Subscribe to Our Youtube Channel

Summary of Contents for SAMES KREMLIN REGPro

- Page 1 REGPro User Manual 582215110 2022-06-09 Index A Translation from the original instructions SAMES KREMLIN SAS 13 Chemin de Malacher 38240 Meylan www.sames-kremlin.com 33 (0)4 76 41 60 60...

- Page 2 Any communication or reproduction of this document, in any form whatsoever, and any exploitation or communication of its contents is prohibited, except with the express written consent of SAMES KREMLIN. The descriptions and features contained in this document are subject to change without notice.

-

Page 3: Table Of Contents

Visual generic presentation ......................15 Context of use ................................16 Non-intended use ..............................16 ..................18 ESCRIPTION OF THE MAIN ELEMENTS OF THE SYSTEM REGPro ..................................18 IDENTIFICATION OF THE EQUIPMENT ....................19 ........................... 19 QUIPMENT PLANS 3.1.1 REGPro............................. 19 ............................ - Page 4 8.5.3 Cleaning / Replacing the Screen (18) ....................35 SPARE PARTS ............................36 ..........................37 EAR PART NUMBERS ..............................38 PTIONS APPENDICES ............................39 10.1 ....................39 PPENDIX REVENTIVE AINTENANCE 582215110-REGPro-EN-indA...

- Page 5 Editor Object Revision Date Modified by F.SEGUIN REGPro Week 06/22 N. PLANTARD Dear customer, you have just purchased your new equipment and we thank you for it. We have taken the utmost care, from design to manufacture, so that this equipment gives you complete satisfaction.

- Page 6 SAMES KREMLIN is limited to the replacement of the Material in its entirety or to the partial replacement of the defective component. SAMES KREMLIN will only bear the cost of the parts necessary to replace the defective material. No guarantee will be granted by SAMES KREMLIN:...

- Page 7 Danger: flammability emanation surfaces start, moving parts hazard Refer to the Grounding manual/instruction Gloves must be worn General obligation leaflet Mandatory respiratory Safety shoes Protective helmet Hearing protection protection Wearing of glasses is Protective visor Protective clothing Material recycling mandatory 582215110-REGPro-EN-indA...

- Page 8 Personnel must be capable of recognising and avoiding possible dangers. The required personnel qualifications are subject to different statutory regulations depending on the implementation site. The owner must ensure compliance with the applicable laws. 582215110-REGPro-EN-indA...

-

Page 9: Safety Instructions

Misuse or operation can cause serious injury. Do not modify or transform the equipment. Parts and accessories must only be supplied or approved by SAMES KREMLIN. The equipment must be checked periodically. Defective or worn parts must be replaced. - Page 10 ATTENTION The use of halogenated hydrocarbon solvents and products containing these solvents in the presence of aluminum or zinc is prohibited. Failure to follow these instructions could result in an explosion hazard causing serious injury or death. 582215110-REGPro-EN-indA...

-

Page 11: Integrity Of The Material

Use only genuine SAMES KREMLIN accessories and spare parts designed to withstand the operating pressure of the pump. REGPro feeding phase / Pump paint phase and pressure gun / Flushing the REGPro It is compulsory to wear PPE (glasses + gloves + safety shoes) during the painting phase. - Page 12 For the assembly of the hoses and the gun: the wearing of PPE is mandatory. Tighten to the stop (Hoses + Gun). Normal stop To make a normal stop: Use the air regulator to gradually depressurize the REGPro. 582215110-REGPro-EN-indA...

- Page 13 Before commissioning, the operator must assess the risks and take appropriate measures. Note: the REGPro is equipped with a 3-way valve at the inlet, to decompress the product part. 582215110-REGPro-EN-indA...

- Page 14 Follow the rules in your locality and do not dispose of your old appliances with your household waste. Proper disposal of this old appliance will help prevent negative effects on the environment and human health. 582215110-REGPro-EN-indA...

