Summary of Contents for Allison Transmission 3000 Series

- Page 1 3000 and 4000 Series Allison 5th and 6th Generation Controls OPERATOR’S MANUAL OM8491EN...

- Page 2 4000 ORS 4600 ORS B 400 T3325 xFE™ 3200 SP 4000 RDS 4700 B 500 T3375 xFE™ 3200 TRV 4000 SP 4700 EVS B3400 xFE™ 3500 4000 TRV 4700 OFS T 260 Copyright © 2021 Allison Transmission, Inc. All Rights Reserved.

-

Page 4: Important Safety Information

These warnings and cautions are not exhaustive. Allison Transmission could not possibly know, evaluate, or advise the service trade of all conceivable procedures by which service might be performed or of the possible hazardous consequences of each procedure. -

Page 5: Abbreviations And Acronyms

Acceleration Based Mode Switch • Acceleration Based Pattern • Anti-lock Brake System • ACCT Allison Calibration Configuration Tool • Acceleration Rate Management • Allison Transmission, Inc. • Bus Series Vocational Model • Clutch 1 • Clutch 5 • Clutch 6 • Clutch 7 •... - Page 6 • LBSS Load-Based Shift Scheduling • Lock in Range • LRTP Low Range Torque Protection • Lockup • Motorhome Series • Original Equipment Manufacturer • Oil Field Series • Oil Level Sensor • Oil Life Monitor • Off Road Series •...

- Page 7 • TCMs Transmission Control Modules • Technical Document • Transmission Identification Number • Transmission Health Monitor • Throttle Position Sensor • Truck RV Series • TSC1 Torque Speed Control 1 • Vehicle Acceleration Control • VEPS Vehicle Electronic Programming Stations •...

-

Page 8: Trademark Usage

Trademark of Allison Transmission, Inc. • 4000 Series is a Trademark of Allison Transmission, Inc. ® • Allison DOC is a Registered Trademark of Allison Transmission, Inc. ® • FuelSense is a Registered Trademark of Allison Transmission, Inc. ®... -

Page 9: Iso 14000

OM7154; OM7155; OM7156; OM7157; OM7158; OM7159; OM7160; OM7161; OM7707 ISO 14000 As a responsible corporate citizen, Allison Transmission, Inc. is dedicated to protecting human health, natural resources and the global environment. End-users and service personnel are responsible for understanding and complying with all applicable environmental laws, safety regulations, and Allison Transmission’s policies and standards. -

Page 10: List Of Warnings

LIST OF WARNINGS This manual contains the following warnings— IT IS YOUR RESPONSIBILITY TO BE FAMILIAR WITH ALL OF THEM. • When starting the engine, make sure the service brakes are applied. Failure to apply service brakes may result in unexpected vehicle movement. - Page 11 LIST OF WARNINGS (cont'd) This manual contains the following warnings— IT IS YOUR RESPONSIBILITY TO BE FAMILIAR WITH ALL OF THEM. • To help avoid injury or property damage caused by sudden movement of the vehicle, do not make shifts from N (Neutral) to D (Drive) or R (Reverse) when the engine is above low idle rpm.

- Page 12 LIST OF WARNINGS (cont'd) This manual contains the following warnings— IT IS YOUR RESPONSIBILITY TO BE FAMILIAR WITH ALL OF THEM. • D (Drive) may not be attained due to an active inhibitor. Always apply the service brakes when selecting D (Drive) to prevent unexpected vehicle movement and because a service inhibit may be present.

- Page 13 Any miswiring or use of this feature which differs from that shown could result in damage to equipment or property, personal injury, or loss of life. Allison Transmission is not liable for the consequences associated with miswiring or unintended...

- Page 14 LIST OF WARNINGS (cont'd) This manual contains the following warnings— IT IS YOUR RESPONSIBILITY TO BE FAMILIAR WITH ALL OF THEM. • DO NOT USE THE RETARDER DURING INCLEMENT WEATHER OR WHEN ROAD SURFACES ARE SLIPPERY. Use of the hydraulic retarder during inclement weather or when road surfaces are slippery could result in death, serious injury, or property damage.

- Page 15 LIST OF WARNINGS (cont'd) This manual contains the following warnings— IT IS YOUR RESPONSIBILITY TO BE FAMILIAR WITH ALL OF THEM. • Assuming proper installation of direction signal wire 134, most Allison shift selectors may still be used to command transmission direction changes in these circumstances.

-

Page 16: Table Of Contents

TABLE OF CONTENTS IMPORTANT SAFETY INFORMATION ....... . 3 ABBREVIATIONS AND ACRONYMS ....... . . 4 TRADEMARK USAGE . - Page 17 4.2.11 LOW SPEED GRADE ASSIST ..... . . 68 ® 4.2.12 ALLISON TRANSMISSION FUELSENSE 2.0 (N/A for OFS Models) ........69 ®...

- Page 18 5.8.2.2 ELECTRONIC FLUID LEVEL CHECK PROCEDURE ..90 5.8.2.3 FLUID RANGE DETECTED FOR OIL LEVEL SENSOR (OLS) ....... . 92 5.8.2.4 INVALID FOR DISPLAY CODES .

- Page 19 7.0 SHIFT SELECTORS COMPONENTS AND FUNCTIONS SELECT/MONITOR DISPLAY ......129 BACKLIGHTING ........129 MODE BUTTON .

- Page 20 12.4 ALLISON TRANSMISSION DISTRIBUTORS ....156 REVISION HISTORY ........157...

-

Page 21: Scope Of Manual

Refer to the Sales and Service Locator at www.allisontransmission.com to find contact and location information for Allison Transmission distributors and dealers. If you need to contact an Allison Transmission representative, refer to the Customer Service section at the end of this publication for contact information. -

Page 22: Introduction

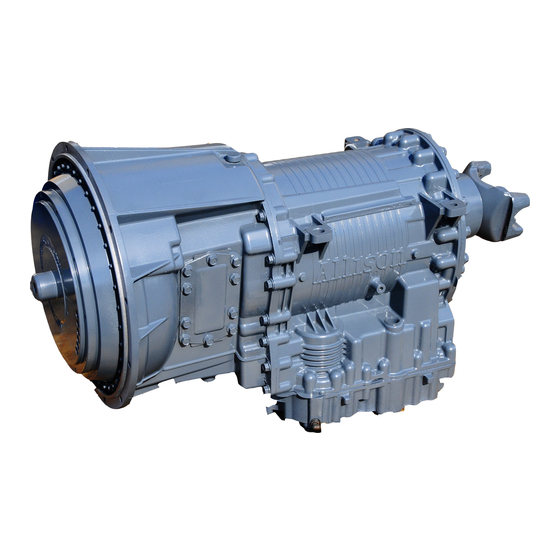

2.0 INTRODUCTION 2.1 KEEPING THAT ALLISON ADVANTAGE Allison transmissions provide many advantages for the driver who must “stop and go” or change speeds frequently. Driving is easier, safer, and more efficient. Each transmission series (INT, MH, OFS, PTS, RDS, SP, HS, EVS, T-Series, ORS, BUS, and TRV) contains features which have been designed for specific vocational needs. - Page 23 The transmissions are rugged and designed to provide long, trouble-free service. This manual will help you gain maximum benefits from your Allison-equipped vehicle. Refer to Figure 2–1 Figure 2–2 for non-PTO applications and Figure 2–3, Figure 2–4 Figure 2–5 for PTO applications. Refer to Figure 2–6 for 4700/4800 transmissions.

