Summary of Contents for SOMAG RSM 400

- Page 1 RSM 400 User Manual Document Number: 111710-901-08/07 SOMAG AG Jena Am Zementwerk 8 mail: info@somag-ag.de 07745 Jena | Germany web: www.somag-ag.de...

- Page 2 Section 3 ‘Specifications’ Layout update ‘SOMAG Mount Control App Installation’ / chapters removed and docu- ment referenced April 01,2019 Section 5.1 ‘Set Up via SOMAG Mount Control App’ / chapters removed and document referenced New: Section 5.3 ‘Mount Communication Protocol’ / document referenced Updated: Section 3 ‘Specifications’...

-

Page 3: Table Of Contents

4.1.3 Continuous Torque Estimation ......................13 4.1.4 Dimensions of Fastening Holes / Footprint ..................14 4.1.5 Installation / Installing the RSM 400 ....................15 4.1.6 Main Dimensions / Mounting the Payload ..................15 Electrical Installation ..........................18 4.2.1 General Advice ........................... 18 4.2.2... - Page 4 Operation with an IMU........................21 Mount Communication Protocol ......................21 Maintenance, Transport and Storage ......................22 Maintenance ............................22 Transport and Storage ........................... 22 Troubleshooting .............................. 23 Firmware Update ............................ 23 Reshipment ............................. 23 111710-901-08/07 RSM 400 4 / 23...

-

Page 5: Safety

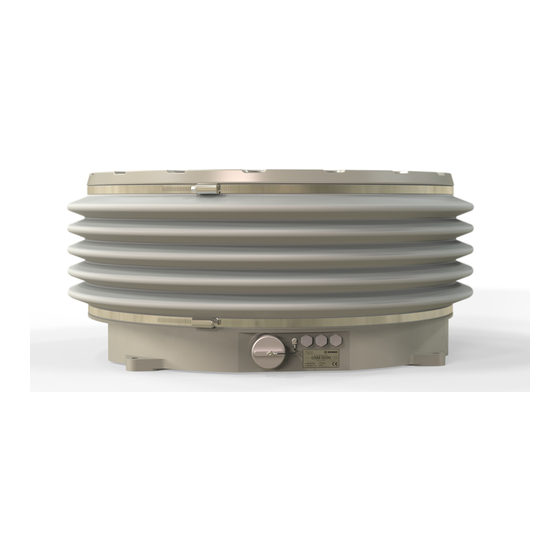

Handling instruction / DO NOT use marked place to handle the device 1.2 Proper Usage The RSM 400 (Ruggedized Gyro Stabilization Mount) is designed to automatically stabilize cameras, scanners, LIDARs and all other surveying equipment in two rotational axes. The device is used to compensate random vehicle movements. -

Page 6: Watertightness Disclaimer

Before use, please check the protective bellow for any tears or cracks. SOMAG AG Jena reserves the right to perform a cause analysis of devices damaged by water ingress to de- termine whether the defect is covered by the warranty. -

Page 7: Environmental- And Application Conditions

1.6 Falling or ejected objects Regularly check the tightening of the Stabilization Mount and payload fas- teners. 111710-901-08/07 RSM 400 7 / 23... -

Page 8: Safety Area

Mount. It is the user’s responsibility to do a risk analysis to define the right area size according to the circumstances as shown in Figure 1and in accordance with the used payload. Distance between Mount pivot and top mounting plate; compare Figure 5. 111710-901-08/07 RSM 400 8 / 23... -

Page 9: General Safety Tips

• DO NOT lift the RSM 400 by the areas marked by the red crosses. You will likely squeeze your hands if you use these positions to lift and carry the device. Furthermore, it is possible to damage the shell of the unit. -

Page 10: Standard Scope Of Delivery

Please make sure that the items according to your quote, purchase order and delivery are included in your package and contact the manufacturer (SOMAG AG Jena) if an item is missing! Software pre-installed on device / not physically available... -

