concepts and features R&S Operations on traces The stimulus values are arranged in ascending order. 4.4.2.3 Finding the best file format The file format depends on how you want to use the exported data. Use a Touchstone file format to export S-parameter data traces to a file that can be... - Page 144 Allice Messtechnik GmbH ® Concepts and features R&S Operations on traces Set up a shared memory buffer The setup of a shared memory buffer and the allocation of trace data is performed by a sequence of SYSTem:DATA:MEMory... commands, starting with an INITialize and finished by a COMMit.

-

Page 145: Calibration

Allice Messtechnik GmbH ® Concepts and features R&S Calibration 4.5 Calibration Calibration or system error correction is the process of eliminating systematic, reprodu- cible errors from the measurement results (S-parameters and derived quantities; see Chapter 4.1.5, "Data flow", on page 82). The process involves the following stages: 1. -

Page 146: Calibration Types

Allice Messtechnik GmbH ® Concepts and features R&S Calibration Cal Off label A label "Cal Off" appears in the trace line if the system error correction no longer applies to the trace: This can happen for one of the following reasons: ●... - Page 147 Allice Messtechnik GmbH ® Concepts and features R&S Calibration Calibration Type Standards Parameters Error Terms General Accuracy Application One Path Two Ports Open, Short, for fixed source Reflection tracking, Medium to high Unidirectional trans- mission measure- Match (at source...

- Page 148 Allice Messtechnik GmbH ® Concepts and features R&S Calibration Calibration Type Standards Parameters Error Terms General Accuracy Application Through, Attenua- Reflection tracking, High, lowest Reflection and tion, Symmetric requirements on transmission mea- (2-port) Source match, network standards surements, espe-...

-

Page 149: Reflection Osm Calibration

Allice Messtechnik GmbH ® Concepts and features R&S Calibration ● Manual reflection normalizations offer Complementary Match standard measure- ments ● Manual transmission normalizations support Complementary isolation measure- ment (optional). Complementary Match standard measurements For reflection normalizations, the mandatory Open or Short measurements can be complemented by optional Match measurements. -

Page 150: Tosm And Uosm Calibration

Allice Messtechnik GmbH ® Concepts and features R&S Calibration With a unidirectional R&S ZND (see Chapter 4.1.4.3, "R&S ZND: unidirectional vs. bidirectional operation", on page 80) only the forward direction (source port 1) is availa- ble. 4.5.1.4 TOSM and UOSM calibration TOSM A TOSM (Through –... -

Page 151: Adapter Removal

Allice Messtechnik GmbH ® Concepts and features R&S Calibration After acquiring the calibration sweep data for the unknown through, the analyzer auto- matically determines its delay time/transmission phase. 4.5.1.5 Adapter removal Many DUTs use different connector types on their RF ports (e.g. port 1: N-type connec- tor, female;... -

Page 152: Tom Calibration

Allice Messtechnik GmbH ® Concepts and features R&S Calibration Figure 4-7: Adapter Removal vs. UOSM The obtained adapter characteristics are mathematically removed from the obtained error coefficients. Uncertainties arising from a non-ideal characterization of the unknown through almost cancel, whereas they add up in the UOSM technique. As a consequence, Adapter Removal will provide more accurate results. -

Page 153: Trm Calibration

Allice Messtechnik GmbH ® Concepts and features R&S Calibration 4.5.1.8 TRM calibration A TRM (Through – Reflect – Match) calibration requires a low-reflection, low-loss Through standard with an electrical length that can be different from zero, a Reflect, and a Match. The magnitude of the reflection coefficient of the Reflect standard can be unknown but must be nonzero;... - Page 154 Allice Messtechnik GmbH ® Concepts and features R&S Calibration To shift the calibrated sweep range to smaller or larger frequencies, you can use a lon- ger or shorter Line. To extend the calibrated range, use one of the following methods: ●...

