Table of Contents

Advertisement

Quick Links

Operators & Parts

Manual

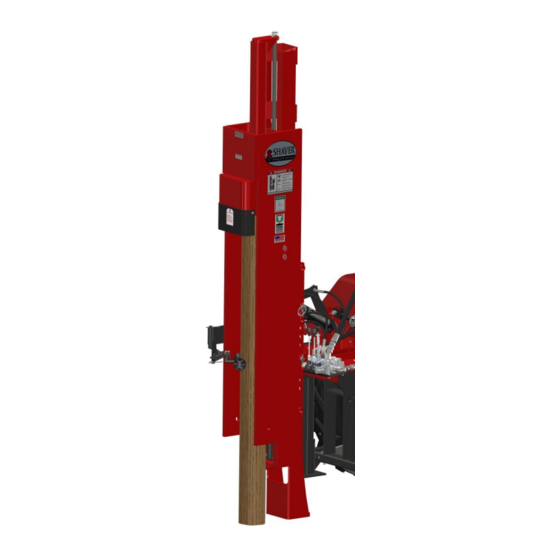

"Grand Slam"

Springless

Post Driver

Model HD-12-S-S

Safety

Operation

Maintenance

Repair

Troubleshooting

Parts

2015 and Newer Drivers

Shaver Manufacturing Company

103 South Washington Avenue, Graettinger, Iowa 51342

Phone: (712) 859-3293 — Fax: (712) 859-3294 — www.shavermfg.com

1

Advertisement

Table of Contents

Summary of Contents for Shaver Grand Slam

- Page 1 Operators & Parts Manual “Grand Slam” Springless Post Driver Model HD-12-S-S Safety Operation Maintenance Repair Troubleshooting Parts 2015 and Newer Drivers Shaver Manufacturing Company 103 South Washington Avenue, Graettinger, Iowa 51342 Phone: (712) 859-3293 — Fax: (712) 859-3294 — www.shavermfg.com...

-

Page 2: Table Of Contents

Seal Replacement ........31 Contents Spring Replacement ........ 31 Safety .............3 Post Driver Reassembly ......31 General ............4 Forward and Side Tile Cylinder Seal Safety Alert Symbols ........4 Replacement ........... 33 Safety Icon Nomenclature ......5 Three-Point Hitch/Post Driver Assembly . . 33 Safety Warnings .......... -

Page 3: Safety

Improper operation and maintenance of this implement could result in a dangerous situation that could cause injury or death. Do not assemble, operate, or maintain the Shaver Post Driver until you read understand information contained in this manual. Safety precautions and warnings are provided in this manual and on the product. -

Page 4: General

If you have any questions not answered in this manual or require additional copies or the manual is damaged, please contact your dealer or Indicates an imminently hazardous situation Shaver Manufacturing Company which, if not avoided, will result in death or 103 South Washington Avenue P.O. Box 358 serious injury. -

Page 5: Safety Icon Nomenclature

Safety Icon Nomenclature Read the manual Eye protection Foot protection Hand protection Hearing protection Inspect equipment Two person operation Warning decal alert Bending hazard (hydraulic hose) Crushing hazard Crushing hazard (hand) Do not weld Electrocution hazard Explosion hazard High-pressure fluid hazard Impact hazard (hydraulic hose) Pressurized fluid Projectile hazard (body) -

Page 6: Safety Warnings

Post Driver. While transporting, applicable manuals. Contact Shaver never ride on or permit others to ride on the Manufacturing Company if Post Driver. instructions provided are unclear or not understood. -

Page 7: Hydraulic Hoses

WARNING WARNING Do not drop heavy objects on Potential pinch points. hoses. A sharp impact may cause Keep hands clear of Post internal damage to the hose. Driver while operating. Applying pressure to a damaged Never place hand(s) on hose may cause it to rupture, resulting in top o f a post when inserting it into the personal injury. -

Page 8: Introduction

Introduction The Shaver Manufacturing Company would like to congratulate you on your purchase of the Shaver Hydraulic Post Driver. You have selected the best Post Driver in its class. The clean design and uncomplicated working principle have made Shaver the largest selling Post Driver in the country. -

Page 9: Safety Sign Locations

Safety Sign Locations Driver Safety Signs and Informational Labels Item Part Number Description MS-162 Decal, Danger Instructions MS-165 Decal, Danger Safety Arm Attachment MS-163 Decal, Warning Pinch Point MS-181 Decal, Warning Pinch Point MS-171 Decal, Warning High Pressure Hydraulics MS-105 Decal, Important Valve Instructions MS-166 Decal, Important Leave Arm Open... -

