Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Subscribe to Our Youtube Channel

Summary of Contents for Mold-Masters Fusion Series

- Page 1 User Manual version 14 Original Instructions...

-

Page 3: Table Of Contents

1.2 Documentation ....................1-1 1.3 Release Details ....................1-1 1.4 Warranty ......................1-2 1.5 Returned Goods Policy ..................1-2 1.6 Movement or Resale of Mold-Masters Products or Systems ......1-2 1.7 Copyright ......................1-3 1.8 Units of Measure and Conversion Factors ............1-3 1.9 Trademarks and Patents ..................1-4 Section 2 - Global Support ..........2-1... - Page 4 5.17.1 Hydraulic Valvebank Connection ............5-50 5.17.2 Pneumatic Valve Bank Connection ............5-51 5.18 Install Hydraulic Flow Control Valve ...............5-52 5.19 Install Actuator Position Sensor ..............5-54 5.20 Water Cooled Gate Insert Installation .............5-59 © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual...

- Page 5 Section 6 - SeVG Plus Actuator ........6-1 6.1 Introduction ......................6-1 6.2 SeVG Plus Actuator Models ................6-1 6.3 SeVG Plus Actuator in FUSION SERIES Systems .........6-1 ® 6.4 SeVG Plus Models .....................6-2 6.4.1 SE40-20 Actuator - Non Cooled ..............6-2 6.4.2 SE40-20C Actuator - Cooled ..............6-3 6.5 Manifold Mounted Systems ................6-4...

- Page 6 12.5.15 Sinks or Voids ..................12-19 12.5.16 Splay ....................12-20 12.5.17 Streaks ....................12-21 12.5.18 Stringing .....................12-22 12.5.19 Warped Parts ..................12-23 12.5.20 Weld Lines ..................12-24 Index ..................I Section 13 - Index ..............I © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual...

- Page 7 Systems: SeVG Plus Actuator ® Selection ......................6-1 Table 11-1 Recommended Torque Settings ............11-2 Table 11-2 Actuator Spare Seal Kits ..............11-13 Table 11-3 Nozzle Spring Clip ................11-13 FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved.

- Page 8 Figure 5-18 Bolt clamp plate ...................5-42 Figure 5-19 Hydraulic flow control valve - connections ..........5-50 Figure 5-21 Actuator with position sensor ..............5-51 Figure 5-20 Top sensor mounting assembly installation .........5-54 © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual...

- Page 9 Figure 11-1 Pressure reducing and relieving valve ..........11-7 Figure 11-2 Manometer mounting port ..............11-8 Figure 11-3 Solenoid connector ................11-9 Figure 11-4 Manual override switch ..............11-12 FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved.

-

Page 11: Section 1 - Introduction

Section 1 - Introduction The purpose of this manual is to assist users in the integration, operation and maintenance of Mold-Masters systems. This manual is designed to cover most system configurations. If you need additional information specific to your system, or information in another language, please contact your representative or a Mold-Masters office. -

Page 12: Warranty

Mold-Masters representative. 1.5 Returned Goods Policy Please do not return any parts to Mold-Masters without pre-authorization and a return authorization number supplied by Mold-Masters. Our policy is one of continuous improvement and we reserve the right to alter product specifications at any time without giving notice. -

Page 13: Copyright

INTRODUCTION 1.7 Copyright © 2020 Mold-Masters (2007) Limited. All Rights Reserved. Mold-Masters ® and the Mold-Masters logo are trademarks of Mold-Masters. 1.8 Units of Measure and Conversion Factors NOTE The dimensions given in this manual are from original manufacturing drawings. -

Page 14: Trademarks And Patents

Information contained herein is, to our best knowledge, true and accurate, but all recommendations or suggestions are made without guarantee. Since the conditions of use are beyond our control, Mold-Masters disclaims any liability incurred in connection with the use of our products and information contained herein. No person is authorized to make any statement or recommendation not contained herein, and any such statement or recommendation so made shall not bind Mold-Masters. -

Page 15: Section 2 - Global Support

+39 049/5019955 South Korea El Marques, Queretaro C.P. 76246 fax: +39 049/5019951 Tel: +82-31-431-4756 Mexico italy@moldmasters.com korea@moldmasters.com tel: +52 442 713 5661 (sales) tel: +52 442 713 5664 (service) mexico@moldmasters.com FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 16: International Representatives

Gaydamatska str., 3, office 116 123308 Moscow 2310 Slovenska Bistrica Kemenskoe City Dnipropetrovsk Russia Slovenija Region 51935, Ukraine tel: +7 (495) 199-14-51 +386 59 969 117 tel: +38 (038) 277-82-82 moldmasters@system.com.ru info@picta.si moldmasters@parkgroup.com.ua © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 17: Section 3 - Safety

Section 3 - Safety 3.1 Operator Training and Safety Please be aware that the safety information provided by Mold-Masters does not absolve the integrator and employer from understanding and following international and local standards for safety of machinery. It is the... -

Page 18: Safety Hazards

9. Hoses 10. Area inside the guards and outside the mold area Front view with guards removed Front View with Guards Removed Figure 3-1 Injection molding machine hazard areas © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... - Page 19 Hazards due to reduction in mechanical strength of the plasticizing and / or injection cylinder due to overheating. Feed Opening Pinching and crushing between injection screw movement and housing. See Figure 3-1 area 6 FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved.

-

Page 20: Table 3-1 Safety Hazards

Crush or impact hazards caused by the movement of the power operated Gate gates. Vapors and gases Certain processing conditions and / or resins can cause hazardous fumes or vapors. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 21: Operational Hazards

• Never perform any work on the mold machine unless the hydraulic pump has been stopped. • Check frequently for possible oil leaks / water leaks. Stop the machine and make repairs. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. - Page 22 Failure to support the machine can result in severe injury or death. • Mold cable from the controller to the mold must be removed before servicing the mold. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual...

