Table of Contents

Advertisement

Quick Links

INSTALLATION AND OPERATION

SX TRANSISTOR CONTROL

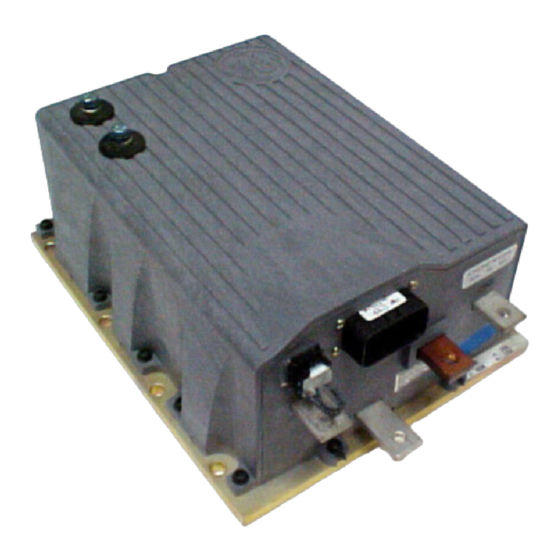

SEPARATELY EXCITED (SX) TRANSISTORIZED TRACTION MOTOR CONTROL

IC3645SR4W746HL1, IC3645SR4W10010HL1 and IC3645SR7W10010HL1

Note: The information contained herein is intended to assist OEM's, Dealers and Users of electric vehicles

in the application, installation and service of GE solid-state controllers. This manual does not purport to

cover all variations in OEM vehicle types. Nor does it provide for every possible contingency to be met

involving vehicle installation, operation or maintenance. For additional information and/or problem

resolution, please refer the matter to the OEM vehicle manufacturer through his normal field service

channels. Do not contact GE directly for this assistance.

Section 1.0

INTRODUCTION .................................................................................................................................................... 4

1.1

1.2

1.3

1.4

Section 2.0

FEATURES OF SX FAMILY OF MOTOR CONTROLLERS .................................................................................. 6

2.1

2.1.1

2.1.1.a

2.1.1.b

2.1.1.c

2.1.2

2.1.3

2.1.3.a

2.1.3.b

INSTALLATION AND OPERATION MANUAL

Table of Contents

Copyright by General Electric Company March 2000

Motor Characteristics ................................................................................................................. 4

Solid-State Reversing .................................................................................................................. 5

Flexible System Application........................................................................................................ 5

More Features with Fewer Components .................................................................................. 5

Performance.................................................................................................................................. 6

Oscillator Card Features.............................................................................................................. 6

Standard Operation ..................................................................................................... 6

Creep Speed.................................................................................................................. 6

Controlled Acceleration and 1A Time ....................................................................... 6

Current Limit .................................................................................................................................. 6

Braking 6

Plug Braking.................................................................................................................. 6

Regenerative Braking to Zero Speed ........................................................................ 6

Page 1

November 2002

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for GE IC3645SR4W746HL1

- Page 1 Note: The information contained herein is intended to assist OEM's, Dealers and Users of electric vehicles in the application, installation and service of GE solid-state controllers. This manual does not purport to cover all variations in OEM vehicle types. Nor does it provide for every possible contingency to be met involving vehicle installation, operation or maintenance.

-

Page 2: Table Of Contents

INSTALLATION AND OPERATION SX TRANSISTOR CONTROL Page 2 Table of Contents ( Continued ) 2.1.3.c Pedal Position Plug Braking..................6 2.1.3.d Auto Braking ......................... 6 2.1.3.e Brake Pedal Regenerative Braking ................6 2.1.4 Auxiliary Speed Control....................... 6 2.1.4.a Field Weakening ........................6 2.1.4.b Speed Limits ......................... - Page 3 TMM7A Typical Brush Wear Sensor Connections ................ 37 5.4.3 TMM Pump Control Connections ..................... 38 TMM7A Outline Drawings........................38 Section 6.0 SX FAMILY - GE HANDSET INSTRUCTIONS ....................39 General Features ..........................39 Purpose/Setup Functions ........................39 Setup Function Procedures ....................... 40 6.3.1 Setup Mode ..........

