Table of Contents

Advertisement

Quick Links

Installation, Maintenance, and Repair Manual

Colt

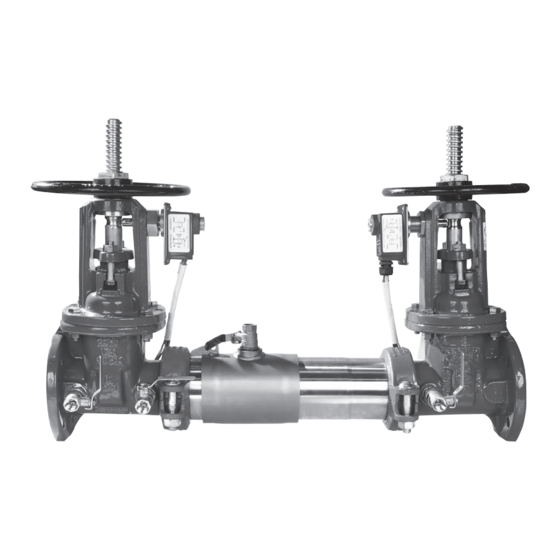

Series C200, C300, LFC300

™

Double Check Valve Assemblies

Double Check Detector Assemblies

Sizes: 2

⁄

" – 10"

1

2

WA R N I NG

!

Read this Manual BEFORE using this equipment.

Failure to read and follow all safety and use information

can result in death, serious personal injury, property

damage, or damage to the equipment.

Keep this Manual for future reference.

WA R NI N G

!

You are required to consult the local building and plumbing

codes prior to installation. If the information in this manual

is not consistent with local building or plumbing codes,

the local codes should be followed. Inquire with governing

authorities for additional local requirements.

WA R N I NG

!

Need for Periodic Inspection/Maintenance: This product must

be tested periodically in compliance with local codes, but at least

once per year or more as service conditions warrant. If installed on

a fire suppression system, all mechanical checks, such as alarms

and backflow preventers, should be flow tested and inspected in

accordance with NFPA 13 and/or NFPA 25. All products must be

retested once maintenance has been performed. Corrosive water

conditions, and/or unauthorized adjustments or repair could render

the product ineffective for the service intended. Regular checking

and cleaning of the product's internal components helps assure

maximum life and proper product function.

Testing

For field testing procedure, refer to Ames installation sheets

IS-A-ATG-1 at watts.com..

For other repair kits and service parts, refer to the Backflow

Prevention Products Repair Kits & Service Parts price list

PL-A-RP-BPD at watts.com..

For technical assistance, contact your local Ames representative.

Integrated supervisory tamper switches on

gate valves add protection against fire

NOTICE

Inquire with governing authorities for local installation

requirements.

NOTICE

For Australia and New Zealand, line strainers should be installed

between the upstream shutoff valve and the inlet of the backflow

preventer.

It is important that this device be tested periodically in

compliance with local codes, but at least once per year or more

as service conditions warrant. If installed on a fire sprinkler

system, all mechanical checks, such as alarm checks and

backflow preventers, should be flow tested and inspected

internally in accordance with NFPA 13 and NFPA 25.

NOTICE

Due to shipping, storage, and general handling, the Victaulic

Coupling for the shutoff valves may have loosened and should be

retightened during installation.

RP/IS-A-C200/C300

C200-OSY-TS

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Watts Ames Colt Series

- Page 1 For field testing procedure, refer to Ames installation sheets compliance with local codes, but at least once per year or more IS-A-ATG-1 at watts.com.. as service conditions warrant. If installed on a fire sprinkler For other repair kits and service parts, refer to the Backflow system, all mechanical checks, such as alarm checks and Prevention Products Repair Kits &...

- Page 2 (For Installation of Fire Alarm Systems Assure All Devices Are Properly more information refer to Tamper Switch Wiring Instructions at Grounded. watts.com.) CAUTION Wiring Notes • Connection to power limited circuitry is required.

- Page 3 Maintenance Instructions 2 ⁄ " – 6" Figure A Figure C Figure B Figure F Figure D Figure E WARNING 5. Repeat step 4 to remove check module No. 2. (For servic- ing 6" checks, see the maintenance instructions for 8"–10" Before servicing any Ames valve, it is mandatory to shut down checks on p.

- Page 4 Maintenance Instructions 8" – 10" Material/Tool Requirements • No. 4 Phillips screwdriver or " diameter rod, length suf- ficient to span diameter of check (See Figures A and B.) • – 13" x 5" fully threaded hex bolt (Service bolt) •...

- Page 5 Testing Double Check Valve Assemblies Test for Leaky No. 2 shutoff Test Check Valve No. 1 1. Connect the high side to test cock No. 1, the low side to test 1. Ensure shutoff No. 1 is open, and shutoff No. 2 is closed. cock No.

- Page 6 7. Closure Sleeve 5. E-clip and Clevis Pin 4. Elastomer Shutoff Disc 1. First Check Module 2. Second Check Module For repair kits and parts, refer to the Backflow Prevention Products Repair Kits & Service Parts price list PL-A-RP-BPD at watts.com.

- Page 7 Notes...

- Page 8 USA: Backflow T: (978) 689-6066 • F: (978) 975-8350 • AmesFireWater.com USA: Control Valves T: (713) 943-0688 • F: (713) 944-9445 • AmesFireWater.com Canada: T: (888) 208-8927 • F: (905) 481-2316 • AmesFireWater.ca Latin America: T: (52) 55-4122-0138 • AmesFireWater.com RP/IS-A-C200/C300 2218 EDP#7018382 © 2022 Watts...

Need help?

Do you have a question about the Ames Colt Series and is the answer not in the manual?

Questions and answers