Table of Contents

Advertisement

Quick Links

Combined Chlorine Monitor

Home Office

Analytical Technology, Inc.

6 Iron Bridge Drive

Collegeville, PA 19426

Phone: 800-959-0299

610-917-0991

Fax:

610-917-0992

Email: sales@analyticaltechnology.com

O & M Manual

Model Q46H-63

European Office

ATI (UK) Limited

Unit 1 & 2 Gatehead Business Park

Delph New Road, Delph

Saddleworth OL3 5DE

Phone: +44 (0)1457-873-318

Fax:

+ 44 (0)1457-874-468

Email: sales@atiuk.com

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for ATI Technologies Q46H-63

- Page 1 O & M Manual Model Q46H-63 Combined Chlorine Monitor Home Office European Office Analytical Technology, Inc. ATI (UK) Limited 6 Iron Bridge Drive Unit 1 & 2 Gatehead Business Park Collegeville, PA 19426 Delph New Road, Delph Phone: 800-959-0299 Saddleworth OL3 5DE...

-

Page 2: Table Of Contents

Table of Contents PART 1 - INTRODUCTION ........4 6.24 [CONFIG] .... 40 ONFIGURATION 6.25 [CONTROL] ....45 ONTROL ............4 ENERAL 6.26 D [DIAG] ......49 IAGNOSTICS .......... 5 TANDARD YSTEM ............8 PART 7 – CALIBRATION......... 52 EATURES Q46H/63 S .... - Page 3 ABLE OF IGURES 1 - T ..................5 IGURE YPICAL HLORINE ONITORING YSTEM 2 - C ............... 6 IGURE HLORINE YSTEM W ONVENTIONAL P TYLE ENSOR 3 - S ..............7 IGURE EALED LOWCELL SSEMBLIES WITH ONTROL 4 - Q46 E .....................

-

Page 4: Part 1 - Introduction

Part 1 - Introduction General The Model Q46H/63 is a versatile on-line monitoring system designed for the continuous measurement of combined chlorine in solution. The full scale operating range of the system is user selectable for 0-200.0 ppb, 0-2.000 ppm, 0-20.00 PPM, or 0-200.0 ppm, and the sensing system will operate on water streams with temperatures from -5 to 55°C. -

Page 5: Standard System

Q46H/63 Combined Chlorine System Part 1 - Introduction Standard System The standard model Q46H/63 system includes three main components, the Q46H analyzer, a constant head flow cell, and a combined chlorine sensor. A sealed flowcell is also available for applications where sample flow rate and pressure can be carefully controlled. Figure 1 shows a typical installation including the optional 07-0096 pH sensor. -

Page 6: Figure 2 - Chlorine System W

Q46H/63 Combined Chlorine System Part 1 - Introduction Figure 2 below shows the same standard flowcell assembly and chlorine sensor along with the conventional type pH sensor. A special adapter is required to hold the pH sensor in its proper location in the flowcell inlet chamber. -

Page 7: Figure 3 - Sealed Flowcella

Q46H/63 Combined Chlorine System Part 1 - Introduction Figure 3 below shows an installation using a 00-1522 sealed flowcell for the chlorine sensor and a 00-1527 sealed flowcell for the pH sensor. This type of installation requires careful flow control. We recommend the use of our 03-0372 flow control assembly when using sealed flowcells. -

Page 8: Features

Q46H/63 Combined Chlorine System Part 1 - Introduction Features • Standard Q46H/63 analyzers have fully isolated inputs and outputs. Analog outputs are additionally completely isolated from each other. • Available in either 90-260 VAC or 12-24 VDC power supply systems. All features remain the same in both variations. -