-

Page 23: General Safety Symbols

Warning – Slip, Trip or Fall Hazard Do not climb on equipment surfaces. Serious slip, trip or fall injuries can result from personnel climbing on equipment surfaces. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 24: Wiring Check

/ or equipment. Failure to do wiring or connections properly will result in equipment failure. The use of Mold-Masters standard connections can help to eliminate the potential for wiring errors. Mold-Masters Ltd. cannot be responsible for damage caused by customer wiring and / or connection errors. -

Page 25: Lockout Safety

• Burns from contact with hot parts, materials, or equipment such as furnaces • Fires and explosions • Chemical exposures from gases or liquids released from pipelines FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 26: Electrical Lockout

The last lock to be removed should be that of the person supervising the lockout and this responsibility should not be delegated. © Industrial Accident Prevention Association, 2008. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 27: Energy Forms And Lockout Guidelines

Shut off, lock (with chains, built- • Storage tanks and vessels in lockout devices, or lockout attachments) and tag valves. • Bleed off excess liquids or gases. • Blank lines as necessary. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 28: Disposal

3-12 3.7 Disposal WARNING Milacron Mold-Masters declines any responsibility for personal injury or personal damage arising from reuse of the individual components, if these parts are used other than for the original and proper intended purpose. 1. Hot Runner and system components must be disconnected from the power supply fully and properly before disposal, including electricity, hydraulics, pneumatics and cooling. -

Page 29: Fusion Series ® G2 Safety Hazards

• Never perform any work on the mold unless the hydraulic pump has been stopped. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. - Page 30 • Make sure the lifting eyebolt, lifting chain and crane are rated to adequately support the weight of the plate(s). Failure to do so can cause a serious injury. • All maintenance on Mold-Masters products should be performed by properly trained personnel based on local law or regulation requirements.

- Page 31 • When replacing heater plates or other heated components always replace with Mold-Masters components of the same type and install as originally specified on Mold-Masters General Assembly drawings. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved.

-

Page 32: Section 4 - Preparation

FUSION SERIES G2 system. ® The following section is a step-by-step guide to prepare your Mold-Masters system for use. 4.1 Tools Required Depending on the size and complexity of your Hot Runner system, you will require most of the tools and materials listed below. -

Page 33: Unpacking

5. Clean all surfaces and dowel holes, ensuring that no debris, burrs, shavings, dust, dirt or other foreign material which could interfere with measurements, exists. Ream holes out if necessary. 6. Remove tape from inlet and clean. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 34: Hydraulic Cylinder Assembly

8. Piston seals 9. Retaining ring 10. Rod seal 11. Cooling channel 12. Support spacer 13. Valve pin anti rotation collar Hydraulic cylinder section view Figure 4-2 Hydraulic cylinder components FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. - Page 35 2. Press the seals into the housing. 3. Install the rod seal retainer clip. 4. Place pipe sealant on threads of the water circuit pipe plug. Install the water circuit pipe plug. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual...

- Page 36 Hydraulic Cylinder Assembly - continued 5. Install the piston seals (3 pieces). 1. Piston seal 2. O-ring 3. Split retainer ring 6. Install the O-ring. 7. Install the piston seal. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved.

- Page 37 PREPARATION Hydraulic Cylinder Assembly - continued 8. Install the split retainer ring. 9. Install the valve pin. 10. Install the spring pack. 11. Install the piston top. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual...

- Page 38 Use a soft jaw vise with the piston body to prevent damage to the part. 13. Install the cylinder top seal. 14. Install the piston into the cylinder body. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved.

- Page 39 PREPARATION Hydraulic Cylinder Assembly - continued 15. Assemble the cylinder top to the cylinder body. 16. Apply anti-seize compound to the screws. Install the cylinder top screws. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual...

-

Page 40: Pneumatic Cylinder Assembly

7. Rod seal 8. Rod wiper seal 9. Cooling plate 10. Valve pin anti rotation collar 11. Support spacer 12. Valve pin Pneumatic cylinder section view Figure 4-3 Pneumatic cylinder components FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. - Page 41 1. Install the rod seal (2 pieces). 2. Use the piston to push the seal into position. 3. Install the wiper seal (2 pieces). 4. Use the piston to push the seal into position. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual...

- Page 42 7. Using a soft jaw vise, tighten the piston top to a torque of 10 N∙m (7 lb∙ft). NOTE Use soft vise jaws with cutout for piston body to prevent damage to the part. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved.

- Page 43 PREPARATION 4-12 8. Install the piston into the cylinder body. 9. Install the cylinder top seal. 10. Assemble the cylinder top to the cylinder body. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual...

- Page 44 PREPARATION 4-13 11. Apply anti-seize compound to the screws. 12. Install the cylinder top screws. 13. Install the piston collar on the cylinder body. Piston collar FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved.

-

Page 45: Waterless Hydraulic Actuator Assembly

5. Piston seal 14. Retaining ring 6. Retaining ring 15. Support pillar 7. Rod seal 8. Spring package 9. Piston bottom Figure 4-4 Components of the waterless hydraulic actuator © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 46: Assemble The Piston Assembly Of The Waterless Hydraulic Actuator

1. Examine the piston seal and make sure that it is in good condition. 2. Install the piston seal. 3. Install the valve pin. 4. Install the solid spacer or spring pack. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. - Page 47 Use a soft jaw vise when tightening the piston top to prevent damage to the piston assembly. 6. Using a soft jaw vise, tighten the piston top to a torque of 10 N∙m (7 lb∙ft). © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual...