Page 10: Safety Signs

Safety Signs 1. MS-162 – Decal, Danger Instructions 2. MS-165 – Decal, Danger Safety Arm Attachment 7. MS-166 – Decal, Important Leave Arm Open 8. SM-0011-ST –Tag, Caution Springs 3. MS-163 – Decal, Warning Pinch Point 4. MS-181 – Decal, Warning Pinch Point 9. -

Page 11: Assembly Procedure

Assembly Procedure Assembly - General Unpacking NOTE: Refer to the Service Parts section of this manual for an illustration and description of all the WARNING parts. The Main Carriage Channel has provisions for Due to the size and weight of the mounting the Base Plate in three positions. -

Page 12: Mounting Instructions

with two (2) each 1/2" bolt, lock washer and Mounting Instructions nut (items 9, 10, & 11). Attach the Rear-Mounted (3-Point Hitch) Pump/Motor/Reservoir (item 2) by lining up the slots in the Pump/Motor/Reservoir with 1. Place three-point hitch weldment upside slots in the Universal Mounting Bracket and down on the floor. -

Page 13: Base Plate

Base Plate IMPORTANT NOTICE NOTE: Hydraulic base plate installation is shown. Installation of manual base plate is The following hydraulic fittings and hoses similar. require a paste type sealer. Do not use a tape-type sealer, such as Teflon Tape, as this 1. -

Page 14: Attaching Driver To Base Plate

Ensure the oil is clean and properly filtered before connecting the Post Driver to a hydraulic power source. Failure to follow oil cleanliness standards voids the Shaver Post Driver warranty. Proper lifting device (large arrow above) when attaching Driver to Base... -

Page 15: Triple Lever Control Valve For Hydraulic Base Plate

Triple Lever Control Valve for Hydraulic 3. Screw in hydraulic fittings (items 7, 8, & 9) as Base Plate shown above. The 45° SAE#10MORB- (Item 7) goes into ‘A3’ 3/4FNPT Adapter working port on top of the valve. The 90° 1. - Page 16 from the ‘A2’ port of the valve and the base end hose (item 6d) goes to the 45° fitting from the ‘B2’ port of the valve. IMPORTANT NOTICE If the tilt cylinder hoses are attached differently than shown, the control of the drive ram will not be as described in this manual.

-

Page 17: Rubber Debris Guard

Rubber Debris Guard 1. Locate rubber debris guard and bag containing rivets and caution tag. UPPER MIDDLE LOWER Rubber Debris Guard mounting. 2. Attach Rubber Guard and Caution Tag on Safety Arm Mounting holes shown above drive ram, with guard rivets shown above. 2. - Page 18 6. Install the Swing Arm A ssembly. a. Apply a light film of good quality grease to the pivot shaft on Swing Assembly. b. Slide the pivot shaft into the tube on the Safety Arm Mounting Bracket and secure with cotter pin as shown above. c.

-

Page 19: Document Storage Tube

Document Storage Tube Manual Storage Tube & mounting rivets. 1. If desired, locate the document storage tube in a convenient location on the . Concrete Breaker CB-3 for HD-12 is shown mounted Post Driver. The photo below shows the tube mounted on the base plate, but 2. -

Page 20: Post Driver Operation

2. Secure with supplied mounting hardware wood or steel posts. Maximum driving as shown below. impact is not necessary. 11. Always be aware of the environment in which you are operating the Post Driver. 12. Do not operate the Post Driver on steep slopes, as this could cause a roll over. -

Page 21: Operating Instructions

hose (larger diameter) to hydraulic fill Operating Instructions port/tube. 3-Point Hitch Mounting 1. With the Post Driver positioned on a hard level surface, move the tractor or other power supply toward the Post Driver until the three-point hitch lines up. Pressure Hose 2. -

Page 22: Self-Contained Mounting

1. Position the tractor or power source in place Operating Instructions to drive the first fence post. Self-Contained Mounting 2. Set the brakes on the tractor or power supply. If the machine is equipped with an 1. With the Post Driver positioned on a hard automatic transmission, the transmission level surface, move the skid loader or must be in PARK. -

Page 23: Driving A Post

Driving a Post 1. Lubricate guide bars with clean oil before each daily use and, if necessary, between post installations. IMPORTANT NOTICE Do not use grease on the guide bars or in the main carriage channel. Grease will retain abrasive material, which will result in premature wear. - Page 24 3. Pull up Safety Latch and push Main Hydraulic Control Lever to lower Drive Ram. To avoid personal injury or death, do not operate the Post Driver by yourself. Always have another person to control the machine or power source. NOTE: For operation of valve control levers refer to the illustration below.