- Page 4 GE has introduced a second generation system using separately excited DC shunt wound motors. The separately excited DC motor system offers many of the features that are generally found on the advanced AC systems. Historically, most electric vehicles have relied have on series motor designs because of their ability to produce very high levels of torque at low speeds.

- Page 5 BASIC OPERATION AND FEATURES SX TRANSISTOR CONTROL Page 6 SPEED TORQUE ARMATURE CURRENT Figure 2 In the separately excited motor, the motor is operated as a fixed field shunt motor in the normal running range. However, when additional torque is required, for example, to climb non-level terrain, such as ramps and the like, the field current is increased to provide the higher level of torque.

- Page 6 For GE, the future is now as we make available a new generation of electric traction motor systems for electric vehicles having separately excited DC shunt motors and controls. Features that were once thought to be only available on future AC or brushless DC technology vehicles systems are now achievable and affordable.

- Page 7 BASIC OPERATION AND FEATURES SX TRANSISTOR CONTROL Page 8 Section 2. FEATURES OF SX FAMILY OF TRANSISTOR MOTOR CONTROLLERS Section 2.1 Performance Section 2.1.1 Oscillator Card Features Section 2.1.1.a Standard Operation With the accelerator at maximum ohms or volts, the creep speed can be adjusted by Function 2 of the Handset or a trimpot. The field control section allows the adjustment of the field weakening level in order to set the top speed of the motor.

-

Page 8: Pedal Position Plug Braking

It is important to note that this function is used to optimize motor and control performance, and this setting will be determined by GE and OEM engineers at the time of vehicle development. This setting must not be changed by field personnel, without the permission of the OEM. -

Page 9: System Protective Override

BASIC OPERATION AND FEATURES SX TRANSISTOR CONTROL Page 10 Coil drivers for the LINE and 1A, or bypass, contactors are on-board the control card. These contactors must have coils rated for the vehicle battery volts. Section 2.2 System Protective Override Section 2.2.1 Static Return to Off (SRO) This inherent feature of the control is designed to require the driver to return the directional lever to the neutral position anytime he leaves the vehicle and returns. -

Page 10: Status Codes

Section 2.3.5 Handset This is a multi-functional tool used with the LX, ZX, and SX Series GE solid state controls. The Handset consists of a Light Emitting Diode (LED) display and a keyboard for data entry. Note, for ordering purposes, a separate Handset part is required for SX controls. -

Page 11: Circuit Board Coil Driver Modules

Section 2.3.8 Truck Management Module (TMM) The Truck Management Module is a multifunction accessory card, or an integral function of the GE Pump controls when used with the SX Traction control. The Module provides the OEM the ability to initiate status codes or operator warning codes to be displayed on the Dash Display, whenever a normally open switch or sensor wire provides a signal to the Module. - Page 12 BASIC OPERATION AND FEATURES SX TRANSISTOR CONTROL Page 13 The third speed is obtained by closing SL3 (P20) to control negative. SL3 is adjusted using the Handset and Function 13 similar to SL1. If more than one Speed Limit is activated, the selected speed with the highest motor volts will override the low motor volt speed. The current limit circuit is adjustable and operates the same as the traction current limit.

-

Page 13: Ordering Information, Elementary And Outline Drawings

OUTLINE DRAWINGS, ELEMENTARY DRAWINGS AND INPUTS/OUTPUTS SX TRANSISTOR CONTROL Page 10 Section 3.0 ORDERING INFORMATION, ELEMENTARY AND OUTLINE DRAWINGS Section 3.1 Ordering Information for Separately Excited Controls Example: Part Number: IC3645 Argument Number: Argument 01: Basic Electric Vehicle Control Number Argument 02: Control Type: Series Control (Pump) - Page 14 OUTLINE DRAWINGS, ELEMENTARY DRAWINGS AND INPUTS/OUTPUTS Page 11 SX TRANSISTOR CONTROL November 2002...

