Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Subscribe to Our Youtube Channel

Summary of Contents for CNC-Step T-Rex N Series

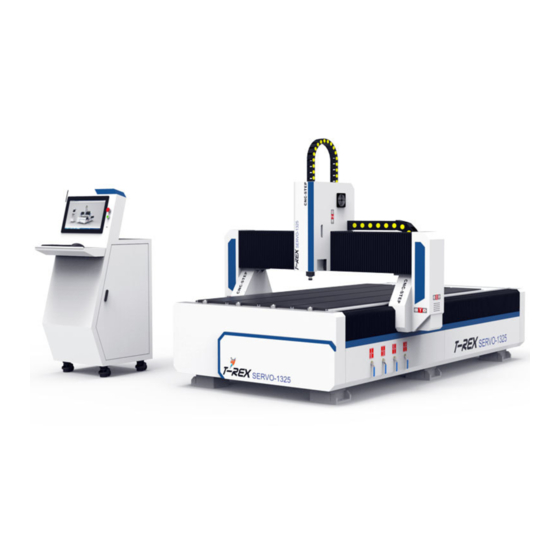

- Page 1 Operating instructions T-Rex N-Serie (Stepper) Rev. 1.3 (April 2021) T-Rex 0609 ▪ T-Rex 0615 ▪ T-Rex 1212 ▪ T-Rex 1218 T-Rex 1325 ▪ T-Rex 1530 ▪ T-Rex 2030 ▪ T-Rex 2040 Technical and optical changes reserved. https://www.cnc-step.com/ Stand: 07.03.2022...

- Page 2 This operating manual describes the installation, commissioning, and maintenance of the CNC gantry system. This guide refers to the T-Rex N series in the standard configuration with a 3.5KW HF spindle from HQD. There are many other options available, which are then described in separate instructions.

-

Page 3: Table Of Contents

Warnings ..........................26 2.9.4 Fire protection Signs ......................27 2.9.5 Safety Sign ......................... 28 TECHNICAL SPECIFICATIONS ................. 29 General information ....................... 29 CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 3 Support: +49 (0)2831/91021-50 07.03.2022... - Page 4 DynaCut MDE ........................53 4.9.2 Careful Minicool........................ 55 4.10 Protective Fencing ....................... 56 WORKING AND HAZARDOUS AREAS ..............57 Workspace ..........................57 CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 4 Support: +49 (0)2831/91021-50 07.03.2022...

- Page 5 Measures after maintenance ....................75 ERRORS ........................76 Safety instructions for troubleshooting ................76 Tab of errors ........................... 78 Troubleshooting work ......................79 CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 5 Support: +49 (0)2831/91021-50 07.03.2022...

- Page 6 Safety instructions for dismantling and disposal ............. 86 11.2 Dismantling .......................... 86 11.3 Disposal ..........................87 ACCESSORIES ....................... 88 CUSTOMER SERVICE .................... 89 CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 6 Support: +49 (0)2831/91021-50 07.03.2022...

-

Page 7: General

This mark precedes activities in areas that are prohibited for people with pacemakers. Warning of dangerous electrical voltage This mark precedes activities on live system components. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 7 Support: +49 (0)2831/91021-50... -

Page 8: Limitation

The contents of this manual are protected by copyright. Their use is permitted in the context of the use of the machine. Any further use is not permitted without the written permission of the manufacturer. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 8 Support: +49 (0)2831/91021-50... -

Page 9: Safety

• Operation of the machine within potentially explosive atmospheres. Claims of any kind due to damage due to improper use are excluded. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 9 Support: +49 (0)2831/91021-50... -

Page 10: Basic Dangers

• Never bridge fuses or put them out of operation. When replacing fuses, comply with the correct current specification. • Keep moisture away from live parts. This can lead to a short circuit. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 10 Support: +49 (0)2831/91021-50... -

Page 11: Dangers From Mechanics

• Do not reach into a column between the mobile unit and the Y-bridge. • Carry out work on the machine only at a standstill. • Wear personal protective equipment when working with the machine. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 11 Support: +49 (0)2831/91021-50... - Page 12 Sharp edges and pointed corners can cause abrasions and cuts on the skin. • When working near sharp edges and pointed corners, proceed carefully. • If in doubt, wear protective gloves. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 12 Support: +49 (0)2831/91021-50 07.03.2022...

