Summary of Contents for Cleantecs SOLA-TECS W BJ 2010 Series

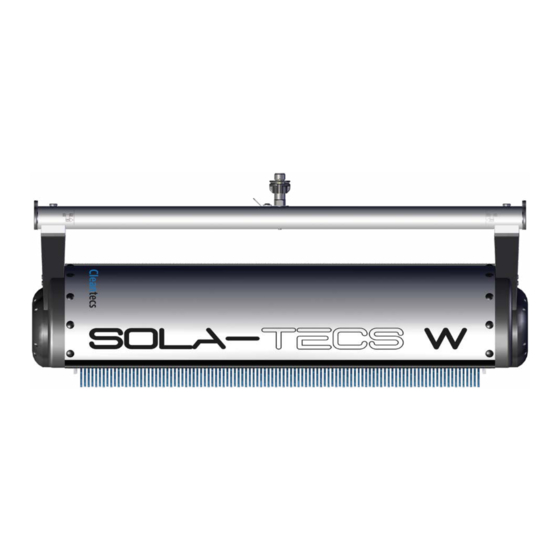

- Page 1 SOLA-TECS W Operating Instructions BJ 2010 … SN 0300 … W800 | W1000 | W800 PRO | W1000 PRO BA 0304029 R00 2021-01 Operating instructions for the Sola-Tecs W cleaning system.

-

Page 2: Table Of Contents

Table of contents Basics Safety information Information about tools required Explanatory information Overview of the cleaner components Included with the cleaner Types of Sola-Tecs W Accessories required for operation Your tool bag Tool How does the Sola-Tecs W work? How does the Sola-Tecs W Pro work? Components and their function Intended use Requirements of the photovoltaic surfaces to be cleaned... - Page 3 Table of contents Commissioning Preparing to connect the cleaner Unpacking out of the shipping box Checking cleaner for defects Checking the high-pressure filter in the connection pin of the cleaner and pendulum tube Transporting the cleaner to the place of use Assembling the guide rollers Assembling the pendulum lance Assembling the high-pressure hose...

- Page 4 Table of contents Transport and storage Transporting and storing the cleaner Checking the high-pressure filter in the connection pin of the cleaner and pendulum tube Allow water to run out of the cleaner Checking components Maintaining the cleaner Preserving the cleaner Lubricating components How to stow the cleaner correctly in the transport box Stowing the pendulum tube...

- Page 5 Notes Notes BA 0304031 R00 2021-01...

- Page 6 It is IMPORTANT that you read these operating instructions CAREFULLY BEFORE USE and RETAIN THEM FOR FUTURE REFERENCE. Visit our homepage at regular intervals and check for the latest version of the operating instructions. The operating instructions are intended for... the Sola-Tecs W manufactured from 2010, serial number 0300.

-

Page 7: Basics

Basics Components and functions of the Sola-Tecs W and W Pro Here you will find information about: Components of the system, tools for maintenance BA 0304031 R00 2021-01... -

Page 8: Safety Information

Basics Explanation of notices Safety notices The notices are for your safety. The notices can be found in the general safety sec- tion and are always accompanied by an action that requires specific attention. Failure to comply will lead to serious injury or death. DANGER Danger to life due to thunderstorms A Avoid using the machine during thunderstorms. -

Page 9: Explanatory Information

Basics Explanatory information This information can be found in the grey shaded illustration area. It helps you to find the right illustration for the heading in the text, to understand the details bet- ter, follow steps, complete movements and identify the position in the room. W / W Pro Here we specify the Sola-Tecs W type Sola-Tecs W…... -

Page 10: Overview Of The Cleaner Components

Basics Overview of the cleaner components BA 0304031 R00 2021-01... -

Page 11: Included With The Cleaner

Basics Included with the cleaner Sola-Tecs W basic device Guide rollers Pendulum tube Guying system Protective screw cap BA 0304031 R00 2021-01... -

Page 12: Types Of Sola-Tecs W

Basics Types of Sola-Tecs W Sola-Tecs W800 Sola-Tecs W1000 BA 0304031 R00 2021-01... - Page 13 Basics Sola-Tecs W800 Pro Sola-Tecs W1000 Pro BA 0304031 R00 2021-01...