- Page 24 – Assembly Pads – Cooler Ports – Breather – Output Speed Sensor – Input Speed Sensor (10) – Torque Converter with Lockup – Fill Tube and Dipstick (Available Clutch and Torsional Damper on Both Sides) (11) – Breather – Nameplate (12) –...

- Page 25 – Breather – Cooler Ports – Mounting Pad – Output Speed Sensor – Input Speed Sensor (10) – Mounting Pad (Both Sides) – Turbine Speed Sensor (11) – Breather – Fill Tube and Dipstick (12) – Cooler Ports – Nameplate (13) –...

- Page 26 – Breather (10) – Breather – Assembly Pads (11) – Assembly Pads (Both Sides) – Output Speed Sensor (12) – Output Retarder – Retarder Valve Body Connector (13) – To Retarder Accumulator – Cooler Ports (14) – Oil Fill Tube and Dipstick –...

- Page 27 – Transfer Case – Feedthrough Harness – Breather Connector – Scavenge Pump – Assembly Pads (Both Sides) – Nameplate – Transfer Case – Oil Fill Tube and Dipstick – Oil Fill Tube and Dipstick (Available on Both Sides) (10) – PTO Provision Figure 2–4.

- Page 28 – Fill Tube – Retarder Temperature – PTO Provision (Top Right Connector Position) (10) – Breather – Torque Converter Module (11) – Mounting Pads (Both Sides) – Engine-Speed Sensor (12) – PTO Provision – Mounting Pad (13) – Standard Rear Cover –...

- Page 29 – Breather (10) – Mounting Pad – PTO Provision (11) – Input Speed Sensor – C6 Adapter Housing (12) – Turbine Speed Sensor – Retarder (13) – Fill Tube – Output Flange (14) – Nameplate – Mounting Pad (15) – Output Speed Sensor –...

- Page 30 Model 3000 • General • Refuse, Concrete Mixer • Fire Truck, Emergency Model 3000 SP • Specialty/Military Model 3200 • General • Refuse, Concrete Mixer • Fire Truck, Emergency Model 3200 ORS • Articulated Dump • Rigid Dump Model 3200 SP •...

- Page 31 Model 4000 SP • Specialty/Military Model 4200 ORS • Articulated Dump Model 4430 • General • Highway, Fire Truck, Emergency, Airport Rescue and Fire Fighting Vehicle (ARFF), Heavy Equipment Transport • Refuse Vehicles • AG Spreader, Sprayer, Blower, Feedlot Truck Model 4430 ORS •...

- Page 32 Model 4700 • General, Construction • Refuse • ARFF • Heavy Equipment Transporter Model 4700 OFS • Oil Field Series Model 4700 SP • Specialty/Military Model 4800 • ARFF Model 4800 SP • Specialty/Military...

-

Page 33: Driving Tips

3.0 DRIVING TIPS 3.1 THE AUTOMATIC EXPERIENCE Smooth automatic upshifts and downshifts, without interruption of power to the wheels, occur in your Allison automatic transmission based on engine rpm, throttle position, vehicle load, road speed, and driver or feature request, such as manually preselecting ranges. - Page 34 labels. This indicates that N (Neutral) has been selected and attained, and the engine may now be started. Strip push button selectors illuminate a lamp in the corner of the N button since they do not have a VFD. Refer to 7.0 SHIFT SELECTORS COMPONENTS AND FUNCTIONS,...

- Page 36 A: Shift Selectors – Hold Override Button – Mode Button – Upshift – Digital Display – Manual Select – Display Mode/Diagnostic Button – Downshift B: Push Button Selectors (B1) – Common (B3) – Compact (B2) – Standard C: Location of Service Icon On Vertical and Horizontal Digital Display –...

-

Page 37: Cold Weather Starts

– Vertical – 6 Position – Horizontal – 3 Position Figure 3–2. Typical Allison Strip Push Button Shift Selectors 3.3 COLD WEATHER STARTS If a vehicle is started in cold ambient conditions below -5°C (23°F), the transmission will be limited to 2 (Second Range), N (Neutral), and R (Reverse) operation (3 (Third Range) for the 4700/4800 transmission) until the sump temperature exceeds -1°C (30°F). -

Page 38: Preheating Requirement

3.3.1 Preheating Requirement. 3.3.1 Preheating Requirement. NOTE: For 3000 Series models, the combination of a retarder and a shallow (2 inch) sump can cause a truck to exhibit a delay when launching in cold ambient conditions with cold transmission fluid. To improve vehicle launch in conditions below 0ºC (32ºF):... -

Page 39: High Fluid Temperature

CAUTION: Transmission malfunction or damage may occur if you operate the transmission with the fluid temperature below the minimum fluid temperature specification limit. 3.4 HIGH FLUID TEMPERATURE The transmission is considered to be overheated when any of the following temperatures are exceeded: Sump fluid 121°C (250°F) Fluid to cooler... -

Page 40: Turning Off The Vehicle

3.5 TURNING OFF THE VEHICLE Always select N (Neutral) before turning the vehicle off. 3.6 PARKING BRAKE WARNING: If you leave the vehicle and the engine is running, the vehicle can move unexpectedly and you or others could be injured. If you must leave the engine running, DO NOT LEAVE the vehicle until you have completed all of the following procedures: •... -

Page 41: Driving On Snow Or Ice

If a PTO is present, it is normally mounted on either the left or right side of the 3000 Series transmission. On the 4000 Series transmission, the PTO is located on the left side or on the top of the transmission. The PTO drive gear is engine-driven and therefore provides direct engine power. -

Page 42: Rocking Out

Accelerate or decelerate very gradually to prevent the loss of traction. It is very important to decelerate gradually when a lower range is selected. It is important that you reach the selected lower range before attempting to accelerate. This avoids an unexpected downshift during acceleration. 3.9 ROCKING OUT WARNING: To help avoid injury or property damage caused by sudden movement of the vehicle, do not make shifts from N (Neutral) -

Page 43: Towing Or Pushing

3.10 TOWING OR PUSHING CAUTION: Failure to lift the drive wheels off the road, disconnect the driveline or remove the axle shafts before towing or pushing can cause serious transmission damage. NOTE: The engine cannot be started by pushing or towing. NOTE: When the axle shafts are removed, make sure the wheel openings are covered to prevent loss of lubricant and entry of dust and dirt. -

