Summary of Contents for Waterax BB-4MD

- Page 1 BB-4 ® Owner’s Manual Publication Date : 04/2015 Publication Number: 701225, Rev. 2...

- Page 2 This document provides information proprietary to WATERAX Inc. and cannot be used or disclosed without WATERAX’s written authorization. WATERAX Inc. reserves the right to make changes without notice in its products or components as research and development or marketing conditions warrant. Changes affecting the operation of any component in this manual will be reflected in a subsequent revision.

-

Page 3: Table Of Contents

WATERAX BB-4 Owner's Manual Contents Important Safety Instructions .................... 2 Personal Safety Advisory ......................2 Warnings ............................2 Preventing Damage to Equipment ..................3 Introduction ........................4 About this Manual ......................... 4 Abbreviations and Terms ......................4 About the BB-4 Series ........................5 Parts Identification ........................ -

Page 4: Important Safety Instructions

READ THIS MANUAL BEFORE OPERATING YOUR PUMP! The improper use of the WATERAX pump could result in serious injuries as well as damage to the pump. Any operator should familiarize himself with the apparatus and its capabilities before trying to operate the equipment in an emergency situation. -

Page 5: Preventing Damage To Equipment

Operating the pump in such a manner can overheat the pump causing damage to seals, or pump internals. It is recommended that all fasteners be replaced with genuine WATERAX parts. When mounting manifolds to the pump, the manifolds must be self-supporting and ®... -

Page 6: Introduction

Kubota D902 25 HP diesel engine These instructions cover most wildland and municipal pump applications. If the application the pump is being used for does not fall into these general guidelines, consult WATERAX Inc. for any additional safeguards, operating, or maintenance considerations that may be required. -

Page 7: About The Bb-4 Series

Accuracy in flow trajectory when structure firefighting Tandem pumping over long distances Parallel pumping for higher volumes Features and Benefits of the WATERAX BB-4 series include: Quick release clamp and swappable pump ends for minimal equipment downtime and inventory ... -

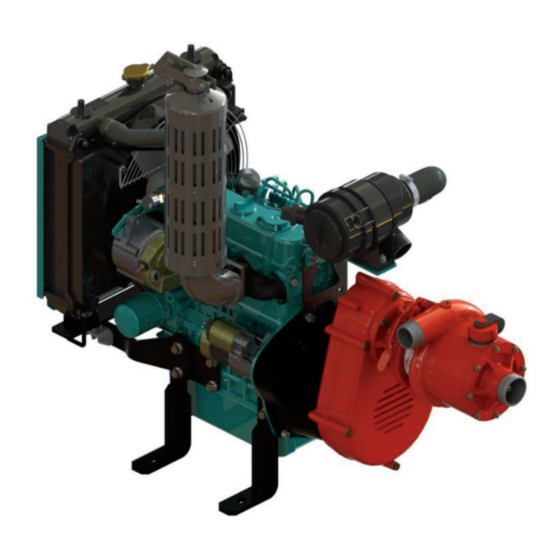

Page 8: Parts Identification

WATERAX BB-4 Owner's Manual Parts Identification BB-4-18/23 A. Priming cap B. Pump intake (suction) C. Pump drain port (not shown) D. Pump discharge E. Quick release pump clamp F. Low-tone muffler G. Fuel pump (not shown) H. Fuel valve (not shown) -

Page 9: Installation

Installation Depending on your model and configuration ordered, you may require additional accessories from WATERAX or from third-party vendors, for example, control panels, batteries, and fuel lines. You will also require hoses and nozzles as well as other fire apparatus plumbing which can be purchased through your WATERAX representative. -

Page 10: Installing A Control Panel

WATERAX BB-4 Owner's Manual Installing a Control Panel See User Instructions shipped with the specific model of control panel you ordered for your pump. Using a Battery for Electric Starters and Control Panels Some BB-4 pumps require a battery to power electrical and electronic components such as starters, pump primers and control panels. -

