Table of Contents

Advertisement

Quick Links

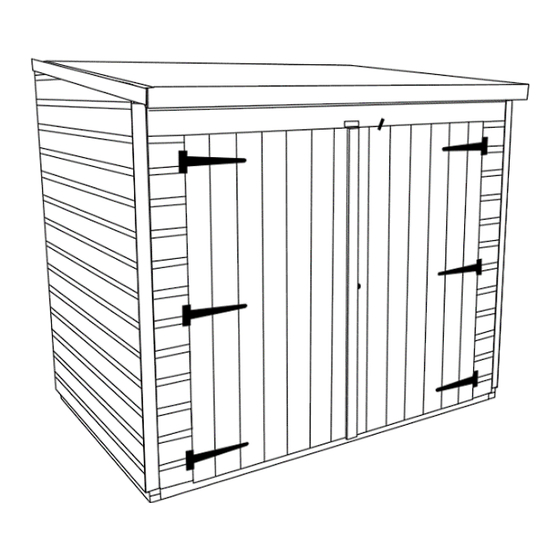

Pent Bike Shed Instruction Manual

__________________________________________________

Please follow these instructions to unpack your garden building safely

_______________________________________________________________________________________

Please note – if you have ordered a base kit it's unlikely you will be able to see the base kit from the

outside of the pack - it will be inside your panels. The fixings are also inside the pack.

8-10ft Models

WARNING

UNPACKING SAFELY

•

Two people minimum to unpack

•

Place the pallet on firm level ground

•

Cut the plastic banding

•

Remove each panel by removing screws one column at a time as indicated below

•

Be careful of loose components inside the pack when removing panels

•

Check all the components against the checklist prior to install

BASE KIT AND FIXING PACK

Advertisement

Table of Contents

Need help?

Do you have a question about the 8ft and is the answer not in the manual?

Questions and answers