Page 9: Q46H/63 System Specifications

Q46H/63 Combined Chlorine System Part 1 - Introduction • Security lock feature to prevent unauthorized tampering with analyzer settings. All settings can be viewed while locked, but they cannot be changed. Q46H/63 System Specifications Displayed Parameters Main input, 0.1 ppb (0.0001 ppm) to 200.0 ppm Sensor temperature, -5.0 to 55.0 °C (23 to 131 ºF) Sensor Current, 0.0 to 99.9 nA, 0.000 to 99.99 uA Loop current, 4.00 to 20.00 mA... - Page 10 Q46H/63 Combined Chlorine System Part 1 - Introduction Sensor 2-electrode polarographic membraned sensor for direct measurement of chlorine Sensor Materials PVC and stainless steel Sensor Cable 25 ft. (7.5 meter) cable with 6-pin plug Max. Sensor-to-Analyzer Distance 100 feet (30.5 meters), with junction box Optional pH Compensation Input Accepts standard combination or Q22P pH Sensors...

-

Page 11: Q46H Performances

Q46H/63 Combined Chlorine System Part 1 - Introduction Q46H Performance Specifications Accuracy 0.5% of selected range or 0.02 PPM Repeatability 0.3% of selected range or 0.01 PPM Sensitivity 0.05% of selected range Non-linearity 0.1% of selected range Warm-up Time 3 seconds to rated performance (electronics only) Supply Voltage Effects ±... -

Page 12: Part 2 - Analyzer Mounting

Part 2 – Analyzer Mounting General All Q46 Series instruments offer maximum mounting flexibility. A bracket is included with each unit that allows mounting to walls or pipes. In all cases, choose a location that is readily accessible for calibrations. Also consider that it may be necessary to utilize a location where solutions can be used during the calibration process. -

Page 13: Wall Or Pipe Mount

Q46H/63 Combined Chlorine System Part 2 – Analyzer Mounting Wall or Pipe Mount A PVC mounting bracket with attachment screws is supplied with each analyzer (see Figure 5 for dimensions). The multi-purpose bracket is attached to the rear of the enclosure using the four flat head screws. -

Page 14: Figure 6 - Wall Mountingd

Q46H/63 Combined Chlorine System Part 2 – Analyzer Mounting Figure 6 - Wall Mounting Diagram Figure 7 - Pipe Mounting Diagram O&M Manual Rev-K (11/18) -

Page 15: Panel Mounting

Q46H/63 Combined Chlorine System Part 2 – Analyzer Mounting Panel Mounting Panel mounting uses the panel mounting flange molded into the rear section of the enclosure. Figure 8 provides dimensions for the panel cutout required for mounting. The panel mounting bracket kit must be ordered separately (part number 05-0094). This kit contains a metal retainer bracket that attaches to the rear of the enclosure, 4 screws for attachment of this bracket, and a sealing gasket to insure that the panel mounted monitor provides a water tight seal when mounted to a panel. -

Page 16: Part 3 - Sensor/Flowcell Mounting

Part 3 – Sensor/Flowcell Mounting General Select a location within the maximum sensor cable length for mounting of the sensor flow cell. Constant-Head Flowcell Chlorine sensors are best used in a constant-head overflow chamber because variations in sample flow rate and pressure can cause unstable readings. When monitoring low concentrations (below 0.5 PPM), this method should always be used. -

Page 17: Sealed Flowcell

Q45H/63 Chlorine Manual Part 3 – Sensor/Flowcell Mounting Once mounted, inlet and drain connections must be made. The flow cell contains a ⅛" MNPT inlet connection and a ⅜" MNPT drain connection. Hose barbs for the inlet and drain connections are supplied with the flow cell for use with flexible tubing. -

Page 18: Figure 11 - Sealed P H Flowcell

Q45H/63 Chlorine Manual Part 3 – Sensor/Flowcell Mounting Figure 11 - Sealed pH Flowcell Details O&M Manual Rev-K (11/18) -

Page 19: Submersion Mounting

Q45H/63 Chlorine Manual Part 3 – Sensor/Flowcell Mounting Submersion Mounting Some applications are much easier done using the submersible sensor. This method can sometimes be used where flow is reasonably constant, and hydraulic head does not vary appreciably. Chlorine sensors can never be used in completely stagnant conditions. A flow velocity of at least 0.3 feet per second is normally required for measurement. -

