Table of Contents

Summary of Contents for REX RG-RH

- Page 1 - Note - Be sure to hand this operation manual to the user. Carefully read through the manual before using the machine to ensure safe and effective use. Be sure to keep the manual where the operator can refer to it whenever necessary.

-

Page 2: Table Of Contents

Be sure to observe the Safety Precautions described below to prevent accidents such as fire, electric shock and injury. Read these Safety Precautions carefully before using the machine, and operate the machine according to the instructions. Do not use the machine in any way other than as described in this operation manual. CONTENTS 1. -

Page 3: Safety Precautions

1. Safety Precautions WARNING 1) Ensure you use the correct voltage. -Be sure to use the voltage indicated on the name plate of the main unit or in the operation manual. If the voltage is different from the voltage indicated, overheating, smoke or fire may occur. 2) Check the switch is OFF, before inserting the plug into the power supply socket. - Page 4 18) Store carefully when the machine is not in use. Store in a dry place away from children and locked with a key. 19) For overhaul and repair of the machine, ask an appointed REX agent. -Our products comply with corresponding safety standards. Do not remodel.

-

Page 5: Precautions When Using The Portable Groover H

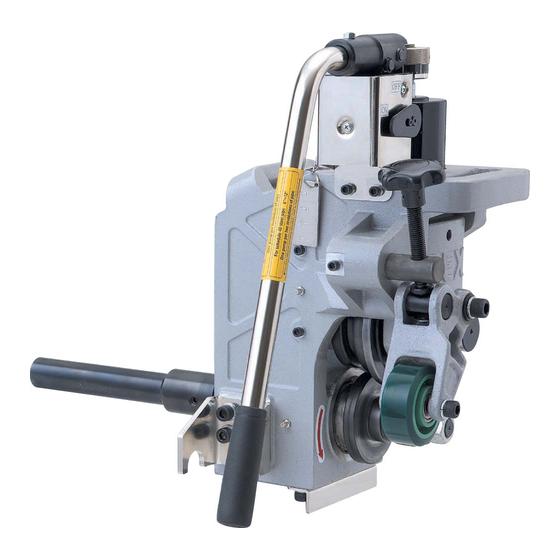

2. Precautions when using the Portable Groover H WARNING 1) Mount the groover on specified pipe threading machines that have been tested for safety. (See Table 1, Pg. 5) Do not attempt to use on any other machines. The correct rotational direction is the direction when threading. 2) Use the rollers that match the pipe. -

Page 6: Main Parts, Specifications, Standard Accessories

Accessories Mount kit M-HR1 REX 50A (N50A, NP50A, NR50A, P50A, R50A) M-HR2 REX 80A (S80A, N80A, NP80A) M-HR3 REX 100A (N100A) M-HE1 #300 (#300) Spacer 1" - 6": Also as standard accessory Spacer 8" - 12" Spacer 14" - 16"... -

Page 7: Setting Up

Fig. 2 resulting in damage. Table 1 Mount Kit Code No. Name For use with M-HR1 REX 50A N50A, NP50A, NR50A, P50A, R50A, NPG150A 341560 (Cannot be used on the NT50. M-HR2 REX 80A S80A, N80A, NP80A 341561... - Page 8 4. Setting Up 2) Attaching the Connecting Shaft: Place the connecting shaft fully over the main shaft, then fix it in position by tightening the two screws against the flat surface of the main Fixing screw shaft. (Fig. 3) CAUTION Be sure to tighten the screws against the flat part of the main shaft as illustrated.

- Page 9 4. Setting Up Replacing the Roller Set (Figs. 5, 6) Removing the rollers 1) Loosen the bolts and turn the safety cover clockwise. (Figs. 5, 6) 2) Remove the upper roller by loosening the fitting screws on the upper roller and pulling out the roller shaft.

-

Page 10: Attaching To The Pipe Threading Machine

4. Setting Up 2. Attaching to the Pipe Threading Machine WARNING Front chuck Be sure to place the pipe threading machine Carriage and pipe stand on a flat stable surface. support bar Avoid using the machine and pipe stand in an unstable position since they may fall over. - Page 11 4. Setting Up Table 4 Machinable Pipe Length Maximum Maximum Machinable Machinable Length Machinable Length Pipe Size Pipe Length (MIN) of Pipe without a of Pipe Using 1 Pipe stand Pipe Stand 1"-2" 120mm 800mm 2000mm 1 /2 "-4" 120mm 700mm 2000mm 5"-6"...

- Page 12 4. Setting Up 3) Pipe shifting adjustment Adjust the pipe by shifting it 0.5 to the main shaft. Pipe centre WARNING If the pipe is set straight on the main shaft or set in the opposite direction, it will come off while grooving and fall off, which could be dangerous.

-

Page 13: Operating Instructions

5. Operating Instructions 1. Operating the pump 1) Check that the hydraulic pump valve is in the ON position. (Fig. 15) Hydraulic pump valve 2) Lift the pump handle firmly in one go and the upper roller will be lowered onto the pipe. -

Page 14: Grooving

5. Operating Instructions 3. Grooving 1) Turn the hydraulic pump valve to the ON Upper Roller position, and pull the pump handle up quickly and firmly to engage the pipe lightly with the upper roller and then raise the pump again. 2) Turn the push knob on the guide roller to Pipe lightly engage the guide roller with the pipe. -

Page 15: Checking The Dimensions

5. Operating Instructions 5) Use the hydraulic pump to start the grooving Pump hundle process. (Fig. 25) Refer to the table below for how to operate the pump safely. Push the handle once for each Schedule 10 rotation of the pipe. Push the handle once for every Schedule 40 two rotations of the pipe. -

Page 16: Before Requesting Repairs Or Servicing / Troubleshooting

6. Before requesting repairs or servicing If there are any abnormalities with the unit, check the following and inform your distributor or our sales department. WARNING If any problems are not dealt with below, do not attempt to overhaul or repair the unit by yourself, but call your distributor or our sales department. -

Page 17: Daily Inspection, Maintenance

7. Daily inspection, maintenance WARNING Before carrying out any inspections or machine maintenance, make sure you unplug the threading machine. If the machine suddenly starts to operate while checking it, it may lead to accidents and injury. A. Overall inspection C. - Page 18 - if blades or consumables need replacing. - if the machine has been handled in an inappropriate way. 2. REX will accept no responsibility under the following circumstances: - fire, damage from flood, earthquakes, lightning or other natural disasters. - malfunction or accident resulting from pollution or abnormal voltage.

Need help?

Do you have a question about the RG-RH and is the answer not in the manual?

Questions and answers