Advertisement

Advertisement

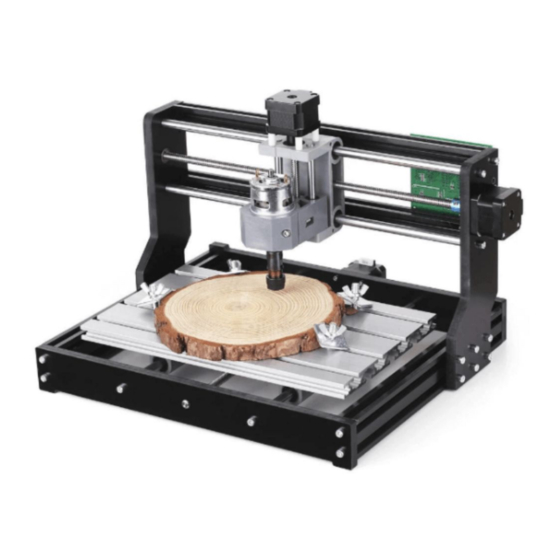

Summary of Contents for YoraHome 3018-PRO

- Page 1 YORA CNC CARVING MACHINE 3018-PRO USER MANUAL Version 1.3 • May, 2020...

-

Page 2: Table Of Contents

Contents Part 1: Packing List Part 2: Mechanical Installation Part 3: Software Installation Part 4: Machine Setup Part 5: Recommended Settings Part 6: Best Practices For Assembly & Setup Part 7: Terminology... - Page 3 Part 1 Packing List...

- Page 4 Part 1 Packing List Bakelite-A Bakelite-B Bakelite-C Bakelite-D...

- Page 5 Part 1 Packing List...

- Page 6 Part 1 Packing List...

- Page 7 Part 2 Mechanical Installation Step 1 Bakelite-A, Bakelite-B & Base Installation 20*40*290mm...

- Page 8 Part 2 Mechanical Installation Step 2 Table Installation...

- Page 9 Part 2 Mechanical Installation Completed...

- Page 10 Part 2 Mechanical Installation Step 3 Bakelite-C Installation...

- Page 11 Part 2 Mechanical Installation Don’t have a metric Completed ruler? See second last page of this manual for a helpful tool!

- Page 12 Part 2 Mechanical Installation 20*20*360mm x2pcs Step 4 X-Z Axis Installation...

- Page 13 Part 2 Mechanical Installation Step 5 Bakelite D Installation...

- Page 14 Part 2 Mechanical Installation Completed...

- Page 15 Part 2 Mechanical Installation Step 6 Spindle Installation Caution Tighten the M4 bolt without using excessive force to prevent plastic damage...

- Page 16 Part 2 Mechanical Installation Step 7 Control Board Installation...

-

Page 17: Part 2: Mechanical Installation

Part 2 Mechanical Installation Connect the red wire to the Stepper Motor port next to the red mark Step 8 Spindle Wiring diagram Laser (12VDC/5A max) Not included 24 DC Power Adapter USB Port to connect your machine to your NOTE: PC or Mac Do not use the Offline... - Page 18 Part 3 Software Installation Step 1 Install the machine’s driver (CH340SER). Download it online here.

-

Page 19: Part 3: Software Installation

Part 3 Software Installation Step 2 Determine your machine’s COM port • Windows XP: Right click on My Computer, select Manage, then Device Manager. • Windows 7: Click on Start on the taskbar, right click on Computer, select Manage, then Device Manager. •... - Page 20 Part 3 Software Installation Step 3 Log into Easel We recommend that our customers use a web application called Easel, which is developed by Inventables for their X-carve machines. It works great with the 3018 CNC machines too. It is free (the pro version is not really needed), powerful and easy to use to design and carve your projects.

- Page 21 Part 3 Software Installation Step 4 Create your account in Easel • Click on the radio button « I am a new customer » • Enter your personal information (see an example in this picture) • When you are done, click on the orange Continue button...

- Page 22 Part 4 Machine Setup Step 1 Your first project in Easel! Create a new project by selecting one document in the Projects tab (it can be “Intro to Easel” or any “Untitled”)

- Page 23 Part 4 Machine Setup Step 2 Easel driver: Click on the blue Carve button.

- Page 24 Part 4 Machine Setup Step 3 Easel driver (Windows): You will be automatically prompted to download and install Easel driver; whether you’re on a Mac or a Windows computer. This driver will allow Easel to talk to the USB port on your computer. If the window below doesn’t open, you can access the driver here. W1.

- Page 25 Part 4 Machine Setup Step 4 Install Easel driver (Windows) W2. Go to your Downloads folder, open the download and you should see the file EaselDriver-0.3.18.exe. W3. Then, right-click the EaselDriver 0.3.18.exe, select "Run as administrator" and follow the installation prompt. Follow the Installer instructions to complete the installation.

- Page 26 Part 4 Machine Setup Step 5 Download and Install Easel driver (MacOS) M2. Click the EaselDriver-0.3.18.pkg file and open it to run the installer. Follow the Installer instructions to M1. Click the green Download for Mac button. complete the installation. You may need to refresh Easel driver will automatically download to your browser and, in some cases, restart your your computer.

- Page 27 Part 4 Machine Setup Step 6 Set up your machine: Now that Easel driver is installed, you need to setup your machine. On the menu bar, click on Machine and then click on the blue Set up your machine button.