- Page 25 NOTE: There should be a 1” to 2” gap between the top of the fence post and the bottom of the drive ram hammer Potential Pinch Points. plate. Never drive a fence post without Keep hands clear of Post the rubber debris guard in place. Driver while o p e r a t i n g .

- Page 26 7. To drive the fence post straight, adjust the main carriage channel side-to-side and fore- and-aft using manual cranks (manual base plate) or second and third hydraulic control valve levers (hydraulic base plate). Tilt top of Drive Ram away from tractor/skid loader pull middle lever toward operator.

-

Page 27: Dismounting Post Driver

8. Pull up Safety Latch and pull back Main IMPORTANT NOTICE Hydraulic Control Lever to raise Drive Ram. Posts will drive into the ground much straighter using shorter strokes. Use caution when driving small diameter wood and steel posts. Maximum impact is not necessary with these smaller diameter posts and can... - Page 28 2. Raise or lower the storage legs (small arrows) to allow drive ram I-beam (large arrow) full contact with the ground. Make sure the Post Driver is stable. Cylinder Scissor Stop Bolt. NOTE: Failure to tighten this bolt could allow the Post Driver to fall over, causing serious injury or even death.

-

Page 29: Service Procedures

Contact Shaver Manufacturing Company if instructions provided are unclear or not understood. Proper care is your responsibility. Always follow all State and Federal health and safety laws and/or local regulations. -

Page 30: Post Driver Disassembly

Post Driver Disassembly Springless Post Driver shown horizontally on suitable stands. NOTE: The upright assembly is heavy. Use an Driver Cylinder removal. appropriate lifting device to position the Post 4. Remove the Drive Cylinder by sliding it out Driver assembly horizontally, on suitable stands (see above), pallet, or blocks on the ground. -

Page 31: Seal Replacement

7. Replace the Piston Guide and Piston Guide Drive Cylinder Seal Nut. Replacement 8. Replace the Cylinder Cap & Piston Rod into NOTE: Follow the disassembly instructions the Cylinder Tube. Use a paste type thread for the Post Driver until the Cylinder is out sealer, DO NOTE USE A TAPE SEALER as of Driving Ram. - Page 32 engage the threads, as shown below. a. Tighten drive cylinder self-locking nuts that were left loose in Step 6. Tighten each nut slightly, in turn, to align the Drive Cylinder inside the Main Carriage Channel. Align the Drive Ram Cylinder. a.

-

Page 33: Forward And Side Tile Cylinder Seal Replacement

WARNING Forward and Side Tilt Cylinder Seal Replacement Main Carriage Channel Assembly is tall and heavy. To WARNING avoid tip over, resulting in serious injury or death, leave the overhead Removing tilt cylinder(s) from the lifting device attached to the Main assembled Post Driver can cause Carriage Channel while assembling an unstable condition. -

Page 34: Storage

1. Before storing, remove debris and clean the entire unit with compressed air or pressure washer. 2. Inspect the Shaver Post Driver. Replace any worn or damaged parts before using the Post Driver again. • Check all bolted connections. Ensure that fasteners are tight, and all pins are secured in place. -

Page 35: Troubleshooting

Troubleshooting Troubleshooting Chart Problem Possible Cause Remedy Drive Ram will not move or Slide Guide Bars lack lubrication Lubricate with clean engine oil or spray freely in Main Carriage Channel. lubricant. Incorrect clearance between Main Refer to Service Information section Carriage Channel and Drive Ram I-Beam. -

Page 36: Service Parts

Service Parts Driver Assembly SM-1212S-DRC - Ram Assembly, HD-12 Driver Stabilized Qty. Part No. Description Item SM-1212-DRO Ram Assembly, Driving, Only, HD-12 SM-1212S-MCC Main Carriage Channel, HD-12 Stabilized SM-1026-S Cylinder Assembly, Complete HD-10/12 SM-10267 Locknut, Piston, 1-8 Nylon SM-1212-9 HD-12-S Road Lock Plate SM-1041-RLC Clip, Road Lock SM-1041-RLP... -