-

Page 48: Assemble The Cylinder Body Assembly Of The Waterless Hydraulic Actuator

1. Insert the die spring into the cylinder bore hole. 2. Insert the washer into the bore hole. 3. Compress the clip and press it into the bore hole. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. - Page 49 4. Push down the clip with a 12.0 mm (0.5 in.) diameter rod. 5. Install the spacer and the rod seal. 6. Use snap ring pliers to install the retaining ring. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual...

-

Page 50: Assemble The Cylinder Assembly Of The Waterless Hydraulic Actuator

3. Install the spacer in the cylinder top (10 mm stroke). 4. Attach the cylinder top to the cylinder bottom. 5. Apply anti-seize compound to the threads of the screws. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 51: Assemble The Anti-Rotation Waterless Hydraulic Actuator

N∙m (11.8 ft∙lb). 4.7.4 Assemble the Anti-Rotation Waterless Hydraulic Actuator Figure 4-5 Piston collar, dowel pin, and screws 1. Install the piston collar in the bottom of the cylinder. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 52: Waterless Pneumatic Actuator Assembly

14. Spacers for pin adjustment 6. Piston guide ring 15. Washer 7. Piston top 16. Spiral retaining ring 8. Rod seal 17. Support pillar 9. Wiper seal Figure 4-6 Waterless pneumatic components FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 53: Piston Assembly For Waterless Pneumatic Actuator

2.3 mm) on top of the valve pin. See Figure 4-8. Spacers Valve pin Figure 4-8 Install valve pin and spacers 5. Install the piston top. CAUTION Make sure that the O-ring is in good condition. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 54: Adjust Valve Pin Length For Waterless Actuator (Optional)

A and B 4.10 C* and D* 4.50 short) *A thickness = 2.00 mm *C thickness = 2.20 mm *B thickness = 2.10 mm *D thickness = 2.30 mm FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 55: Cylinder Body Assembly For Waterless Pneumatic Actuator

1. Insert die spring into cylinder body bore hole. 2. Insert washer into bore hole. 3. Assemble spiral retaining ring. a) Deform the clip and press into bore hole. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 56: Install The Rod Seal (2 Pieces)

4. Install the O-ring for the rod seal. See Figure 4-9. Figure 4-9 Install O-ring for rod seal 5. Install the rod seal. See Figure 4-10. Figure 4-10 Install rod seal FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 57: Use The Piston To Push The Seal Into Position

7. Install the O-ring for the wiper seal. See Figure 4-12. Figure 4-12 Install O-ring for wiper seal 8. Install the wiper seal. See Figure 4-13. Figure 4-13 Install wiper seal © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 58: Use The Piston To Push The Seal Into Position

9. Use the piston to push the seal into position. See Figure 4-14 for an image of the rod seal and wiper seal assemblies. Rod seal assembly Wiper seal assembly Figure 4-14 Rod seal and wiper seal assemblies FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 59: Cylinder Assembly For Waterless Pneumatic Actuator

1. Insert the piston into the cylinder body. See Figure 4-15. Figure 4-15 Install the piston 2. Install the cylinder top seal. See Figure 4-16. Top seal Figure 4-16 Install the top seal © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... - Page 60 Ensure the ports are on the same face. See Figure 4-17. Figure 4-17 Assembled cylinder - note ports 4. Apply anti-seize compound to the screws. 5. Install the cylinder top screws. 6. Torque to 16 Nm (11.8 ft-lbs). FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved.

-

Page 61: Cylinder Assembly For Waterless Pneumatic Actuator - Anti-Rotation Version

9. Insert valve pin. 10. Install the anti rotation dowel to prevent rotation of the lock valve pin. See Figure 4-19. Anti rotation dowel Figure 4-19 Anti rotation dowel © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... - Page 62 Ensure that the O-ring is in good condition. 13. Insert the piston with the anti rotation dowel into the cylinder body. See Figure 4-21. Figure 4-21 Anti rotation version: install the piston FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved.

- Page 63 Ensure the ports are on the same face. See Figure 4-23. Figure 4-23 Anti rotation version: assembled cylinder 16. Apply anti-seize compound to the screws. 17. Install the cylinder top screws. 18. Torque to 16 Nm (11.8 ft-lbs). © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual...

-

Page 65: Section 5 - Assembly

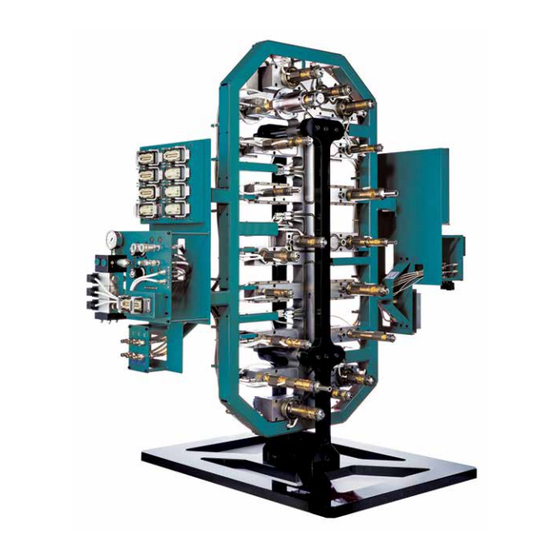

9. Anti rotation step dowel 4. Enclosed wire channels 10. Heated flange G2 nozzle 5. FUSION SERIES G2 manifold 11. G2 nozzle ® 6. System screw 12. Gate seal FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 66: Typical Fusion Series ® G2 Systems

11. Centering ring 4. Valve nut and insert 12. Snap ring 5. Wire harness 13. Gate seal 6. Manifold 7. Manifold locator Figure 5-3 FUSION SERIES G2 hydraulic system ® © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 67: Fusion Series ® G2 Drop-In System

Hot Runner system will be pre-assembled, however, • No wire channel, adapter plate and E-Box • No wiring and no plumbing • No fittings Figure 5-5 FUSION SERIES lite system ® FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 68: Gate Seal Finishing

The gate seals supplied with your system may need to be adjusted to tolerances based on the material grade and cooling in the cavity. Refer to your Mold-Masters General Assembly Gate Detail drawing to determine if gate seal finishing is required. Refer to the General Assembly drawing to determine which gating method applies. -

Page 69: Re-Torque At Process Temperature

4. Re-torque nozzles and gate seals to recommended torque values in “11.1 Recommended Torque Settings” on page 11-1. 5.4 Check Nozzle Core to Manifold Fit 5. Inspect threads for burrs. 6. Apply die spotting blue compound to nozzle core. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. - Page 70 8. Assemble nozzle to manifold and torque to specified value. 9. Verify transfer of die spotting blue compound from nozzle core to manifold. 10. Clean die spotting blue compound from components. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual...

