Table of Contents

Advertisement

Quick Links

Using the Vise Kit

• To ensure safe use with a full understanding of this machine's performance, please be sure to read

through this manual completely.

• Store this manual in a safe place where it can be referred to when needed.

• Reproduction, citation, or translation, in whole or in part, of this manual is prohibited without the

express written consent of DGSHAPE Corporation.

• The contents of this operation manual and the specifications of this product are subject to change

without notice.

• DGSHAPE Corporation assumes no responsibility for any damage that may occur through use of

this product, regardless of any failure to perform on the part of this product or of any errors in this

document. Damage includes but is not limited to damage caused by the specifications or performance

of the product, damage caused by non-use of the product, and damage caused by deliverables obtained

through use of this product. Such damage can be either direct or indirect.

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for DGSHAPE VL-300

- Page 1 • The contents of this operation manual and the specifications of this product are subject to change without notice. • DGSHAPE Corporation assumes no responsibility for any damage that may occur through use of this product, regardless of any failure to perform on the part of this product or of any errors in this document.

-

Page 2: Table Of Contents

Cleaning the Adhesive Sheet ...........................12 Cleaning the Film Frame ............................13 Location of Serial Number Label ................14 Center Vise ................................14 Grid Table.................................14 Company names and product names are trademarks or registered trademarks of their respective holders. Copyright © 2020 DGSHAPE Corporation https://www.dgshape.com/... -

Page 3: Getting Started

Getting Started What This Document Assumes • This document describes how to use the LD-300 VISE KIT. • Refer to the LD-300 User's Manual for information such as important notes and basic usage guidelines for using the LD-300. Features The VISE KIT includes a center vise that can be used to secure pens and other such three-dimensional objects that cannot be secured using the material retainers included with the machine, allowing for imprinting to be performed on products having a variety of shapes. -

Page 4: Material Conditions

Getting Started Material Conditions In order for a material to be used for imprinting, the material must meet all of the following conditions. Material • Acrylic • Polypropylene • Polystyrene • ABS • Leather • Polyurethane • Vinyl chloride Thickness Maximum: 26 mm (1.02 in.) * Height from the base table to the upper surface of the material loaded on the VISE KIT: 50 mm (1.96 in.) or less Size... - Page 5 Getting Started Conditions for Material When Imprinting Curved Surfaces The table and figure below show the recommended imprint area with respect to the diameter of the cylinder formed from an extended curved surface. Note, however, that the following conditions are assumed. Material with an extended curved surface has circularity.

-

Page 6: Center Vise Specifications

Getting Started Center Vise Specifications The maximum width of loadable material is 50 mm (1.96 in.). Change the loading orientation and secure the material in a way that matches its size. You can vary the orientation and front and back sides of the vise when using it. "... -

Page 7: Vise Kit Explanation

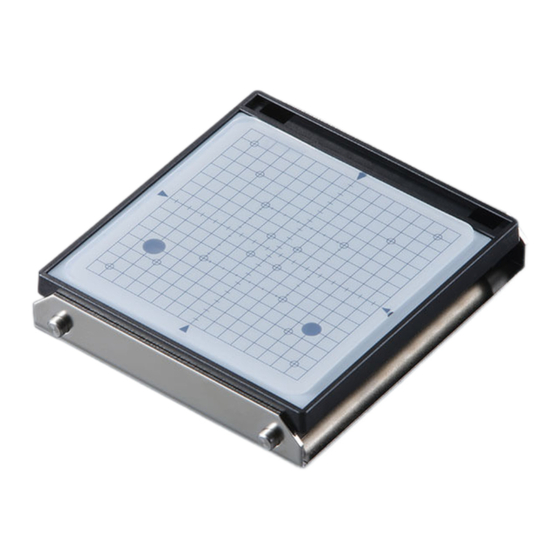

Vise Kit Explanation Material Retainer Types Center vise Vise Clamp plates Retaining screw Grid table Adhesive sheet Grid table Selecting Material Retainers according to Material Shapes Retainers have various characteristics. Select the retainer that matches the material shape. The grid table is suited to securing material that has a flat bottom surface. The center vise is suited to securing material that has a curved bottom surface. -

Page 8: How To Secure Material

Vise Kit Explanation Material shape Retainer Clamp plates (center vise) " P. 4 "Conditions for Material When Imprinting Curved Surfaces" Grid table Grid table Grid table How to Secure Material Center vise • Use the resin vise to clamp the material and secure it. You can use the center vise to secure material that has a curved bottom surface. - Page 9 Vise Kit Explanation • You can vary the orientation and front and back sides of the vise when using it. Use the vise in a way that matches the size and shape of the material. The vise can be replaced with clamp plates. You can also vary the orientation and front and back sides of the clamp plates when using them.

-

Page 10: Light-Absorbing Film

Vise Kit Explanation Light-absorbing Film To use the light-absorbing film, attach it to the film frame. Orient the film frame so that the adhesive sheet surface faces up. Peel the protective film off the adhesive sheet. Protective film Affix the light-absorbing film to the film frame. Important: The light-absorbing film has a material side and a lens side. -

Page 11: Mounting On The Ld-300

Vise Kit Explanation Mounting on the LD-300 Insert the protrusions on the bottom surface into the holes on the base table to attach the center vise or grid table. To attach the film frame, insert its supports into the holes on the base. Important When not using the base, store it after removing it from the machine. -

Page 12: Selecting The Head Detection Jig

Vise Kit Explanation Selecting the Head Detection Jig Use different head detection jigs depending on the height from the base table to the imprinting surface. Important: Use the head detection jig with the correct height. If you use the incorrect jig, the head will strike the material, leading to defective imprinting and part damage. Height to the imprinting surface Head detection jig to use 24 to 36 mm... -

Page 13: Daily Care

Daily Care Cleaning the Center Vise/Grid Table Using a cloth moistened with water and wrung well, wipe the parts gently to clean them. Cleaning the Adhesive Sheet Buildup of dust or the like on the grid table's adhesive sheet can reduce the sheet's adhesive force, making it difficult to secure material. -

Page 14: Cleaning The Film Frame

Daily Care Cleaning the Film Frame Buildup of dust or the like on the film frame's adhesive sheet can reduce the sheet's adhesive force, making it impossible to secure the light-absorbing film. If the adhesive force has been reduced, wash the film frame's adhesive sheet. -

Page 15: Location Of Serial Number Label

Location of Serial Number Label Center Vise Position where the label is affixed Grid Table Position where the label is affixed... - Page 16 FA02211 R1-200608...

Need help?

Do you have a question about the VL-300 and is the answer not in the manual?

Questions and answers