Page 20: Part 4 - Electrical Installation

Part 4 – Electrical Installation General The Q46 is powered in one of two ways, depending on the version purchased. The 12-24 VDC powered analyzer requires a customer supplied DC power supply. The 90-260 VAC version requires line power. Please verify the type of unit before connecting any power. WARNING: Do not connect AC line power to the DC version. -

Page 21: Power Connection

Q46H/63 Combined Chlorine System Part 4 – Electrical Installation Power Connection Verify the AC power supply requirement before installing. Also verify that power is fully disconnected before attempting to wire. AC powered Q46 systems are supplied with 5 cable gland fittings. Connect HOT, NEUTRAL, and GROUND to the matching designations on terminal strip TB7. -

Page 22: Figure 13 - Line Powerc

Q46H/63 Combined Chlorine System Part 4 – Electrical Installation Figure 13 - Line Power Connection The power strip, TB7, allows up to 12 AWG wire. A wire gauge of 16 AWG is recommended to allow for an easy pass-through into the ½” NPT ports when wiring. O&M Manual Rev-K (11/18) -

Page 23: Figure 14 - Optional Relayb

Q46H/63 Combined Chlorine System Part 4 – Electrical Installation Three SPDT relays are provided on the power supply board. None of the relay contacts are powered. The user must supply the proper power to the contacts. For applications that require the same switched operating voltage as the Q46 (115 or 230 V), power may be jumpered from the power input terminals at TB7. -

Page 24: Figure 15 - Optional Relayb

Q46H/63 Combined Chlorine System Part 4 – Electrical Installation is used to connect to the optional 3-relay card (Figure 15) OR the optional third analog output Out#3, (Figure 16). The Q46 can be configured for only one of these optional features, and the hardware for either option must be factory installed. -

Page 25: Direct Sensor Connection

Q46H/63 Combined Chlorine System Part 4 – Electrical Installation Direct Sensor Connection The sensor cable can be routed into the enclosure through one of cord-grips supplied with the unit. Routing sensor wiring through conduit is only recommended if a junction box is to be used. Some loose cable is needed near the installation point so that the sensor can be inserted and removed easily from the flowcell. -

Page 26: Sensor Wiring

Q46H/63 Combined Chlorine System Part 4 – Electrical Installation Sensor Wiring The sensor cable can be quickly connected to the Q46 terminal strip by matching the wire colors on the cable to the color designations on the label in the monitor. A junction box is also available to provide a break point for long sensor cable runs. -

Page 27: Junction Box Connection

Q46H/63 Combined Chlorine System Part 4 – Electrical Installation Junction Box Connection Installations where the sensor is to be located more than 25 feet from the monitor (max. 100 feet) require the use of a junction box. The junction box is shown in, and is supplied with two cable glands on the bottom of the enclosure. -

Page 28: Optional Ph Sensor Input

Q46H/63 Combined Chlorine System Part 4 – Electrical Installation Optional pH Sensor Input The Q46H may be configured for pH sensor input in applications where the pH can vary. To utilize the feature, a pH sensor must be connected to terminals 3 and 5 as shown in Figure 18.. Note that jumpers are installed at the factory between terminals 3 and 5, and terminals 6 and 9. - Page 29 Q46H/63 Combined Chlorine System Part 4 – Electrical Installation Note: The BLUE wire is NOT used when connecting a Flow Style Probe to the analyzer Figure 20 - Junction Box Wiring w/Optional pH Sensor O&M Manual Rev-K (11/18)

-

Page 30: Part 5 - Sensor Assembly

Part 5 – Sensor Assembly Chlorine Sensor Preparation The chlorine sensor supplied with the Q46H is shipped dry. It will not operate until it is prepared by adding electrolyte and a membrane. Preparation of the sensor for operation must be done carefully. -

Page 31: Figure 21 - Submersiblec

Q46H/63 Combined Chlorine System Part 5 – Sensor Assembly Figure 21 - Submersible Chlorine Sensor Assembly Follow the procedure below to prepare the chlorine sensor for operation: 1. Unscrew the electrolyte chamber from the assembled sensor and also remove the vent screw from the side of the sensor body. -

