Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Huawei CG1-2

- Page 2 CG1-2A H Beam cutter INSTRUCTION Thank you very much for purchasing this product. Read this instruction manual thoroughly to insure correct, safe and effective use of the machine. Read the manual first to understand how to operate and maintain the machine.

- Page 3 CG1-2A H Beam cutter Symbol Title Meaning General General caution, warning and danger Be careful not to get your Possible injury to fingers if caught in the fingers caught. insertion part. Possible electric shock under special Caution: Electric shock! conditions. Operators must ground the equipment Ground this equipment.

-

Page 4: Table Of Contents

CG1-2A H Beam cutter CONTENTS 1. Safety Information .................... 1 1.1General machine safety precautions ..............1 1.2 Gas cutting safety precautions ................3 2. Outline of machine ................... 5 2.1Features of machine .................... 5 2.2 Name and function of each section ..............6 2.3 Specifications ..................... -

Page 5: Safety Information

CG1-2A H Beam cutter Safety instruction Operation, inspection, and maintenance that disregard the basic safety rules cause many accidents. Carefully read, understand, and master the safety measures and precautions described in this instruction manual and on the machine before operating, inspecting, and maintaining the machine. - Page 6 CG1-2A H Beam cutter 1.1.2 Safety clothing 1. Be sure to wear protector’ s gauntlets, goggles, helmet, and safety shoes during operation. 2. Avoid operating the machine with wet clothes or hands in order to prevent electric shock. 1.1.3 Operation and handling safety precautions 1.

-

Page 7: Gas Cutting Safety Precautions

CG1-2A H Beam cutter 18. You must not drag the cable conductor of power supply. 19. Don’ t leave the machine alone before it flames out. 20. The gas-in junction must be locked tightly used the hose-hoop in order to prevent serious accident caused by gas leakage. - Page 8 CG1-2A H Beam cutter 1.2.2 Pressure regulator safety precautions 1. Before starting operation, check that all pressure regulators are operating correctly. 2. Ask a skilled repair engineer to perform maintenance and inspection service. 3. Do not use pressure regulators from which gas is leaking, or malfunctioning pressure regulators.

-

Page 9: Outline Of Machine

CG1-2A H Beam cutter 1.2.6 Safety precautions for skin burns Observe the safety precautions to prevent skin burns. Ignoring heat, spatter, and sparks during operation could cause a fire or burned skin. 1. Do not perform cutting near flammables. (Move flammables well away from the sparks.) 2. -

Page 10: Name And Function Of Each Section

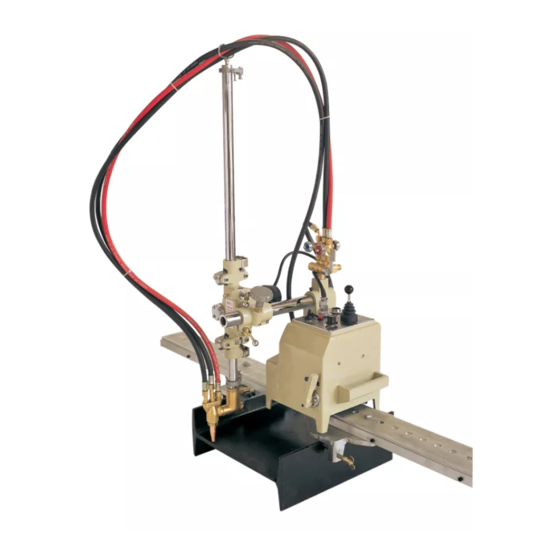

CG1-2A H Beam cutter 2.2 Name and function of each section 1. Torch 7. Quick distributor: Flame is adjusted 2.Gas hose: connected between torch and only once and not adjusted again. gas distributor to deliver gas, 8.Handle: It is to move machine 3. -

Page 11: Preparation For Operation

CG1-2A H Beam cutter 6.Cutting thickness :5-50mm 7.Bevel angle :0~30°( wing plate; web plate) 8.Maximum fly past of web plate cutting :A=1600mm 9.Maximum fly past of wing plate cutting : B=800mm 10.Maximum angle of wing plate slanting :30°(maximum height of slanting cutting 690mm) cutting 11.Maximum angle of web plate slanting :35°(maximum length of slanting cutting 1300mm... - Page 12 CG1-2A H Beam cutter Cutting position: preheating flame and cutting oxygen turn on and cutting begins. State of close State of preheat State of cutting 2) Application introduction Pull quick distributor switch knob in the preheating position, ignition and adjust flame. Adjust valve to get best preheating flame.