Page 11: Operating Bb-4 Series Pumps

WATERAX BB-4 Owner's Manual Operating BB-4 Series Pumps Pre-Operation Checklist Before using your pump, follow this verification procedure: 1. Visually inspect product When you first receive your BB-4 pump, inspect the product and check for any damage. Notify the supplier if any damage is found. -

Page 12: Drafting

WATERAX BB-4 Owner's Manual Drafting Before you draft Pumps should not be run dry, and therefore the pump ends require priming prior to operation. Use this procedure if you are drafting water from an open tank or natural water source. -

Page 13: Priming The Pump

A shut off valve should also be placed between the pump and the primer to shut off the priming line once the pump has been primed. WATERAX Hand Primer: Connect hand primer to discharge port and pump until water is drawn Priming into the pump. -

Page 14: Startup And Discharge

WATERAX BB-4 Owner's Manual Startup and Discharge 1. Fill fuel tank with recommended fuel grade. For models with an integral fuel tank, fill tank and securely replace cap. For models without an integral fuel tank, fill external fuel tank and connect fuel supply line to the fuel filter. -

Page 15: Shutdown

WATERAX BB-4 Owner's Manual 3. Discharge water. Once the pump is primed, and with the engine running, you can begin to discharge water. a. Slowly open the discharge valve. If pressure does not build in the discharge hose, the pump has not been fully primed. -

Page 16: Basic Care And Storage

WATERAX BB-4 Owner's Manual Basic Care and Storage The basic care described in this section does not require any disassembly of the pump. For any servicing procedures that require removing any part of the pump to access a component, please see the Service section. -

Page 17: Troubleshooting

WATERAX BB-4 Owner's Manual Troubleshooting This section provides brief troubleshooting instructions for verifying the set-up and operation of the pump. Each section describes a condition and lists possible causes along with a list of items to check to identify the source of the problem and resolve it. - Page 18 WATERAX BB-4 Owner's Manual Pump Does Not Meet Performance Incompatible Piping size and configuration may be too restrictive. Contact a WATERAX Inc. Installation representative if assistance is needed in evaluating the unit’s piping. Gauge or Check that all gauges are calibrated and that all equipment is in proper Instrument condition.

-

Page 19: Service

Service This section includes instructions for overhaul and maintenance requiring disassembly of the WATERAX 4-stage pump end model 12-16S that is integrated in the BB-4 series pumps. It does not include engine maintenance. For maintenance instructions regarding the engine, as well as for oil and fuel recommendations, please refer to the engine manufacturer’s manual. -

Page 20: Installing The Drive Assembly

WATERAX BB-4 Owner's Manual ID ITEM NO DESCRIPTION 1 800538 PART-8 RETAINING RING EXT. 2 800541 PART-9 RING RETAINING INT. 3 800836 PART-10 BEARING, 4 POINT CONTACT, SEALED 4 700083 A-6956 SPACER FOR C-7220, ALU. 5 700086 A-7239 SHAFT ASSEMBLY FOR C-... - Page 21 WATERAX BB-4 Owner's Manual Procedure Place the rear cover on engine. Make sure the rear cover is properly positioned and lying flat against the engine face. Securely tighten the four cap screws and lock washers. If the drive assembly is installed horizontally (see Fig.

- Page 22 WATERAX BB-4 Owner's Manual Since tightening the cap screws will affect IMPORTANT: The torque value for the the axial position of the pulley, make sure driven pulley (small) cap screws is pulleys are properly aligned: 108 in-lbs, not 180 in-lbs.

-

Page 23: Removal Of Pulley Assembly

WATERAX BB-4 Owner's Manual Removal of Pulley Assembly Remove all the cap screws sequentially. Remove the set screw. For the large driver pulley, insert the cap screws into the threaded holes of the bushing. For the small driven pulley, insert... -

Page 24: Pump Tool Kit

10 800360 12-38 LOCKWASHER 1/4 SPLIT SS lockwashers and nylon lock screws is 11 800359 12-39 SCREW 1/4-28X9/16 SLOT FILLISTER available from WATERAX (item no 250228). 12 700022 A-5537 PROTECTIVE CAP FOR 2" SUCTION 13 700029 12-40 BUSHING BEARING, BRONZE... -

