Table of Contents

Advertisement

Quick Links

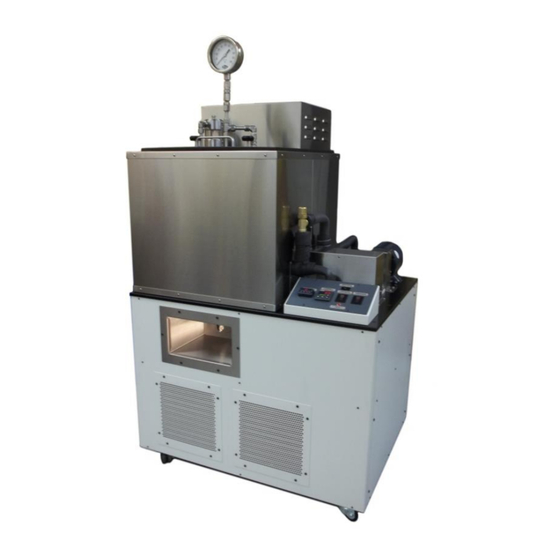

K2269X

Low Temperature Pressure Viscometer

Operation and Instruction Manual

REV B

Koehler Instrument Company, Inc.

1595 Sycamore Avenue • Bohemia, New York 11716-1796 • USA

Toll Free: 1-800-878-9070 (US only) • Tel: +1 631 589 3800 • Fax: +1 631 589 3815

http://www.koehlerinstrument.com • e-mail: info@koehlerinstrument.com

Petroleum Testing & Analysis Instrumentation • Custom Design & Manufacturing

Advertisement

Table of Contents

Summary of Contents for Koehler K2269X

- Page 1 Low Temperature Pressure Viscometer Operation and Instruction Manual REV B Koehler Instrument Company, Inc. 1595 Sycamore Avenue • Bohemia, New York 11716-1796 • USA Toll Free: 1-800-878-9070 (US only) • Tel: +1 631 589 3800 • Fax: +1 631 589 3815 http://www.koehlerinstrument.com •...

- Page 3 CERTIFICATE OF CONFORMANCE Low Temperature Pressure Viscometer K2269X This certificate verifies that part number K2269X, Low Temperature Pressure Viscometer, was manufactured in conformance with the applicable standards set forth in this certification. Specifications: ASTM D1092 This unit is tested before it leaves the factory, to ensure total functionality and compliance to the above specifications and ASTM standards.

-

Page 5: Table Of Contents

K2269X Low Temperature Pressure Viscometer Operation and Instruction Manual Table of Contents 1 Introduction ........................2 1.1 Koehler’s Commitment to Our Customers ..................... 2 1.2 Recommended Resources and Publications ..................2 1.3 Instrument Specifications ........................2 2 Safety Information and Warnings ................3 3 Getting Started....................... -

Page 6: Introduction

Volume: 20 Gallons (75.71 Liters) provide you with the best solutions. You can depend on Koehler for a full range of accurate and 640 lbs (290.3 kg) Net Weight: reliable instrumentation as well as support for your Shipping Weight: 900 lbs (408.2 kg) -

Page 7: Safety Information And Warnings

The instructions for preparing the equipment assume that the user is aware of the contents of this document, which lists the warranty conditions and important precautions. Packing List K2269X Low Temperature Pressure Viscometer K2269X-Manual Operation Instruction Figure 1. Packing List... -

Page 8: Unpacking

When submitting a claim for Viscometer will ship and arrive in two large shipping damage, request that the carrier packages: inspect the shipping container and equipment. Do not return goods to Koehler without written - Wooden Crate authorization. - Cardboard Box Setup 2. -

Page 9: Description

K2269X Low Temperature Pressure Viscometer Operation and Instruction Manual 5. Gear Box and Motor Assembly. This section 4 Description of the apparatus contains the gear pump, Instrument Descriptions gears, drive motor required to power the hydraulic system. Refer to section 4.4 for detailed descriptions on this section of the apparatus. -