Page 44: Operating Down Steep Grades (Rear-Discharge Mixer)

3.11 OPERATING DOWN STEEP GRADES (REAR- DISCHARGE MIXER) CAUTION: With this transmission, the service brakes must be used when backing a loaded rear-discharge mixer down a grade. But too much brake application, particularly on an unpaved surface, can lock the front brakes and reduce steering control. A crash could then occur. -

Page 45: Selecting Range And Shift Schedules

DISPLAY MODE/DIAGNOSTIC (DMD) button, if equipped with the bump-shift lever selector. With an Allison Transmission, the shift selector is used by the operator to select N (Neutral), R (Reverse), or a range of forward gears. When a forward... -

Page 46: Using Keypad Push Button Shift Selector To Select Range

deeper reverse ratio. During certain operating conditions the control system may inhibit transmission operation or range shifts. 4.1.1 USING KEYPAD PUSH BUTTON SHIFT SELECTOR TO SELECT RANGE. Refer to Figure 4–1. • R – REVERSE: selects R (Reverse) gear. • N – NEUTRAL: selects N (Neutral). The area around the N button is a raised ridge so the driver can identify the push buttons by touch, without looking at the display. -

Page 47: Using Bump-Shift Lever Selector To Select Range

4.1.2 USING BUMP-SHIFT LEVER SELECTOR TO SELECT RANGE. Refer to Figure 4–1. • R – REVERSE: selects R (Reverse) gear. Bumping the lever toward R will select the alternate reverse gear range in select 4700/4800 model calibrations. • N – NEUTRAL: must be selected prior to starting the engine. •... - Page 48 • Lever Right-hand, Reverse to Front (LRRF) • Lever Right-hand, Reverse to Rear (LRRR) • Lever Left-hand, Reverse to Front (LLRF) • Lever Left-hand, Reverse to Rear (LRRR)

-

Page 50: Using Strip Push Button Selector To Select Range

A: Shift Selectors – Hold Override Button – Mode Button – Upshift – Digital Display – Manual Select – Display Mode/Diagnostic Button – Downshift B: Push Button Selectors (B1) – Common (B3) – Compact (B2) – Standard C: Location of Service Icon On Vertical and Horizontal Digital Display –... - Page 51 • D – DRIVE (Primary (ROAD) Mode OFS Model): selects the highest available forward range. Transmission shifts to starting gear and will automatically upshift through the gears, as operating conditions permit, until the highest available gear is attained. • D – DRIVE (Secondary (RIG) Mode OFS Model): goes to the range set in the calibration set for stationary mode.

-

Page 52: Selector Display Flashing (Inhibits)

– Vertical – 6 Position – Horizontal – 3 Position Figure 4–2. Typical Allison Strip Push Button Shift Selectors 4.1.3 SELECTOR DISPLAY FLASHING (INHIBITS). When appropriate, the transmission control system automatically invokes an inhibit to protect against certain types of abusive operation, such as: •... - Page 53 • Direction change inhibit: prevents shifting the transmission from forward-to-reverse or from reverse-to-forward if transmission output speed or throttle percentage is present. Rocking out by shifting from D (Drive) to R (Reverse) and R (Reverse) to D (Drive) is still available to the operator provided these parameters are below the limit allowed for rocking out the vehicle.

- Page 54 Table 4–1. DESCRIPTION OF AVAILABLE RANGES Description of Available Ranges (refer to Figure 4–1) WARNING: If you leave the vehicle and the engine is running, the vehicle can move unexpectedly and you or others could be injured. If you must leave the engine running, DO NOT LEAVE the vehicle until you have completed all of the following procedures: •...

- Page 55 Table 4–1. DESCRIPTION OF AVAILABLE RANGES (cont'd) Description of Available Ranges (refer to Figure 4–1) R or R2 Completely stop the vehicle and let the engine return to idle before shifting from a forward range to R (Reverse) or R2 and from R (Reverse) or R2 to a forward range.

- Page 56 Table 4–1. DESCRIPTION OF AVAILABLE RANGES (cont'd) Description of Available Ranges (refer to Figure 4–1) WARNING: D (Drive) may not be attained due to an active inhibitor. Always apply the service brakes when selecting D (Drive) to prevent unexpected vehicle movement and because a service inhibit may be present.

- Page 57 Table 4–1. DESCRIPTION OF AVAILABLE RANGES (cont'd) Description of Available Ranges (refer to Figure 4–1) WARNING: To avoid loss of control, use a combination of downshifting, braking, and other retarding devices. Downshifting to a lower transmission range increases engine braking and can help you maintain control.

-

Page 58: Shift Selector Transition And Oil Field Pumping (Input Function Bz: Wire 142) (Ofs Models)

4.1.3.1 SHIFT SELECTOR TRANSITION AND OIL FIELD PUMPING (INPUT FUNCTION BZ: WIRE 142) (OFS Models) WARNING: This input function involves the use of complex algorithms in the control logic. If the function is enabled in the calibration but the control circuit for the function is not installed, there is a potential risk for one or more system failure modes which could result in undesirable transmission operation. - Page 59 When the function is disabled, operation in primary mode resumes, controlled by shift selector 1. USES: For oil field dual-mode vehicles which are driven on-road in primary mode, then use secondary mode for stationary oil field operations such as pumping, swabbing, or winching. CUSTOMER MODIFIABLE CONSTANTS: None VOCATIONS: Oil field pumper, cementer, winch FUNCTION RESPONSE TO TCM POWER INTERRUPTION (power-off,...

- Page 60 Any miswiring or use of this feature which differs from that shown could result in damage to equipment or property, personal injury, or loss of life. Allison Transmission is not liable for the consequences associated with miswiring or unintended use...