-

Page 155: Tna Calibration

Allice Messtechnik GmbH ® Concepts and features R&S Calibration ● The shorter Line can be used from a frequency f where its transmission phase short is equal to 20 deg. This frequency is equal to /[18*(l – l short short ●... -

Page 156: Full N-Port Calibration With Reduced Number Of Through Connections

Allice Messtechnik GmbH ® Concepts and features R&S Calibration must be well matched on both sides and cause an attenuation different from 0 dB; the exact value of the transmission coefficient is not important. As with TRL, TNA calibration is especially useful for planar DUTs. If TNA is not practi- cable, TRL can be an alternative. -

Page 157: Calibration Standards And Calibration Kits

Allice Messtechnik GmbH ® Concepts and features R&S Calibration possible through connections are measured by default. If you want to apply the "Reduced Through" logic also for each port assignment, you can activate it in the system configuration. 4.5.1.12... - Page 158 Allice Messtechnik GmbH ® Concepts and features R&S Calibration 4.5.2.1 Calibration standard types The following table gives an overview of the different standards and their circuit models (offset and load models). Table 4-8: Calibration standard types Standard Type Characteristics...

- Page 159 Allice Messtechnik GmbH ® Concepts and features R&S Calibration ● The loss is the energy loss along the transmission line due to the skin effect. For resistive lines and at RF frequencies, the loss is approximately proportional to the square root of the frequency.

- Page 160 Allice Messtechnik GmbH ® Concepts and features R&S Calibration 4.5.2.2 Cal kit parameter types The analyzer uses three types of parameters to describe the calibration standards. The parameter type is the same for all standards in a kit and therefore appended to the kit name: ●...

- Page 161 Allice Messtechnik GmbH ® Concepts and features R&S Calibration The following additional parameters are used: ● Characteristic impedance: Z (characteristic impedance of the connector type) ● Loss: 0 dB / sqrt(GHz) or (0 GΩ / s) in Keysight mode ●...

- Page 162 Allice Messtechnik GmbH ® Concepts and features R&S Calibration ● The Sliding Match results are used for frequencies above the Min Freq. In general, the Sliding Match provides better results than the Match within its specified fre- quency range.

-

Page 163: Calibration Pool

Allice Messtechnik GmbH ® Concepts and features R&S Calibration The network analyzer expects the dot as a separator and displays an error message when a *.csv file with commas is loaded. Please install the VNA Cal Kit Manager ®... -

Page 164: Automatic Calibration

Allice Messtechnik GmbH ® Concepts and features R&S Calibration 4.5.5 Automatic calibration A calibration unit is an integrated solution for automatic system error correction of vec- tor network analyzers. Rohde & Schwarz offers a wide range of calibration units for dif- ferent frequency ranges and connector types. - Page 165 Allice Messtechnik GmbH ® Concepts and features R&S Calibration 4.5.5.1 Connecting the calibration unit The calibration units provide the following connectors: ● USB type B connector at the rear, which is used to power-supply and control the unit. A USB cable for connection to the network analyzer is provided with the cali- bration unit.

- Page 166 Allice Messtechnik GmbH ® Concepts and features R&S Calibration 4.5.5.2 Performing an automatic calibration After connection and initialization of the calibration unit, perform the automatic calibra- tion of the related test ports using the "Calibration Unit" wizard (CHANNEL – [CAL] >...

- Page 167 Allice Messtechnik GmbH ® Concepts and features R&S Calibration ● A one path two port calibration. The node port is the source port for the one path two port calibration (fully calibrated port). ● A transmission normalization (bidirectional, forward or reverse). "Forward" trans- mission normalization means that the signal direction is from port 1 to port 2.

- Page 168 Allice Messtechnik GmbH ® Concepts and features R&S Calibration 4.5.5.4 Inline calibration Any disturbance of the measurement setup after the calibration process inevitably pro- duces errors. If a massive system error correction is required, e.g. if long RF cables with high damping are used, those disturbances can lead to inaccurate and unreprodu- cible measurement results.

- Page 169 Allice Messtechnik GmbH ® Concepts and features R&S Calibration Figure 4-10: ICC R&S ZN-Z30 For more information, see the R&S ZN-Z3x product pages at https://www.rohde- schwarz.com/product/NetworkAnalyzer_Acc_ZNZ3. Firmware integration The control connection between R&S ZND and ICC is established via USB. After the VNA firmware has detected the ICC, it requests information about connected ICUs from the ICC.

- Page 170 Allice Messtechnik GmbH ® Concepts and features R&S Calibration Because the ICC does not support hot plugging of ICUs, connect the ICUs to the ICC before connecting the ICC to the R&S ZND. The VNA firmware supports: ● Pulling characterization data for the connected ICUs from the ICC ●...