-

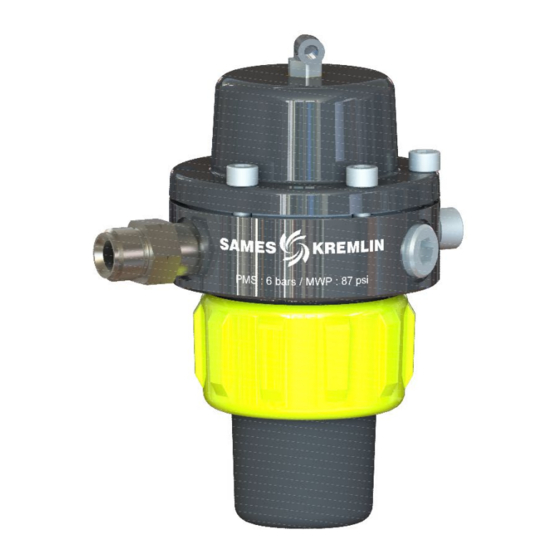

Page 15: Presentation Of The Material

Presentation of the material 2 Presentation of the material Complete system 2.1.1 Visual generic presentation Description Regulator part Filter part Pump fitting Pilot air fitting Spray Gun Fitting Wall mount Drain valve Plug 582215110-REGPro-EN-indA... -

Page 16: Context Of Use

Its diaphragm has a very large surface area, which allows for excellent regulation. The REGPro has been designed to be perfectly flushable. The regulation is done by adjusting the pilot air pressure. Since the pressure ratio is 1, the product pressure can be read directly on the air pressure gauge. - Page 17 The operator of the pump must check the chemical compatibility of the pumped fluid. Conveying fluid with parameters (e.g. ignition temperatures) that compatible with information on the marking of the pump. Operating the regulator with bypassed safety devices is prohibited. 582215110-REGPro-EN-indA...

-

Page 18: Description Of The Main Elements Of The System

Presentation of the material Description of the main elements of the system REGPro Expected use Easy design: easy operation and maintenance. High density membrane technology: constant and extremely low pulsation delivery for superior finish. 3-way valve at the inlet with purge. -

Page 19: Identification Of The Equipment

Fixation avec ét rier Mou nting with sc rews Mou nting with b racket Composition The REGPro controller is available in: Screw mounting, Mounting with bracket. For these versions it is possible to install an M 3/8 "NPS or M 1/2 "JIC fluid outlet. -

Page 20: Technical Features And Performances

Technical features and performances 4 Technical features and performances Technical features REGPro regulator Product inlet connection PA 8/10 hose Product outlet connection x2 M 3/8"NPS + (for 2nd outlet F RP 3/8) M 1/2"JIC + (for 2nd outlet F RP 3/8) Air piloting F 1/8 BSP 2/4"... -

Page 21: Changing The Inlet Pressure From Bar To 6 Bar

Technical features and performances Changing the inlet pressure from 0 bar to 6 bar 4.2.1 Gun with 23 nozzle 4.2.2 Gun with 12 nozzle 582215110-REGPro-EN-indA... -

Page 22: Installation

Personnel are in danger due to improper installation. Connections are to be used whose material is compatible with the fluid and with the material of the REGPro. The regulator does not have a separate pneumatic shut- off valve. Use the shut-off valve on the air plate. -

Page 23: Transport

Examine the regulator for any transport damage. Transport damage must immediately communicated to the transport company and SAMES KREMLIN in writing. Protect the pump from further damage. Use the packing slip to verify the completeness of the delivery. Recommendation materials WARNING Trained personnel with PPE mandatory. -

Page 24: Storage

We recommend the replacement of the diaphragms at the latest after one year of storage under the storage conditions stated above. Handling No slinging foreseen for the regulator due to its weight (1.3 kg / 2.9 Lbs). The regulator must therefore be handled by hand. 582215110-REGPro-EN-indA... -

Page 25: Start Up

Operate the regulator with a maximum compressed air pressure of 6 bar / 87psi. ATTENTION Risk of destruction and bursting of the regulator due to excessive air pressure. Risk of diaphragm destruction due to excessive air pressure. 582215110-REGPro-EN-indA... -

Page 26: User Settings

NOTA The start-up below mentions the materials you will need to purchase (air equipment, suction rod, pump, etc.) to operate the REGPro regulator correctly. Visual with PRIMA 01D100 pump fitted with a 3 regulators and REGPro regulator Description Pump Plate... - Page 27 Connect all the hoses (air hoses and material hose) as well as the spray gun. Open the purge valve of the REGPro and direct the purge hose into the container where the suction rod is located. Open the motor-air shut off valve supply air (C)(P ≥ 1 bar / 14.5 psi).