-

Page 61: Shift Schedules And Automatic Range Shifts

For additional details regarding these shift schedules and/or other options for primary and secondary shift schedules, contact a qualified Allison Transmission service outlet for further information. 4.2.1 UPSHIFTING. As long as the TCM calculates that there is enough vehicle power and vehicle acceleration available to grant and keep the... -

Page 62: Downshifting

active, the shift points for upshifts are raised in order to hold the transmission in its current gear and inhibit upshifting beyond the current range. Holds are activated by selecting the current range or a lower range on the shift selector. CAUTION: A typical use of the "hold"... -

Page 63: Engine Brake Or Exhaust Brake Operation

following choices is selected when the TCM is programmed by the vehicle OEM: • Standard Preselects – downshifts occur so the engine speed after the shift is approximately 300 rpm above the engine governed speed • Low Preselects – downshifts occur so the engine speed after the shift is approximately 150 rpm above the engine governed speed 4.2.2.3 ENGINE BRAKE OR EXHAUST BRAKE OPERATION When the TCM detects the engine brake is enabled, it commands use of... -

Page 64: Retarder Mode Shift Schedule

Range), downshifts from the Alternate Engine Brake Preselect Range to 2 (Second Range) uses normal (non-preselect) closed throttle shift speeds. NOTE: If an exhaust brake or engine compression brake is installed on the engine, then they must be integrated to the transmission controls. -

Page 65: Performance/Economy Shift Schedules (N/A For Ofs Models)

4.2.5 PERFORMANCE/ECONOMY SHIFT SCHEDULES (N/A for OFS Models). Currently, Allison Transmission offers the following commonly available shift schedules to the OEM(s): • S1 & S5 - Performance: WOT upshifts near Full Load Governed Speed (FLGS) •... -

Page 66: Dynamic Shift Sensing (Dss) (N/A For Ofs Models)

same WOT upshifts as the corresponding S1 through S4 schedules. However, the S5 through S8 part throttle shift schedules have been modified. 4.2.6 DYNAMIC SHIFT SENSING (DSS) (N/A for OFS Models). NOTE: DSS was known as Load-Based Shift Scheduling (LBSS) prior to July 2014. - Page 67 load. SESS is not available with acceleration-based DSS. In addition, DSS uses an inclinometer/accelerometer in the TCM to refine the selection of the appropriate shift schedule based on vehicle operating requirements. The TCM will initialize in the same mode, Economy or Performance, that it was in when last shutdown.

-

Page 68: Over-Temperature Shift Schedule (N/A For Ofs Models)

Table 4–2. DSS ECONOMY MODE (cont'd) CMC Setting Selection Description High This setting keeps the vehicle in economy mode in most circumstances. Performance will typically be commanded only when negotiating severe when heavily loaded. This setting permits higher powered vehicles to be in economy mode for most operations except during the most demanding operating conditions. -

Page 69: Acceleration Rate Management (Arm) (N/A For Ofs Models)

4.2.10 ACCELERATION RATE MANAGEMENT (ARM) (N/A for OFS Models). NOTE: ARM was known as Vehicle Acceleration Control (VAC) prior to July 2014. ARM is an engine management function where the TCM manages engine torque to limit vehicle acceleration to a calibrated rate. This function will allow full torque from the engine if the vehicle is unable to reach the calibrated acceleration rate, such as on steep grades or when the vehicle is heavy. -

Page 70: Allison Transmission Fuelsense 2.0 (N/A For Ofs Models)

® 4.2.12 ALLISON TRANSMISSION FUELSENSE 2.0 (N/A for OFS Models). ® Vehicles equipped with an Allison Transmission and a FuelSense package will save fuel when compared to vehicles without the package, depending on the duty cycle. ® FuelSense 2.0 is an initiative that groups software and calibration fuel economy features into packages that can be easily selected when specifying a TCM calibration in the Allison Calibration Configuration Tool (ACCT). - Page 71 ® Table 4–4. 5th Generation FuelSense 2.0 Features and Package Designations ® FuelSense ® ® ® Former FuelSense FuelSense FuelSense Terminology 2.0 Plus 2.0 Max Terminology Low Speed Shift EcoCal Calibrations Load-Based Shift Scheduling (LBSS) Acceleration Dynamic Based Mode Shift Sensing Switch (ABMS) (DSS) Super Economy...

-

Page 72: Fuelsense ® 2.0 Terminology Descriptions

NOTE: For school bus and truck vocations, Neutral at Stop and ® FuelSense 2.0 are purchased separately. ® Table 4–6. 6th Generation FuelSense 2.0 Transit and Coach Bus Features ® Features FuelSense ® DynActive Dynamic Shift Sensing Neutral at Stop Acceleration Rate Management NOTE: Applicable to North America only. -

Page 73: Using The Hydraulic Retarder

2.0 logo. At the discretion of the OEM, vehicles not equipped with ® an Allison shift selector display can provide the FuelSense message on a dash display. The Allison shift selector will display the “Allison Transmission” ® initialization screen followed by a “FuelSense 2.0” screen upon vehicle... - Page 74 NOTE: The transmission retarder is configured as either a low, medium, or high capacity retarder by TCM calibration. Allison Transmission requires written vehicle OEM approval before a service outlet increases the retarder capacity at a customer's request. Existing vehicle drivelines, differentials, axles, and the cooling system must be designed for the additional retarder torque generated if a higher capacity retarder calibration is installed.

- Page 75 NOTE: If your transmission has a retarder but it is not functioning, it may not have been autodetected during vehicle manufacture. Consult the nearest Allison Transmission service outlet to have ® autodetect reset or the retarder enabled using the Allison DOC...

- Page 76 NOTE: A common cause for retarder performance complaints is incorrect transmission fluid level. Fluid level must be set correctly for maximum retarder effectiveness. As little as 2 liters (2 quarts) too high or too low can reduce retarder effectiveness and increase transmission temperature.

-

Page 77: Retarder Capacity Reduction

Table 4–7. Types of Retarder Control (cont'd) Type Description Amount of Application Brake Pressure Apply Single pressure Off or “Full On” (based on brake switch pressure) Three pressure 1/3, 2/3, or “Full On” (based on switches brake pressure) Pedal Position Special brake pedal 1/3, 2/3, or “Full On”... -

Page 78: Based On Retarder Temperature

• engine water temperature as communicated to the TCM with an engine coolant sensor or via an SAE J1939 datalink, or • detection by an engine water temperature sensor which provides an analog input signal to the TCM. This sensor is supplied and installed by the vehicle builder. -

Page 79: Retarder/Cruise Control Interactions

The capacity is reduced at the rate/slope programmed into the calibration and may continue to be reduced at this rate until: • The retarder is operating at approximately 27.5% of its maximum capacity. • The retarder is deactivated by the operator or by vehicle operating conditions which eliminate the need for retardation. -

Page 80: Care And Maintenance

• Presence of engine coolant in the transmission fluid. NOTE: Transmission overhaul is required when the transmission has been contaminated with engine coolant. Allison Transmission recommends all clutch friction plates, lockup clutch, solenoids, and rusted/damaged parts be replaced during the rebuild. -

Page 81: Prevent Major Problems

5.2 PREVENT MAJOR PROBLEMS You can help keep minor problems from becoming major problems by contacting an Allison Transmission distributor or dealer when one of these conditions occur: • A shift quality issue • A driveability issue such as a vibration •... -

Page 82: Recommended Automatic Transmission Fluids

TES 668 or TES 389 in your transmission. For a list of currently approved transmission fluids, go to the Allison Transmission web site at: www.allisontransmission.com, select SERVICE, Fluids. Allison Transmission recommends you take the following into consideration when selecting the appropriate fluid type for your transmission: ®... -