Page 25: Assembly Procedure For Pump End 12-16S

WATERAX BB-4 Owner's Manual Assembly Procedure for Pump End 12-16S ID ITEM NO DESCRIPTION 16 700006 12-17 COUPLING BUFFER (2/2) 17 700037 12-2C PUMP SHAFT FOR 12-16 18 800364 12-25 SCREW #8-32X7/16 PHILLIPS FLAT NYLON LOCK SS 19 700032 12-3 RETAINING RING FOR BEARING, ALU. -

Page 26: Pump Clamp

WATERAX BB-4 Owner's Manual 14. Slide impeller #22 into position, aligning with previous impeller. 15. Repeat steps 12 and 13 for remaining distributor. 16. Slide impeller #25 into position, aligning with previous impeller. 17. Place lockwasher #26 on shaft with locating tab in milled groove. Slightly bend lockwasher tab downwards to facilitate insertion. -

Page 27: Assembly Of Bb-4-D902 Stub Shaft And Engine Housing

WATERAX BB-4 Owner's Manual Assembly of BB-4-D902 Stub Shaft and Engine Housing ITEM NO DESCRIPTION 600572-2** SCREW M8 X 30 HEX SOCKET 600572-1** FLAT WASHER M8 600572 BELL HOUSING K106 ALU SAE "A" PILOT, HARDWARE INCL 600572-3** GUIDING PIN 600582 KEY 3/8"... -

Page 28: Assembly Of Bb-4-D902 Engine High Temp. Sending Unit

WATERAX BB-4 Owner's Manual Assembly of BB-4-D902 Engine High Temp. Sending Unit ID ITEM NO DESCRIPTION 801232 TEMPERATURE SENDER & SWITCH 120 801252 ADAPTER BUSHING 3/8” FNPT TO 3/8” MBSPT HEX BRASS Assembly of BB-4-D902 Low Oil Pressure Sending Unit... -

Page 29: Bb-4 Wiring

XCP vs. Engine Controls: A WATERAX XCP control panel should not be operated simultaneously with the original engine controls; undesired behaviors may occur. It is recommended to remove the key switch from the engine and store it in a safe location if equipped with an XCP. - Page 30 WATERAX BB-4 Owner's Manual Original Engine Wiring Configuration: To revert back to the Original Engine Controls refer to the instructions below. ENGINES FOR XCP FOR ENGINE CONTROLS Key Switch Magneto Grounding Stud Magneto Ground Wire Key Switch Harness Connect the Key Switch Magneto Ground Wire to the Magneto Grounding Stud.

-

Page 31: Fastwire Wiring Diagrams

WATERAX BB-4 Owner's Manual FastWire Wiring Diagrams WIRING FOR GASOLINE PUMPS *Pins 7 & 8 connected on GX630 engine only. 04/2015 Page 29... - Page 32 WATERAX BB-4 Owner's Manual WIRING FOR DIESEL PUMP 04/2015 Page 30...

-

Page 33: Pump End Technical Data

WATERAX BB-4 Owner's Manual Pump End Technical Data Threads Discharge port 1-1/2” [38 mm] NPSH male Suction (intake) port 2” [51 mm] NPSH male Priming port 1-1/2” [38 mm] NPSH male Torque Values Retaining ring screw 22-25 in-lbs 2.5-2.8 Nm... - Page 34 WATERAX BB-4 Owner's Manual Notes 04/2015 Page 32...

-

Page 35: Warranty

WATERAX, (the “Purchaser”) that its products, including any pump parts products manufactured by WATERAX (the “Products”) sold under Seller’s brands will be free of defects in material and workmanship for the applicable Warranty Period (as set out in full at www.waterax.com/eng/warranty). - Page 36 All information contained in this document including drawings is proprietary to WATERAX and may not be copied, reproduced or used in whole or in part without our prior written permission. The information in this document is subject to change without notice. Model displayed with multiple options.

Need help?

Do you have a question about the BB-4MD and is the answer not in the manual?

Questions and answers