Advertisement

Quick Links

RP3k CCD laser for upgrade D-E.odt

English

System requirements:

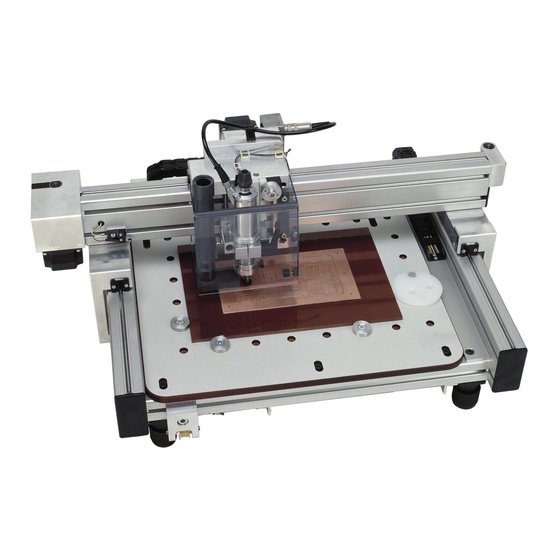

Bungard CCD with Controller 2006 or younger.

Computer with Windows XP SP3 till Windows 7 64 bit. 900 MHz Processor, 500MB main memory and 100 MB free disc

space.

Internet connection during setup and registration. The internet connection is necessary to install updates like Visual C++

and Framework 4. In addition you need to register your RoutePro3000-version and, if so, activate licenses for special

modules (laser, dispense, calibrate etc.).

After installation you can of course work offline.

Content:

New machine: all necessary files including the specific parameters for your machine are packed into the file

"SetupRoutePro3000.exe", which is located on the delivered CD. If you want to read the help file prior to installation, you

can download the help file from our homepage.

Existing machines with RoutePro2008: all necessary files including our standard parameters for machine and tools are

packed into one file. After installation you have to adapt the parameters for your machine from RoutePro2008 into

RoutePro3000 (correction factors, table size, values for sensor and tool slots). If you want to read the help file prior to

installation, you can download the help file from our homepage.

Existing machines with RoutePro3000: We created a separate file "UpdateRoutePro3000.exe". This file does not

contain the resource data and thus your already existing parameters for machine and tools will not be overwritten.

Make sure your resource data are in the correct location.

(standard: C:\Program Files\RoutePro3000\Resources)

Procedure:

Read the manual of RoutePro3000. Connect CCD to your computer. Then install RoutePro3000: Double-click on

"SetupRoutePro3000.exe" and follow the routine. Depending on your system Microsoft Framework 4 and Microsoft Visual

C++ will be installed automatically. If you do not have the latest firmware on your CCD controller, then your controller will

be flashed automatically. A restart of RoutePro3000 may be required in this case.

If you use special modules like laser, calibration or dispensing, then please read the special instruction for these modules

coming with the hardware and refer to the applying help topics in the RoutePro manual/help system.

The standard RoutePro3000 is for free, but after a trial time of 14 days, you need to register. The registration process is

described in the help file.

All special modules can also be tested for 14 days. After that a license has to be acquired. Please note that special

hardware needs to be obtained for the modules (laser head, camera, etc.). To apply for a license or to register the

standard RoutePro, you need to have a Computer with internet connection.

If you have a new machine the CD coming with the machine is already adapted to your specific machine. No further

action beyond registration and activating licenses need to be done.

If you update from RoutePro2008 to RoutePro3000, you need to establish the correct parameters for your machine.

Process like this: Start RoutePro3000 and go to options and machine. Hoover over the CCD-picture and insert correct

parameters for XYZ-motors, spindle, tool slots, sensor and table. You can copy the values from your RoutePro.ini-file of

your older Software RoutePro2008.

Note: there is one exception concerning the Z-position of the tool slots. In RoutePro2008 the z-position of the tool slots

was 0.5 – 1 mm less than z-max. E.g. if z-max was 37.65, then z-position of the tool slots was approx. 37.00mm. In

RoutePro3000 the table is the 0-Position of the z-axis and you almost put the tool to 0. So now you have to insert 0.5 –

1.0 mm in the ATC-tool position table.

Now your Software RoutePro3000 is ready to use.

Have fun with your CCD and the new software RoutePro3000!

Safety instructions

Please observe the general rules for handling electronic parts, especially ESD-protection.

Before touching the laser head, perform a potential compensation. E.g put you both hands on an ESD-suitable support

before removing the laser from the package. Do the same please, before you reassemble the laser from the machine. By

unfavorable conditions (eg, PVC flooring and shoes with plastic soles) high static charges can happen. When these are

discharged directly onto the laser head, a damage is not excluded.

Bungard Elektronik GmbH & Co. KG, Rilkestraße 1, 51570 Windeck – Germany

Tel.: +49 (0) 2292/5036, Fax: +49 (0) 2292/6175, E-mail: support@bungard.de

I.

Software Preparations

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for Bungard CCD

- Page 1 “SetupRoutePro3000.exe” and follow the routine. Depending on your system Microsoft Framework 4 and Microsoft Visual C++ will be installed automatically. If you do not have the latest firmware on your CCD controller, then your controller will be flashed automatically. A restart of RoutePro3000 may be required in this case.