- Page 171 Allice Messtechnik GmbH ® Concepts and features R&S Calibration Step 1: OSM g) Step 2: Unknown Through 5. Connect the DUT to the calibrated setup and perform the required measurements. 6. Refresh the calibration in situ, whenever required. a) "Repeat" the calibration b) Perform OSM measurements.

- Page 172 Allice Messtechnik GmbH ® Concepts and features R&S Calibration brated channel, only the two connected instrument ports are validated against the cal unit. The validation logic proceeds through the connected ports p ∈ {1, ..., 4} in ascending order, measuring S for the Open, Short and Match standard.

- Page 173 Allice Messtechnik GmbH ® Concepts and features R&S Calibration For a channel with more calibrated ports than cal unit ports available, you can change the port assignments and rerun the automated validation. Or you can switch to advanced mode and validate each port manually.

- Page 174 Allice Messtechnik GmbH ® Concepts and features R&S Calibration the calibration type, a "minimal" valid and complete solution can be described as fol- lows: Calibration Minimal solution Default solution (minimal) type Full One Port Each calibrated test port must appear in exactly one Subdivide the n test ports into port assignment.

-

Page 175: Scalar Power Calibration

Allice Messtechnik GmbH ® Concepts and features R&S Calibration Example: The following examples show minimal port assignments for a Full 9-Port calibration using a four-port calibration unit: Table 4-11: Full n-port: Star-shaped optimum solution Test Port Assignment 1 Assignment 2... - Page 176 Allice Messtechnik GmbH ® Concepts and features R&S Calibration Table 4-13: System error correction and power calibration for various measurements Measurement System error correction Scalar power calibration S-parameter meas. on linear Yes, necessary Not necessary DUTs Meas. of wave quantities or ratios...

- Page 177 Allice Messtechnik GmbH ® Concepts and features R&S Calibration calibration plane or to any other point in the test setup where the signal power is known to be proportional to the power at the calibration plane. By default, the source power calibration involves several steps: 1.

- Page 178 Allice Messtechnik GmbH ® Concepts and features R&S Calibration A measurement receiver calibration generally improves the accuracy of power (wave quantity) measurements. The correction data acquired in a frequency or power sweep is re-used if a "Time" or "CW Mode" sweep is activated.

- Page 179 Allice Messtechnik GmbH ® Concepts and features R&S Calibration Calibration of S-parameters S-parameters and derived quantities (e.g. impedances, admittances, stability factors) are assumed to be linear. Therefore, a scalar power calibration is not applied to S-parameters and derived quan- tities;...

- Page 180 Allice Messtechnik GmbH ® Concepts and features R&S Calibration manually or automatically (CHANNEL – [CAL] > "Pwr Cal Settings" > "Transm. Coeffi- cients..."). The R&S ZND supports two different test scenarios. A: Two-port at DUT (during measurement) Test and measurement procedure: 1.

-

Page 181: Parallel Calibration Of Multiple Channels

Allice Messtechnik GmbH ® Concepts and features R&S Calibration Practical example: An adapter or attenuator with known attenuation is needed to con- nect the power sensor to the test port of the network analyzer. The transmission coeffi- cients of the adapter are used for the power meter correction. -

Page 182: Offset Parameters And De-/Embedding

Allice Messtechnik GmbH ® Concepts and features R&S Offset parameters and de-/embedding 4.6 Offset parameters and de-/embedding The R&S ZND functionality described in this section complements the calibration, com- pensating for the effect of known transmission lines or matching networks between the calibrated reference plane and the DUT. - Page 183 Allice Messtechnik GmbH ® Concepts and features R&S Offset parameters and de-/embedding In the limit case, where the length of the transmission line is considered to be "almost zero", the loss is considered constant: Otherwise, if the loss at DC and one additional frequency f...

- Page 184 Allice Messtechnik GmbH ® Concepts and features R&S Offset parameters and de-/embedding This yields the delay for propagation in forward and reverse direction and should be approx. twice the "Auto Length" result. For transmission measurements, both results should be approx. equal.

- Page 185 Allice Messtechnik GmbH ® Concepts and features R&S Offset parameters and de-/embedding "Auto Length and Loss" involves a two-step procedure: ● An "Auto Length" correction modifies the phase of the measured quantity, minimiz- ing the residual group delay. The magnitude of the measured quantity is not affec- ted.

