Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Adast Systems AdBlue V-line 47 Series

- Page 1 USER´S MANUAL Instructions for Operation, Maintenance and Installation ® AdBlue dispenser MAJOR ® V-line AdBlue 47xx.xxx Adast Systems, a.s., 679 04 Adamov No. 496, Czech Republic MKT 010-004-2007/A T +420 516 519 201, F +420 516 519 102, sales@adastsystems.cz VII/2017 www.adastsystems.cz...

-

Page 3: Table Of Contents

® USER’S MANUAL V-line AdBlue 47xx.xxx OBSAH IMPORTANT NOTICE ..........................1 USE ................................2 INSTRUCTIONS FOR THE SAFETY OF WORK ..................2 3.1. Safety of the equipment design ...................... 2 3.2. Operation safety ..........................3 3.3. Ecological safety ..........................3 3.4. - Page 4 ® USER’S MANUAL V-line AdBlue 47xx.xxx 10.2 Setting of unit price values from the control system in AUTO mode..........16 10.3 Display of electronic totalizers ...................... 16 11. MAINTENANCE OF A DISPENSER AND ITS INDIVIDUAL OPERATING UNITS ....... 17 11.1. Filter .............................. 17 11.2.

-

Page 5: Important Notice

® USER’S MANUAL V-line AdBlue 47xx.xxx IMPORTANT NOTICE ® This document is user guide, how to provide installation, operation and maintenance and service of AdBlue dispenser. Stated information in this manual is strictly recomended and producer can not response for damages caused by non keeping rules described in this guide. -

Page 6: Use

® USER’S MANUAL V-line AdBlue 47xx.xxx i) Service operations and installation can be provided only by trained service persons. Service operation must be in accordance with operation rules of the filling station. Producer does not response for damages made by non qualified persons. j) Provider can start delivery after close of filling station revision and after official metrologic ®... -

Page 7: Operation Safety

® USER’S MANUAL V-line AdBlue 47xx.xxx ® For the AdBlue dispenser has been made conformity assesment by type described in EC - Type Examination Certificate No TCM 141/07 - 4518 and technical requirements according to Annex II, Module D of the Directive of European Parliament and the Council 2014/32/EU The producer is competent for “The Declaration of Conformity”... -

Page 8: Description

® USER’S MANUAL V-line AdBlue 47xx.xxx DESCRIPTION 4.1. Design of the dispenser ® ® The V-line R AdBlue 47xx.xxx dispensers with electronic counter are used to the dispensing of AdBlue These dispensers are one-sided or two-sided simultaneous output of 1 products. The dispensers are designed as self-holding sectional construction. - Page 9 ® USER’S MANUAL V-line AdBlue 47xx.xxx Above the display is placed IR sensor (5) for controlling and adjusting the dispenser calculator manager or servicing keyboard. On the outer side of the case cover is placed (optional) keyboard local user preferences - an independent keyboard for each dispensing point.

-

Page 10: Hydraulic System Of V-Line Adblue ® 47Xx.xxx Dispenser

® USER’S MANUAL V-line AdBlue 47xx.xxx ® 4.3. Hydraulic system of V-line AdBlue 47xx.xxx dispenser ® Figure. 1 – Hydraulic scheme of V-line AdBlue 47xx.xxx dispenser Legend Submersible pump Closing valve Filter Electronic meter ADAST M 403.25 EAP/1 + el. counter ADP1/L, ADP1/T, ADP2/T Delivery nozzle ®... - Page 11 ® USER’S MANUAL V-line AdBlue 47xx.xxx Figure. 2...

-

Page 12: Filter

® USER’S MANUAL V-line AdBlue 47xx.xxx ® V-line AdBlue 47xx.xxx series dispensers (pressure design) differ from suction dispensers because they are not equipped with the pumping monoblock. A safety breaking valve shall be fitted in the connection. ® The valve prevents AdBlue leakage in case of the dispenser damage. -

Page 13: Electromagnetic(Solenoid) Valve

® USER’S MANUAL V-line AdBlue 47xx.xxx 4.3.3 Electromagnetic(solenoid) valve Electromagnetic valve is placed on meter output. Valve control is provided by electronic counter. Body of the valve is nicle plated, pistons and bushes are finished from material on teflon basis. Electromagnetic valve is supplied as option upon costumer request. -

Page 14: Communication To The Control System

® USER’S MANUAL V-line AdBlue 47xx.xxx Providing of calibration is allowed to authorised person, only. The DIP calibration switches must be fixed by plomb after calibration finish. Displays: LCD type with BACK LIGHT illumination LCD displays with BACK LIGHT DISPLAY (BLD) illumination are used especially for their good readability. The duration of data holding on the display after supply voltage failure is 30 minutes at least. -

Page 15: Sopa Design

® USER’S MANUAL V-line AdBlue 47xx.xxx 4.6. SOPA design On Client’s special request the dispenser in service mode can be equipped with magnetic release switch (SOPA design). The operator of the filling station can release the dispenser for single filling operation in this mode. -