-

Page 14: Accessories Required For Operation

Basics Accessories required for operation The Sola-Tecs W belongs to a cleaning system. The accessories listed here are required for operation. High-pressure cleaner High-pressure hose NW8 Your tool bag BA 0304031 R00 2021-01... -

Page 15: Tool

Basics Tool Hex key size 6 Hex key size 4 Socket wrench size 8 Socket wrench set* O-rings * The socket wrench set is needed for repairs, e.g. for loosening the clamping nut on the nozzle needle. The repair work is described with the delivery of the spare parts. -

Page 16: How Does The Sola-Tecs W Work

Basics How does the the gearbox housing. This converts the impact energy into mechanical work. Sola-Tecs W work? After the drive work, the water is used The Sola-Tecs W system consists of a to moisten and wash off the surface to brush roller with a gearbox housing on be cleaned. -

Page 17: How Does The Sola-Tecs W Pro Work

Basics How does the the gearbox housing. This converts the impact energy into mechanical work. Sola-Tecs W Pro work? After the drive work, the water is used The Sola-Tecs W Pro system consists to moisten and wash off the surface to of a brush roller with a gearbox housing be cleaned. -

Page 18: Components And Their Function

Basics Components and their function Gearbox housing right and left W / W Pro The gearbox housing is the drive unit of the cleaner. All components neces- sary for the drive of the brush rollers are installed here. The drive force is trans- mitted from the gearbox housing to the brush roller via a drive gear wheel. - Page 19 Basics W / W Pro Pendulum tube The pendulum tube reduces the trans- mission of vibrations and movements from the cleaner to the high-pressure hose, thereby reducing work fatigue. W / W Pro The guying system reinforces the con- nection between the high-pressure hose Guying system and the cleaner.

- Page 20 Basics W Pro Switch button The switch button changes the point of impact of the high-pressure water on the turbine wheel, thereby enabling the direction of rotation of the brush roller to be changed. In this way, the cleaner is pushed away from the operator or back towards him.

- Page 21 Basics W / W Pro Safety eyelet The safety eyelet on the connection pin is for attaching the safety rope, which is used to secure the cleaner to an anchor point to prevent it from falling off the roof. W / W Pro The eyelets on the profile tube are for attaching the guying system to the cleaner.

- Page 22 Basics Intended use Here you will find the following information: What is the cleaner to be used for, where can the cleaner be used, who can use the cleaner? BA 0304031 R00 2021-01...

-

Page 23: Intended Use

Space requirement Intended use � Space requirements for storage: The SOLA-TECS W and the SOLA-TECS 1.4 metres x 0.31 x 0.59 metres. W PRO are designed for cleaning pho- � The following work surface is tovoltaic modules in the commercial necessary: sector. -

Page 24: Working Width And Weight

Basics Working width and weight �Working widths with safety roller: - W800 > 1.1 metres - W1000 > 1.3 metres - W800 Pro > 1.1 metres - W1000 Pro > 1.3 metres � Weight of cleaner, safety roller, pendulum tube, guying system: - W800 >... -

Page 25: Ec Declaration Of Conformity

Basics EC Declaration of Conformity BA 0304031 R00 2021-01... -

Page 26: Safety Principles

Safety principles General safety instructions Important instructions for safe use of the system and for establishing safe cleaning operations. BA 0304031 R00 2021-01... -

Page 27: For Your Safety

Safety principles For your safety Important instructions for safe use of the system. This allows you to protect your- self and others from dangerous situations and injuries. DANGER Danger to life due to thunderstorms A Avoid using the machine during thunderstorms. This protects you from injury caused by lightning and from hypothermia. - Page 28 Safety principles CAUTION Risk of injury when lifting heavy parts �A When lifting the machine, lift it ergonomically correctly. This will protect you from back-strain injuries. CAUTION Risk of injury from overloading/strain �A Take regular breaks. This will prevent injuries caused by physical and mental overload and fatigue.