-

Page 15: Traction Elementary

OUTLINE DRAWINGS, ELEMENTARY DRAWINGS AND INPUTS/OUTPUTS SX TRANSISTOR CONTROL Page 12 Section 3.3 Traction Elementary November 2002... - Page 16 OUTLINE DRAWINGS, ELEMENTARY DRAWINGS AND INPUTS/OUTPUTS SX TRANSISTOR CONTROL Page 13 Section 3.6 Traction Input/Output List CONNECTIONS TO MAIN PLUG (23 PIN) AND "Y" PLUG (12 PIN) TRACTION INPUT/OUTPUT DESCRIPTION BATTERY VOLTS FROM BATTERY BATTERY VOLTS FROM KEY BATTERY VOLTS FROM START SWITCH BATTERY VOLTS FROM FORWARD SWITCH BATTERY VOLTS FROM REVERSE SWITCH BATTERY VOLTS FROM SEAT SWITCH...

-

Page 17: Troubleshooting And Diagnostic Status Codes

The semiconductor junctions have finite temperature limits, above which these devices GE does not recommend that any type of welding be may be damaged. For these reasons, normal maintenance performed on the vehicle after the installation of the should guard against any action which will expose the control(s) in the vehicle. -

Page 18: High Level Signals (Level H)

DIAGNOSTIC STATUS CODES SX TRANSISTOR CONTROL Page 15 • Control common tie customer must apply the general guidelines (section 4.2.3.a), outlined below. • DC buses feeding sensitive analog or digital hardware • All wiring connected to components associated with 4.2.3.a General Cable Spacing sensitive analog hardware with less than 5V signals (for example, potentiometers and tachometers) The following general practices should be used for all... -

Page 19: Recommended Lubrication Of Pins And Sockets Prior To Installation

EV100/EV200 and Gen II products. Any Clean each terminal using Chemtronics contact connection made by GE to the A, B, X, Y, or Z plugs will cleaner “Pow-R-WasH CZ “ as shown in Figure 1. have the lubricant NYE 760G added to prevent fretting of these connections during vehicle operation. -

Page 20: Controller Mounting Guidelines

Prepare the two mounting surfaces (control flatness is maintained at 0.005” per linear inch (not to and vehicle) as indicated above. exceed 0.025” per 10.0 inches). The surface finish of the GE b) Using a triangular notched trowel of 3/32” control has an R (average roughness) of 64 (microinches), (.09”... -

Page 21: Mounting The Ge Control

If it is necessary to remove the control for service, careful consideration must be given to removing the old thermal Section 4.4.5 Mounting the GE Control compound from the control and mounting surface, prior to a) Place the control unit with desired orientation on replacement of the unit. - Page 22 DIAGNOSTIC STATUS CODES SX TRANSISTOR CONTROL Page 19 With the status code number, follow the procedures outlined in the status code instruction sheets to determine the problem. Important Note: Due to the interaction of the logic card with all vehicle functions, almost any status code or control fault could be caused by the logic card.

- Page 23 DIAGNOSTIC STATUS CODES SX TRANSISTOR CONTROL Page 20 Section 4.6 Traction Control Codes TRACTION DESCRIPTION OF STATUS CAUSE OF STATUS INDICATION STATUS CODE Segments do not illuminate on the No input voltage to the control card or the display NONE Dash Display and/or the Handset.

- Page 24 DIAGNOSTIC STATUS CODES SX TRANSISTOR CONTROL Page 21 TRACTION DESCRIPTION OF STATUS CAUSE OF STATUS INDICATION STATUS CODE Forward directional switch is closed on This status code will be displayed when P4 is greater initial power up. than 60% of battery voltage at initial key switch on. MEMORY RECALL CORRECTIVE ACTIONS TROUBLE-SHOOTING DIAGRAM...

