Advertisement

Quick Links

Installation, Operation and Maintenance

Model 912GD/612GD

Pressure Reducing Control Valve with Pressure Sustaining Feature

Sizes: 11/4" to 24"

WARNING

!

Read this Manual BEFORE using this equipment.

Failure to read and follow all safety and use information

can result in death, serious personal injury, property

damage, or damage to the equipment.

Keep this Manual for future reference.

WARNING

!

Local building or plumbing codes may require modifica-

tions to the information provided. You are required to

consult the local building and plumbing codes prior

to installation. If the information provided here is not

consistent with local building or plumbing codes, the

local codes should be followed. This product must be

installed by a licensed contractor in accordance with

local codes and ordinances.

WARNING

!

Need for Periodic Inspection/Maintenance: This product

must be tested periodically in compliance with local codes,

but at least once per year or more as service conditions

warrant . All products must be retested once maintenance

has been performed . Corrosive water conditions and/or

unauthorized adjustments or repair could render the product

ineffective for the service intended . Regular checking and

cleaning of the product's internal and external components

helps assure maximum life and proper product function .

NOTICE

For Australia and New Zealand: Pipeline strainers should be

installed between the upstream shutoff valve and the inlet of

the backflow preventer.

It's important that this device be tested periodically in compli-

ance with local codes, but at least once per year or more as

service conditions warrant. If installed on a fire sprinkler system,

all mechanical checks, such as alarm checks and backflow

preventers, should be flow tested and inspected internally in

accordance with NFPA 13 and NFPA 25.

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Setting the Pressure Reducing Control . . . . . . . . . . . . . . . . . . . . . . 3

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Trouble Shooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Valve Disassembly Instructions . . . . . . . . . . . . . . . . . . . . . . . . 8

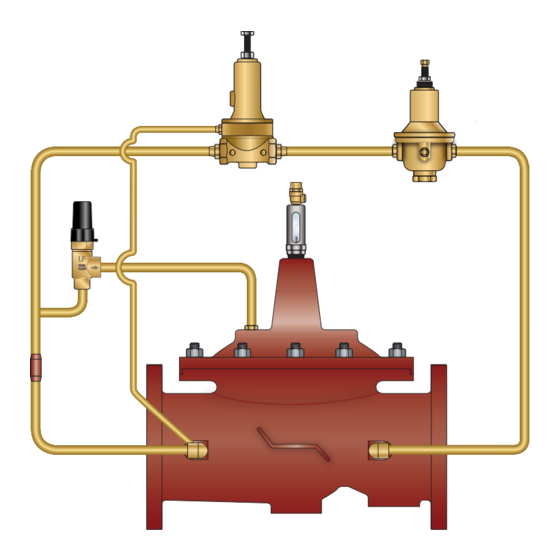

ACV Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

IOM-A-ACV-912_612

Page

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for Watts Ames 912GD

-

Page 1: Table Of Contents

IOM-A-ACV-912_612 Installation, Operation and Maintenance Model 912GD/612GD Pressure Reducing Control Valve with Pressure Sustaining Feature Sizes: 11/4" to 24" WARNING Read this Manual BEFORE using this equipment. Failure to read and follow all safety and use information can result in death, serious personal injury, property damage, or damage to the equipment. -

Page 2: Introduction

Only remove the pilot control system from the valve if necessary. Tubing and fittings should be kept clean and replaced exactly as removed. Consult appropriate hydraulic schematic to ensure proper re-assembly. After installation, vent entrapped air from valve cover and pilot system by following instructions on Technical Bulletin. IOM-A-ACV-912_612 2115 EDP# 1917034 © 2021 Watts... -

Page 3: Setting The Pressure Reducing Control

Air is vented through the air bleed valve or loosened fitting. Tighten the fitting when liquid begins to vent (See Figure 1). Figure 1 Position Indicator Repeat the process until no air is trapped in the system. IOM-A-ACV-912_612 2115 EDP# 1917034 © 2021 Watts... - Page 4 If the downstream pressure fluctuates slightly above the desired set point, turn the adjustment screw OUT, counterclockwise, increasing the rate of closing. Figure 3 Flow Control IOM-A-ACV-912_612 2115 EDP# 1917034 © 2021 Watts...

- Page 5 PV20C — Pressure Sustaining Control Step 4 Allow pressure to stabilize. Step 5 Fine-tune the relief/sustaining setting as required as detailed in Step 3. Step 6 Open the upstream isolation valve to return to normal operation. IOM-A-ACV-912_612 2115 EDP# 11917034 © 2021 Watts...

-

Page 6: Maintenance Schedule

Automatic Control Valve Maintenance Schedule To ensure peak performance and longevity of your automatic • Annual Maintenance control valve, Watts/Ames recommends following the below – Conduct monthly & quarterly inspections. standard maintenance schedule. – Inspect & clean all strainers. • Monthly Maintenance –... - Page 7 Blockage in main valve. Perform freedom of movement test; if valve does not close, disassemble and remove blockage. Worn/damaged valve seat. Perform seat sealing check; disassemble and inspect/repair seat if required. IOM-A-ACV-912_612 2115 EDP# 1917034 © 2021 Watts...

-

Page 8: Valve Disassembly Instructions

5. Before removing Stem Nut, examine stem threads for mineral build-up. Remove deposits with a fine wire brush. Extreme care should be taken not to damage the finish on stem guiding surfaces when disassembling. Avoid applying pipe wrenches to top or bottom stem guide surfaces. IOM-A-ACV-912_612 2115 EDP# 1917034 © 2021 Watts... - Page 9 E Dia. 4 Holes Angle or 90 Apart Nut and Washer Channel Iron 2PLCS All-Thread B (Min) C TYP <3 PLCS> Valve Seat Valve Body D TYP <3 PLCS> 120 Apart Figure 6 Figure 5 IOM-A-ACV-912_612 2115 EDP# 1917034 © 2021 Watts...

- Page 10 11. Test the integrity of the Seat Seal by following the Seat Seal Test procedure in previous section. 12. Return valve to service by following instructions on the Technical Bulletin matching the valve function. IOM-A-ACV-912_612 2115 EDP# 1917034 © 2021 Watts...

-

Page 11: Acv Schematic

ASTM A743 CF8M (316) Stainless Steel Seat Screw** (8" and Larger) ASTM A276 304 Stainless Steel Seat Gasket* Buna-N (Nitrile) * Contained in Main Valve Repair Kit **Note: 6 inch and Smaller Valves, Seat Ring is threaded IOM-A-ACV-912_612 2115 EDP# 1917034 © 2021 Watts... - Page 12 USA: Backflow T: (978) 689-6066 • F: (978) 975-8350 • AmesFireWater.com USA: Control Valves T: (713) 943-0688 • F: (713) 944-9445 • AmesFireWater.com Canada: T: (888) 208-8927 • F: (905) 481-2316 • AmesFireWater.ca Latin America: T: (52) 55-4122-0138 • AmesFireWater.com IOM-A-ACV-912_612 2115 EDP# 1917034 © 2021 Watts...

Need help?

Do you have a question about the Ames 912GD and is the answer not in the manual?

Questions and answers