Page 16: Marking

All manufactured and delivered dispensers are provided with a rating plate, which includes the following data and is located on a visible point of the dispenser body: 1. Measuring device manufacturer and address Adast Systems, a.s., CZ – 679 04 ADAMOV 496 ® 2. Name of measuring device... -

Page 17: Wiring

® USER’S MANUAL V-line AdBlue 47xx.xxx ® The AdBlue dispenser can be joined only to process equipment (tanks, piping) of perfect tightness and cleanness. The supplier of the process equipment is responsible for its tightness and cleanness. Prior to the installation the organisation shall perform the inspection of used power and communication cables. -

Page 18: Puting Of Adblue ® Dispenser To Off Mode

® USER’S MANUAL V-line AdBlue 47xx.xxx ® 8.2. Puting of AdBlue dispenser to OFF mode Switch off power feed in filling station main terminal. ® 8.3. New reseting of AdBlue dispenser into operation after power supply failure After power supply failure or voltage fluctuation will stay data on display about the price and volume of last provided transaction since interval of last time of nozzle hang out. -

Page 19: Manual Setting Of Unit Prices

® USER’S MANUAL V-line AdBlue 47xx.xxx Note If the nozzle has been lifted at least once since the last activation of the counter, the transition to the setting of unit prices is not executed in the MAN mode. The transition to the setting is also not executed even in case the nozzle has been either hung up again without fuel dispensing or previous transaction has not been deactivated by means of RLS entry. -

Page 20: Setting Of Unit Price Values From The Control System In Auto Mode

® USER’S MANUAL V-line AdBlue 47xx.xxx Unit price seting Shift from most significent Shift from most significent digit, side A , nozzle 1 digit, side B , nozzle 1 10.2 Setting of unit price values from the control system in AUTO mode In AUTO mode the unit price values are set from the control system for all transactions independently on unit price values set for the MAN mode. -

Page 21: Maintenance Of A Dispenser And Its Individual Operating Units

® USER’S MANUAL V-line AdBlue 47xx.xxx Volume total side A, nozzle 1 Volume total side B, nozzle 1 Power fail counter MAINTENANCE OF A DISPENSER AND ITS INDIVIDUAL OPERATING UNITS The user of the dispenser is obliged to operate the device safely, reliably and in economic way. First of all he is obliged to: –... -

Page 22: Piston Flowmeter

® USER’S MANUAL V-line AdBlue 47xx.xxx 11.2. Piston flowmeter The meter unit consists of the proper meter with integrated impulse detector. Only authorised specialists can handle the metering unit because the meter is officially sealed. If the seals are damaged, it is necessary to carry out an official inspection and new official sealing. -

Page 23: Electronic Counter

® USER’S MANUAL V-line AdBlue 47xx.xxx hinged door covering the hose and gun, and unscrewing the 4 screws M8 at the top level cover and 2 screws M8 connecting the cover to the base of the dispenser. Winding mechanism hose may be removed from the column after removing the nuts M10 at the bottom connecting the winding mechanism with a base and removing the two screws located at the upper pulley and the winding mechanism connecting to the web and the column. -

Page 24: Summary Of Basic Principles For Dispenser Maintenance

The customer shall agree to the method of AdBlue dispenser transport from the manufacturer in the contract. In case Adast Systems, a.s. provides the transport for the customer, the product will be delivered to the agreed destination. The manufacturer possesses the necessary knowledge of handling and... -

Page 25: Packing And Storage

® USER’S MANUAL V-line AdBlue 47xx.xxx transportation methods. In case the customer is responsible for another method of transport, the manufacturer shall ensure professional loading of the product but is not responsible for the transport itself. ® It is generally accepted that the AdBlue dispenser shall be shipped properly boxed and always fixed to the frame. -

Page 26: Spare Parts Catalogue

® USER’S MANUAL V-line AdBlue 47xx.xxx incorrect earthing system incorrect cable distribution systems - power cables together with communication cables Defects from faulty low power wiring at the filling station, faulty wiring of communication cables – especially as far as interference is concerned missing UPS (ON LINE) - mains supply standardised voltage values: U nominal ±15 % with frequency 50 Hz The guarantee does not cover consumable supplies: filter bushings, V-belts, etc. - Page 27 The model marking on the V-line R AdBlue 47xx.xxx dispenser ® Enclosure No The model marking on the V-line R AdBlue 47xx.xxx/CAx © Adast Systems, a.s., 679 04 Adamov No. 496, Czech Republic Regarding continuous development the producer stipulates the right to pursue technical changes!