-

Page 29: Working Safely

Working safely Safe cleaning operation Here you will find information about: choosing a safe cleaning location, hazards in the working area, hazards when working. BA 0304031 R00 2021-01... -

Page 30: Working Safely

Working safely Working safely Safety when cleaning � When cleaning, make sure that you do not damage any components or lines. This section describes how to work safely with the Sola-Tecs W system. Checking and preparing high- pressure equipment Selecting a safe starting point �... - Page 31 Working safely WARNING CAUTION Electric shock from photovoltaics Risk of injury due to defective hoses and connections �ACables and components of photovoltaic installations are always �ACheck all high-pressure hoses and live during incidence of light. connections for damage. Touching live parts can lead to electric In this way you will protect yourself from shock and is prohibited.

-

Page 32: Commissioning

Commissioning Commissioning the Sola-Tecs W and W Pro Here you will find information about how to prepare the cleaner for work. BA 0304031 R00 2021-01... -

Page 33: Preparing To Connect The Cleaner

Commissioning Preparing to Opening the transport box connect the cleaner In this step, the Sola-Tecs W and W Pro are prepared for connection. W / W Pro Unpacking out of the shipping � Open the turn-lock fasteners on the lid of the transport box with a Removing the safety splint screwdriver. -

Page 34: Checking Cleaner For Defects

Commissioning � Remove the cleaner [1]. Removing the cleaner � Position the cleaner on a clean sur- face with the brush facing downwards. W / W Pro Checking cleaner for defects � Check the following for damage: � the connection pin �... -

Page 35: Checking The High-Pressure Filter In The Connection Pin Of The Cleaner And Pendulum Tube

Commissioning Info box The following Tool is required Also check: � the ropes and carabiners of the guying system � the drive, by lifting the cleaner by the gearbox housing and turning the brush roller (chopping noise) � visual inspection of the bristles on the brush roller W / W Pro Checking the high-pressure... -

Page 36: Transporting The Cleaner To The Place Of Use

Info box Commissioning The following Tool is required. Transporting to place of use W / W Pro Transporting the cleaner to the place of use � Plan in advance how you will trans- port the cleaner to its place of use. �... -

Page 37: Assembling The Pendulum Lance

Commissioning Info box The following Tool is required. W / W Pro Assembling the pendulum lance � Remove the yellow protective screw from the connection pin of the cleaner. � Grease the O-ring on the quick- action screw connection of the pendulum lance[9] �... -

Page 38: Assembling The High-Pressure Hose

Commissioning � Screw the union nut of the quick-action screw connection onto the connection pin so that the union nut clicks into place on the anti-twist protection [2]. W / W Pro Assembling the high-pressure hose � Unroll the high-pressure hose [3]. �... -

Page 39: Assembling The Guying System

Commissioning Info box The following Tool is required W / W Pro Assembling the guying system Assembling the guying system � Lay the components out ready. � 2 x rope with carabiner � 2 x hose clamp � 2 x inlay sheet [10] �... - Page 40 Commissioning � Attaching the hose clamp: � Place the high-pressure hose[1] one half of the hose clamp [9]. The two eyelets must face towards the cleaner. � Position one inlay sheet [10] on the right wing and one on the left wing in the same way.

- Page 41 Commissioning Info box The following Tool is required � Insert the cylinder head screws [11] in the hose clamp. Make sure that there are round and hexagonal holes: round for the head of the cylinder head screw and hexagonal for the lock nut [12]. �...

- Page 42 Info box Commissioning The following Tool is required � Remove the protective film from the hose protection tape [13] attach the hose protection tape [13] directly behind the hose clamp on the high-pressure hose. � Pull the hose clamp over the hose protection tape [13].