-

Page 28: Diagnostic Help / Troubleshooting Guide

Open the gun (valve, tap) to drain the network. Lock the gun (valve, tap) to OFF. Check the conformity of the wiring before intervention. Purge the controller before replacing components. 582215110-REGPro-EN-indA... -

Page 29: Possible Symptoms Of Faults / Causes Of Faults / Remedies To Apply - Fast Operation

Non-sealed seat and ball. Clean or replace. Leak at regulator cap. Defective diaphragm. Replace. Lower cup not tight. Tighten. In order to regulate the flow of product correctly, it is necessary to clean the filter element regularly to avoid clogging. 582215110-REGPro-EN-indA... -

Page 30: Maintenance

Keep the suction strainer clean and in good condition. Clean it regularly and replace it periodically. Flush REGPro as often as necessary, especially when using a loaded fluid that tends to settle. Make sure the fluid hoses and other components can withstand the fluid pressure generated by the REGPro. -

Page 31: Maintenance Periods

Take note of the of the controller and the Cleaning It is recommended to clean the REGPro with compatible products without using abrasive materials that could damage them. Empty the excess product and remove any residual traces that may cause deterioration of the ball. -

Page 32: Disassembly / Reassembly

When the solvent flows out, point the spray gun into a recovery container. When the solvent flows out clear and clean, release the gun trigger. Fully turn counterclockwise fluid regulator and shut off the compresed air supply. Trigger the gun again to decompress the hoses. 582215110-REGPro-EN-indA... -

Page 33: Replacing The Seat (12)

Reassemble the assembly by carrying out the operations in the opposite direction. Do not forget the flat seal (11). Note: The seat is reversible: at the time of the first intervention, it is enough to turn it over. Tools needed 582215110-REGPro-EN-indA... -

Page 34: Replacing The Diaphragm (6)

Tighten the nut (4) on the needle shaft assembly (7) with a 17 mm torque wrench to 5 N.m, Position the cap (3) on the filter body (9), Tighten the 6 screws (2) with a 5 mm torque wrench to a torque of 4 N.m. Tools needed 582215110-REGPro-EN-indA... -

Page 35: Cleaning / Replacing The Screen (18)

Maintenance 8.5.3 Cleaning / Replacing the Screen (18) Time required 1 minute 50 Unscrew the nut (21) manually, Manually remove the bowl (20), Manually remove the screen (18), Clean or replace the screen (18). 582215110-REGPro-EN-indA... -

Page 36: Spare Parts

Spare parts 9 Spare parts Use only genuine SAMES KREMLIN accessories and spare parts designed to withstand the operating pressures of the pump. 582215110-REGPro-EN-indA... -

Page 37: Wear Part Numbers

Elbow 3/8" G x tube 8x10 155 581 683 Rilsan pipe 905 190 418 Fitting 953 010 019 Nut HM 8 88 733 Washer 155 581 618 Support bracket 88 150 ScrewCHc 8x16 CL 8.8 88 152 ScrewCHc 8x25 CL 8.8 TE FMF 3/8" 582215110-REGPro-EN-indA... -

Page 38: Options

Level 2 : Corrective maintenance. Level 3 : Exceptional maintenance. Options # Part numbers Description Level** 000 160 104 Filter screen n°4 000 160 106 Filter screen n°6 000 160 108 Filter screen n°8 000 160 112 Filter screen n°12 582215110-REGPro-EN-indA... -

Page 39: Appendices

Appendices 10 Appendices 10.1 Appendix A Preventive Maintenance Plan 582215110-REGPro-EN-indA...

Need help?

Do you have a question about the REGPro and is the answer not in the manual?

Questions and answers