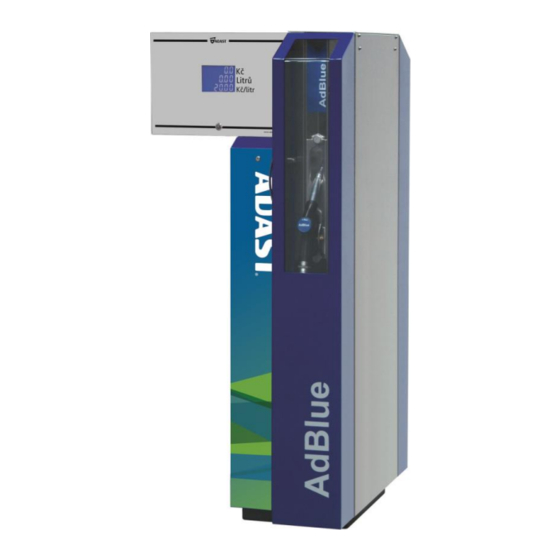

- Page 29 ® USER’S MANUAL V-line AdBlue 47xx.xxx ® View of dispensers ADAST MAJOR V-line R AdBlue 47xx.xxx Enclosure No 1...

- Page 30 ® USER’S MANUAL V-line AdBlue 47xx.xxx ® Main dimensions of dispensers V-line R AdBlue 47xx.xxx Enclosure No 2...

- Page 31 ® USER’S MANUAL V-line AdBlue 47xx.xxx ® Installation dimensions of V-line R AdBlue 47xx.xxx dispensers Enclosure No 3...

- Page 32 ® USER’S MANUAL V-line AdBlue 47xx.xxx ® Manipulation with delivery nozzle AdBlue ® Tank for AdBlue must be equipped by magnetic adaptor ELAFIX 40 to open the spout. Correct position of dispensing nozzle during filling The dispensing nozzle is almost in the horizontal position, the ball does not prevent ®...

- Page 33 ® USER’S MANUAL V-line AdBlue 47xx.xxx Enclosure No 5...

- Page 34 ® USER’S MANUAL V-line AdBlue 47xx.xxx Conditions of wiring and operation of UPS for feeding a control system and electronic part of V-line dispensers 1. All the cooperating electronic circuits of the control system and dispensers must be connected to the UPS and for this point of view they are considered as a closed electronic unit.

- Page 35 ® USER’S MANUAL V-line AdBlue 47xx.xxx ® Connection of V-line AdBlue 47xx.xxx dispenser to the filling station switchboard Enclosure No 7...

- Page 36 ® USER’S MANUAL V-line AdBlue 47xx.xxx Connection of the magnetic pulse transmitter ME01-06, MTX 076 and ADAST 41 to the electronic counter ADP1/L - connector X1 ELTOMATIC ME01-06 Magnetic pulse transmitter Magnetic pulse transmitter Magnetic pulse transmitter ME 01-06 MTX 076 ADAST 41 Enclosure No 8...

- Page 37 ® USER’S MANUAL V-line AdBlue 47xx.xxx Connection of the magnetic pulse transmitter ME01-06, MTX 076 and ADAST 41 to the electronic counter ADP1/T, ADP2/T - connector X2 ELTOMATIC ME01-06 ELTOMATIC ME01-06 Enclosure No 9...

- Page 38 ® USER’S MANUAL V-line AdBlue 47xx.xxx Connection of the magnetic pulse transmitter ME01-06, MTX 076 and ADAST 41 to the electronic counter ADPMPDx/T, ADPMPDx/T-PWM - connector X3 ELTOMATIC ME01-06 ELTOMATIC ME01-06 Enclosure No 10...

- Page 39 ® USER’S MANUAL V-line AdBlue 47xx.xxx The sealing of M403.25EAP measuring transducer for electronic calibration The sealing of M403.25EAP/1 measuring transducer for electronic calibration Enclosure No 11...

- Page 40 ® USER’S MANUAL V-line AdBlue 47xx.xxx The sealing of ADP1/L electronic calculator The sealing of Beta Control ADP1/T and ADP2/T electronic calculator Enclosure No 12...

- Page 41 ® USER’S MANUAL V-line AdBlue 47xx.xxx The sealing of Beta Control ADPMPDx/T and ADPMPDx/T-PWM electronic calculator The sealing of totalizing indicating device of the ADP1/T and ADP2/T electronic calculator Enclosure No 13...

- Page 42 ® USER’S MANUAL V-line AdBlue 47xx.xxx The sealing of totalizing indicating device of the ADPMPDx/T and ADPMPDx/T-PWM electronic calculator Enclosure No 14...

- Page 43 ® USER’S MANUAL V-line AdBlue 47xx.xxx A location scheme verification marks on electromagnetic total counter (case version 2017) Enclosure No 15...

- Page 44 ® USER’S MANUAL V-line AdBlue 47xx.xxx The sealing of UNIDATAZ CDC electronic calculator (CPU unit with S3 switch and totalizer) Enclosure No 16...

- Page 45 ® USER’S MANUAL V-line AdBlue 47xx.xxx ® The model marking on the V-line R AdBlue 47xx.xxx dispenser Enclosure No 17...

- Page 46 ® USER’S MANUAL V-line AdBlue 47xx.xxx ® The model marking on the V-line R AdBlue 47xx.xxx/CA Enclosure No 18...

Need help?

Do you have a question about the AdBlue V-line 47 Series and is the answer not in the manual?

Questions and answers