- Page 28 Part 4 Machine Setup Step 7 Enter your machine settings: Use the ones shown in the picture below. You can use either Other (grbl) or X-carve in the machine type. Enter the other settings as shown below. No dust shoe with our 3018, so don’t check the box. Then, click on the blue Confirm settings button.

-

Page 29: Part 4: Machine Setup

Part 3 Machine Setup Step 8 Connect your 3018 to your computer 1. Plug in your power cord 2. Plug in your USB cable into your computer 3. Turn on your 3018 Easel will automatically connect to your 3018... - Page 30 Part 4 Machine Setup Step 9 Enter your COM port if needed If Easel is unable to find your 3018 automatically: 1. Click on the blue “Carve” button in Easel 2. In the "Easel can't find your machine“ window that popups, check the "Enter COM port manually"...

- Page 31 Part 4 Machine Setup Step 10 Test your wiring When the machine successfully connects, you’ll be presented with a set of controls for jogging your machine. Try jogging the machine using the directional arrows. If everything is wired correctly you should get proper motion on each axis.

- Page 32 Part 4 Machine Setup Step 11 Set your spindle settings: The 3018 does not have a manual spindle. So, select ‘Automatic’ for your spindle control preference. Automatic...

- Page 33 Part 4 Machine Setup Step 12 No limit switch setup: After you confirm your spindle setting, you’ll be prompted to enable or disable homing. Our 3018 does not come with limit switches. Click on the blue No, disable homing button.

- Page 34 Part 4 Machine Setup Step 13 No Z-Probe: Our 3018 does not a Z-Probe. Click on the red No button.

- Page 35 Part 4 Machine Setup Step 14 Run the test carve: After setting your machine, you can run a test carve to ensure that the machine is operating properly. Clicking on the green button here will take you to the test carve project itself.

- Page 36 Part 5 Recommended Settings - Router Key GRBL Settings Intro The 3018 motherboard has a series of settings on it that allow your machine to work correctly. Some may be wrong (which shouldn’t be the case), so you may have to adjust them to take a full advantage of your machine.

- Page 37 Part 5 Recommended Settings - Router Key GRBL Settings $3 - Direction port invert mask If an axis is moving in the wrong direction, you need to change one of the settings, namely $3, the direction port invert mask to be precise. This is very easy to do.

- Page 38 Part 5 Recommended Settings - Router Key GRBL Settings $3 - Direction port invert mask Use the following table: Select the row for your current $3 value, go across to the column for the axis to change and the value there is your new $3 value. This only allows you to change one axis at a time. If you need to change more than one, make multiple passes through the process.

- Page 39 Part 5 Recommended Settings - Router Key GRBL Settings $100,$101,$102 - [X,Y,Z] steps/mm These parameters controlled the distance travelled by each axis. These values are the number of microsteps required to move the spindle on each axis by 1mm. $100 sets the X axis, $101 the Y axis, and $102 the Z axis. These should all be the same.

- Page 40 $13=0 to set back to mm. We want to work in mm. So leave $13 at 0. You can check all the defined GRBL settings and what they mean using the link below: https://github.com/gnea/grbl/wiki/Grbl-v1.1-Configuration Note – changing GRBL settings beyond those mentioned above is not recommended by YoraHome, and is done at your own risk.

- Page 41 Part 5 Recommended Settings - Easel Step 1 Metric system settings in Easel: We recommend that our customers use the mm (metric) settings for better readings and precision, especially in the CNC world.

-

Page 42: Part 5: Recommended Settings

Part 5 Recommended Settings - Easel Step 2 Material type and Dimensions 3. Take the measurements (Length, Width, Depth) of your material 1. Find the piece of wood or material you want to carve 4. Enter the Material Dimensions in Easel 2. - Page 43 (This will allow you not to have to purchase the Easel Pro Version) If you don’t know the width or diameter of the bits you bought from YoraHome, check the product page description of the bits in our Router Bits category.

- Page 44 Part 5 Recommended Settings - Easel Step 4 Cut settings Use the cut settings we recommend below. This will allow your machine to last longer. Feed rate (How fast the machine will move the bit through the material when cutting and is critical to get it right for leaving a good quality cut edge): 150 mm/min Plunge rate (How fast the bit is driven down into the material when starting a cut.

-

Page 45: Part 6: Best Practices For Assembly & Setup

Part 6 Best Practices For Assembly & Setup Quick Guide 6. Next, you need to make sure your machine is 1. Ensure everything is wired and powered correctly per the moving in the correct directions according to a manufacturer guidelines. Cartesian(XYZ) coordinate frame. - Page 46 Part 7 Terminology Grbl : This is the software which runs on the CNC (Computer Numerical Control): A CNC machine is a motherboard. It takes the G-code and translates it motorized platform controlled by a computer according to into the movements and speeds needed to cut a line specific input instructions.

- Page 47 Part 7 Terminology Toolpath: The path that the tool is moved along in ER11: This is the piece that fits onto the end of the spindle order to do the job. Your software will provide a and holds the bit. toolpath simulation so you can see on your computer what is going to happen before you send Collet: The piece inside the tool holder (ER11) which as it is...

- Page 49 SUPPORT@YORAHOME.COM WWW.YORAHOME.COM...

Need help?

Do you have a question about the 3018-PRO and is the answer not in the manual?

Questions and answers