-

Page 13: Hazards From High Or Low Temperatures

• In the event of a fire, stop work immediately. Leave the danger zone until the all-clear is given. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 13 Support: +49 (0)2831/91021-50 07.03.2022... -

Page 14: Dangers From Radiation

• Do not bring storage media, credit cards, etc. close to the magnetic source. Data can be deleted. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 14 Support: +49 (0)2831/91021-50 07.03.2022... -

Page 15: Hazards From Chemical Substances

Contact with oil and fat can lead to damage to health. • Avoid skin contact. • Remove oil and fat from the skin immediately. • Do not inhale vapors. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 15 Support: +49 (0)2831/91021-50 07.03.2022... -

Page 16: General Hazards In The Workplace

• Remove objects that are no longer needed from the work area and especially from the ground. • Mark unavoidable tripping points with yellow-black marking tape. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 16 Support: +49 (0)2831/91021-50... -

Page 17: Responsibility Of The Operator

• The operator must ensure that the maintenance intervals described in these instructions are adhered to. The operator must have all safety devices regularly checked for functionality and completeness. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 17 Support: +49 (0)2831/91021-50 07.03.2022... -

Page 18: Staff Requirements

Certain work may only be carried out by specialist personnel of the manufacturer. Other personnel are not authorized to carry out this work. To carry out the work involved, please contact our customer service. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 18 Support: +49 (0)2831/91021-50... -

Page 19: Instruction

Chemical-resistant protective gloves are used to protect hands from harsh chemicals. Hearing protectors Hearing protection is used to protect against hearing damage caused by noise exposure. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 19 Support: +49 (0)2831/91021-50 07.03.2022... -

Page 20: Safety

• Before starting work, check whether all safety devices are functional and correctly installed. • Never override or bridge safety devices. • Ensure that all safety devices are always accessible. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 20 Support: +49 (0)2831/91021-50 07.03.2022... -

Page 21: Description Of The Safety Devices Installed

• Do not unlock the emergency stop button (Fig. 2 /1) until there is no longer any danger. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 21 Support: +49 (0)2831/91021-50 07.03.2022... - Page 22 The main switch (Fig.2/1) also serves as an EMERGENCY STOP switch. This is only rotated and switches off the machine completely. 1 Main switch 2 Emergency stop button Fig.2: Operator terminal CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 22 Support: +49 (0)2831/91021-50 07.03.2022...

-

Page 23: Safety Devices That The Operator Must Retrofit

• Inform those responsible at the place of use. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 23 Support: +49 (0)2831/91021-50... -

Page 24: Environmental Protection

Observe the manufacturer's safety data sheet. It is recommended to use a Environmentally-friendly cooling lubricant. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 24 Support: +49 (0)2831/91021-50... -

Page 25: Signing

Persons wearing a pacemaker are not allowed to approach a machine marked with this safety mark. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 25 Support: +49 (0)2831/91021-50... -

Page 26: Warnings

Leave the danger zone after signaling.Keep enough distance to all parts that can move, there is a risk of crushing or moving in. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 26 Support: +49 (0)2831/91021-50... -

Page 27: Fire Protection Signs

Before fire extinguishers are brought to the source of the fire, warn or rescue all persons in the danger zone. Remove the fire extinguisher only to extinguish a fire. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 27 Support: +49 (0)2831/91021-50... -

Page 28: Safety Sign

Escape route In an emergency, follow the specified escape route in the direction of the arrow. Escape routes must always be kept clear. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 28 Support: +49 (0)2831/91021-50... -

Page 29: Technical Specifications

Lower edge bridge to the vacuum table - without accessories! Passage height measured 220mm Load capacity Z-axis 20 KG 20 KG 20 KG 20 KG attachment weight CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 29 Support: +49 (0)2831/91021-50 07.03.2022... - Page 30 1200 mm 1800 mm Y-axis 600 mm 600 mm 1200 mm 1200 mm Z-axis 200/300/400 200/300/400 200/300/400 200/300/400 (200 mm is standard) CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 30 Support: +49 (0)2831/91021-50 07.03.2022...