- Page 2 Diese Werte wie auch die anderen Maschinenparameter entnehmen Sie bitte Ihrer alten RoutePro2008 Software. Wandern Sie jetzt über das CCD-Bild und tragen Sie die korrekten Werte für XYZ-Motoren, Spindel, Tool Slots, Sensor und Tisch. Diese Werte entnehmen Sie bitte Ihrer alten RoutePro2008 Software.

- Page 3 Aufladungen kommen. Wenn diese direkt über den Laserkopf entladen werden, so ist eine Beschädigung nicht ausgeschlossen. Hardware Preparations 1. Controllerbox einbauen / install controller box Adjust box here Bungard Elektronik GmbH & Co. KG, Rilkestraße 1, 51570 Windeck – Germany Tel.: +49 (0) 2292/5036, Fax: +49 (0) 2292/6175, E-mail: support@bungard.de...

- Page 4 2. Controllerbox an Motoranschlussbox anschließen / connect controller box to motor connection box Insert flat cable into motor connection box here Bungard Elektronik GmbH & Co. KG, Rilkestraße 1, 51570 Windeck – Germany Tel.: +49 (0) 2292/5036, Fax: +49 (0) 2292/6175, E-mail: support@bungard.de...

- Page 5 RP3k CCD laser for upgrade D-E.odt 3. Leitung zu Motoranschlussbox verlegen / Place cable to motor connection box Fix with cable ties Bungard Elektronik GmbH & Co. KG, Rilkestraße 1, 51570 Windeck – Germany Tel.: +49 (0) 2292/5036, Fax: +49 (0) 2292/6175, E-mail: support@bungard.de...

- Page 6 Use a flat screw driver to open the channel a bit, so you can insert the laser cable coming from the laser head through the energy chain Bungard Elektronik GmbH & Co. KG, Rilkestraße 1, 51570 Windeck – Germany Tel.: +49 (0) 2292/5036, Fax: +49 (0) 2292/6175, E-mail: support@bungard.de...

- Page 7 5. Zuleitung zum Belichtungskopf verlegen / Place wiring to laser head Fix with cable ties Fit into cable channel, continue via the energy chain up to the z-axis Bungard Elektronik GmbH & Co. KG, Rilkestraße 1, 51570 Windeck – Germany Tel.: +49 (0) 2292/5036, Fax: +49 (0) 2292/6175, E-mail: support@bungard.de...

- Page 8 Failures and damages due to violation of these instructions will not be treated as warranty cases and their repair will be charged in each case. Bungard Elektronik GmbH & Co. KG, Rilkestraße 1, 51570 Windeck – Germany Tel.: +49 (0) 2292/5036, Fax: +49 (0) 2292/6175, E-mail: support@bungard.de...

- Page 9 Press this magnet including housing into the spindle holder Flush with upper edge Press in this direction Use only wooden tools (e.g. hammer handle) Bungard Elektronik GmbH & Co. KG, Rilkestraße 1, 51570 Windeck – Germany Tel.: +49 (0) 2292/5036, Fax: +49 (0) 2292/6175, E-mail: support@bungard.de...

- Page 10 Insert magnet with wooden tool – take care of precise fitting! Must fit tightly straighten No overlapping allowed! Bungard Elektronik GmbH & Co. KG, Rilkestraße 1, 51570 Windeck – Germany Tel.: +49 (0) 2292/5036, Fax: +49 (0) 2292/6175, E-mail: support@bungard.de...

- Page 11 This way it is very easy to exchange the laser head against the routing spindle or a dispenser Magnet switches off Magnet switches on Bungard Elektronik GmbH & Co. KG, Rilkestraße 1, 51570 Windeck – Germany Tel.: +49 (0) 2292/5036, Fax: +49 (0) 2292/6175, E-mail: support@bungard.de...

- Page 12 Wenn der Laser nicht benutzt wird , bitte Anschlusskabel befestigen If you do not use the lase, please secure the cable! Bungard Elektronik GmbH & Co. KG, Rilkestraße 1, 51570 Windeck – Germany Tel.: +49 (0) 2292/5036, Fax: +49 (0) 2292/6175, E-mail: support@bungard.de...

- Page 14 wiring diagram for communication module laser operate only with closed lid! otherwise danger of short cut at the connection socket (terminal block) 3-wire cable to laser head green brown white flat cable to motor connection box grün / green Terminal 5 braun / brown Terminal 12 gelb / yellow...

- Page 16 MOTORANSCHLUSSBOX CCD gemeinsames + Potential: 24V Last max 40mA je Ausgang keine Freilauf-Dioden erforderlich Anschluss Laserbox an CCD Byte RESV1 ON:193 Connection laser box to CCD violette Leitung darf erst Byte RESV4 ON:224 RESV1 schwarz - black angeschlossen werden , wenn...

- Page 17 Connection of Laser head to CCD/2 blue black green/white purple...

- Page 18 Anschluss Laser an CCD - Versionen mit ITEM Profil-Anschlussgehäuse ( Baujahr vor 2005 ) ACHTUNG ! Sicht auf die Bestückungsseite , Platinen-Layout kann ggf. abweichen. Beim Anlöten der Litzen darauf achten daß keine Kurzschlüsse entstehen und auf korrekte Zuordnung achten.

Need help?

Do you have a question about the CCD and is the answer not in the manual?

Questions and answers