Page 83: Keeping Fluid Clean

5.5 KEEPING FLUID CLEAN CAUTION: Containers or fillers that have had antifreeze solution or engine coolant in them must NEVER be used to hold transmission fluid. Antifreeze and coolant solutions contain ethylene glycol and water which, if put into the transmission, can cause damage. Make sure that transmission fluid is clean, free of chemical contaminants, and within fluid specification limits. -

Page 84: Periodic Fluid Level Checks

NOTE: Only use this check to confirm adequate fluid volume for a cold start-up and not to set fluid levels for continued operation. The OLS is designed to automatically compensate for fluid temperature fluctuations (thermal expansion) within its operating band parameters for fluid temperature. Allison Transmission recommends using the Allison 5th... -

Page 85: Fluid Check Using Dipstick

Generation controls shift selector to check the OLS. This method is more accurate than the dipstick method. Use the dipstick method if any of the following situations exist: • If transmission fluid temperature is below the temperature to check it electronically, conduct a COLD CHECK to determine whether there is enough fluid to start and move the vehicle. - Page 86 6.35 mm (0.250 in.) – Transmission Control Module REFERENCE. Blade can Split Line be as narrow as 4.76 mm (NOTE) – 3000 Series shown on left. (0.187 in.). 4000 Series shown on right. – Fill Tube Figure 5–1. Standard Transmission Dipstick Markings...

- Page 87 NOTE: Calibrate level marking locations with respect to transmission control module split line and fill tube. COLD CHECK: The COLD CHECK band verifies the transmission has adequate fluid for start-up and operation until it can be checked at the operating (hot) temperature. Only use this check to confirm adequate fluid level for a cold start-up and not to set fluid levels for continued operation.

-

Page 88: Cold Check Procedure

5.8.1.1 COLD CHECK PROCEDURE NOTE: The correct fluid level cannot be determined unless the transmission is in a level position. CAUTION: DO NOT start the engine until the presence of sufficient transmission fluid has been confirmed. Remove the transmission fluid dipstick and be sure the static fluid level is near the HOT FULL mark. -

Page 89: Hot Check Procedure

6. Insert the dipstick into the fill tube, pushing down until it stops, but still in its loose or unscrewed position. 7. Remove the dipstick and observe the fluid level. If the fluid on the dipstick is within the COLD CHECK band (refer to Figure 5–1), the level is satisfactory. -

Page 90: Transmission Dipstick Markings Illustration

2. Park the vehicle on a level surface and shift to N (Neutral). 3. Apply the parking brake and allow the engine to idle (500–800 rpm). 4. Clean debris from around the end of the fill tube before removing the dipstick. -

Page 91: Electronic Fluid Level Check Procedure

5.8.2.2 ELECTRONIC FLUID LEVEL CHECK PROCEDURE NOTE: The TCM delays the fluid level check until the following conditions are met: • The fluid temperature is above 40°C (104°F) or below 104°C (220°F). • The transmission is in N (Neutral). • The vehicle has been stationary for approximately two minutes to allow the fluid to settle. - Page 92 Figure 5–2. Correct Fluid Level Display 7. Low fluid level is displayed and the number indicates the number of quarts of fluid the transmission requires (refer to Figure 5–3). NOTE: Confirm a low fluid level condition by making a manual fluid level check.

-

Page 93: Fluid Range Detected For Oil Level Sensor (Ols)

If these conditions cannot be corrected, contact the nearest distributor or dealer in your area (look in the telephone directory for the Allison Transmission service outlet nearest you). Table 5–4. Invalid for Display Codes Code... - Page 94 Transmission Health Monitor (TM) Notifies that one or more clutches, C1-C5, needs replacement Allison Transmission 5th Generation and 6th Generation Controls with Prognostics and later uses a wrench icon (TRANS SERVICE indicator) located on the shift selector display (refer to Figure 5–5).

-

Page 95: Prognostics Prerequisites

Prognostics features and functions: • Vehicle harness has a wire for the filter life indicator switch (wire 118). • The OEM has ordered your calibration from Allison Transmission with Prognostics enabled. NOTE: It is important to note that if Prognostics is disabled, it is not available in the calibration. - Page 96 • Through the shift selector (if allowed by TCM programming). Refer to 5.9.3 PROCEDURE TO TURN PROGNOSTICS ON AND OFF. ® • Using the Allison DOC , Customer Modifiable Constant (CMC) can be toggled to enabled or disabled for the Allison Prognostics Feature Package, provided the OEM ordered a calibration that has the Allison Prognostics Feature Package as a programmable feature.

-

Page 97: Procedure To Turn Prognostics On And Off

NOTE: An Allison service outlet can assist with programming and recalibration to enable Prognostics, at customer expense, as long as all Allison Transmission requirements are met prior to the enabled feature being turned on. NOTE: The three Prognostics functions, OM, FM, and TM, are enabled or disabled as a group and cannot be enabled or disabled individually. -

Page 98: Normal Prognostics Indication At Engine Start

4. Watch for the TRANS SERVICE indicator located in the shift selector display to illuminate and then turn off. This indicates that the operator has successfully enabled the Allison Prognostics Feature Package, consisting of the OM, FM, and TM. If another TRANS SERVICE indicator is installed in the dash or incorporated in an OEM message display, it should also briefly illuminate in similar fashion as the TRANS SERVICE indicator. -

Page 99: Setting Fluid Type For Prognostics

NOTE: If the shift calibration permits a maximum allowable gear in primary mode that is different than the maximum allowable gear in secondary mode, Prognostics enabling/disabling is only permitted in the shift mode with the highest maximum allowable range. If you have a higher range set of gears in secondary mode than in primary mode to enable Prognostics, push the MODE button so MODE appears on the selector display first. -

Page 100: Oil Life Monitor (Om)

The selector exits 30 seconds after entering transmission fluid type mode or the ignition may be turned off to exit earlier. Only one transmission fluid type selection may be made after entering transmission fluid type mode. All other attempts will be ignored. Transmission fluid type mode needs to be entered again if the wrong type of transmission fluid is selected. -

Page 101: Read And Reset Oil Life Monitor (Om) From Selector

requirements and then reset the OM. Calendar requirements are not required if a fluid analysis program is in place. Refer to 5.6 FLUID ANALYSIS. 5.9.6.2 READ AND RESET OIL LIFE MONITOR (OM) FROM SELECTOR READ OM. With engine off and ignition on, push the DISPLAY MODE/DIAGNOSTIC (DMD) button twice on the bump-shift lever selector to enter OM mode. -

Page 102: Filter Life Monitor (Fm)

5.9.7 FILTER LIFE MONITOR (FM). This feature provides an alert when the transmission’s fluid filters need to be replaced. It helps extend filter change intervals to reduce routine maintenance downtime and saves you money in the long run, all while providing maximum protection for the transmission. The FLI pressure switch signals the TCM when fluid exiting the main filter drops below a predetermined pressure. -

Page 103: Transmission Health Monitor (Tm)

Reset FM. The FM automatically resets once the new filters have been installed and the FLI pressure switch no longer detects low pressure at the filter. The FM can also be reset manually through the selector (if allowed in the calibration) by either of these methods: •... -

Page 104: Read And Reset Tm From Selector

HEALTH LO”is displayed. An acceptable clutch life status is displayed as “TRANS HEALTH OK”. An unacceptable clutch life status is displayed as “TRANS HEALTH LO”. DTC P2789, Transmission Clutch Life Expired (Clutch Adaptive Learning at Limit), sets if multiple warnings have occurred due to the TM actively detecting issues with the clutch system and illuminating the CHECK TRANS light. - Page 105 There are three methods recommended by Allison Transmission to help you determine when to change the fluid and filters in your Allison Transmission. The methods are as follows: • When a Prognostics indicator becomes active (shown by illuminating the TRANS SERVICE indicator in the selector VF display).