- Page 25 DIAGNOSTIC STATUS CODES SX TRANSISTOR CONTROL Page 22 TRACTION DESCRIPTION OF STATUS CAUSE OF STATUS INDICATION STATUS CODE Start switch fails to close. This status code will be displayed when P7 is less than 2.5 volts and P3 is less than 60% of battery volts.

- Page 26 DIAGNOSTIC STATUS CODES SX TRANSISTOR CONTROL Page 23 TRACTION DESCRIPTION OF STATUS CAUSE OF STATUS INDICATION STATUS CODE Accelerator input voltage too high This status code will be displayed when the during run mode. accelerator input voltage at P7 is higher than 4.2 volts, and a directional contactor is picked up.

- Page 27 DIAGNOSTIC STATUS CODES SX TRANSISTOR CONTROL Page 24 TRACTION DESCRIPTION OF STATUS CAUSE OF STATUS INDICATION STATUS CODE Both the forward and reverse This status code will be displayed when P4 and P5 directional switches are closed at the are greater than 60% of battery volts at the same same time.

- Page 28 DIAGNOSTIC STATUS CODES SX TRANSISTOR CONTROL Page 25 TRACTION DESCRIPTION OF STATUS CAUSE OF STATUS INDICATION STATUS CODE Battery voltage is too low or control This status code will be displayed when the battery card is mis-adjusted. volts are less than 1.95 volts per cell at initial key switch on.

- Page 29 DIAGNOSTIC STATUS CODES SX TRANSISTOR CONTROL Page 26 TRACTION DESCRIPTION OF STATUS CAUSE OF STATUS INDICATION STATUS CODE Motor field current is high on start up in This status code will be displayed when the current the reverse direction. draw in the motor field is too high at start up in the reverse direction.

- Page 30 DIAGNOSTIC STATUS CODES SX TRANSISTOR CONTROL Page 27 TRACTION DESCRIPTION OF STATUS CAUSE OF STATUS INDICATION STATUS CODE Control’s power supply is less than 10 This status code will be displayed when the control’s Volts DC. power supply is less than 10 volts. MEMORY RECALL CORRECTIVE ACTIONS TROUBLE-SHOOTING DIAGRAM...

- Page 31 DIAGNOSTIC STATUS CODES SX TRANSISTOR CONTROL Page 28 TRACTION DESCRIPTION OF STATUS CAUSE OF STATUS INDICATION STATUS CODE Open thermal protector (TP) or This status code will be displayed when the voltage at transistor over temperature. the thermal protector is too high. MEMORY RECALL CORRECTIVE ACTIONS TROUBLE-SHOOTING DIAGRAM...

- Page 32 DIAGNOSTIC STATUS CODES SX TRANSISTOR CONTROL Page 29 TRACTION DESCRIPTION OF STATUS CAUSE OF STATUS INDICATION STATUS CODE Motor armature offset voltage is too This status code will be displayed when the voltage at low. the current sensor input is less than 2.4 volts with no current flowing in the motor circuit.

- Page 33 DIAGNOSTIC STATUS CODES SX TRANSISTOR CONTROL Page 30 TRACTION DESCRIPTION OF STATUS CAUSE OF STATUS INDICATION STATUS CODE Armature transistor did not turn on This status code will be displayed when, during properly. control operation, the armature transistor fails to turn on properly.

- Page 34 DIAGNOSTIC STATUS CODES SX TRANSISTOR CONTROL Page 31 TRACTION DESCRIPTION OF STATUS CAUSE OF STATUS INDICATION STATUS CODE Motor field current is too low during the This status code will be displayed when the current run mode. draw in the motor field is less than 3.1 amps, while the armature current is greater than 100A for 2.0 seconds during run mode.