-

Page 43: Connecting The High-Pressure Hose To The High-Pressure Cleaner

Commissioning Connecting the high-pressure cleaner W / W Pro Connecting the high-pressure hose to the high-pressure cleaner � Take the already greased free end of the high-pressure hose and use the quick-action screw connection position it on the high-pressure outlet of the high-pressure cleaner [3]. -

Page 44: Switching High Water Pressure On/Off

Commissioning W / W Pro Water stop Switching the high water pressure on/off We offer two optional products for switching the high water pressure on/ off. These products are briefly pre- sented here. For the exact operation, please refer to the respective operating instructions. -

Page 45: Working

Working Working with the Sola-Tecs W and W Pro Here you will find information about working with the cleaning system. BA 0304031 R00 2021-01... -

Page 46: Working With The Sola-Tecs W

Working Working with the Setting the direction of rotation Sola-Tecs W Working with the cleaning system is described here: � How do I switch the direction of rotation on for the W PRO? � How do I position the SOLA-TECS W and W PRO on the surface to be cleaned? �... -

Page 47: Positioning The Cleaner At The Starting Point

Working W / W Pro Positioning the cleaner Positioning the cleaner at the starting point � Position the cleaner on the first module of the surface to be cleaned. � Make sure that the Sola-Tecs W Pro is set with the correct direction of rotation. -

Page 48: The Cleaning Process

Working W / W Pro Starting the cleaning process The cleaning process � Pull the cleaner up to the top edge of the module to clean it. � Push the cleaner to about the middle of the first module. � Lower the cleaner until the guide rollers are resting on the module. - Page 49 Working � Slowly release the cleaner at the Stopping the cleaner before the high-pressure hose to just before the lower module edge lower edge of the module strip. � Allow the cleaner to slide slowly over the lower edge of the module until it rests on the retraction aid [4].

- Page 50 Working � Pull the cleaner back over the edge Pulling back over the module edge of the module until the guide roller rests on the module again. � Pull the cleaner to the upper edge of the module strip. In the case of heavy soiling, you may need to clean a module strip again before you can move the cleaner to the next module.

-

Page 51: Switching Off The Cleaner

Working Stopping the cleaner W / W Pro Switching off the cleaner � Hold the cleaner at the connection of the high-pressure hose. � Lift the quick-action screw connection back up to waist height so that the cleaner is at an angle. �... - Page 52 Working � Turn the cleaner 180° [1]. Turning the cleaner 180° � Position the cleaner on the splash guard [2]. The splash guard is attached with plastic body screws. The cleaner sits in the park position on these body screws. This way you can also park the cleaner on a module without it causing any damage.

-

Page 53: Additional Option To Prevent The Cleaner From Falling

Working W / W Pro Eyelet on the retaining plate Additional option to prevent the cleaner from falling � Hook the carabiner of the safety rope onto the eyelet of the connec- tion pin retaining plate [5]. � Release the cleaner on the module strip. - Page 54 Working � Release the cleaner all the way to the Releasing the cleaner end of the module strip. � Attach the end of the safety rope to a suitable anchor point with an allow- ance of approx. 1-2 metres. A suitable anchor point must provide sufficient stability.

-

Page 55: Taking Out Of Operation

Taking out of operation Taking the Sola-Tecs W and W Pro out of operation Information about disassembling the cleaning sys- tem can be found here. BA 0304031 R00 2021-01... -

Page 56: Disassembling The Guying System

Taking out of operation Disassembling the guying system W / W Pro Disassembling the guying system Components that are disassembled: � 2 x rope with carabiner Only the ropes with the carabiners are unhooked. The mounted hose clamp can remain on the high-pressure hose. Disassembly: �... -

Page 57: Disassembling The High-Pressure Hose

Taking out of operation W / W Pro Disassembling the high-pressure hose Disassembling the high-pressure hose � Pull the locking tab of the screw-on lock towards the rubber buffer [2]. � Unscrew the union nut of the quick-action screw connection from the connection on the pendulum tube. - Page 58 Taking out of operation � Unscrew the union nut of the Disassembling the high-pressure hose quick-action screw connection from the connection on the high-pressure cleaner. � Close the connection of the pen- dulum tube with the protective screw cap [3]. �...