- Page 31 20mm 20mm 20mm X /Y/Z axis Repeatability 0,01mm 0,01mm 0,01mm 0,01mm Measured in diagonal travel X+Y (depending on the contour shape) CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 31 Support: +49 (0)2831/91021-50 07.03.2022...

- Page 32 0,01mm 0,01mm Backlash +- 0,015mm +- 0,015mm +- 0,015mm +- 0,015mm Measured in diagonal travel X+Y (depending on the contour shape) CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 32 Support: +49 (0)2831/91021-50 07.03.2022...

-

Page 33: Connection Values

S e r v i c e c o n d i t i o n s Environment Specification Value Unit Temperature range 15-30 °C Relative humidity, maximum CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 33 Support: +49 (0)2831/91021-50 07.03.2022... -

Page 34: Supplies

The nameplate (Fig. 4) is located at the back of the terminal and contains the following information: Fig.4: Type plate ➢ Manufacturer ➢ Machine Type ➢ Year of construction ➢ Serial number ➢ Execution CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 34 Support: +49 (0)2831/91021-50 07.03.2022... -

Page 35: Construction And Functions

5 Y-axis with carriage (bridge) 14 Vacuum sections 6 Z-axis with slide 7 RF Spindle 8 Energy Cable Chain 9 Bellows CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 35 Support: +49 (0)2831/91021-50 07.03.2022... -

Page 36: Brief Description Of The Scope Of Application

The motors for the axis movement are controlled via the control system. The motors and the recirculating ball screw in Z or the racks in X and Y convert rotating displacement into linear movement. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 36 Support: +49 (0)2831/91021-50... -

Page 37: Module Description

The conversion of the rotary movement of the motor into the linear movement of the X-axis takes place via the gear wheel on the rack. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 37 Support: +49 (0)2831/91021-50 07.03.2022... -

Page 38: Y-Axis

The conversion of the rotational movement of the motor into the linear movement of the Y-axis takes place via the gear wheel on the rack. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 38 Support: +49 (0)2831/91021-50 07.03.2022... -

Page 39: Z-Axis

Z-axis is moved up and down on the profile rails. The transfer from the stepper motor to the ball screw is carried out via a timing belt with a ratio of 1:1. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 39 Support: +49 (0)2831/91021-50 07.03.2022... -

Page 40: Z-Axis 300Mm (Optional)

Thus, in addition to the standard RF spindle, many other tools can be attached to the Z-axis. For example, oscillating knives, milling spindles CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 40 Support: +49 (0)2831/91021-50... -

Page 41: Central Lubrication

Fig. 9.1: Oil tank for central lubrication 1 Oil distributor 2 Check valve Fig. 9.3: Oil distributor X-axis Fig. 9.2: Oil distributor Z-axis CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 41 Support: +49 (0)2831/91021-50 07.03.2022... - Page 42 Duty cycle of the oil pump when the lubrication interval is reached. The lubricant intervals should be checked regularly, so that all profile guides, spindles etc. get enough oil. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 42 Support: +49 (0)2831/91021-50...

-

Page 43: Operator Terminal

2 - Emergency stop button 3 - Control On (Reset) 4 - Vacuum pump(s) on/off 5 - Industrial PC 6 - USB-Connections Fig.10: Operator terminal CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 43 Support: +49 (0)2831/91021-50 07.03.2022... -

Page 44: Machine Control

1 - Inverter for HF spindle 2 - Power supply 24V motherboard etc. 3 - Transformer for stepper motor power amplifiers Fig.10.2: Control CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 44 Support: +49 (0)2831/91021-50 07.03.2022... -

Page 45: Connections On The Controller

The LAN connection for integrating the machine into the company network or the Internet can only be used if a network switch has been ordered for the machine. This is then installed and connected in the controller. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 45 Support: +49 (0)2831/91021-50... -

Page 46: Connections On The Machine

If the pressure is not reached, the software interrupts the process and issues an error message. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 46 Support: +49 (0)2831/91021-50 07.03.2022... -

Page 47: Hf Spindle

All tools used must be right-handed. If other HF spindles or interchangeable systems are used, please refer to the separate instructions of these systems! CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 47 Support: +49 (0)2831/91021-50... -

Page 48: Vacuum Clamping System

7) Switch on the vacuum pump at the operator terminal 8) Vacuum meter (Fig.12. 2) control. The display should show min. -0.1. 9) Check the fixed fit of the workpiece. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 48 Support: +49 (0)2831/91021-50... - Page 49 Operating instructions T-Rex N-Serie (Stepper) Fig.12: Machine with vacuum table and C-rails Fig.12.1: Vacuum zones and shut-off valves Fig.12.2: Vacuum meters CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 49 Support: +49 (0)2831/91021-50 07.03.2022...