- Page 186 Allice Messtechnik GmbH ® Concepts and features R&S Offset parameters and de-/embedding 4.6.1.5 Fixture Compensation "Fixture Compensation" is an automated length offset and loss compensation for test fixtures. The analyzer performs a one-port reflection measurement at each port, assuming the inner contacts of the test fixtures to be terminated with an open or short circuit.

- Page 187 Allice Messtechnik GmbH ® Concepts and features R&S Offset parameters and de-/embedding fixture compensation sweeps to compensate for the inaccuracies of the individual "Open and Short" compensations. 4.6.1.6 Application and effect of offset parameters Offset and loss parameters can be particularly useful if the reference plane of the cali- bration cannot be placed directly at the DUT ports, e.g.

-

Page 188: Embedding And Deembedding

Allice Messtechnik GmbH ® Concepts and features R&S Offset parameters and de-/embedding ● "Auto Length" corrects the length offset of both physical ports of a logical port by the same amount. 4.6.2 Embedding and deembedding The R&S ZND allows you to define virtual networks to be added to/removed from the measurement circuit for a DUT with single ended or balanced ports. - Page 189 Allice Messtechnik GmbH ® Concepts and features R&S Offset parameters and de-/embedding Single-ended Balanced port port Balun Matching circuit The idea of virtual embedding is to simulate the matching network and avoid using physical circuitry so that the analyzer ports can be directly connected to the input and output ports of the DUT.

- Page 190 Allice Messtechnik GmbH ® Concepts and features R&S Offset parameters and de-/embedding To be numerically removed, the real network must be described by a set of S-parame- ters or by an equivalent circuit of lumped elements. Deembedding the DUT effectively extends the calibration plane towards the DUT ports, enabling a realistic evaluation of the DUT without the distorting network.

- Page 191 Allice Messtechnik GmbH ® Concepts and features R&S Offset parameters and de-/embedding The following networks are composed of a shunt C or L (as seen from the analyzer port), followed by a serial C or L. They are named Shunt C, Serial L / Shunt L, Serial C / Shunt C, Serial C / Shunt L, Serial L.

- Page 192 Allice Messtechnik GmbH ® Concepts and features R&S Offset parameters and de-/embedding parameters, or the entire transformation network can be described by imported 4-port S-parameters. The first network is defined by its S-parameters stored in an imported four-port Touch- stone file (*.s4p).

- Page 193 Allice Messtechnik GmbH ® Concepts and features R&S Offset parameters and de-/embedding Since FW version 1.93, the "capacitance C<i> in parallel with resistance R<i>" circuit blocks can alternatively be represented as "capacitance C<i> in parallel with conduc- tance G<i>" circuit blocks.

- Page 194 Allice Messtechnik GmbH ® Concepts and features R&S Offset parameters and de-/embedding Network Analyzer Embedding Network 2m-1 Figure 4-11: Port Set De-/Embedding As shown in section Combining Several de-/embedding networks, port set deembed- ding is calculated after single-ended deembedding, and the port set embedding step precedes single ended embedding.

- Page 195 Allice Messtechnik GmbH ® Concepts and features R&S Offset parameters and de-/embedding ● For the R&S ZND, each port set can consist of m = 2 ports ● For these port pairs, the de-/embedding network can be defined either via lumped...

- Page 196 Allice Messtechnik GmbH ® Concepts and features R&S Offset parameters and de-/embedding Differential Matching Network Balun In contrast to standard balanced embedding (4-port), the matching circuit is only applied to the differential mode port (2-port). It can be specified via a Touchstone s2p file or by parametrizing a lumped "Shunt L, Shunt C"...

- Page 197 Allice Messtechnik GmbH ® Concepts and features R&S Offset parameters and de-/embedding Fixture Modeling Process For all supported tools, the fixture modeling proceeds as follows: 1. Perform a calibration to the fixture connectors. 2. Measure one or more PCB test coupons for the related fixture.

- Page 198 Allice Messtechnik GmbH ® Concepts and features R&S Offset parameters and de-/embedding Test Coupons for Lead-ins Test Coupons for Lead-outs 2x Through 2x Through 1x Open 1x Short 1x Open 1x Short Figure 4-13: Test Coupons (balanced) Test Coupons for Lead-ins...

