Table of Contents

Advertisement

Quick Links

OPERATION & MAINTENANCE MANUAL

INTRODUCTION

I - GENERALITY

I.A - SYMBOLS

8.A - TERMS & CONDITIONS

8.B - WARRANTY REGISTRATION

INDEX

ANNEX

A1 - EU DECLARATION OF CONFORMITY

A2 - SOVEMA PRODUCT RANGE

A3 - SPARE PARTS CATALOGUE

_____________________________________________________________________________________

CONTENTS

CONTENTS - 1/1

Revision 2022

Advertisement

Table of Contents

Summary of Contents for Sovema ERX-3 Series

-

Page 1: Table Of Contents

VI – TOXICOLOGICAL INFORMATIONS VII – DISPOSAL & RECYCLING VIII – WARRANTY 8.A – TERMS & CONDITIONS 8.B – WARRANTY REGISTRATION INDEX ANNEX A1 – EU DECLARATION OF CONFORMITY A2 – SOVEMA PRODUCT RANGE A3 – SPARE PARTS CATALOGUE _____________________________________________________________________________________ CONTENTS - 1/1... - Page 2 Failure to do could result in personal injury or property damage. Of course, if you should have any problems or questions, please do not hesitate to contact your local SOVEMA dealer or, alternatively, to contact us at the addresses or numbers indicated in this manual.

- Page 3 I - GENERALITY The manual is the translation of the original manual in italian language (official language). If you should notice any unclear points, omissions, etc., feel free to contact SOVEMA. I.A - SYMBOLS These following safety pictograms appear throughout the manual.

-

Page 4: General Informations

MOUNTED! KEEP THE MANUAL IN A SAFE AREA FOR ALL OF LIFE OF THE IMPLEMENT. IF IT IS PARTIALLY RUINED OR LOST YOU HAVE TO REQUEST A NEW ONE CONTACTING A DEALER SOVEMA OR SOVEMA ITSELF. _____________________________________________________________________________________ I - 2/2... -

Page 5: Safety

OPERATION & MAINTENANCE MANUAL Revision 2022 II – SAFETY This section is very important because even if the implement is well-designed and even if safety guards are present on the implement, residual risks remain and the operator have to know them in order to avoid injuries. II.A - LABELS Safety pictograms (hereafter decals), placed in a visible position on the implement contain important safety warnings. - Page 6 OPERATION & MAINTENANCE MANUAL Revision 2022 Hands and feet can be injured by moving tines. Keep away from the implement Your feet can be injured. Keep away from the implement Your hands can be injured. Do not remove safety guards and keep away from moving parts Your hands can be injured.

- Page 7 OPERATION & MAINTENANCE MANUAL Revision 2022 In the following figure it is indicated the location of decals described above. _____________________________________________________________________________________ II - 3/6...

-

Page 8: Ii.b - Recommendations

Before using the implement you must be sure to know the main safety recommendations; many accidents are caused by not observing these simple rules. SOVEMA Srl declines to the full extent allowed by the applicable laws all liability and responsibility for any damages of any kind resulting from the non-observance of the rules... - Page 9 OPERATION & MAINTENANCE MANUAL Revision 2022 The rotating parts of the implement have been designed and tested for rugged use. However they can damage due to impact with heavy solid objects. Such impact can cause fragments to be thrown outward at very high speed. To reduce the possibility of serious injury, or even death, never allow the rotating parts to go to the contact with such obstacles Stop the implement and tractor immediately upon hitting an obstacle.

- Page 10 When replacing a mechanical part, always use original spare parts in order not to compromise the implement and your own personal safety. SOVEMA assumes no liability if the replacement of non original parts is performed...

-

Page 11: Operation

OPERATION & MAINTENANCE MANUAL Revision 2022 III – OPERATION III.A – CHECKLIST Before connecting the implement to the tractor, please read the following instructions: Make sure that the weight and power of the tractor is suitable to the implement you want to connect. -

Page 12: Iii.b - Technical Data

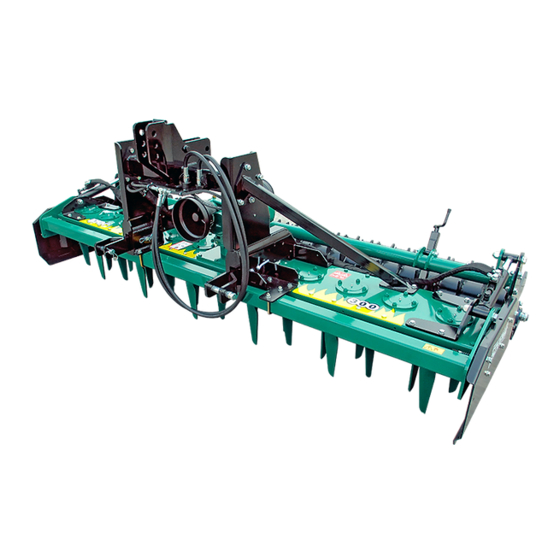

Revision 2022 III.B - TECHNICAL DATA The implement described in this manual is a fixed rotary harrows from the ERX-3 series. The identification plate is located on the right-upper side of implement frame. The image shown is for illustrative purpose only... -