- Page 106 ® ® NOTE: Either TES 295 , TES 668 or TES 389 fluid types are required to use the OM feature with Prognostics on. A mixture of ® ® TES 389 and TES 295 or TES 668 fluid must continue to use ®...

- Page 107 Table 5–6. Recommended Filter Change/Fluid Change Intervals 3000/4000 Series Fluid And Filter Change Interval Recommendations Prognostics Turned Off or Prognostics Turned On Not Calibrated in TCM Allison Allison Allison Allison Approved Approved Duty Approved Approved TES 668 TES 668 ® ®...

-

Page 108: Fluid And Filter Change Procedure

Table 5–6. Recommended Filter Change/Fluid Change Intervals (cont'd) 3000/4000 Series Fluid And Filter Change Interval Recommendations Prognostics Turned Off or Prognostics Turned On Not Calibrated in TCM Allison Allison Allison Allison Approved Approved Duty Approved Approved TES 668 TES 668 ®... - Page 109 2. Remove the drain plug from the control module and allow the fluid to drain into a suitable container. 3. Examine the fluid for contamination. NOTE: At each fluid change, examine the drained fluid for evidence of dirt or water. A normal amount of condensation appears in the fluid during operation.

-

Page 110: Refill Transmission

3000 Series (Shown on Right) and 4000 Series (Shown on Left) – Lube (C) – Drain Plug – Main (D) – Filter Cover A and B – Bolt – O-Ring – Filter Cover – O-Ring – Gasket – Filter Figure 5–6. Location of Filters for Service 3. -

Page 111: Diagnostics

6.0 DIAGNOSTICS 6.1 OVERVIEW Diagnostic features are provided with the transmission control system to assist in troubleshooting of malfunctions and/or the monitoring of specific operating parameters. When a control system malfunction is detected, a series of Diagnostic Trouble Codes (DTCs) are used to identify and clarify the nature of the malfunction. -

Page 112: Check Trans Light

SELECT and only shows a range the transmission has locked into in the MONITOR window of the selector, seek immediate attention from a qualified Allison Transmission technician. Perform service as soon as possible in order to minimize the potential for damage to the transmission or vehicle. -

Page 113: Using Shift Selector For Accessing Diagnostics Information

CHECK TRANS light is active at time of engine restart. NOTE: Some DTCs may be logged without the TCM activating the CHECK TRANS light. Contact your Allison Transmission authorized service outlet whenever there is a transmission-related concern. They have the equipment to access and troubleshoot DTCs. -

Page 114: Read/Clear Dtcs With Keypad Push Button Selector

6.3.2 READ/CLEAR DTCs WITH KEYPAD PUSH BUTTON SELECTOR. NOTE: The strip button shift selector has no display or diagnostic capabilities. 6.3.2.1 READING DTCs WITH PROGNOSTICS PACKAGE ON To read DTCs with prognostics on using the keypad push button shift selector: •... -

Page 115: Exiting Diagnostic Mode

NOTE: If an active indicator is cleared while the transmission is locked in range because of the diagnostic response to an active DTC, the transmission remains in that locked range even after clearing the active indicator. N (Neutral) must be manually selected or the ignition must be cycled. -

Page 116: Clearing Dtcs

• Press the MODE button to read the next code in the queue, if any. NOTE: For 3700 SP and 4700/4800 transmissions equipped with a retarder, press the MODE button once. 6.3.3.3 CLEARING DTCs While in diagnostic mode, clear all active codes by pressing and holding the MODE button for approximately three seconds until the MODE message flashes. -

Page 117: Dtc List And Description

• After approximately 10 minutes of inactivity at the bump-shift lever selector, the diagnostic mode automatically exits and returns to normal operating mode. 6.3.3.5 DTC LIST AND DESCRIPTION Table 6–2. DTC List and Descriptions Description CHECK Inhibited Operation TRANS Light Description May inhibit retarder C1312... - Page 118 Table 6–2. DTC List and Descriptions (cont'd) Description CHECK Inhibited Operation TRANS Light Description P0604 Control Module Random TCM returns to the boot Access Memory (RAM) program, Transmission operates in hydraulic default: N (Neutral), 3 (Third Range), 4 (Fourth Range) and 5 (Fifth Range) P0607 Control Module...

- Page 119 Table 6–2. DTC List and Descriptions (cont'd) Description CHECK Inhibited Operation TRANS Light Description P0703 Brake Switch Circuit No Neutral to Drive shifts for refuse packer. TCM inhibits retarder operation if a TPS code is also active. P0708 Transmission Range Ignore defective strip Sensor Circuit High selector inputs...

- Page 120 Table 6–2. DTC List and Descriptions (cont'd) Description CHECK Inhibited Operation TRANS Light Description P0720 Output Shaft Speed Shift not in process, Sensor Circuit LIR Shift in process, complete shift then LIR. TCM forces VMMS off. TCM inhibits TCC engagement. TCM freezes shift adapts.

- Page 121 Table 6–2. DTC List and Descriptions (cont'd) Description CHECK Inhibited Operation TRANS Light Description P0752 Shift Solenoid 1 Valve Performance–Stuck On P0776 Pressure Control Solenoid (PCS2) Stuck P0777 Pressure Control DNS, RPR Solenoid (PCS2) Stuck P077F Incorrect Reverse 2 Ratio DNS, Lock in Neutral P07CE Neutral At Stop Not...

- Page 122 Table 6–2. DTC List and Descriptions (cont'd) Description CHECK Inhibited Operation TRANS Light Description P0881 TCM Power Input Signal None Performance P0882 TCM Power Input Signal DNS, SOL OFF (hydraulic default) P0883 TCM Power Input Signal None High P088A Transmission Filter None Maintenance Alert P088B...