-

Page 71: Assemble Nozzle To Manifold

12. Assemble the nozzle to the manifold. 13. Torque the nozzles to value on the General Assembly drawing. IMPORTANT Remember to re-torque at process temperature when system assembly is complete. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 72: Nozzle Assembly For Systems With Protective Sleeves

ASSEMBLY 5.6 Nozzle Assembly for Systems with Protective Sleeves Mold-Masters recommends the use of protective sleeves with FUSION SERIES nozzles. ® For systems without protective sleeves, please see “5.7 Nozzle Assembly for Systems without Protective Sleeves” on page 5-13. 14. Install the bottom end cap of the protective sleeve onto the coredel. - Page 73 16. Install the heater sleeve onto the coredel. 17. Route the cables through the cut on the bottom end cap. Cutout in bottom end cap 18. Install all other heated or unheated sleeves, if applicable. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved.

- Page 74 19. Install the protective sleeve. 20. Install the top end cap over the protective sleeve. NOTE Ensure proper seating of the top end cap. Move the thermocouple clip down, if necessary. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual...

-

Page 75: Heater Retaining Clip Installation

22. Using snap ring pliers, expand the clip and install it into the snap ring groove on the nozzle core, which protrudes above the body of the protective sleeve. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. - Page 76 ASSEMBLY 5-12 Heater Retaining Clip Installation - continued See Figure 5-7 for completed protective sleeve assembly. Figure 5-7 Completed protective sleeve assembly © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual...

-

Page 77: Nozzle Assembly For Systems Without Protective Sleeves

1. Install heaters and sleeves per specified drawings. 5.7.2 Install Thermocouple 2. Insert the thermocouple into the thermocouple slot until it bottoms out. Bend the thermocouple 180 degrees. 3. Install the thermocouple retainer clip. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 78: Install Thermocouple Onto Nozzle Body (Optional)

2. Slide front heater onto the nozzle body and line up the slot on the heater with thermocouple. 3. Bend the thermocouple 180 degrees, and then install the retainer clip. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 79: Install The Thermocouple Onto The Nozzle Body (F3000/4000 Nozzles)

1. Insert the thermocouple into the thermocouple slot until it reaches the bottom of the slot. 2. Bend the thermocouple along the path of the thermocouple groove. 3. Install the thermocouple clip. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 80: Heater Retaining Clip Installation

Installation of a guiding ring is an option for systems without protective sleeves. Please see “Figure 5-8 Nozzle center guiding ring” on page 5-16. Nozzle center guiding ring Figure 5-8 Nozzle center guiding ring © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 81: Flange Nozzle Assembly

3. Apply anti-seize compound to the nozzle threads and then thread the nozzle into the flange. Torque nozzles to specified value. Remember to re-torque at process temperature when system assembly is complete. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. - Page 82 Make sure the balls sit completely inside the dimple. 6. Torque the two M5 shoulder bolts to 9.5 Nm (84 lbf.in.). © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual...

-

Page 83: Gate Seal And Nozzle Assembly

3. Remove gate seal and verify transfer of die spotting blue compound from gate to the liner. Verify transfer of die spotting blue compound to nozzle core. If not 100% blue on face, contact your Mold-Masters representative. 4. Clean die spotting blue compound from components. -

Page 84: Assemble Gate Seals To Nozzle

6. Ensure all sealing surfaces are clean and dry. 7. Install the gate seal and liner. 8. Torque to specified values. Remember to re-torque at process temperature when system assembly is complete. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 85: Install Manifold Locator

See “11.1 Recommended Torque Settings” on page 11-1. 3. Verify the height of the manifold locator to the dimension specified on the General Assembly drawing. 5.10 Install Support Bushings 4. Apply anti-seize compound to the screw. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. - Page 86 6. Repeat for the other support bushings. Typical application will require one support bushing per nozzle. 7. Verify the height of the support bushing and the manifold locator to the specification on the General Assembly drawing. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual...

-

Page 87: Install Manifold Thermocouple

Repeat for all manifold thermocouples. 3. Bend the thermocouples into the slot. 4. Install the manifold ground strap and the thermocouple retention screw combination. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 88: Install Inlet

6. Apply die spotting blue compound to the bottom of the inlet. 7. Apply anti-seize compound to the screw and install the inlet to the manifold. 8. Torque screws in a crossing pattern, gradually increasing torque to the specified value. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... - Page 89 11. Re-install the inlet. Torque screws in a crossing pattern gradually increasing the torque to the specified value. 12. Install the inlet heater and sleeve to the inlet. Ensure the terminal end connection is facing in the correct direction. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved.

-

Page 90: Install Inlet Thermocouple

5.12.2 Install Inlet Extension Tip 15. Apply die spotting blue compound to the inlet extension tip and install it into the inlet. Verify blued surfaces to check for correct fit. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... - Page 91 16. Clean die spotting blue compound from the inlet extension tip and the inlet. 17. Apply anti-seize compound to the threads and install the inlet extension tip to the inlet. 18. Torque to the specified value. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved.

