Summary of Contents for EFORT ECR5

- Page 1 ECR5 Collaborative Robot User Manual ------------------ Please read this manual carefully before usage.

- Page 2 EFORT INTELLIGENT EQUIPMENT CO.,LTD. ECR5 User Manual (Mechanical and Electrical Part) Version:V1.1 ------(Tel):4000528877---...

- Page 3 Thank you for purchasing EFORT robot products. In order to ensure that the ECR5 products have been set correctly, please read this operation manual carefully before using. The contents mentioned in this announcement and the manual are related to your personal and property safety.

-

Page 4: Table Of Contents

Catalog EFORT INTELLIGENT EQUIPMENT CO.,LTD..................................1 ..............................3 1.1 Introduction ............................3 1.2 Warning Signs ............................3 1.3 Attention Notice ............................ 4 1.3.1 Instruction ..........................4 1.3.2 Personnel Security ........................8 1.4 Risk Assessment ............................9 1.5 Responsibility Norm ..........................9 1.6 Application Scenario .........................10 1.7 Emergency Stop and Emergency Handling ................ - Page 5 Catalog EFORT INTELLIGENT EQUIPMENT CO.,LTD......................38 5.1 Maintenance and Repair ......................38 5.1.1 Regular Maintenance ......................38 5.1.2 Joint Slip Compensation ....................38 5.2 Disposal ..............................39 ........................40 6.1 Product Quality Assurance ......................40 6.2 Disclaimers ............................40 ..........................42 7.1 Robot Power-on ..........................42 7.1.1 Check before Power -on .....................

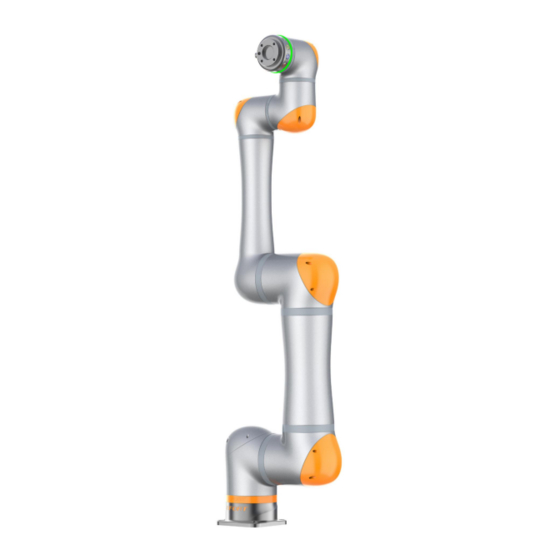

- Page 6 Preface EFORT INTELLIGENT EQUIPMENT CO.,LTD. Thank you for purchasing our 5kg level 6-DOF collaborative robot ECR5 ECR5 is a collaborative robot independently developed by EFORT. The whole machine adopts modular design, and there is no mechanical limit for the joints. The theoretical limit can reach ±...

- Page 7 Preface EFORT INTELLIGENT EQUIPMENT CO.,LTD. Package List: When you order a complete set of ECR5 cooperative robots, you will receive two packages: Package A:length725 mm × width435 mm × height397.5 mm 1 ECR5 manipulator 1 teach pendant (including wiring harness) Package B:length560 mm ×...

-

Page 8: Introduction

EFORT INTELLIGENT EQUIPMENT CO.,LTD. 1.1 Introduction This chapter contains important safety information of ECR5 collaborative robot. Integrators and users must carefully read and understand the operation rules and safety specifications in this manual. The contents with warning signs should be mastered and strictly observed. -

Page 9: Attention Notice

1.3 Attention Notice ECR5 has a wide range of applications. This manual describes the feasible and prohibited items in use as far as possible, but it can not cover all the applications. - Page 10 Safety EFORT INTELLIGENT EQUIPMENT CO.,LTD. Danger! 1. Please install the robot and related electrical equipment in strict accordance with the requirements and specifications in this manual; 2. Before putting into production, please conduct a comprehensive safety inspection on the robot;...

- Page 11 3. ECR5 itself contains a brake, but there is a gap in the brake. After the power cutting-off of the robot, the brake system can keep all joints of the robot within a certain range of motion (within 0.5 degrees).

- Page 12 3. The smooth and streamlined appearance of ECR5 robot can reduce the risk of injury from operators in the process of use, but it needs to ensure that there are no sharp points to reduce the safety risk when installing the end execution tools and peripheral pipelines or other accessories.