Page 13: Iii.c Hitching

OPERATION & MAINTENANCE MANUAL Revision 2022 III.C HITCHING The implement described in this manual can be connected to any kind of tractor provided of universal three-point linkage. The characteristics of this linkage depend on the type of tractor, therefore it is necessary to setting up the tractor in order to properly connect the implement. - Page 14 OPERATION & MAINTENANCE MANUAL Revision 2022 Lift up the implement off the ground While remaining in the driving seat, put the tractor PTO in neutral position When the PTO drive shaft has completely stopped, turn off the engine, engage the parking brake and remove the ignition key Get off the tractor and place wheels in a desired working position by using the rubber bushes...

- Page 15 OPERATION & MAINTENANCE MANUAL Revision 2022 Shorten the PTO drive shaft Due to the many different types of tractors, it may be necessary to shorten the PTO shaft. Listed below are some basic guidelines on performing this modification. First, determine the length that has to be removed 1) remove plastic protection on both sections 2) cut the excess length of both tubes using a saw...

-

Page 16: Iii.d - Preparation For Work

OPERATION & MAINTENANCE MANUAL Revision 2022 III.D - PREPARATION FOR WORK Working depth adjustment In order to set up the implement’s working depth, adjust the rear roller actuating the hydraulic cylinders, as indicated in figure 1 : CYLINDER CYLINDER Figure 1 After adjusting the rear roller it is necessary to adjust the position of the levelling bar as follows (see figure 2): unblock the screw register crank of the levelling bar by taking out the stop of the crank... -

Page 17: Iii.e - Usage

The implement must be used only if equipped with all its components as supplied by SOVEMA (safety devices included). No components can be modified _____________________________________________________________________________________... -

Page 18: Iii.f - Unhitching

OPERATION & MAINTENANCE MANUAL Revision 2022 III.F – UNHITCHING The disconnection of the implement from the tractor must be carried out on a flat and firm surface. It’s a dangerous operation, pay attention. Please read the following instructions carefully: Once reached the parking position, while remaining in the driving seat, put the tractor PTO in neutral position When the PTO drive shaft has completely stopped, turn off the engine, engage the parking brake and remove the ignition key... -

Page 19: Iii.g Troubleshooting

In order to avoid damages, please replace all the tines at the same time with the new genuine ones supplied by SOVEMA Check the lubrification of the gears contained in the box •... - Page 20 • Check tines The tines can be worn and less effective. Please replace them. Use original tines SOVEMA only. During the working if the the tines rub along the soil instead of penetrating it, please advance more slowly. During the working if the tines are clogged raise the levelling bar in order to keep clods away the tines •...

- Page 21 OPERATION & MAINTENANCE MANUAL Revision 2022 Check type of soil • If the soil is too hard further runs will be required. Do not work in excessively wet soil in order to avoid rotors clogging. If the clods are excessively crumbled lower, if possible, the tines speed or raise the levelling bar or increase the advancement speed If the clods are insufficiently crumbled increase, if possible, the tines speed or lower the advancement speed...

-

Page 22: Storage

OPERATION & MAINTENANCE MANUAL Revision 2022 IV - STORAGE The implement represents an investment for the operator, so it’s fundamental to spend the utmost care in order to keep it always efficient and extend his lifetime. When you park your implement we suggest to follow these following rules: •... -

Page 23: Maintenance

OPERATION & MAINTENANCE MANUAL Revision 2022 V – MAINTENANCE The efficiency and lifetime of this implement strongly depend on the observance of its maintenance schedule. The schedule reported below is subject to change since it refers to a normal usage and does not take into consideration heavier working conditions which require a more frequent maintenance. - Page 24 EVERY 50 WORKING HOURS Check tines for excessive wear or damages. Replace them if necessary. Use genuine parts supplied by SOVEMA. Make sure PTO drive shaft and is in place and in a good condition. If damaged or worn, replace spare parts.

- Page 25 OPERATION & MAINTENANCE MANUAL Revision 2022 A. Unscrew the filler plug for grease located on top of the lid, near the gearbox B. Insert a metallic rod vertically in the frame, through the filler hole until touching the bottom of the case itself C.

- Page 26 If you need to replace missing, wear or damaged parts, please always refer to the spare parts catalogue attached to this manual. The spare parts to be used must meet the technical requirements specified by SOVEMA. This is always ensured with original spare parts. _____________________________________________________________________________________...