- Page 123 Table 6–2. DTC List and Descriptions (cont'd) Description CHECK Inhibited Operation TRANS Light Description P0966 Pressure Control DNS, SOL OFF Solenoid (PCS2) Control (hydraulic default) Circuit Low P0967 Pressure Control DNS, SOL OFF Solenoid (PCS2) Control (hydraulic default) Circuit High P0968 Pressure Control DNS, SOL OFF...

- Page 124 Table 6–2. DTC List and Descriptions (cont'd) Description CHECK Inhibited Operation TRANS Light Description P1739 Incorrect Low Gear Ratio Command 2nd and allow shifts 2 through 6, N, R P1790 Gear Shift Module 1 Shift selector language Calibrated Invalid or units incorrect P1791 Gear Shift Module 2 Shift selector language...

- Page 125 Table 6–2. DTC List and Descriptions (cont'd) Description CHECK Inhibited Operation TRANS Light Description P27B2 Internal Control Module Hydaulic default. Transmission Range Transmission is restricted Control Performance to N (Neutral)3 (Third Range)4 (Fourth Range)5 (Fifth Range) P27B4 Output Shaft Direction Shift not in process, Plausibility LIR Shift in process,...

- Page 126 Table 6–2. DTC List and Descriptions (cont'd) Description CHECK Inhibited Operation TRANS Light Description P2723 Pressure Control DNS, RPR Solenoid (PCS) 1 Stuck P2724 Pressure Control DNS, RPR Solenoid (PCS) 1 Stuck P2727 Pressure Control DNS, SOL OFF Solenoid (PCS) 1 Control (hydraulic default) Circuit Open P2728...

- Page 127 Table 6–2. DTC List and Descriptions (cont'd) Description CHECK Inhibited Operation TRANS Light Description P2761 Torque Converter Clutch Inhibit TCC operation (TCC) Pressure Control Solenoid (PCS) Control Circuit Open P2763 Torque Converter Clutch Inhibit TCC operation (TCC) Pressure Control Solenoid (PCS) Control Circuit High P2764 Torque Converter Clutch...

- Page 128 Table 6–2. DTC List and Descriptions (cont'd) Description CHECK Inhibited Operation TRANS Light Description P2815 Pressure Control DNS, SOL OFF Solenoid (PCS) 6 Control (hydraulic default) Circuit High U0073 CAN Communication Bus Use default values 1 Off U0074 CAN Communication Bus Use default values 2 Off U0100...

- Page 129 Table 6–2. DTC List and Descriptions (cont'd) Description CHECK Inhibited Operation TRANS Light Description U0592 Gear Shift Module 2 Maintain range selected, Invalid Data observe gear shift direction circuit Depending on OEM configuration, may or may not allow direction changes during faults U1401 J1939 TSC1 Engine None...

-

Page 130: Shift Selectors Components And Functions

7.0 SHIFT SELECTORS COMPONENTS AND FUNCTIONS 7.1 SELECT/MONITOR DISPLAY A two-character vacuum fluorescent blue-green display is included on the face of each bump-shift lever and keypad push button shift selector. The strip push button selector does not have a Vacuum Flourescent Display (VFD). The left character, called the SELECT display appropriately designates N (Neutral), R (Reverse), or the highest gear available of the selected forward range. - Page 131 • Activates a special function programmed into the TCM, which is typically an alternate ECONOMY or PERFORMANCE shift schedule. • Toggles to the next DTC while in DTC display mode. • Clears (erases) active and inactive DTCs from TCM memory. NOTE: DTCs cannot be cleared individually.

-

Page 132: Trans Service Indicator (Wrench Icon)

– MODE Button Figure 7–2. MODE Button and Display on a Push Button Shift Selector 7.4 TRANS SERVICE INDICATOR (WRENCH ICON) The TRANS SERVICE (wrench icon) indicator illuminates in the event a service condition relating to a transmission clutch, fluid or filter life occurs. The TRANS SERVICE indicator is located on the shift selector display (refer to Figure 7–3). -

Page 133: Selector Display Descriptions For Active Diagnostic Trouble Codes (Dtcs) And Inhibits

– Wrench Icon Figure 7–3. Typical Allison Trans Service Indicator For additional information regarding these conditions, refer to 5.9.6 OIL LIFE MONITOR (OM), or 5.9.7 FILTER LIFE MONITOR (FM), or 5.9.8 TRANSMISSION HEALTH MONITOR (TM). 7.5 SELECTOR DISPLAY DESCRIPTIONS FOR ACTIVE DIAGNOSTIC TROUBLE CODES (DTCs) AND INHIBITS RANGE SELECT Blank: With an active DTC, the SELECT display on the shift selector is blank. -

Page 134: Selector Display Is Inoperative

varies for each of the conditions monitored by the system (refer to 7.4 TRANS SERVICE INDICATOR (WRENCH ICON)). All Segments Illuminated: If all segments of the display are on for more than 12 seconds, the TCM has not completed initialization. A DTC is associated with this condition. -

Page 135: Bump-Shift Lever Selector

7.7 BUMP-SHIFT LEVER SELECTOR The Allison Bump-Shift Lever selector is an electromechanical control that has locked positions to prevent accidentally selecting R (Reverse), N (Neutral), or D (Drive). Bump-Shift Lever selector positions are: • R (Reverse): selects reverse gear. Bumping the lever forward will select the alternate reverse gear range in select models. -

Page 136: Keypad Push Button Shift Selector

• HOLD OVERRIDE BUTTON: The HOLD OVERRIDE button is a finger-controlled button integrated into the top and front side of the bump-shift lever selector knob. This button uses a detent feature with locked positions to prevent accidental range selection. Press the HOLD OVERRIDE button to release the detent and move the bump-shift lever from any of these locked positions. -

Page 137: Strip Push Button Shift Selector

COMPONENTS AND FUNCTIONS). If the transmission is locked in range due to an active DTC, the system still allows the operator to review the DTC in the selector with simultaneous button presses on the ↑ (Upshift) and ↓ (Downshift) arrows even though the transmission is not in N (Neutral). Conditions which illuminate the CHECK TRANS indicator disable the shift selector. -

Page 138: Customizing Controls And Tcm Programming

8.0 CUSTOMIZING CONTROLS AND TCM PROGRAMMING 8.1 VEHICLE AND TRANSMISSION SIGNAL INTERFACE OVERVIEW This section describes the vehicle interface connections to the transmission controls and transmission signals. The vehicle interfaces discussed in this section may be provided through a SAE J1939 vehicle communications interface and include: •... - Page 139 Control signals are generally needed by each I/O function to work. These control signals, known as inputs, may be a combination of the following: • Discrete analog switched signal voltages or switched-to-ground signals that control the on/off state of the needed input(s) that in turn allow the enabled I/O function to switch to on or off.