-

Page 92: Install Valve Insert Or Valve Disk

19. Verify the height of the valve insert and the depth of manifold bore to the dimension specified on the General Assembly drawing. 20. Apply die spotting blue compound to the contact surfaces of the valve insert. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... - Page 93 21. Apply anti-seize compound to the screw. 22. Install the screw in a crossing pattern. 23. Remove the valve insert, and verify blue on all surfaces. 24. Clean die spotting blue compound from all components. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved.

- Page 94 ASSEMBLY 5-30 Install Valve Insert (Valve Insert Design) - continued 25. Install and torque in a crossing pattern. 26. Install the valve pin to verify fit. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual...

-

Page 95: Install Valve Disk (Valve Disk Design)

1. Apply die spotting blue compound to the valve disk stem. 2. Install the valve disk stem into the manifold hole. 3. Install the valve disk flange on top of the valve disk stem. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. - Page 96 6. Clean die spotting blue compound from all components. 7. Re-install the valve disk stem and valve disk flange. Torque in a crossing pattern. 8. Install the valve pin to verify fit. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual...

-

Page 97: Install Cylinder On Manifold

1. Install the spacers on top of the manifold or valve disk flange. 2. Locate the pneumatic cylinder cooling plate onto the spacers. 3. Apply anti-seize compound to the threads of the screws. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. - Page 98 4. Tighten the screws in a cross pattern, gradually increasing the torque. 5. Place the cylinder housing onto the cylinder cooling plate. 6. Insert the valve pin into the piston. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual...

- Page 99 8. Install the piston top in the piston. Using a soft jaw vise, tighten the piston top to a torque of 10 N∙m (7 lb∙ft). 9. Install the piston into the cylinder housing. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved.

- Page 100 10. Install the cylinder top O-ring. 11. Install the cylinder top. 12. Apply anti-seize compound to the threads of the screws. Tighten the screws in a cross pattern, gradually increasing the torque. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual...

- Page 101 ASSEMBLY 5-37 13. Connect compressed air and cooling water hoses as per the system design. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved.

-

Page 102: Hydraulic System

1. Install the spacers on top of the manifold or valve disk flange. 2. Locate actuator on top of the spacers. 3. Apply anti-seize compound to the screws. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... - Page 103 ASSEMBLY 5-39 4. Torque the screws in a cross pattern, gradually increasing the torque. 5. Connect hydraulic and cooling water hoses as per the system design. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved.

-

Page 104: Waterless Hydraulic And Pneumatic Actuator Systems

1. Install the valve insert or the valve disk on top of the manifold. See Figure 5-10. Install valve insert Install valve disk Figure 5-10 Install valve insert or valve disk © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... - Page 105 Support pillars Figure 5-12 Valve disk design: install support pillars 3. Torque support pillars to 20 Nm (14.8 ft-lbs). 4. Locate the actuator on top of the support pillars. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved.

- Page 106 Ensure the bolts are fully seated in the support pillars. See Figure 5-13. 7. Torque the shoulder bolts in a crossing pattern. Gradually increase torque to 9.5 Nm (7 ft-lbs). See Figure 5-14. Figure 5-14 Torque shoulder bolts © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual...

- Page 107 L1 = distance from manifold plate / pocket to cylinder top L2 = distance from manifold plate to top of mounting plate / pocket Figure 5-15 Check tooling pocket FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved.

- Page 108 Figure 5-16 Bolt clamp plate This action should press the cylinder down to close the gap. See Figure 5-16. 11. Torque the bolts to the value specified on the General Assembly drawing. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual...

-

Page 109: Install Wiring

2. Apply anti-seize compound to the button head cap screws (BHCS). Using the BHCS screws install the bracket, over the insulation plate, in the appropriate location(s) on the manifold. 3. Mount the wire armor to the bracket. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 110: Install Wiring

7. Install thermocouple and heater wires into the electrical plugs according to the wiring schematic in MM General Assembly “EWS” drawing. 8. Install the plugs into the electrical box. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 111: Solenoid Valve Wiring

ASSEMBLY 5-47 5.16.4 Solenoid Valve Wiring 1. Install the solenoid coil wires into the electrical plugs according to the wiring schematic. 2. Install the plugs into the electrical box. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. - Page 112 5-48 Plumbing Cylinders NOTE For ease of hose assembly, the actuator has three optional plumbing cylinders: 1. Connect the hoses to the actuators. 2. Label and group the hoses. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual...

- Page 113 ASSEMBLY 5-49 3. Route the hoses on top of the wire armor and secure with ties. 4. Connect the hoses to the adapter plate according to the drawing schematic. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved.

-

Page 114: Connect Solenoid Valve Bank

7. Similarly, connect the return hoses starting with white “G1 OPEN” label from the lower port on cylinder body to the same solenoid valve unit. White “G1 Open” hoses go to the lower ports © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 115: Pneumatic Valve Bank Connection

5. Repeat above steps to connect each hose with “Gxx OPEN” from the lower port on cylinder body to same solenoid valve unit as above. Current Bosch Rexroth solenoid valve bank: “2” port = CLOSE “4” port = OPEN FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 116: Install Hydraulic Flow Control Valve

2. Install all fittings onto the mounting plate. 3. Install the flow control valve onto mounting plate using M5 screw. 4. Install all flow control valves onto mounting plate. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... - Page 117 Hydraulic Cylinder VP OPEN PORT (LOWER) VP OPEN PORT VP CLOSE PORT PORT “B” CONTROL ELEMENT PORT “A” VP CLOSE PORT (TOP) Figure 5-17 Hydraulic flow control valve - connections FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved.