Page 37: Rubber Guard Assembly

Rubber Guard Assembly SM-1211-G – Rubber Guard Kit HD-8/10/12 Item Qty. Part No. Description SM-1211-G3 Shield, Rubber 6” x 14-3/4” SM-0011-ST Tag, Caution Springs OPMAN-RIVET Rivet, 3/16” 5/8” to 3/4"... -

Page 38: Safety Arm Assembly

Safety Arm Assembly SM-0011-SAA - Safety Arm Assembly Qty. Part No. Description Item 300106 Pin, Cotter 3/16 x 2-1/2 300148 Pin, Roll 1/4 x 1-1/2 300167 Nut, Lock 3/4-10 Nylon Hex Zn 300172 Bolt, Tap 3/4-10 x 2 Hex Head Gr5 Zn MS-165 Decal, Danger Safety Arm Attachment MS-166... -

Page 39: Hydraulic Base Plate Assembly

Hydraulic Base Plate Assembly Qty. Part No. Description Item HBP-912111 HD-12 Hydraulic Base Plate Assembly (Includes mounting hardware) HBP-912115 Plate Weldment, Base, Hyd. HD-10 HBP-91217 Cylinder, Hyd. Forward Tilt HBP-912177 Seal Kit, 2-1/2” Tilt Cylinder (Not Shown) HBP-91218 Cylinder, Hyd. Side Tilt HBP-912177 Seal Kit, 2-1/2”... - Page 40 Hydraulic Base Plate Valve & Hose Assembly Item Qty. Part No. Description V-03-SP Valve – 3 Spool SM-003-VBP Plate, Valve Bracket V-03 Adapter, 90° SAE #12MORB – 3/4FNPT SC-50-H52 Adapter, 90° SAE #10MORB – 1/2NPSM SC-2550-C Adapter, 45° SAE #10MORB – 3/4FNPT F-6902-10-12 Adapter, 90°...

-

Page 41: 3-Point Hitch Assembly

3-Point Hitch Assembly MB-1201-A - Bracket Assembly, CAT-II 3-Point Mounting w/Stands (HD-10/HD-12) Part No. DESCRIPTION Item MB-1201-AA Bracket Wldt., 3-Point Mounting CAT-2 MB-1201A-12 Pin, Top 3-Point OS-4-22 Stand Package, Manual 300106 Pin, Cotter 3/16 x 2-1/2 OS-4-22 - Stand Package, Manual Part No. -

Page 42: 3-Point Hitch Cat Iii

3-Point Hitch Assembly MB-1301-A - Bracket Assembly, CAT-III 3-Point Mounting w/Stands (HD-10/HD-12) Part No. DESCRIPTION Item MB-1301-AA Bracket Wldt., 3-Point Mounting CAT-3 OS-4-22SFA Leg Wldt., Storage Stand MB-1201A-12 Pin, Top 3-Point 300106 Pin, Cotter 3/16 x 2-1/2 300218 Screw, Cap 5/8-11 x 1-3/4 Hex Head Gr5 Zn (included in MB-1301-A) Skid Steer/Loader Mounting Assembly MBS-77-20 - Bracket Assembly, Universal Mounting Part No. -

Page 43: Hydraulic Control Valves

Hydraulic Control Valves Multiple Control Lever Valves V-03-SP Valve – 3-Spool (shown) & V-04-SP Valve – 4-Spool Qty. Qty. Part No. Description Item V-03-SP V-04-SP UTD-G38DARV Valve, Main Relief , Direct Acting 1800-3000 PSI (set at 2538 PSI) UTD-G38SCK Spring Kit, Centering UTD-G38SL Handle, Safety Lever UTD-G38H... -

Page 44: Self-Contained Mounting Package

Self-Contained Hydraulics OH-101 - Self-Contained Mounting Package Less Bracket Qty. Part No. DESCRIPTION Item OH-101-2B Frame Weldment, Reservoir Bracket. OH-101-1 Self-Contained Mtg. Pkg. Less Brkt. 300326 Screw, Cap 1/2 -13 x 3 Hew Head Gr5 Zn 300101 Washer, Lock 1/2 Zn 300102 Nut, Hex 1/2-13 Zn 300189... -

Page 45: Pump/ Motor Kit

Self-Contained Hydraulics OH-101-1 – Pump/Motor Kit, Part No. DESCRIPTION Item 700109 Adaptor, 90° SAE#16MJIC- 1” MNPT 700110 Adaptor, Straight SAE#16MORB- #8FORB 700111 Adaptor, 90° SAE#16MJIC- #20MORB 700112 Adaptor, 45° SAE#8MORB- 1/2” FNPT CT-FC10 Valve, Check, SAE #10 Inline OH-101-1F2 Cap, Breather OH-101-1H Hose Assy., Hyd. -