-

Page 13: Personnel Security

3. The end of ECR5 is equipped with a status light band, which can display the running status of the robot. When the status light band is in yellow, it indicates that the robot is in non-cooperative mode, at this time, do not touch the robot. -

Page 14: Risk Assessment

EFORT INTELLIGENT EQUIPMENT CO.,LTD. 1.4 Risk Assessment In principle, ECR5 collaborative robot can be used without external fence, but the risk of operation and normal running must be assessed. The risk assessment must be completed before the robot is put into use. Integrators and users must fully consider all tasks of the robot in its whole life cycle to measure the risk level and acceptability. -

Page 15: Application Scenario

1.6 Application Scenario ECR5 belongs to industrial robot, which is intended to be used in industrial scenes. It can cooperate with the corresponding end effector for handling, loading and unloading or other general work. In addition, the robot has collaborative properties and is equipped with a series of cooperative safety functions. -

Page 16: Return To Normal From Emergency

Safety EFORT INTELLIGENT EQUIPMENT CO.,LTD. 1.7.2 Return to Normal from Emergency The general e-stop device can release the pressing state by rotating the button to make the robot return to normal state. Danger! This step is simple but crucial. Make sure the danger is completely eliminated before operation. -

Page 17: Outlines

EFORT INTELLIGENT EQUIPMENT CO.,LTD. 2.1 Outlines A complete set of ECR5 robot system consists of a manipulator, a control cabinet and a teach pendant, as shown in the figure below. They are connected by the connection cables to realize communication, power supply and other functions. -

Page 18: Tool Flange

I/O and communication. Fig. 2.2 ECR5-Mechanical System 2.2.1 Tool Flange The tool flange is equipped with 4 quick operation buttons with the following... - Page 19 Interface and Installation EFORT INTELLIGENT EQUIPMENT CO.,LTD. Fig. 2.3 Buttons in tool flange Mode Switching: click this button to switch the operation mode of the robot. Normal mode (off); point drag teaching mode (flashing), path drag teaching mode (always on) External I / O: click this button to control the switch of IO output of the end flange.

-

Page 20: Control Cabinet

After the communication is established with the controller, the state changes to yellow breathing. 2.3 Control Cabinet The control cabinet is the control center of ECR5 robot, which contains controller, universal IO interface board, switching power supply and safety protection components. The control cabinet is powered by alternating current with voltage of 127V-240V and frequency of 50Hz-60Hz. - Page 21 Interface and Installation EFORT INTELLIGENT EQUIPMENT CO.,LTD. Item Description Turn on the main power switch to supply power to AC 220V Power Switches the robot system Power Supply Interface of Supply the power to manipulator by cable manipulator TPU Interface...

-

Page 22: Teach Pendant

Interface and Installation EFORT INTELLIGENT EQUIPMENT CO.,LTD. 2.4 Teach Pendant Fig. 2.7 Teach Pendant Title Description Membrane panel 3 Company LOGO Touch Screen 8-inch resistive touch screen LCD screen 8-inch TFT LCD, resolution 1024 * 768 Membrane panel 2 10 buttons included... - Page 23 Interface and Installation EFORT INTELLIGENT EQUIPMENT CO.,LTD. Title Description Touch Pen Used to operate the touch screen USB cover After uncovering, you can insert a USB device here Enable Switch Double circuit Enable Switch Prevent the teaching pendant from getting out of...

-

Page 24: Outlines

The working space of the robot is shown in Fig. 3.1. Fig. 3.1 Maximum Working Space of ECR5, unit mm Danger! The robot must be fixed firmly and reliably! - Page 25 IP level marked on the product, otherwise it may cause damage to the robot and the operator! The theoretical rod length of the ECR5 robot is shown in Fig. 3.2 Fig. 3.2 ECR5 Rod Length Parameters, unit mm ECR5 collaborative robot can be mounted in any angle, see in Fig.

-

Page 26: Mechanical Interface

3.2 Mechanical Interface 3.2.1 Base Installation Size There are 4 Φ9 through holes on the ECR5 base, which are evenly distributed on the Φ140 indexing circle, which are used to connect the robot to the base with 4-M8 screws. In addition, the ECR5 base also has 1-Φ6 positioning pin hole and 1 6×8 positioning slot. -

Page 27: End Effector Installation Size

3.2.3 End Effector Installation Size The end effector can be installed on the ECR5 tool flange with 4 M6 screws. The detailed mechanical interface of the ECR5 tool flange is shown in the figure. It is recommended that the tool with higher installation accuracy should be installed with a Φ6 pin and assembled with the stop. -

Page 28: Electrical Interface

Interface and Installation EFORT INTELLIGENT EQUIPMENT CO.,LTD. 3.3 Electrical Interface 3.3.1 Control Cabinet Electrical Interface 3.3.1.1 Cable Interface This control cabinet uses AC220V mains power, and the size of the circuit breaker required to supply power is 8A and above. The power interface of this control cabinet adopts a three-in-one structure of on-off switch, fuse, and filter. - Page 29 Do not disconnect the robot cable when the robot arm is turned Do not extend or modify the original cable. 3.3.1.2 I/O Interface Board The ECR5 robot standard control cabinet provides a variety of electrical interfaces for connecting external equipment and tools. Users can use these interfaces conveniently.