-

Page 118: Install Actuator Position Sensor

7. Inductive sensor 2. Piston top 3. Retainer ring 8. Spacer (sensing target) 4. Cylinder top 9. Rod seal 10. O-ring 5. BHCSM5 Figure 5-19 Actuator with position sensor © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... - Page 119 5. Install the O-ring, rod seal and the retainer ring into the cylinder top. Make sure that the rod seal open side faces downwards. 6. Install the cylinder top onto the cylinder body. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved.

- Page 120 9. Install the locker to hold sensor into place and lock the nuts. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual...

- Page 121 1. SCHSM5 2. Sensor 3. Dowel pin 4. Sensor bracket Figure 5-18 Top sensor mounting assembly installation 11. Run the sensor wires into the wire channel and route the sensor amplifier to the external mounting plate. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved.

- Page 122 13. Connect the wires to the connectors according to the wiring schematic. BN (1) output BK (4) BU (3) 14. Follow the similar procedure to assemble the pneumatic actuator with sensors. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual...

-

Page 123: Water Cooled Gate Insert Installation

CAUTION Clean all surfaces and dowel holes. Make sure that there is no debris, burrs, shavings, dust, dirt or any other foreign material. Check that all mold base dimensions are in accordance with Mold-Masters General Assembly drawings. IMPORTANT Water cooled gate inserts cannot be used in systems with protective sleeves. - Page 124 Tighten it with the required torque. See torque table for torque specifications. 7. If it is necessary to lift up gate insert assembly, use the lift holes on gate insert or support tube. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual...

-

Page 125: Section 6 - Sevg Plus Actuator

The size and options for the SeVG Plus actuator depend on the system requirements. Please check your General Assembly drawings to confirm the type of SeVG Plus actuator in your system. 6.3 SeVG Plus Actuator in FUSION SERIES ® Systems... -

Page 126: Sevg Plus Models

5. Motor locating spigot 2. Valve pin holder (bottom) 6. Motor mount flange 3. Valve pin holder (top) 7. SHCSM6X25 4. Motor rod 8. Motor Figure 6-1 SE40-20 actuator © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 127: Se40-20C Actuator - Cooled

IMPORTANT Mold-Masters assumes no responsibility for connection, monitoring and / or maintenance of any cooling system associated with an SeVG Plus system. 6. Motor mount flange 1. -

Page 128: Manifold Mounted Systems

7. Valve pin holder (bottom) 8. Valve disk stem 9. Valve pin 10. Valve disk flange 11. Spacer 12. Water fitting 13. Cooling plate 14. Assembly screw Figure 6-3 SE40-20 actuator © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 129: Se40-20C Model

8. Valve disk stem 9. Valve pin 10. Valve disk flange 11. Spacer 12. Water fitting 13. Cooling plate 14. Assembly screw 15. Quick connections for motor cooling Figure 6-4 SE40-20C actuator FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 130: Sevg Plus In Manifold Mounted Systems

SEVG PLUS ACTUATOR 6.6 SeVG Plus in Manifold Mounted Systems Figure 6-5 SE40-20 actuator in a manifold mounted system © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 131: Assembly And Installation

A template for the appropriate hole pattern is provided in Figure 6-6. Front view Rear view Bulkhead connectors Hole pattern template Figure 6-6 Bulkhead connectors and template FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 132: Figure 6-7 Motor Rod Flats

10 Nm [6 to 7 ft-lbs]. See “Figure 6-8 Valve pin holder components” on page 6-9. 3. Align the four spacers and insert into the counterbores of the valve disk © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 133: Figure 6-8 Valve Pin Holder Components

9. Place the motor locating spigot and valve pin assembly onto the cooling plate. NOTE Ensure that the motor shaft is aligned with the cooling plate bore. Motor locating spigot FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 134: Figure 6-9 Motor Locating Spigot

Figure 6-10 Insert the screws to fasten the assembly 11. Attach the water hoses. 12. Place the cables in an insulated sheath with a heat rating of 280˚C / 535˚F. See Figure 6-11. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 135: Figure 6-11 Place Cables Into Insulated Sheath

Figure 6-12 Attach cables to wiring channel IMPORTANT The cables must not be allowed to touch the manifold or other heated components. 14. Continue assembly with the clamp plate. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 136: Disassembly

Damaged cables can cause a permanent failure of the motor. 1. Cool the system to room temperature, between 10°C and 40°C (50°F and 104°F). 2. Disconnect the water hoses from the actuator and / or clamp plate. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 137: Figure 6-13 Remove B Screws

Heat the system to allow any plastic to become soft. • Remove the four SHCSM6X90 mounting screws from the motor flange, which is attached to the cooling plate. 7. Remove the motor / valve pin assembly. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 138: Section 7 - Electrical Testing

WARNING Ensure that you have fully read “Section 3 - Safety” before beginning electrical testing. This section contains guidelines for electrical testing of your Mold-Masters Hot Runner system. The testing is based on the following European and North American standards: •... -

Page 139: Electrical Safety Testing

The conditions for automatic shutdown of the supply are set at Mold-Masters and usually set such that the protective conductor resistance between the grounding conductor connection and all of the protective earth conductor connected parts, is Maximum 0.3 Ω. -

Page 140: Verification Of Fault Loop Impedance

If there is a pinch point in the thermocouple there will be no change in the reading until the pinch point on the thermocouple is immersed in water. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 141: Heating Element Check

Stay a minimum of 5 minutes at 100°C (212°F) before increasing heat. 7.9 Retesting If a portion of the electrical equipment is changed or modified, that portion must be re-verified and re-tested, as appropriate. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 142: Section 8 - System Installation

Potential pinch point for wires. Ensure that all wires are in the retainer grooves. The following section is a general guide to installing your FUSION SERIES ® G2 Hot Runner into an existing manifold plate system or spacer block system. -

Page 143: Pre-Installation

If the molding elevation is out of tolerance within + / - 1.0mm of the General Assembly drawings, a support bushing with extra stock can be ordered from Mold-Masters. This bushing can then be machined from its bottom face to compensate for the system height difference caused by mold plate thickness. -

Page 144: System Installation

8. Carefully install the system in the mold, ensuring that the manifold remains level to avoid damage to the nozzle wiring. Lower the system, and make sure that it is correctly seated. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 145: Installation Of A System With Flanged Nozzles

4. Tighten the shoulder bolts to the specified torque. 5. Follow the system installation instructions called out in General Assembly drawings to install the system into the cavity plate. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 146: System Test

- pin open solenoid deactivate - pin close NOTE For a pneumatic solenoid valve bank that is supplied by Mold-Masters, the test can be done with the manual override function that is built into the valve, without connecting it to sequential controller. - Page 147 • the proximity sensor is mounted properly and that the sensing probe is also mounted within its sensing distance and in the correct position • if mechanical limit switch is used, then the switch is being pressed down properly © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual...

