Summary of Contents for SAMWAY P20NMS

- Page 1 OPERATING INSTRUCTIONS SAMWAY P20NMS / P32NMS Released 01/2019 WUXI SAMWAY CO.LTD whatsapp +86 138 120 22928 SKYPE : samway.company SAMWAY Tel: 0086-510 8378 8458 Mobile: 0086 13812022928...

- Page 2 Keep this manual for future needs. The machine has been designed for crimping hose fittings. SAMWAY shall not be held liable for any product which has been crimped on the machine. The machine has been designed to operate in room temperature, in dry indoor conditions and in sufficient illumination.

-

Page 3: Table Of Contents

CONTENTS CONTENTS ..........................5 GENERAL ..........................6 TRANSPORT ............................6 STORAGE............................6 MOUNTING............................6 HELP PROTECT OUR ENVIRONMENT................. 7 DISPOSAL OF THE PACKING MATERIAL ..................7 DISPOSAL OF YOUR OLD MACHINE ....................7 WARNINGS..........................7 GENERAL ............................7 DANGER ZONES ..........................8 COMMISSIONING........................ -

Page 4: General

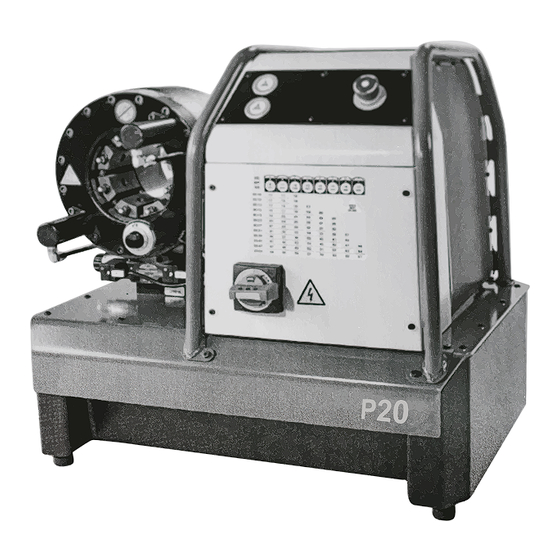

GENERAL SAMWAY crimping machines are electrically operated hydraulic crimping machines for hydraulic hose assemblies. Machines are designed for single piece- and low production. The crimping machine comprises a crimping head, a hydraulic unit which serves as machine frame. SAMWAY crimping machine is normally delivered with a 3-phase electric motor. -

Page 5: Help Protect Our Environment

WARNINGS GENERAL Use only original SAMWAY die sets in your SAMWAY crimping machines. Installing and using third party die sets are voiding any warranties, and all liability what so ever nature is rejected. Using third party dies sets will be done solely on users own risk and recourse. -

Page 6: Danger Zones

DANGER ZONES LABEL DEFINITION General Warning label.There are items that require attention. WARNINGS 1 AND 2 CAUTION: DANGER OF SQUEEZE When crimping a fitting, hold the hose far enough to avoid crimping your hand! Do not put your hands inside the dies while the machine is set on! Dies open and close by depressing the hand emergency push- WARNINGS 3 buttons at both ends of the valve. -

Page 7: Commissioning

Bring the supply cable through the hole on the rear of the machine and guide it through the hole on the rear of the electric box. Secure the cable with a stress relief plug. The minimum size for the cable: SAMWAY 20 SAMWAY 32... -

Page 8: Running In

RUNNING-IN Recommended running in period for a new machine is 50 000 crimps. It will be enough if the greasing cycle is halved during the running in period. The purpose of frequent greasing is to ensure that there is always grease enough between the sliding surfaces. -

Page 9: Operation

OPERATION The crimping machine is switched on by turning the supply disconnecting device. However, the motor won’t run until the crimping- or retraction -push button is pressed. The motor stops automatically and the indicator light starts flash, if the machine is not used in 6 seconds. The motor springs to life when the crimping- or retraction -button is repressed. -

Page 10: Selecting The Die Set, P20 Model

SELECTING THE DIE SET, P20 MODEL Use only original SAMWAY die sets in SAMWAY crimping machines. Refer to the fitting manufacturer's specifications for proper crimping diameter for the fitting. Each die set has its own crimping range. Follow it to assure the roundest possible crimping result. -