- Page 30 Interface and Installation EFORT INTELLIGENT EQUIPMENT CO.,LTD. analog output interfaces on the control cabinet. The analog IO can be set to work in voltage mode or current mode through software. You can use the I/O in the control box to control various devices, including relays, PLCs, and emergency stop buttons.

- Page 31 Interface and Installation EFORT INTELLIGENT EQUIPMENT CO.,LTD. Fig. 3.9 Default Wiring of Internal Power Supply Note: If higher current is needed, connect an external power supply as shown in the figure below. Proceed as follows: Unplug the short wires between 51 and 52 Connect external 24V+ to 51;...

- Page 32 Interface and Installation EFORT INTELLIGENT EQUIPMENT CO.,LTD. cause the loss of safety functions. When in use, safety devices and equipment must be installed in accordance with the safety instructions and can be used after a comprehensive risk assessment. Warning! Do not connect the safety signal to a non-safety PLC with an inappropriate safety level.

- Page 33 Interface and Installation EFORT INTELLIGENT EQUIPMENT CO.,LTD. Default Security Configuration The factory-built robots are all equipped with default safety configuration. As shown in the figure below, the robot can be used safely without adding additional safety equipment. Fig. 3.11 Wiring Diagram of Safety Configuration X2 Terminal Default...

- Page 34 Interface and Installation EFORT INTELLIGENT EQUIPMENT CO.,LTD. pneumatic relays, or to communicate with other PLC systems. The following sections give a few examples. These examples use regular digital outputs. The construction of digital I/O follows IEC 61131-2. The electrical specifications are as follows.

- Page 35 Interface and Installation EFORT INTELLIGENT EQUIPMENT CO.,LTD. Fig. 3.15 Example of Button Digital Connection 3) Analog I/O The analog I/O interface can be used to set or measure the voltage (0-10V) or current (4-20mA) entering and leaving other devices. For the highest accuracy, the following instructions are recommended: •...

- Page 36 Interface and Installation EFORT INTELLIGENT EQUIPMENT CO.,LTD. Name Analog Output (AI) DA resolution 12 bits Voltage output 0~10V Voltage output load resistance ≧1kΩ Voltage output impedance 2kΩ Voltage output accuracy 0.2% Current output 0~20mA Current output load resistor ≦1kΩ Current output impedance ∞...

-

Page 37: Connection Between The Control Cabinet And The Manipulator

3.3.2 Connection between the Control Cabinet and the manipulator The ECR5 manipulator and the control cabinet are connected by cables. The cable drawings are as follows (the "CTRL" terminal is connected to the control cabinet, and the ROB terminal is connected to the manipulator):... - Page 38 2,0-24V PIN5、PIN6 Warning! Recommend to use the connector delivered together with the robot, please contact EFORT for support when select other connectors, otherwise it may cause damage to the equipment! 在图形用户界面的 I/O 选项卡中,将内部电源设为 0V、12V 或 24V。电气 Warning! 规范如下所示:In the I/O tab of the graphical user interface, set the internal power supply to 0V, 12V, or 24V.

- Page 39 Interface and Installation EFORT INTELLIGENT EQUIPMENT CO.,LTD. load is turned off, there is still voltage between the power connector and the protective cover/ground. Fig. 3.20 Wiring Diagram of Tool Output Load Tool Digital Input The digital input is equipped with a pull-up resistor, which means that the reading of the floating input is always high.

- Page 40 Interface and Installation EFORT INTELLIGENT EQUIPMENT CO.,LTD. The end tool analog input is a non-differential input, which can be configured as voltage (0-24V) or current (4-20mA) on the teach pendant. The electrical specifications are as follows. Typical Parameter Minimum Maximum...

- Page 41 Interface and Installation EFORT INTELLIGENT EQUIPMENT CO.,LTD. Fig. 3.22 Wiring Diagram of Tool Analog Input...