-

Page 148: Section 9 - System Startup And Shutdown

4. Connect all electrical components and monitor to ensure that all zones are receiving heat and all thermocouples are reacting appropriately. 5. If applicable, test the valve pin actuation, but only if the FUSION SERIES ® G2 system is at processing temperature. See CAUTION above. -

Page 149: Startup

SYSTEM STARTUP AND SHUTDOWN 9.2 Startup WARNING When the mold is open never inject material through FUSION SERIES ® system under high pressure. Failure to do so can result in serious injury or death. CAUTION CAUTION Failure to follow this procedure may result in leakage / damage occurring in the FUSION SERIES G2 system. -

Page 150: Shutdown

G2 system prior to shutdown using a thermally stable material with a similar processing temperature. 12. Turn off all heat to the system. 13. Leave the mold cooling system turned on until the FUSION SERIES ® system temperature is within 55°C (130°F) of the mold temperature. -

Page 152: Section 10 - Color Change

9. Bring machine barrel back in. 10. Increase injection speed and (mold temperature) until the color change is acceptable. 11. Continue processing while re-setting Hot Runner system temperatures and injection speed back to normal. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 153: Color Change For A Valve Gate System

12. Continue to purge until no trace of the first color appears. 13. If the second color appears in the molded product then the problem is in the injection unit. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 154: Section 11 - Maintenance

3 steps (1/3, 2/3 and full torque). Quality and length of screws must be as specified on Mold-Masters General Assembly drawings. FSG2 User Manual... -

Page 155: Table 11-1 Recommended Torque Settings

(Hex Key) SHCS M16 14 (0.55) (Hex Key) Heated Flange SHCS M6 5 mm 10.3 Mounting Screw (Hex Key) * For these components, torque value is at processing temperature. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 156: Tubular Heater Installation And Replacement

For Field Replacement of Ø 8.0 mm and Ø 8.5 mm Flexible Heaters Only Mold-Masters only recommends field replacement of Ø 8.0 mm (0.31 in.) and Ø 8.5 mm (0.33 in.) flexible heater elements. We do not recommend field replacement of heater elements that are brazed or pasted into the manifold. - Page 157 9. For the curved areas of the groove, pre-bend the heater element manually before hammering it into the groove. This will prevent the shielding from being damaged by the groove edge. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual...

- Page 158 35 mm (1.4 in) area on each end. See below. 35 mm (1.4 in) 12. Crimp the wire with the proper size crimper pin. Connect it to the heater threaded pin with the ceramic terminal connecter. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved.

-

Page 159: New Heater Startup

The parts need to be ordered and replaced are only the bolt kits and new valve elements if adding station required. Contact your Mold-Masters representative for detail. -

Page 160: Figure 11-1 Pressure Reducing And Relieving Valve

80 bar, as long as the reduce valve is working properly. The default setting of the PRV is 45-50 Bar (653-725 PSI), which is safe for actuators. Figure 11-1 Pressure reducing and relieving valve FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 161: Components Of A Hydraulic Solenoid Valve Bank

Manual Override Pin This allows you to push the spool to reset the valve in emergency conditions, for example, when there is a power shortage the solenoid cannot be energized. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 162: Pneumatic Solenoid Valve Bank

Figure 11-3 Solenoid connector 11.3.3 Pneumatic Solenoid Valve Bank The stackable valve bank could be supplied from 2 to 12 units. If reducing or adding new solenoid stations are needed, contact Mold-Masters representative for details. 11.3.4 Components of a Hydraulic Solenoid Valve Bank a) Valve Element TC08 5/2 Single Solenoid - Specification •... - Page 163 15. Insert the gasket and O-ring into the right end plate. 16. Insert the screws with your hand and assemble the end plates into the lower two tie rods. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual...

- Page 164 18. Evenly tighten the tie rod mounting screws with a torque of 2+0.5 Nm (17.7+4.43 lbf.in.). 19. Install solenoid connectors and hose fittings. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved.

-

Page 165: Figure 11-4 Manual Override Switch

ISO 15217:2000, 3 m (9.84 ft.) wire length, housing color: black • Rated voltage max.: 24V AC / DC • Rated current max.: 6 Amps • LED status display: yellow © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 166: Recommended Spare Parts

MAINTENANCE 11-13 11.4 Recommended Spare Parts Mold-Masters recommends that you keep the following spare parts ready for quick replacement in order to prevent any long shutdown time. • Inlet tip if applicable. • Heaters: • Common heater sleeves of the nozzles and inlet extension in the system •... -

Page 167: Section 12 - Troubleshooting

Document the solution so that a repeat occurrence can be solved quickly. • Consult other resources to augment the troubleshooting information in this manual. • Use your resin supplier as one of the best resources available. FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 168: Moisture Related Issues

Recycled resins can have higher hygroscopic properties due to greater surface area and should be dried separately from fresh resins. If moisture issues are ruled out, continue with the troubleshooting tables in the following pages. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 169: Pre-Molding Precautions