Page 32: Optional Ph Sensors

Q46H/63 Combined Chlorine System Part 5 – Sensor Assembly the chamber until the o-ring at the top of the chamber is compressed. Once again, do not use tools to tighten. 7. Shake excess electrolyte from the fill hole on the side of the sensor and replace the vent screw. -

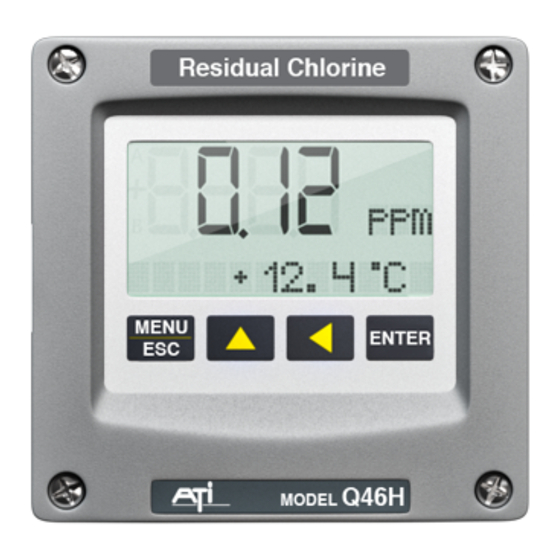

Page 33: Part 6 - Configuration

Part 6 – Configuration User Interface The user interface for the Q46 Series instrument consists of a custom display and a membrane keypad. All functions are accessed from this user interface (no internal jumpers, pots, etc.). RELAY 4-DIGIT INDICATOR MAIN DISPLAY MENU ICONS MENU ICONS SIGN... -

Page 34: Keys

Q46H/63 Combined Chlorine System Part 6 – Configuration 6.11 Keys All user configurations occur through the use of four membrane keys. These keys are used as follows: MENU/ESC To scroll through the menu section headers or to escape from anywhere in software. -

Page 35: Software

Q46H/63 Combined Chlorine System Part 6 – Configuration Icon Area The icon area contains display icons that assist the user in set-up and indicate important states of system functions. The CAL, CONFIG, and DIAG icons are used to tell the user what branch of the software tree the user is in while scrolling through the menu items. -

Page 36: Software Navigation

Q46H/63 Combined Chlorine System Part 6 – Configuration 6.21 Software Navigation Within the CAL, CONFIG, CONTROL, and DIAG menu sections is a list of selectable items. Once a menu section (such as CONFIG) has been selected with the MENU key, the user can access the item list in this section by pressing either the ENTER key or the UP arrow key. -

Page 37: Figure 23 - Software Map

Q46H/63 Combined Chlorine System Part 6 – Configuration MENU MEASURE CONFIG CONTROL DIAG SECTIONS Temperature Entry Lock Set Hold Cal Cl2 PID 0% #1 PID 100% #1 Fault List Set Delay Cal pH PID % Output PID Setpoint #1 Sim Out Contrast Cal Temp Loop Current (#1) -

Page 38: [Measure]

Q46H/63 Combined Chlorine System Part 6 – Configuration 6.22 Measure Menu [MEASURE] The default menu for the system is the display-only menu MEASURE. This menu is a display-only measurement menu, and has no changeable list items. When left alone, the instrument will automatically return to this menu after approximately 30 minutes. -

Page 39: [Cal]

Q46H/63 Combined Chlorine System Part 6 – Configuration Slope = 100% pH sensor slope response vs. ideal calibration. This value will update after each calibration. As the pH sensor ages, the slope reading will decay. This is useful for solving sensor problems (if enabled). Offset = X.X V pH sensor voltage output at 7 pH. -

Page 40: Configuration Menu

Q46H/63 Combined Chlorine System Part 6 – Configuration 6.24 Configuration Menu [CONFIG] The Configuration Menu contains all of the general user settings: Entry Lock This function allows the user to lock out unauthorized tampering with instrument settings. All settings may be viewed while the instrument is locked, but they cannot be modified. - Page 41 Q46H/63 Combined Chlorine System Part 6 – Configuration Com Mode Sets digital communication mode of analyzer. Optional digital communication card must be plugged into the power supply slot for this function to work. Press ENTER to initiate user entry mode, and the entire value will flash.