- Page 35 DIAGNOSTIC STATUS CODES SX TRANSISTOR CONTROL Page 32 TRACTION DESCRIPTION OF STATUS CAUSE OF STATUS INDICATION STATUS CODE Controller “motor current sensor” This status code will be displayed when the voltage input too low during running. input from the current sensor is too low during running. MEMORY RECALL CORRECTIVE ACTIONS TROUBLE-SHOOTING DIAGRAM...

- Page 36 DIAGNOSTIC STATUS CODES SX TRANSISTOR CONTROL Page 33 TRACTION DESCRIPTION OF STATUS CAUSE OF STATUS INDICATION STATUS CODE The line coil current is too high during This status code will be displayed when the current the run mode limit in the line coil is exceeded during the run mode. The line contactor will drop out and the key switch will have to be recycled to reset the control.

- Page 37 DIAGNOSTIC STATUS CODES SX TRANSISTOR CONTROL Page 34 TRACTION DESCRIPTION OF STATUS CAUSE OF STATUS INDICATION STATUS CODE The armature current exceeds the This status code will be displayed when the armature armature transistor limit. transistor exceeds its specific current limit. The control is reset by recycling the key switch.

- Page 38 DIAGNOSTIC STATUS CODES SX TRANSISTOR CONTROL Page 35 TRACTION DESCRIPTION OF STATUS CAUSE OF STATUS INDICATION STATUS CODE Capacitor (1C) voltage too high. This status code will be displayed when the voltage on the capacitor goes above limit voltage* during the regenerative braking cycle. MEMORY RECALL CORRECTIVE ACTIONS TROUBLE-SHOOTING DIAGRAM...

- Page 39 DIAGNOSTIC STATUS CODES SX TRANSISTOR CONTROL Page 36 TRACTION DESCRIPTION OF STATUS CAUSE OF STATUS INDICATION STATUS CODE If the armature current is greater than 1100 This status code will be displayed when the armature current amps in 1A mode; or greater than 730 amps for exceeds 1100 amps in the 1A mode, or 730 amps for 3.5 sec and longer than 3.5 seconds in control mode, the the accelerator pedal is calling for maximum performance in the...

-

Page 40: Truck Management Module (Tmm)

INSTALLATION AND OPERATION MANUAL Page 37 SX TRANSISTOR CONTROL Section 5. TRUCK MANAGEMENT MODULE (TMM) IMPORTANT NOTE: Status Codes 93, 94 and 95 are only checked when a neutral signal is present (i.e., open start Section 5.1 General Features switch or open F/R switch). The status code is displayed and the speed limit enabled when the control is returned The Truck Management Module is a multi-functional to the run mode. -

Page 41: Tmm7A Outline Drawings

INSTALLATION AND OPERATION MANUAL Page 38 SX TRANSISTOR CONTROL PUMP CONTROL CONNECTIONS BRUSH WEAR SENSOR CONNECTIONS (TYPICAL) BATTERY NEGATIVE TRACTION PL2-14 TRACTION BATTERY PUMP PWR STEER POSITIVE TRACTION Section 5.4.3 TMM Pump Control Connections PL2-20 Section 5.5 TMM7A Outline Drawings 1.60 (40.6) (20.3) -

Page 42: Sx Family - Ge Handset Instructions

INSTRUCTIONS Section 6.1 General Features Key Switch On The GE Handset is a multi-functional tool to be used with the LX, ZX, and SX Series GE solid-state controls. The Handset consists of a Light Emitting Diode (LED) display and a Verify Each LED Segment keyboard for data entry. -

Page 43: Setup Mode

NOTE: The term “Push” means to depress key for ACCESSING STORED STATUS CODES approximately one second. WITH GE HANDSET Section 6.3.1 Setup Mode Key Switch Off SET-UP MODE Push ESC and CONT... -

Page 44: Setup Functions For Traction Controller

SX TRANSISTOR CONTROLS Page Important Note: This function is used to optimize motor and control performance and this setting will be determined by GE and OEM engineers HANDSET at the time of vehicle development. This setting must not be changed by field personnel without the permission of the OEM. - Page 45 Important Note: The function is used to optimize motor and Resolution Example control performance and this setting will be determined by Volts Per unit value If set at 20 GE and OEM engineers at the time of vehicle development. 36/48 183A 597A 0 to 255 1.625+183 215 amp This setting must not be changed by field personnel without the permission of the OEM.