12.3.4 Settings Ensure that all batch job parameters are correct: • temperatures • pressures • injection speed • back pressure FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 170: Establishing Root Cause

• screw speed • locking • melt temperature • cushion • back pressure • mold heating For a more thorough analysis of the defect, refer to the following pages. © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 171: Troubleshooting Typical Problems

2. Trace source of contamination and repair, remove or discard 3. Adjust melt temperature if necessary 4. Inspect for dead spots: gates, runners, nozzle, back flow valve 5. Inspect feed screw for degradation FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 172: Blisters Or Bubbles

1. Verify control and / or holding pressure 2. Increase back pressure 3. Increase mold temperature 4. Inspect back flow valve 5. Ensure proper venting 6. Increase gate size 7. Decrease vent land length © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 173: Flow Marks

2. Add a large cold slug area 3. Add cold wells at the end of the runner system 4. Use hot sprue bushing 5. Identify and eliminate dead pockets / sections FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 174: Burn Marks

5. Check thermocouple functionality 6. Reduce feed screw rotation 7. Reduce melt temperature 8. Increase mold cavity venting 9. Enlarge gate 10. Change gate position and / or size © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 175: Delaminating Parts

2. Increase mold temperature 3. Decrease injection speed 4. Eliminate contamination 5. Adjust regrind ratio 6. Adjust or change resin moisture content 7. Purge system 8. Reduce sharp corners at gate FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 176: Dimensional Irregularities

5. Monitor molding machine for irregularities 6. Balance regrind ratio 7. Increase gate size 8. Decrease gate land length 9. Balance the runner and / or gate system 10. Decrease cavity quantity © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 177: Discolored Parts

4. Adjust residence time 5. Adjust regrind ratio 6. Adjust cycle time 7. Check for external contamination sources 8. Ensure proper cooling in all areas 9. Increase mold venting FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 178: Flash

5. Inspect the mold for irregularities 6. Reduce the melt temperature 7. Inspect vent depth 8. Switch to higher tonnage clamping machine 9. Establish correct transfer position 10. Reduce hold pressure © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 179: Jetting

Cold melt Solution (in sequence): 1. Decrease injection speed 2. Verify nozzle temperature 3. Increase mold temperature 4. Increase melt temperature 5. Increase gate size 6. Modify gate location FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 180: Pitted Parts

Solution (in sequence): 1. Reduce shear 2. Reduce back pressure 3. Reduce injection speed 4. Modify temperature 5. Modify regrind ratio 6. Modify shot size 7. Inspect Hot Runner and nozzles © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 181: Rough Surface

Irregularities in mold surface, defective polishing 3. Material • Cold melt Solution (in sequence): 1. Increase injection speed 2. Increase injection pressure 3. Increase melt temperature 4. Increase mold temperature 5. Inspect mold surface FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 182: Parts Sticking To Cavity

5. Reduce injection time 6. Adjust feed 7. Inspect mold finish 8. Increase mold opening cycle 9. Lower mold temperature 10. Adjust differential temperatures 11. Inspect for appropriate mold release © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 183: Parts Sticking To Core

5. Adjust feed 6. Reduce mold closed time 7. Increase core temperature 8. Decrease nozzle temperature 9. Inspect mold for undercuts and / or improper draft 10. Verify mold bending ratio FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 184: Short Parts

3. Increase feed temperature by increasing cylinder temperature 4. Increase injection time 5. Increase mold temperature 6. Increase nozzle diameter 7. Inspect for restrictions 8. Increase gate size of sprue and runner system © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 185: Sinks Or Voids

8. Increase sprue or runner size 9. Increase gate size / reduce gate land length 10. Relocate gate closer to heavy / thicker areas 11. If possible, core out heavy wall sections FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 186: Splay

6. Decrease or eliminate screw decompression 7. Reduce cycle time 8. Check for drooling 9. Check for contamination in mold cavity 10. Open gates 11. Try mold in smaller shot-size press © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 187: Streaks

3. Inspect back flow ring for wear or cracks 4. Inspect feed screw for wear and tear 5. Inspect screw / barrel for tolerances 6. Verify heater operation 7. Verify thermocouple operation FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 188: Stringing

Solution (in sequence): 1. Reduce back pressure 2. Modify nozzle temperature 3. Modify temperature profile 4. Eliminate sprue breaks 5. Increase cooling time 6. Decrease mold temperature at the gate © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 189: Warped Parts

6. Increase cooling time 7. Adjust injection pressure 8. Adjust mold temperature; set sequential temperatures based on part geometry 9. Check gate dimensions, quantities and locations 10. Re-design part if necessary FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. -

Page 190: Weld Lines

4. Increase cylinder temperature 5. Increase mold temperature 6. Check for venting 7. Provide an overflow well adjacent to the weld area 8. Modify the gate location 9. Decrease gate land length © 2020 Mold-Masters (2007) Limited. All Rights Reserved. FSG2 User Manual... -

Page 191: Index

Pressure Reducing and Relieving Valve 11-7 Safety Hazard Areas 3-2 Lockout 3-10 Safety Symbols General Descriptions 3-7 Solenoid Connector 11-9 Solenoid Form C Connector 11-12 Solenoid Valve Bank 11-6 Spare Parts 11-13 FSG2 User Manual © 2020 Mold-Masters (2007) Limited. All Rights Reserved. - Page 192 +86 512 86162882 e: singapore@moldmasters.com e: korea@moldmasters.com e: china@moldmasters.com INDIA JAPAN tel: +91 422 423 4888 tel: +81 44 986 2101 e: india@moldmasters.com e: japan@moldmasters.com © 2020 Mold-Masters (2007) Limited. All Rights Reserved. Fusion-Series G2 User Manual ®...

Need help?

Do you have a question about the Fusion Series and is the answer not in the manual?

Questions and answers