- Page 42 Q46H/63 Combined Chlorine System Part 6 – Configuration Relay B Mode Relay C Mode Relay B and C can be used in two ways: as a setpoint control, or as an alarm. The two settings for Relay B Mode are CON and FAIL. The CON setting enables normal setpoint operation for Relay B/C.

- Page 43 Q46H/63 Combined Chlorine System Part 6 – Configuration pH Buffer This is a multiple variable function that allows the user to choose which pH buffer sets that will be utilized in the 2-point calibration mode. The Q46H contains 3 sets of buffer tables with compensation values ranging from 0 to 95 °C.

-

Page 44: Figure 24 - Automatic P H B

Q46H/63 Combined Chlorine System Part 6 – Configuration Table 1 Table 2 4.00 pH 7.00 pH 9.18 pH 7.00 pH 10.00 pH ºC °C °C ºC °C °C 4.00 7.10 9.46 4.00 7.10 10.27 3.99 7.06 9.33 3.99 7.06 10.15 4.00 7.02 9.23... -

Page 45: Control Menu

Q46H/63 Combined Chlorine System Part 6 – Configuration 6.25 Control Menu [CONTROL] The Control Menu contains all of the output control user settings: Set PID 0% Set PID 100% [Iout1=PID] If the PID is enabled, this function sets the minimum and maximum controller end points. - Page 46 Q46H/63 Combined Chlorine System Part 6 – Configuration PID Deriv [Iout1=PID] Derivative is a second order implementation of Integral, used to suppress “second-order” effects from process variables. These variables may include items like pumps or mixers that may have minor impacts on the measured value.

-

Page 47: Figure 25 - Control Relaye

Q46H/63 Combined Chlorine System Part 6 – Configuration NOTE: If the temperature units are changed between °C and °F (see Temp Units in this section), the default settings for this output will be stored (present data is not converted.) A Setpoint This function establishes the chlorine trip point for relay A. -

Page 48: Figure 26 - Alarm Relay Example

Q46H/63 Combined Chlorine System Part 6 – Configuration If Relay A Mode is set to Alarm Mode, AL, then the following settings will Setpnt A-HI appear in the Config Menu list automatically. In this mode, two setpoints Hyst A-HI can be selected on the same relay, to create an alarm band. Phase HI Delay A-HI selection causes the relay to energize outside of the band, and Phase Setpnt A-LO... -

Page 49: Diagnostics Menu

Q46H/63 Combined Chlorine System Part 6 – Configuration If Relay D,E, or F Mode is set to CON (see Relay D,E,F Modes), then D,E,F Setpoint the Relay will function identically to Relay A. Relay settings appear in D,E,F Hyster the CONFIG menu list automatically. D,E,F Delay D,E,F Phasing 6.26 Diagnostics Menu [DIAG]... - Page 50 Q46H/63 Combined Chlorine System Part 6 – Configuration After 30 minutes or if power to the analyzer is cycled, the failure for calibration will be cleared until calibration is attempted again. If the problem still exists, the calibration failure will re-occur. Press ENTER to initiate view of the highest priority failure.

- Page 51 Q46H/63 Combined Chlorine System Part 6 – Configuration the UP arrow key to modify desired value; selections are between 4mA, and 20mA. Press ENTER to store the new value. Fail Out #2 This function sets the fail-mode of current loop output #2 under a FAIL condition.