-

Page 59: Disassembling The Pendulum Tube

Taking out of operation Disassembling the pendulum tube W / W Pro Disassembling the pendulum tube � Pull the locking tab of the screw-on lock towards the profile tube [5]. � Unscrew the union nut of the quick-action screw connection from the connection on the cleaner. -

Page 60: Pushing Guide Rollers Into The Park Position

Info box Taking out of operation The following Tool is required. Guide rollers in park position W / W Pro Pushing guide rollers into the park position � Use hex key 6 to open the cylinder head screw [2]. � Slide the guide roller inwards. -

Page 61: Taking The Cleaner Off The Roof

Taking out of operation Removing from the roof W / W Pro Removing the cleaner from the roof � Plan in advance how you will trans- port the cleaner from its place of use. � Consider using possible transport aids to assist safe transport and to prevent putting yourself or the cleaner at risk. -

Page 62: Transport And Storage

Transport and storage Transport and storage Here you will find information about transporting and storing the system. BA 0304031 R00 2021-01... -

Page 63: Transporting And Storing The Cleaner

Info box Transport and storage The following Tool is required Transporting and Checking the high-pressure filter storing the cleaner This section explains how to transport and store the cleaner safely and without damage. W / W Pro Checking the high-pressure filter in the connection pin of the cleaner and pendulum tube �... -

Page 64: Allow Water To Run Out Of The Cleaner

Transport and storage Water from the cleaner – connection pin W / W Pro Allow water to run out of the cleaner � Hold the cleaner with the opening of the connection pin facing down- wards. Let the water drain until it is only just dripping. -

Page 65: Preserving The Cleaner

Transport and storage CAUTION W / W Pro Preserving the cleaner Risk of injury due to defective hoses and connections To protect and maintain the system over the storage period, preserve the com- �ACheck all high-pressure hoses and ponents before storing them. connections for damage. -

Page 66: How To Stow The Cleaner Correctly In The Transport Box

Transport and storage W / W Pro Putting the cleaner into the transport box How to stow the cleaner correctly in the transport box To stow the cleaner in the transport box, proceed as follows: � Turn the cleaner and the brush roller towards the transport lock [3]. -

Page 67: Closing The Transport Lock

Transport and storage W / W Pro Closing the transport lock Closing the transport lock � Fold the transport lock down. � Insert the locking pin into the locking holes. � Secure the locking pin with the spring pin [10]. Closing the transport lock Securing the locking pin CAUTION... -

Page 68: How To Seal The Box

Transport and storage W / W Pro Putting the lid on How to seal the box � Put the lid � Make sure that the rim of the lid rests in the body of the box. � Turn the lock by 90°... - Page 69 Notes Notes BA 0304031 R00 2021-01...

-

Page 70: Disposal

Disposal Disposing of the system Information about disposal of the product and the associated components can be found here. BA 0304031 R00 2021-01... -

Page 71: What Happens With The Waste

Disposal What happens with the waste? Packaging � The packaging is made of wood and metal and can be recycled. Resin for ultra-pure water production � Please refer to the safety data sheet for disposal regulations. Gearbox housing, gearbox parts, plastic parts, guying system and brush roller �... - Page 72 Cleantecs GmbH | Grundweg 10 | 89250 Senden | +49 (0)7307 - 9265 0 | info@cleantecs.de | www.cleantecs.com...

Need help?

Do you have a question about the SOLA-TECS W BJ 2010 Series and is the answer not in the manual?

Questions and answers