- Page 199 Allice Messtechnik GmbH ® Concepts and features R&S Offset parameters and de-/embedding Figure 4-15: De-/Embedding calculation flow This means that the real networks are removed before virtual networks are added. The (de-)embedding steps are carried out in the following order: 1.

-

Page 200: Optional Extensions And Accessories

Allice Messtechnik GmbH ® Concepts and features R&S Optional extensions and accessories 3. Balanced port deembedding 4. Balanced port embedding 5. Single ended port embedding 4.7 Optional extensions and accessories The instrument can be upgraded with various software and hardware options, provid- ing enhanced flexibility and an extended measurement functionality. -

Page 201: Frequency Range Extension To 8.5 Ghz For Unidirectional R&S Znd

Allice Messtechnik GmbH ® Concepts and features R&S Optional extensions and accessories 4.7.1 Frequency range extension to 8.5 GHz for unidirectional R&S ZND Option R&S ZND-K1 Software option R&S ZND-K1 increases the upper frequency limit of a unidirectional R&S ZND (i.e. not equipped with R&S ZND-K5) from 4.5 GHz to 8.5 GHz. -

Page 202: Time Domain Analysis

Allice Messtechnik GmbH ® Concepts and features R&S Optional extensions and accessories Recalibration Required Although this is a software option, the R&S ZND has to be recalibrated at Rohde & Schwarz service to comply with the specifications of the data sheet. - Page 203 Allice Messtechnik GmbH ® Concepts and features R&S Optional extensions and accessories ● The time domain response is repeated after a time interval which is equal to Δt = 1/ Δf, where Δf is the spacing between two consecutive sweep points in the frequency domain.

- Page 204 Allice Messtechnik GmbH ® Concepts and features R&S Optional extensions and accessories The two alternative responses are mathematically equivalent; the step response can be obtained by integrating the impulse response: Integrate impulse response Obtain step response The step response is recommended for impedance measurements and for the analysis of discontinuities (especially inductive and capacitive discontinuities).

- Page 205 Allice Messtechnik GmbH ® Concepts and features R&S Optional extensions and accessories The point symmetry with respect to the DC value makes harmonic grids suitable for lowpass time domain transformations. Visualization of the harmonic grid algorithms The R&S ZND provides three different algorithms for harmonic grid calculation. The three harmonic grids have the following characteristics: ●...

- Page 206 Allice Messtechnik GmbH ® Concepts and features R&S Optional extensions and accessories The figures above are schematic and do not comply with the conditions placed on the number of sweep points and interpolated/extrapolated values. The harmonic grids cannot be calculated for any set of sweep points. If the minimum number of sweep points is smaller than 5, then the interpolation/extrapolation algorithm for additional sweep points does not work.

- Page 207 Allice Messtechnik GmbH ® Concepts and features R&S Optional extensions and accessories The properties of the time gates are analogous to the properties of the frequency domain windows. The following table gives an overview: Table 4-18: Properties of time gates...

- Page 208 Allice Messtechnik GmbH ® Concepts and features R&S Optional extensions and accessories The rectangular "No Profiling (Rectangle) "windows minimize numerical inaccuracies near the boundaries of the measured frequency span. In the limit where the effect of the time gate vanishes (e.g. a gate of type "Notch" and a very small width), the time gated trace is equal to the original measured trace.

-

Page 209: Distance-To-Fault Measurements

Allice Messtechnik GmbH ® Concepts and features R&S Optional extensions and accessories blue arrow = direct signal red and green arrows = reflected signal TD S Calculation VSWR The ANSI time-domain method relies on a complex transmission measurement (S using a vector network analyzer (VNA). - Page 210 Allice Messtechnik GmbH ® Concepts and features R&S Optional extensions and accessories Adjust the frequency sweep to the length of the transmission line and the expected dis- tance to fault: ● The maximum distance that can be measured is proportional to the number of sweep points.