-

Page 13: Machine Assembly

CG1-2A H Beam cutter 6) Wing plate angle control equipment Set angle when slanting cut wing plate. 7) Speed modulation Velocity label is divided ten grills. The relationship between grill and velocity is shown in the diagram. 8) Clutch knob It is mainly used in web plate cutting automatic running, as well as adjusting distance between tip and wing plate and fixing the machine on the track. -

Page 14: Preparation Before Operation

CG1-2A H Beam cutter 3.4 Preparation before operation 3.4.1 Connection of power cable 1. Before plugging the metal plug on the cabtyre code side into the socket on the machine side, check there is no sundries or dust. 2. The metal plugs are screw-threaded, therefore, fully tighten them so that they will not come loose during operation. -

Page 15: Cutting Operation

CG1-2A H Beam cutter Cutting operation 4.1 Safety measures prior to operation 4.1.1 Safety precautions for grounding the machine The cable of this machine is equipped with a grounding wire. For safety, be sure to ground the wire as follows, in addition to checking the connection of the power cable. -

Page 16: Cutting And Piercing Method

CG1-2A H Beam cutter 5. Neutral flame ensures good quality cut surfaces. (Oxygen flame may be used for bevel cutting.)Oxygen flame causes short cutting-oxygen current, allowing slugs to adhere, melting the upper edge of the cutting surface, and causing adverse effects on the cut surface. Similar defects will result when the cutting oxygen pressure is too high. - Page 17 CG1-2A H Beam cutter 6.Preheat cutting starting point fully. Put quick knob in the cutting position and put quadruple switch in the ascending position. Torch moves upwards. Cutting oxygen ejects automatically through interlocking between electromagnetic valve and quadruple switch and cutting works automatically.

- Page 18 CG1-2A H Beam cutter 12. When torch moves over the surface of wing plate 3mm to 4mm, pull up quadruple switch. Hold lifting bar to rise and rotate torch in order to keep horizontally. When torch center rises over wing plate upper limb 30mm, torch stops running.(as shown in the diagram 5) 13.Release clutch and push the machine to go forwards and remove outboard of H structural section wing plate.

-

Page 19: Notice Of Slanting Cutting Web Plate

CG1-2A H Beam cutter Notice of slanting cutting web plate 1.There is an angle scale plate on the fixed track pressure plate. Track mark allocates on the specified angle which is locked with nuts. Use nuts to lock. Then fix track and machine on the H structural section. -

Page 20: Safety Measures Against Backfire And Flashback

CG1-2A H Beam cutter oxygenized flame will lead to an increase of efficiency and set the speed with a decrease of 20%~30%.The bevel cutting surface in the diagram is a result of inadequate preheating, which requires to change the tip and readjustment of the preheating and speed. 4.7 Safety measures against backfire and flashback 4.7.1 Prevention of backfire Backfires may cause serious accidents or fire. -

Page 21: Maintenance Of The Tip

CG1-2A H Beam cutter 6.2 Maintenance of the tip The durability and security of the tip used in HK-305 is very good. So the operator should abide the right maintenance and carriage precautions in order to ensure cutting quality. 1. Put the torch up a little and keep a 15mm distance from the plate when piercing, in order to avoid injury when the flame back up. - Page 22 CG1-2A H Beam cutter of wing plate is not accurate. Calibrate as b step. 2) The injection stream of cutting oxygen is abnormal a. The injection stream has offset angle b. The injection stream has bifurcation. c. The injection stream is too short (the length must be above 80mm.) Clean tip or adjust cutting oxygen valve.

-

Page 23: Wiring Diagram

CG1-2A H Beam cutter 4)Gas leakage and fire leakage. Possible Cause Correction 1)The 30°taper is not contacted Mend the 30°traper carefully with thin emery well due to incorrect usage. cloth to make it contacted well. 2)The cater nut is not tightened. Tighten the cater nut. -

Page 24: Maintenance Illustration

CG1-2A H Beam cutter Maintenance illustration: If you operate the machine according to the operating manual and the machine generates occurs accidents because of the product quality, we guarantee to keep the machine in good repair free of charge in half year based on invoice from the day we sell. According to the rules, if the following cases occur, we can’...

Need help?

Do you have a question about the CG1-2 and is the answer not in the manual?

Questions and answers