-

Page 42: Lifting And Handling

The ECR5 body is light and can be moved manually when there is no corresponding hoisting equipment. It should be handled gently to prevent bumps. -

Page 43: Maintenance And Repair

The repair work of ECR5 must be carried out by the integrator authorized by Efort and the after-sales team. Do not repair it privately or hand it over to an unauthorized repair unit or individual 5.1.1 Regular Maintenance... -

Page 44: Disposal

Repair And Maintenance EFORT INTELLIGENT EQUIPMENT CO.,LTD. Manual-Teach Pendant System" Installation Setting Tab/General/Joint Slip Compensation Function). Warning! Please follow the user manual to use the self-maintenance function, otherwise it may cause serious damage to the equipment or personal injury! 5.2 Disposal... -

Page 45: Product Quality Assurance

If the product exceeds the warranty period, EFORT reserves the right to charge the user (customer) for replacement or repair. Outside the warranty period, if the equipment fails / defects, EFORT shall not be liable for any damage or loss caused by it, such as production loss or damage to other production equipment. - Page 46 Quality Assurance EFORT INTELLIGENT EQUIPMENT CO.,LTD. Unauthorized changes to software or internal data The fault cannot be reproduced or identified by EFORT Intelligent Equipment Co., Ltd The use of product in high-intensity magnetic equipment, radioactive equipment, biologically hazardous chemical equipment or other dangerous uses determined by EFORT Intelligent Equipment Co., Ltd...

-

Page 47: Robot Power-On

Getting Started EFORT INTELLIGENT EQUIPMENT CO.,LTD. 7.1 Robot Power-on 7.1.1 Check before Power -on Due to the properties of the robot system, the space between the manipulator and the external equipment must be checked before the robot is powered on. The joints of the robot will be slightly adjusted before the servo is enabled. -

Page 48: Path Drag Teaching Procedure

Getting Started EFORT INTELLIGENT EQUIPMENT CO.,LTD. Make sure that the installation mode, load selection and quality of the robot are correct. Press the mode switch button to switch to the point drag teaching mode (the green light flashes). Press the drag confirmation button to turn on. If the operation setting or dynamic parameters are not accurate, it will be unable to drag and the alarm will pop up. -

Page 49: A Mounting Screw Tightening Torque

Appendix EFORT INTELLIGENT EQUIPMENT CO.,LTD. A Mounting Screw Tightening Torque A.1 Tightening Torque of Hexagon Socket Screw 12.9 (N-m)Tightening (N-m)Tightening torque of level torque of steel parts aluminum parts 2±0.18 1.57±0.18 4.5±0.33 3.63±0.33 9.01±0.49 7.35±0.49 15.6±0.78 12.4±0.78 37.2±1.86 30.4±1.86 73.5±3.43 59.8±3.43... -

Page 50: B Technical Terms

Appendix EFORT INTELLIGENT EQUIPMENT CO.,LTD. B Technical Terms Stop Category 0 Robot motion is stopped by immediate removal of power to the robot. It is an uncontrolled stop, where the robot can deviate from the programmed path as each joint brake as fast as possible. This protective stop is used if a safety-related limit is exceeded or in case of a fault in the safety-related parts of the control system. -

Page 51: C Stopping Time And Stopping Distance

Appendix EFORT INTELLIGENT EQUIPMENT CO.,LTD. C Stopping Time and Stopping Distance See stopping time/distance for emergency stop at max speed, max stretched out and max load in below table. Joint 1 test was conducted by performing a horizontal movement, where the rotational axis was perpendicular to the ground. - Page 52 Appendix EFORT INTELLIGENT EQUIPMENT CO.,LTD. E Technical Specifications Manipulator Type ECR5 Payload Weight 20.5kg Reach 928mm Position repeatability ±0.03mm Maximum speed 2.5m/s Power supply DC48V Stand-by power consumption ≤200W Maximum power consumption ≤1.2kW Environmental requirement 0-50℃,5-95%(no condensation) IP Grade IP54 Axis 1 rotation ±180°...

- Page 53 Appendix EFORT INTELLIGENT EQUIPMENT CO.,LTD. Weight 17kg Communication EtherCAT,ProfiNet,Modbus/TCP,Ethernet/IP etc. Power supply AC220V±10%,50~60Hz Digital Inputs 16,PNP Digital outputs 16,Max600mA IO ports Analog inputs 4,0-20mA/0-10V Analog outputs 4,0-20mA/0-10V...

- Page 54 The technical data and illustrations are for reference only, and the right to change is reserved. Efort Intelligent Equipment Co.,Ltd Address: No.96 Wanchun East Road, Jiujiang Economic Development Zone, Wuhu, Anhui. Website:http://www.efort.com.cn...

Need help?

Do you have a question about the ECR5 and is the answer not in the manual?

Questions and answers