Page 10: Control Box Descriptions

K2269X Low Temperature Pressure Viscometer Operation and Instruction Manual build-up of the system and rupturing of the Control Box Descriptions over-pressure emergency valve. Always make sure opposing valve is in the open position prior to closing a valve. 9. Refrigerated Chamber Lid. Keep lid in... -

Page 11: Gear Box And Motor Descriptions

K2269X Low Temperature Pressure Viscometer Operation and Instruction Manual 16. Chamber Temperature Controller. required to simulate flow rates attained by 40- temperature controller regulates the chamber tooth gear and 64-tooth gear as per ASTM temperature for the test procedure. Set point D1092. - Page 12 K2269X Low Temperature Pressure Viscometer Operation and Instruction Manual 1. Process Temperature Display. is a value observed in the upper red LED upper red LED display shows the process display, add it to the calculated difference temperature as read from the RTD probe.

-

Page 13: Operation

K2269X Low Temperature Pressure Viscometer Operation and Instruction Manual Calibrate Hydraulic System 5 Operation Prior to calibrating the hydraulic system, check Refrigerated Test Chamber and confirm that the hydraulic oil reservoir is filled Remove the Chamber lid (Figure 3, Item 9) and with hydraulic oil at least ¾... - Page 14 K2269X Low Temperature Pressure Viscometer Operation and Instruction Manual 2. Connect the 5000psi maximum pressure gauge to the upper connection of the NOTE: It is recommended to place a Calibration Piping Assembly using the quick small collection beaker or towel underneath connect coupling assembly.

-

Page 15: Loading Grease Cylinder

K2269X Low Temperature Pressure Viscometer Operation and Instruction Manual 20. Disconnect the Calibration Piping Assembly 5. Fill Grease Cylinder with approximately one- from the Hydraulic System Connection Port half pound of the grease to be tested in a (Figure 3, Item 11). -

Page 16: Testing Procedure

K2269X Low Temperature Pressure Viscometer Operation and Instruction Manual Figure 13. Standard Piping Connection_2 Figure 15. Thermocouple Connection_Close Up 11. Using the quick connect coupling that comes 14. The grease cylinder loading procedure is now attached to the pressure gauge, connect a complete. -

Page 17: Maintenance

If you have any questions 8. Press the Gear Switch (Figure 4, Item 15) to about maintaining your equipment, then please do simulate the 64-tooth gear speed. not hesitate to contact the Koehler technical service department. 9. Observe the pressure once again until equilibrium established. -

Page 18: Replacement Parts

K2269X Low Temperature Pressure Viscometer Operation and Instruction Manual Replacement Parts Part Number Description 091-032-001 Relay, Solid State, 4-32VDC, 20A 278-001-002 Fuse, 1A, Slo-Blo, 5 X 20 MM 278-020-004 Fuse, 20A, 600VAC, Time Delay 278-104-002 Fuse,.25A Slo-Blo 5X20 M.M. 220-240-013 Cartridge Heater, 500W, 240V RTD Temperature Probe ¼”... -

Page 19: Wiring Diagrams

K2269X Low Temperature Pressure Viscometer Operation and Instruction Manual 7 Wiring Diagrams 220-240V 50Hz Unit Wiring (K22695) -15- K2269X-Manual... -

Page 20: Service

Warranty sender. Goods must be returned freight prepaid. We, at Koehler, would like to thank you for your Returns will be subject to a restocking charge, the equipment purchase, which is protected by the application of which will depend upon the following warranty. -

Page 21: Notes

K2269X Low Temperature Pressure Viscometer Operation and Instruction Manual Notes -17- K2269X-Manual... - Page 22 K2269X Low Temperature Pressure Viscometer Operation and Instruction Manual Notes -18- K2269X-Manual...

Need help?

Do you have a question about the K2269X and is the answer not in the manual?

Questions and answers