-

Page 52: Part 7 - Calibration

Part 7 – Calibration Chlorine Calibration After power is applied, the sensor must be given time to stabilize. This is best done by following the zeroing procedure below. Establishing a stable zero is critical to the proper operation of the monitor. -

Page 53: Chlorine Span Cal

Q46H/63 Combined Chlorine System Part 7 – Calibration carefully inspect the sensor for a tear in the membrane. It will probably be necessary to rebuild the sensor as described in section 5.4, Chlorine Sensor Assembly. Should the offset value remain high and result in calibration failures, review the Service section of this manual, and then contact the service dept. -

Page 54: Temperature Calibration

Q46H/63 Combined Chlorine System Part 7 – Calibration 8. The screen will display the last measured ppm value and a message will be displayed prompting the user for the lab value. The user must then modify the screen value with the arrow keys and press ENTER. -

Page 55: Ph Calibration

Q46H/63 Combined Chlorine System Part 7 – Calibration equilibrium, or there may be a problem with the temperature element. In the event of calibration failure, it is recommended to attempt the calibration again immediately. pH Calibration The pH calibration menus will not be seen unless the optional pH sensor input is turned ON and a pH sensor is connected to the instrument. -

Page 56: Two-Point Ph Cal

Q46H/63 Combined Chlorine System Part 7 – Calibration [CONFIG] 6.24 Configuration Menu for more details. The pH calibration functions appear in the CAL menu listing when the optional pH input is enabled in the CONFIG menu. Calibration of pH is performed in one of two methods; one-point or two-point. -

Page 57: One-Point Ph Cal

Q46H/63 Combined Chlorine System Part 7 – Calibration compensated number for pH buffers is typically written on the side of the buffers shipping container. Once value has been adjusted, press the ENTER key. The message Accepted! will be displayed, or an error describing the cause the failure. If the cal point was accepted, rinse the sensor in distilled or de-ionized water and move it into the second pH buffer. -

Page 58: Part 8 - Pid Controller Details

Part 8 – PID Controller Details PID Description PID control, like many other control schemes, are used in chemical control to improve the efficiency of chemical addition or control. By properly tuning the control loop that controls chemical addition, only the amount of chemical that is truly required is added to the system, saving money. - Page 59 Q46H/63 Combined Chlorine System Part 8 – PID Controller The most notable feature of the algorithm is the fact the proportional gain term affects all components directly (unlike some other algorithms - like the “series” form.) If a pre-existing controller utilizes the same form of the algorithm shown above, it is likely similar settings can for made if the units on the settings are exactly the same.

-

Page 60: Classical Pid Tuning

Q46H/63 Combined Chlorine System Part 8 – PID Controller Classical PID Tuning Unlike many high speed position applications where PID loops are commonly used, the chemical feed application employed by this instrument does not require intense mathematical exercise to determine tuning parameters for the PID. In fact, the risk of instability is far greater with overly tuned PID control schemes. - Page 61 Q46H/63 Combined Chlorine System Part 8 – PID Controller The easiest processes to control with closed-loop schemes are generally linear, and symmetrical, in nature. For example, controlling level in tank where the opening of valve for a fixed period of time corresponds linearly to the amount that flows into a tank.

-

Page 62: Part 9 - System Maintenance

Part 9 – System Maintenance General The Q46H/63 Combined Chlorine System will generally provide unattended operation over long periods of time. With proper care, the system should continue to provide measurements indefinitely. For reliable operation, maintenance on the system must be done on a regular schedule. -

Page 63: Sensor Acid Cleaning

Q46H/63 Combined Chlorine System Part 9 – System Maintenance Sensor Acid Cleaning Over an extended operating period, chlorine sensors can slowly accumulate deposits on the surface of the platinum electrode. Typically, this type of buildup occurs over years of operation, but can sometimes occur more quickly if high levels of manganese, iron, or other metals are dissolved in the water. -

Page 64: Replacing The Saltbridge Andr

Q46H/63 Combined Chlorine System Part 9 – System Maintenance NOTE: DO NOT use a soap containing any oils (such as lanolin). Oils can coat the glass electrode and harm sensor performance. Soak the sensor for several minutes in the soap solution. Use a small, extra-soft bristle brush (such as a mushroom brush) to thoroughly clean the electrode and saltbridge surfaces. -