Page 11: Installing The Die Set

INSTALLING THE DIE SET QUICK CHANGE (OPTION) An optional QC Tool Base enables storing die sets under the machine. The whole die set can be installed into the master dies with a quick change tool at one time. Before installing dies, make sure that the master dies are clean. OPEN THE SUPPLY DISCONNECTING DEVICE PRIOR TO CLEANING DIES. -

Page 12: Setting The Crimping Diameter

Setting the crimping diameter From crimping diameter chart, delivered together with the machine, you can see the die numbers corresponding crimping ranges. The upper section of the chart shows the corresponding dial position each crimping iameter in the columns. Crimping diameters in the grey zone of the chart are not recommended to be used with he die set in question. -

Page 13: Crimping

CRIMPING WHEN CRIMPING A FITTING, HOLD THE HOSE FAR ENOUGH TO AVOID CRIMPING YOUR HAND! DO NOT CRIMP THE EDGE OF THE DIE! The machine can be operated manually by using the crimping- and the opening - push buttons or with semi-automatism. 1. -

Page 14: If The Machine Does Not Work

IF THE MACHING DOES NOT WORK . . . If the motor doesn’t start up To start up the machine, turn the switch completely to the left (0) and then to the upright position (I). If the problem is not disappearing, contact the service. If the motor starts up but the dies don’t move Check the rotation of the motor. -

Page 15: Preventive Maintenance

NEVER USE COMPRESSED AIR FOR CLEANING! GREASING Lubricate the inner surface of the conical flanges daily with SAMWAY grease : order n:o 019302 Apply the grease to the conical surfaces at the front and back of the die with a small brush. -

Page 16: Cylinder Protection Inserts

CYLINDER PROTECTION INSERTS machine has four cylinder protection inserts between the lowest dies in the crimping head. These inserts protect the cylinder from dirt and falling parts. NOTE! Protection inserts have to be interposed always between the lowest dies. Because the master dies try to rotate during the operation, the inserts have to be moved into correct places every now and then. -

Page 17: Master Die Spring Change

-craftsmanship are needed. In order to get the master die springs replaced contact your SAMWAY representative. Warning: Do not use the machine if there are broken or twist springs in the machine. Broken or twist spring can damage the machine or cause personal injuries. -

Page 18: Guarantee

GUARANTEE The machines produced by SAMWAY are guaranteed against defects in material and manufacture. Within the limits of the guarantee, the defective part will be replaced with a new one, or when possible, repaired free of charge. The guarantee is valid for 12 months after commissioning, yet for a period not exceeding 18 months after elivery ex works SAMWAY, China. -

Page 19: Technical Data

TECHNICAL DATA TECHNICAL DATA P20NMS 3-phase 1-phase y t i ½ ½ Crimping diameter range *) Ø (mm) 10...61 10...61 Theoretical production capacity **) per hour Enclosure class IP 54 IP 54 Closing speed of master dies mm/s Frequency 50 Hz... -

Page 20: Technical Data P32

TECHNICAL DATA P32NMS 3-phase 1-phase y t i Crimping diameter range *) Ø (mm) 10...87 10...87 Theoretical production capacity **) per hour Sound pressure level dB(A) Enclosure class IP 54 IP 54 Closing speed of master dies mm/s Frequency 50 Hz Voltage V / Current A / Fuse A 200 / 20.5 230 / 12.6... -

Page 21: Maintenance History / Huoltohistoria

Maintenance history / Huoltohistoria SAMWAY Type of machine: Serial n:o: Koneen tyyppi: Sarjanumero: Date / pvm: 1.General visual inspection for external damages / Ulkoisten vahinkojen tarkistus 2.Check of mechanics and crimping head / Koneen ja puristusyksilön tarkistus 3.Check of hydraulics / hydrauliikan tarkistus 4.Lubrication of crimping head / Puristusyksikön tarkistus... - Page 22 Maintenance history / Huoltohistoria SAMWAY Type of machine: Serial n:o: Koneen tyyppi: Sarjanumero: Date / pvm: 1.General visual inspection for external damages / Ulkoisten vahinkojen tarkistus 2.Check of mechanics and crimping head / Koneen ja puristusyksilön tarkistus 3.Check of hydraulics / hydrauliikan tarkistus 4.Lubrication of crimping head / Puristusyksikön tarkistus...

Need help?

Do you have a question about the P20NMS and is the answer not in the manual?

Questions and answers