Page 11: Specifications

Maximum duration 90 s at 55 °C surrounding temperature / longer if temperature inside the unit is < 55 °C Minimum: 132.5 mm / Maximum: 180.5 mm Horizontal payload CoG offsets are not considered; without wind force and other possible external forces 111710-901-08/07 RSM 400 11 / 23... -

Page 12: Installation

(caused by the vessel on which the Mount is installed) of 0.3 g. Any other conditions which fit the diagram will work as well. Figure 3: RSM 400 mass – center of gravity – lateral acceleration correlation (left: standard motor / right: optional motor configuration / high payload) -

Page 13: Continuous Torque Estimation

= �� ∙ �� ∙ √�� + �� Horizontal offset between payload CoG �� and center of stabilization Mount’s sur- face – x-direction Horizontal offset between payload CoG �� and center of stabilization Mount’s sur- face – y-direction 111710-901-08/07 RSM 400 13 / 23... -

Page 14: Dimensions Of Fastening Holes / Footprint

Mount shown in chapter 3. 4.1.4 Dimensions of Fastening Holes / Footprint • 4x Ø6.7 mm through holes in the RSM 400 base plate to fasten the device. • Screws must be longer than 9.5 mm to run through the RSM 400 base plate. -

Page 15: Installation / Installing The Rsm 400

Position the device straight over the installation holes. • Install the RSM 400 with four screws. A torque of 5 Nm is required to secure the device safely. 4.1.6 Main Dimensions / Mounting the Payload Figure 5 illustrates the main dimensions of the device, the payload mounting holes and the pivot. 10x M5 / 8 mm deep threaded holes are provided for installation purposes. - Page 16 Torque: 3.5 Nm Figure 5: RSM 400 payload mounting holes, main dimensions and pivot 111710-901-08/07 RSM 400 16 / 23...

- Page 17 48 mm (see Figure 6 / maximum height) and finally it moves to its working position (see Figure 5). The installation conditions need to be adapted accordingly to these possible movements. Figure 6: RSM 400 maximum height (top) / minimum height (bottom) 111710-901-08/07 RSM 400...

-

Page 18: Electrical Installation

4.2.2 Cabling of the RSM 400 Figure 7: Cabling of the RSM 400 A – Grounding Use the M5 / 5 mm deep threaded hole to ground the RSM 400. Replace the protective nylon screw with a metal screw! •... -

Page 19: Power J1 Cable

TABLET Port • usable with a 3rd party USB device. • should only be used to link the Mount with a computer to use the SOMAG Mount Control App. • connector type: USB 2.0 / Type-A plug. Connector D-Sub 9-way,... -

Page 20: Getting Started

If necessary, the device runs the electronic test phase (ETP) to check proper functionality of all sensors and electronic components. When the MTP, RTP and ETP are completed, the RSM 400 turns into its preset default mode (can be set up with the SOMAG Mount Control App / see chapter 5.1). -

Page 21: Manual Operation (Man Mode)

Check that the ‘MAN’ Mode is selected (‘MAN’ Mode button shines yellow) in the SOMAG Mount Control App (see chapter 5.1) and use the sliders to move Roll and Pitch (yaw axis is not enabled on the RSM 400). Under certain movement conditions (strong turbulence, harsh environmental conditions), for troubleshooting purposes or for checking the safety area of the payload it can be necessary to control the Mount manually with the SOMAG Mount Control App (see chapter 5.1). -

Page 22: Maintenance, Transport And Storage

The RSM 400 should be returned to the manufacturer for maintenance every two years. The requirement for service is also signaled in the SOMAG Mount Control App (see chapter 5.1). Should a malfunction of the Mount occur, please contact SOMAG AG Jena to solve the problem as quickly as possible. -

Page 23: Troubleshooting

Troubleshooting • It is strongly recommended to contact the manufacturer (SOMAG AG Jena) immediately if a problem occurs. Any repairs which are not authorized by the manufacturer will void the war- ranty. 7.1 Firmware Update If you need to change or update the firmware version, please contact your local support or the manufacturer, SOMAG AG Jena.

Need help?

Do you have a question about the RSM 400 and is the answer not in the manual?

Questions and answers