-

Page 211: Frequency Resolution 1 Mhz

Allice Messtechnik GmbH ® Concepts and features R&S Optional extensions and accessories ● For a unidirectional R&S ZND, only port 1 can be used for distance-to-fault mea- surements. ● A more flexible approach with additional configuration possibilities is available with time domain option R&S ZND-K2 (see... - Page 212 Allice Messtechnik GmbH ® Concepts and features R&S Optional extensions and accessories Figure 4-16: Fixture modeling: EZD – Single Ended Ports dialog Figure 4-17: Fixture modeling: EZD – Balanced Ports dialog ● For general information about fixture de-embedding, see Chapter 4.6.2.9, "Fixture...

-

Page 213: In-Situ De-Embedding

Allice Messtechnik GmbH ® Concepts and features R&S Optional extensions and accessories 4.7.9 In-situ de-embedding Option R&S ZND-K220 This option offers a pre-installed or service-retrofitted version of AtaiTec's In Situ De- Embedding (ISD) tool for fixture de-embedding. The tool is integrated into the de-embedding functionality of the analyzer firmware. -

Page 214: Delta-L 4.0 Pcb Characterization

Allice Messtechnik GmbH ® Concepts and features R&S Optional extensions and accessories 4.7.11 Delta-L 4.0 PCB characterization Option R&S ZND-K231 Delta-L is a de-embedding methodology developed by Intel Corporation and is used for de-embedding strip lines that include vias. Delta-L calculates the loss of PCB intercon- nects and can be performed on single-ended or balanced interconnects. -

Page 215: Health And Usage Monitoring Service (Hums)

Allice Messtechnik GmbH ® Concepts and features R&S Optional extensions and accessories 4.7.12 Health and usage monitoring service (HUMS) Option R&S ZND-K980 The R&S ZND comes with a health and utilization monitoring system (HUMS) providing information about the R&S ZND. Aim is to increase the overall utilization, to avoid downtime and to increase the overall security level of a fleet of instruments. -

Page 216: High Output Power For R&S Znd

Allice Messtechnik GmbH ® Concepts and features R&S Optional extensions and accessories 4.7.13 High output power for R&S ZND Option R&S ZND-B7 With hardware option R&S ZND-B7, the output power of the R&S ZND can be signifi- cantly increased:... -

Page 217: Additional Removable System Drive

Allice Messtechnik GmbH ® Concepts and features R&S Optional extensions and accessories 4.7.16 Additional removable system drive Option R&S ZND-B19 Option R&S ZND-B19 provides an additional removable system drive for the R&S ZND, including operating system and VNA firmware. -

Page 218: External Power Meters

Allice Messtechnik GmbH ® Concepts and features R&S Optional extensions and accessories 4.7.19 External power meters The connection of an external power meter to the R&S ZND can serve different purpo- ses. ● Extended measurement functionality: Each external power meter represents an additional receive port. - Page 219 Allice Messtechnik GmbH ® Concepts and features R&S Optional extensions and accessories USB ports Control connection From VNA (e.g. USB) source port Power meter / sensor Power calibration plane External power meters must be configured with their connection type and device address before they are available as additional receivers (SYSTEM –...

-

Page 220: External Switch Matrices

Allice Messtechnik GmbH ® Concepts and features R&S Optional extensions and accessories 4.7.20 External switch matrices 4.7.20.1 Overview From the perspective of the VNA, the purpose of a switch matrix is to extend the num- ber of test ports. I.e. it converts an N-port network analyzer into an N'-port network analyzer (N'>N) without modifying the instrument itself. - Page 221 Allice Messtechnik GmbH ® Concepts and features R&S Optional extensions and accessories After this initial setup, the R&S ZND takes control of the attached matrices: it allows you to configure the test ports and dynamically establishes the required matrix routes according to the current measurement task.

- Page 222 Allice Messtechnik GmbH ® Concepts and features R&S Optional extensions and accessories Example: The 4x24 extension of switch matrix R&S ZN-Z84 consists of 2 separate 2x12 subma- trices, where matrix VNA ports of the "left" submatrix cannot be connected to the test ports of the "right"...

- Page 223 Allice Messtechnik GmbH ® Concepts and features R&S Optional extensions and accessories ZV-Z82-16 Figure 4-21: ZV-Z82-16: limited connectivity 4.7.20.4 Multiple paths: precision vs. speed A switch matrix may offer multiple routes to a given matrix test port and hence mea- surements may be performed using different physical paths (where a path consists of the traversed VNA connections and matrix routes).