-

Page 27: Toxicological Informations

OPERATION & MAINTENANCE MANUAL Revision 2022 VI – TOXICOLOGICAL INFORMATIONS The informations listed on table below concern lubrificants, oil and grease, present in the implement: PROTECTIVE TYPE OF DANGER FIRST CARE EQUIPMENT Possible irritation Safety gloves or Wash thoroughly with SKIN after prolonged lotion... -

Page 28: Disposal & Recycling

OPERATION & MAINTENANCE MANUAL Revision 2022 VII – DISPOSAL & RECYCLING At the end of lifetime, the implement must be demolited. Make sure the implement is unhitched from the tractor. This activity must be carried out by customer. Before proceeding, it is recommend to wear all personal protective equipment including, besides safety shoes and protective gloves, overalls, goggles and helmet. -

Page 29: Warranty

SOVEMA's obligation shall terminate 12 (twelve) months after the date of purchase of the product by the original purchaser. This warranty cannot be assigned or transferred to anyone unless SOVEMA consent in writing has first been obtained. All warranty claims must be forwarded to SOVEMA or a SOVEMA dealer within 8 (eight) days after occurrence. - Page 30 OPERATION & MAINTENANCE MANUAL Revision 2022 _____________________________________________________________________________________ VIII - 2/6...

- Page 31 The purchaser was given operation and machine and made aware of its limitations maintenance manual and instructed in safe and correct usage of machine and on limitation of war-ranty • The machine was tested and operates correctly DELIVER TO SOVEMA Srl _____________________________________________________________________________________ VIII - 3/6...

- Page 32 OPERATION & MAINTENANCE MANUAL Revision 2022 _____________________________________________________________________________________ VIII - 4/6...

- Page 33 OPERATION & MAINTENANCE MANUAL Revision 2022 SOVEMA Srl Via Olmo 6/8/10 41013 Gaggio di Piano (MODENA) - Italy PHONE: 0039.059.938585 FAX: 0039.059.938512 E-MAIL: commerciale@sovema.com WEBSITE: www.sovema.com VIII.B - WARRANTY REGISTRATION This warranty will become valid only if this form is completed and signed by both the Purchaser and the Dealer and is returned within 8 days of purchase date, otherwise the warranty is not valid.

- Page 34 OPERATION & MAINTENANCE MANUAL Revision 2022 _____________________________________________________________________________________ VIII - 6/6...

- Page 35 OPERATION & MAINTENANCE MANUAL Revision 2022 INDEX ADJUSTMENT, SEE PREPARATION FOR WORK ............... ACCESSORIES ......................III.IV CARE ..........................IV,V CE MARKING ........................III.B CHARACTERISTICS, SEE TECHNICAL DATA ..............CHECKLIST ........................III.A CLEANING ......................... IV DECALS ........................... II.A DECLARATION OF CONFORMITY .................. A1 DISPOSAL ........................

- Page 36 OPERATION & MAINTENANCE MANUAL Revision 2022 LUBRIFICANTS ........................V MAINTENANCE ......................II.B, V OIL, SEE LUBRIFICANTS ....................V PICTOGRAMS, SEE LABELS ....................PREPARATION FOR WORK ..................III.IV PTO SHAFT ......................... II.B, V RECOMMENDATIONS ....................II.B RECYCLING ........................VII SAFETY ..........................II SERIAL NUMBER ......................

- Page 37 Revision 2022 SOVEMA Srl Via Olmo 6/8/10 41013 Gaggio di Piano (Modena) - ITALY TEL.: 059.938585 FAX: 059.938512 E-MAIL: commerciale@sovema.com WEB SITE: http://www.sovema.com EU DECLARATION OF CONFORMITY The undersigned company, SOVEMA Srl hereby declares that the machine Model: ……………………………………………… Serial No.: ………………………………………………...

- Page 38 Revision 2022 SOVEMA Srl Via Olmo 6/8/10 41013 Gaggio di Piano (Modena) - ITALY TEL.: 059.938585 FAX: 059.938512 E-MAIL: commerciale@sovema.com WEB SITE: http://www.sovema.com UK DECLARATION OF CONFORMITY The undersigned company, SOVEMA Srl hereby declares that the machine Model: ……………………………………………… Serial No.: ………………………………………………...

- Page 39 OPERATION & MAINTENANCE MANUAL Revision 2022 SOVEMA PRODUCT RANGE IXED OTARY ILLERS WITH CHAIN OR GEARS DRIVE • over 100 different models • for tractors from 20 hp to 130 hp • working width from 100 cm to 350 cm...

- Page 40 OPERATION & MAINTENANCE MANUAL Revision 2022 LAIL OWERS FIXED OR WITH SIDE SHIFT • 42 different models • for tractors from 15 hp to 100 hp • working width from 100 cm to 320 cm EVERSIBLE FLAIL OWERS • 6 different models •...

- Page 41 OPERATION & MAINTENANCE MANUAL Revision 2022 RAKES • 7 different models • for tractors from 30 hp to 55 hp • working width from 5,3 m to 11 m AY TEDDERS • 10 different models • for tractors from 15 hp to 50 hp •...

Need help?

Do you have a question about the ERX-3 Series and is the answer not in the manual?

Questions and answers