-

Page 140: Controls System Overview

NOTE: At the customer's request, and usually at the customer's expense, an Allison Service Outlet can: • Run a report showing the present vehicle I/O configuration • Enable/disable different I/O features and set the related CMC(s) • Calibrate the TCM in order to get a different I/O packages Proper chassis wiring and connectors, switches, relays, lamps, indicators, datalink messages, and CMC(s) must all be integrated into the vehicle and verified to be working properly before a newly... -

Page 142: Transmission Control Module (Tcm) Hardware Description

– Transmission Control Module (13) – Shift Selector Connector (TCM) (14) – Retarder Temp Sensor – Vehicle Interface Module (VIM) Connector (Optional) (15) – Throttle Position Sensor (TPS) – J1939 Connector Connector (Optional) – SAE J1962 Diagnostic Tool (16) – Turbine Speed Sensor Connector Connector (4000 Series) –... -

Page 143: Autodetect

Manufacturers, assemblers, and installers of radio-telephone or two-way communication radios have the sole responsibility to correctly install and integrate those devices into Allison Transmission-equipped vehicles to the customer's satisfaction. 8.5 AUTODETECT The Autodetect software feature automatically detects the presence of transmission components or input signals, thus permitting the use of different features or input signals with a common TCM. -

Page 144: Communication Through Vehicle Datalinks

Check with your vehicle OEM or Allison Transmission distributor or dealer for the capabilities of the TCM in your vehicle, or if you need assistance in determining the datalink types available for your vehicle. -

Page 145: External Wire Harnesses, Vehicle Interface Module, And Retarder Controls

NOTE: The external harness connecting transmission controls is part of the vehicle chassis harness and typically will not have an Allison Transmission part number. The harness parts are usually only available through the vehicle manufacturer and their vendors. Check with the OEM or dealer first to determine their wire harness service parts availability. -

Page 146: Vehicle Interface Module (Vim)

In order to meet the needs of operators in a wide variety of applications, vocations, and vehicle configurations, several retarder apply systems are offered for transmission models in the Allison Transmission 3000 and 4000 Series. Certain types of apply systems may not be recommended for specific vocations. - Page 147 control over retarder operation and include various types of retarder operator and vehicle interface controls. Some of the available operator controls, known also as Retarder Modulation Request (RMR) devices include: • Foot pedal • Hand lever • Automatic apply at closed throttle •...

-

Page 148: Transmission Components

10.0 TRANSMISSION COMPONENTS 10.1 TORQUE CONVERTER The torque converter multiplies engine torque and transfers smooth, uninterrupted power to the wheels quickly. The torque converter consists of these four components: • Pump–input element driven directly by the engine • Turbine–output element hydraulically driven by the pump •... -

Page 149: Planetary Gears And Clutches

10.2 PLANETARY GEARS AND CLUTCHES A series of three helical, constant mesh planetary gear sets and shafts provides the mechanical gear ratios and direction of travel for the vehicle. The planetary gear sets are controlled by five multi-plate clutches that work in pairs to produce up to six forward speeds and one reverse speed. -

Page 150: Transmission Speed Sensors

The mounting provision for the turbine speed sensor differs between the transmission model families: • For transmission models in the 3000 Series, the turbine speed sensor is internal to the transmission and does not require an external connection. • For transmission models in the 4000 Series, the turbine speed sensor is external to the transmission and requires a connection to the wiring harness. - Page 151 Transfer case design features include helical transfer gears and a self-contained lubrication oil pump. The transfer gears provide a ratio of 1.2:1. The lubrication oil pump is driven directly by the output to the drive axles. Since lubrication is present whenever the drive axle is turning, it is not necessary to disconnect the drivelines or axle shafts when the vehicle is towed or pushed.

- Page 152 – Transfer Case – Feedthrough Harness – Breather Connector – Scavenge Pump – Assembly Pads (Both Sides) – Nameplate – Transfer Case – Oil Fill Tube and Dipstick – Oil Fill Tube and Dipstick (Available On Both Sides) (10) – PTO Provision Figure 10–1.

-

Page 153: General Guidelines

• the TCM is not painted. • the elements being painted are properly and continuously grounded during the entire painting process. NOTE: Allison Transmission is not responsible for TCM damage resulting from improper grounding during electrostatic painting of the vehicle. -

Page 154: Painting Of Transmission Control Components

• cover labels or other identification, hindering the process to service these components. 11.3 ENVIRONMENT Allison Transmission designed the Allison controls and components to operate in normal vehicle cab and chassis environments. The Allison controls and components can withstand moisture, direct light, heat, and shock loads. -

Page 155: Customer Service

Figure 12–1. Transmission Nameplate 12.1.2 GENUINE PARTS. Allison Transmission recommends that only genuine Allison parts be used in an Allison Transmission. Order all replacement parts from an authorized distributor or dealer. Service outlets can be located on the Allison Transmission website at www.allisontransmission.com. - Page 156 As an owner of an Allison transmission, you have service locations throughout the world that are eager to meet your parts and service needs with: • Expert service by trained personnel. • Emergency service 24 hours a day in many areas.

-

Page 157: Service Literature

Therefore, it is suggested that Step One be followed when experiencing a problem. Your purchase of an Allison Transmission product is greatly appreciated, and it is our sincere desire to assure complete satisfaction. 12.3 SERVICE LITERATURE Allison Transmission, Inc. -

Page 158: Revision History

REVISION HISTORY This revision history includes a summary of changes made to the following topics between 2021/06 and 2021/09. TRADEMARK USAGE 2021/08 Added trademarks 1-1. SCOPE OF MANUAL 2021/06 Changed Product Family to Series throughout manual Added 6th Generation throughout manual where needed 2-1. - Page 159 NOTES...

- Page 160 NOTES...

- Page 161 NOTES...

- Page 162 Our support starts from the moment an Allison transmission is specified. We work with you to ensure that the model and ratings fit your engine to create a tailored package of powerful performance and reliable efficiency.

Need help?

Do you have a question about the 3000 Series and is the answer not in the manual?

Questions and answers

When I turn the key on both sides of the 29551496 selector shows “N” but when I crank the truck the N on the left side goes off. I put the dash selector in another truck and it worked fine. Is there a sensor somewhere I need to check?

Yes, the Allison Transmission 3000 Series may have an optional oil level sensor that can display fluid level information using the pushbutton or lever shift selector. If the left side of the 29551496 selector goes off after cranking, it may be related to a diagnostic code or sensor issue, and checking for diagnostic codes is recommended.

This answer is automatically generated

If the engine is running at 800 rpm and the transmission is in neutral, does the PTO have an input of 800 rpm?

The PTO of an Allison Transmission 3000 Series is engine-driven, meaning it provides direct engine power. Since the PTO drive gear is in constant mesh with the drive gear in the converter housing, its input speed is directly related to engine speed. If the engine is running at 800 rpm and the transmission is in neutral, the PTO input speed would also be 800 rpm.

This answer is automatically generated