- Page 46 ADJUSTABLE FEATURES SX TRANSISTOR CONTROLS Page 80 volts Between 81 and 183 FUNCTION 14 INTERNAL RESISTANCE COMPENSATION 36/48 volts Between 184 and 250 No BDI Between 251 and 255 ( Push 14 ) This function is used when the Battery Discharge Indicator is present.

- Page 47 Because absolute memory locations need Range 0 to 99 to be known, this function should not be used without 0 to 99 detailed instructions from the GE application engineer. Example 9999 Hours This function should only be adjusted by the vehicle OEM. FUNCTION 20...

- Page 48 ADJUSTABLE FEATURES SX TRANSISTOR CONTROLS Page status codes have caused a PMT controller shutdown and/or disruption of normal vehicle operation. FUNCTION 49 MODE 1 FIELD WEAKENING START ( Push CONT 2) To determine which stored status code was the last one recorded, read the number stored in Function 28.

- Page 49 ADJUSTABLE FEATURES SX TRANSISTOR CONTROLS Page This FIELD WEAKENING START takes effect when the Mode This MAX ARMATURE % ON takes effect when the Mode 3 2 settings are called for by the interactive Dash Display. settings are called for by the interactive Dash Display. FUNCTION 60 MODE 4 ARMATURE CONTROLLED FUNCTION 54...

-

Page 50: Summary Of Current Limit Adjustments

ADJUSTABLE FEATURES SX TRANSISTOR CONTROLS Page Section 6.5 Summary of Current Limit Adjustments The " maximum field current" setting is adjusted by Function 8. This function, along with the "maximum armature current" (Function 4), sets the maximum torque of the motor. MAXIMUM The "... -

Page 51: Dash Displays

Plug "Y" of each control. Shielded cable is required to eliminate signal interference. Part Number IC3645LXTDD The GE Standard Dash Display is a four segment Light T=Traction Only Emitting Diode (LED) instrument that displays the GE LX, ZX, P=Traction & Pump and SX Status Codes, Hourmeter Readings, Battery Discharge Indication, and Maintenance Required Code. -

Page 52: Start-Up Display Sequence

INSTALLATION AND OPERATION MANUAL SX TRANSISTOR CONTROL Page 49 Section 7.4 Start-Up Display Sequence Section 7.5 Outline Drawings START-UP DISPLAY SEQUENCE GE Electric Vehicle Motors & Controls Key Switch On Verify Each LED Segment 8 8 8 8 0.41 (10.4) -

Page 53: Memory Maps

Regen Cancel Point HS or PC None FW Start HS or PC None Monitor HS or PC GE Temporary Storage Ratio HS or PC GE Temporary Storage HM Minutes HS or PC GE Temporary Storage Fault Count Pointer HS or PC... - Page 54 RS-232 MEMORY MAP TABLES SX TRANSISTOR CONTROL Page 51 Func No. Traction Control Access By Restrictions Function Hours (Thou/Hun) 3 PC Only Reset to Zero Only BDI 4 PC Only Reset to Zero Only Hours (Tens/Ones) 4 PC Only Reset to Zero Only Hours (Thou/Hun) 4 PC Only Reset to Zero Only...

- Page 55 OEM Read Only Secure Aux HM (Tens/Ones) PC Only OEM Read Only Secure Aux HM (Thou/Hun) PC Only OEM Read Only Reserved PC Only GE Future Use Reserved PC Only GE Future Use Reserved PC Only GE Future Use Reserved PC Only...

Need help?

Do you have a question about the IC3645SR4W746HL1 and is the answer not in the manual?

Questions and answers