Page 46: Driver Cylinder Assembly

Driver Cylinder Assembly SM-1026-S - Cylinder Assembly, Complete HD-10/12 Qty. Part No. Description Item 300111 Screw, HSSS 5/16-18 x 5/16 SM-0269 Nut, 1/2 F. Piston Guide, HD-8/10 SM-0936C Nut, Cylinder Coars Machine SM-02610 Guide, Piston, HD-8/10 SM-10261-S Tube Wldt., Cyl. HD-10/12 SM-10262 Cap &... -

Page 47: Attachments-Pilot Augers

Attachments – Pilot Augers SM-1201-PA4 – Auger Assembly, 4” Pilot & SM-1201-PA6 – Auger Assembly, 6” Pilot Item Qty. Qty. Part No. Description SM-1201-PA4 SM-1201-PA6 UTD-12PAN Plate Assembly, Auger Mounting HD-12 SM-1011-PA Motor & Hose Assembly Auger Assembly, 4” w/1” Coupler SA-304-ACC Auger Assembly, 6”... -

Page 48: 6" Auger Fish Tail & Tooth Assembly

Attachments – Pilot Augers 6” Auger Fish Tail & Tooth Assembly Qty. Part No. DESCRIPTION Item SA-304-PF Auger Point Fish Tail SA-6230 Auger Teeth 300236 Screw, Cap 1/2-13 x 3 Hex Head Gr2 Zn 300326 Screw, Cap 1/2-13 x 2 Hex Head Gr5 Zn 300101 Washer, Lock 1/2 Zn 300102... -

Page 49: Motor & Hose Assembly

Attachments – Pilot Augers SM-1011-PA – Motor & Hose Assembly Qty. Part No. DESCRIPTION Item SM-1011-PAHM Motor, Hydraulic F-1501-08 Fitting, 90° SM-0234-R Hose Assy., Hyd. 1/2" x 120” 8MXMS 100R2 SD-510-83 Fitting, Swivel SK-10-3P5A Fitting, 45° TU-13-2512D Fitting, 90° 300101 Washer, Lock 1/2 Zn 300361 Screw, AHSS 1/2 -13 x 1-1/2 Gr5 Zn... -

Page 50: Attachments-Concrete Breakers

Attachments – Concrete Breakers CB-3 - Concrete Breaker HD-12 Item Qty. Part No. Description 300107 Nut, Hex 5/8-11 Zn 300216 Washer, Lock 5/8 Zn 300251 Screw, Cap 5/8-11 x 2 Hex Head Gr5 Zn Attachments –Post Holders SM-2-PH – Post Holder (Discontinued 2004) Part No. -

Page 51: Attachments-Steel Post Holders

Attachments – Steel Post Holders Part No. Description Item SM-1211-PH Steel Post Holder SM-1211-PHSQ Square Steel Post Holder Attachments – Stabilizer Extension SM-1226 - HD-12-S Stabilizer Extension (Springless) Qty. Part No. Description Item SM-1226-SEW Extension Weldment, Stabilizer, HD-12-S MS-517 Decal, Warning Do Not Lower H-Beam Past 300326 Screw, Cap 1/2-13 x 2 Hex Head Gr5 Zn 300101... -

Page 52: Replacement Decals

Decal, Important Valve Instructions MS-166 Decal, Important Leave Arm Open SM-0011-ST Tag, Caution Springs MS-180 Decal, Cylinder Nut MS-161A Decal, Shaver Logo Large MS-280 Decal, FEMA Member Large MS-USA Decal, Made in the USA w/Flag MS-220 Paint, Black Spray MS-230... -

Page 53: Warranty Card

Product model number Please make a copy of this WARRANTY REGISTRATION form for your records and return the original. This form must be completed and returned to Shaver within 30 days from receipt of delivery or warranty may become void. - Page 54 This page left intentionally blank.

-

Page 55: Limited Warranty

RGA will be provided. This warranty shall not be interpreted to render Shaver liable for injury or damages of any kind or nature to person or property. This warranty does not extend to the loss of crops, loss because of delay in harvesting, or any expense or loss incurred for labor, substitute machinery, rental, or for any other reason. - Page 56 SHAVER Post Drivers November 2015...

Need help?

Do you have a question about the Grand Slam and is the answer not in the manual?

Questions and answers