- Page 224 Allice Messtechnik GmbH ® Concepts and features R&S Optional extensions and accessories Priority 1 Routes Priority 2 Routes Figure 4-22: ZV-Z81 Routes and priorities Example: For an R&S ZN-Z8x, each route traverses exactly one of the equipped 2x6 modules.

- Page 225 Allice Messtechnik GmbH ® Concepts and features R&S Optional extensions and accessories For every supported switch matrix, the available routes are prioritized according to the number of switches they traverse (the rectangles in Figure 4-22). ● To obtain highest measurement precision, the driving port should always use the "best possible"...

-

Page 226: External Dlls

Allice Messtechnik GmbH ® Concepts and features R&S Optional extensions and accessories 2-port VNA Route 1 Route 2 This kind of "multipath calibration" offers the following additional benefit: During manual calibration, the measured reflection/transmission coefficients are pre- sented as memory traces - one per path. By comparing these traces, it should be pos- sible to track down hardware problems (cables, connectors, matrix, ...) already during... - Page 227 Allice Messtechnik GmbH ® Concepts and features R&S Optional extensions and accessories 4.7.21.1 Basic use case A basic use case is the integration of a power supply into an arbitrary VNA sweep. Suppose that you want to test an amplifier with various bias settings. To do so, you can perform a CW sweep to measure S-parameters with different gate voltages applied to the amplifier at each sweep point.

-

Page 228: R&S Znxsim

Allice Messtechnik GmbH ® Concepts and features R&S Optional extensions and accessories If an external DLL is configured for permanent use, it performs a particular task (such as switching the state of a DUT or controlling external devices) without providing data. - Page 229 Allice Messtechnik GmbH ® Concepts and features R&S Optional extensions and accessories Figure 4-24: Instrument selection For information on installation and licensing, see the R&S ZNXSIM Getting Started manual available at https://www.rohde-schwarz.com/manual/ZNXSIM. 4.7.22.1 Simulation data The firmware simulation displays traces. To this end, it loads simulation data from one...

- Page 230 Allice Messtechnik GmbH ® Concepts and features R&S Optional extensions and accessories By default, the firmware simulation applies InputBufferGroupSimulation.s4p to all channels in all setups. For each setup in the firmware simulation, you have three possibilities to define and refine the simulated DUT.

- Page 231 Allice Messtechnik GmbH ® Concepts and features R&S Optional extensions and accessories ● Since version 3.40 of the analyzer firmware, simulation noise can be activated or deactivated from the analyzer GUI. ● Make sure to deactivate "Simulation Noise" before exporting traces to file (see Chapter 4.4.2, "Trace...

-

Page 232: Gui Reference

Allice Messtechnik GmbH ® GUI reference R&S Function Keys and Softtools 5 GUI reference This chapter describes the Graphical User Interface (GUI) of the analyzer. The most convenient way to access the GUI functions is via Softtools. Hence the GUI reference is structured accordingly. - Page 233 Allice Messtechnik GmbH ® GUI reference R&S Function Keys and Softtools Table 5-1: Function keys and softtools (Virtual) Hardkey Keyboard Shortcut Related Softtool Action TRACE – [MEAS] Alt + Shift + A Meas softtool default TRACE – [FORMAT] Alt + Shift + B...

-

Page 234: Meas Softtool

Allice Messtechnik GmbH ® GUI reference R&S Meas softtool (Virtual) Hardkey Keyboard Shortcut Related Softtool Action CHANNEL – [OFF- Alt + Shift + Q Offset Embed softtool default SET EMBED] SYSTEM – [FILE] Ctrl + O File softtool default SYSTEM –... -

Page 235: S-Params Tab

Allice Messtechnik GmbH ® GUI reference R&S Meas softtool 5.2.1 S-Params tab Selects S-parameters as measured quantities. S-parameters are the basic measured quantities of a network analyzer. They describe how the DUT modifies a signal that is transmitted or reflected in forward or reverse direction. S-parameters (and derived quantities such as Y- and Z-parameters) fully characterize a linear DUT. - Page 236 Allice Messtechnik GmbH ® GUI reference R&S Meas softtool Note: For a unidirectional R&S ZND (see Chapter 4.1.4.3, "R&S ZND: unidirectional vs. bidirectional operation", on page 80) the reverse direction cannot be measured. Hence S and balanced measurements are not available.