Page 65: Flow Cell Maintenance

Q46H/63 Combined Chlorine System Part 9 – System Maintenance Figure 28 - Replacing Saltbridge and Reference Buffer Flow Cell Maintenance The maintenance on the flow cell is simple cleaning. The flow cell is clear to make examination of the condition of the sensor easier without interfering with operations. The flow cell may be cleaned by wiping or by washing with detergents or dilute acids. -

Page 66: Part 10 - Troubleshooting

Part 10 – Troubleshooting 10.1 General The information included in this section is intended to be used in an attempt to quickly resolve an operational problem with the system. During any troubleshooting process, it will save the most time if the operator can first determine if the problem is related to the analyzer, sensor, or some external source. -

Page 67: Analyzer Tests

Q46H/63 Combined Chlorine System Part 10 – Troubleshooting devices. This can be quickly resolved by moving wiring, or by adding very inexpensive snubbers (such As Quencharcs) to the load. 7. Carefully examine any junction box connections for loose wiring or bad wire stripping. If possible, connect the sensor directly to the analyzer for testing. -

Page 68: Display Messages

Q46H/63 Combined Chlorine System Part 10 – Troubleshooting 10.4 Display Messages The Q46 Series instruments provide a number of diagnostic messages which indicate problems during normal operation and calibration. These messages appear as prompts on the secondary line of the display or as items on the Fault List. MESSAGE DESCRIPTION POSSIBLE CORRECTION... - Page 69 Q46H/63 Combined Chlorine System Part 10 – Troubleshooting MESSAGE DESCRIPTION POSSIBLE CORRECTION Temp Low The temperature reading is < -10 ºC Same as “Temp High” above. TC Error TC may be open or shorted. Check sensor wiring and perform RTD test as described in sensor manual.

-

Page 70: Sensor Tests

Q46H/63 Combined Chlorine System Part 10 – Troubleshooting 10.5 Sensor Tests 1. Check the membrane condition. A membrane that is not stretched smoothly across the tip of the sensor will cause unstable measurements. If necessary, change membrane and electrolyte. 2. Residual chlorine sensors can be tested with a digital voltmeter (DVM) to determine if a major sensor problem exists. - Page 71 Q46H/63 Combined Chlorine System Part 10 – Troubleshooting If you suspect that water has gotten into a cable connection on a flow type sensor or into the plug connection of a submersible sensor, disconnect the cable and allow the parts of the sensor to sit in a warm place for 24 hours.

-

Page 72: Spare Parts

Spare Parts Part No. Description 03-0407 P/S Assy, 100-240 VAC 03-0408 P/S Assy, 100-240 VAC with 3 4-20mA output 03-0409 P/S Assy, 100-240 VAC with 3 relay exp. Board 03-0410 P/S Assy, 12-24 VDC 03-0411 P/S Assy, 12-24 VDC with 3 4-20mA output 03-0412 P/S Assy, 12-24 VDC with 3 relay exp. - Page 73 PRODUCT WARRANTY Analytical Technology, Inc. (Manufacturer) warrants to the Customer that if any part(s) of the Manufacturer's equipment proves to be defective in materials or workmanship within the earlier of 18 months of the date of shipment or 12 months of the date of start-up, such defective parts will be repaired or replaced free of charge.

- Page 74 WATER QUALITY MONITORS GAS DETECTION PRODUCTS Dissolved Oxygen Ammonia Carbon Monoxide Free Chlorine Hydrogen Combined Chlorine Nitric Oxide Total Chlorine Oxygen Residual Chlorine Dioxide Cl2 Phosgene Potassium Permanganate Bromine Chlorine Dissolved Ozone Chlorine Dioxide pH/ORP Fluorine Conductivity Iodine Hydrogen Peroxide Acid Gases Peracetic Acid O Ethylene Oxide...

Need help?

Do you have a question about the Q46H-63 and is the answer not in the manual?

Questions and answers