- Page 50 Fig. 12.3: Closure plugs vacuum zone 1 Open Vacuum Hose 2 Sealing Cord Fig. 12.4: Vacuum opening / vacuum sealing cord CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 50 Support: +49 (0)2831/91021-50 07.03.2022...

-

Page 51: Side Channel Compressor (Optional)

The side channel compressor has its own power connection. The control cable is connected to the machine control. For example, the side channel compressor can be switched on and off via the button on the control panel. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 51 Support: +49 (0)2831/91021-50... - Page 52 1x 7,5KW / 2x 5,5KW Selection depends on the material T-Rex 2040 2x 5,5KW / 2x 7,5KW Selection depends on the material CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 52 Support: +49 (0)2831/91021-50 07.03.2022...

-

Page 53: T-Slot Plate (Optional)

The volume of the air flow at the nozzle tip and thus also the pressure are adjusted by an CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 53 Support: +49 (0)2831/91021-50 07.03.2022... - Page 54 The nozzle is flexible and should be brought as close to the tool as possible. !!! Please refer to the separate user manual for this system!!! CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 54 Support: +49 (0)2831/91021-50 07.03.2022...

-

Page 55: Careful Minicool

1. Stop valve 2. Noga Valve unit 3. Spray nozzle, adjustable 4. Lubrication Tank Abb. 17: Noga System Fig. 17.1: Lubricant tanks CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 55 Support: +49 (0)2831/91021-50 07.03.2022... -

Page 56: Protective Fencing

Declaration of Incorporation. The operator of this plant must then ensure the safety of the plant or ensure his own CE declaration. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 56 Support: +49 (0)2831/91021-50... -

Page 57: Working And Hazardous Areas

D a n g e r z o n e 4 Entire range of machinery within the fence during operation Fig. 18.1: Danger zone CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 57 Support: +49 (0)2831/91021-50 07.03.2022... -

Page 58: Installation And Initial Commissioning

Ensure that all installation work has been completed and completed in accordance with the instructions and instructions in this guide. Ensure that there are no people in the danger zone. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 58 Support: +49 (0)2831/91021-50... -

Page 59: Preparations

An uneven surface causes deformations within the machine. This leads to inaccurate machining of the workpieces. • Set up the machine on a flat and flat surface. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 59 Support: +49 (0)2831/91021-50... -

Page 60: Stepper Motor And Control Cable

Improperly attached accessories can fall or be ejected uncontrollably during operation, causing serious injuries to the skin and eyes. • Assemble accessories professionally in compliance with safety regulations. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 60 Support: +49 (0)2831/91021-50 07.03.2022... -

Page 61: Installation

Ensure that required accessories are installed and connected to the power supply. Ensure the firm fit of all plug connections. Inspection of safety devices, such as safety fences, etc. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 61 Support: +49 (0)2831/91021-50... -

Page 62: Safety Instructions For Operation

20–25 °C, it is ensured that no significant influences occur during processing. Therefore, it is recommended to maintain an ambient temperature of 20–25 °C when operating the machine. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 62 Support: +49 (0)2831/91021-50... -

Page 63: Turn On

(zero point of the axis) when initializing the axis. From this position, all other positions are then calculated relatively for the method of the axis via software. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 63 Support: +49 (0)2831/91021-50... -

Page 64: Activities During Operation

• Carry out work on the linear guides only at a standstill. • Wear personal protective equipment in the work area. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 64 Support: +49 (0)2831/91021-50... - Page 65 This allows limbs to be detected. • Make sure that no body parts get into the danger area of the machine. • Secure workspace from accidental access CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 65 Support: +49 (0)2831/91021-50...

- Page 66 • Remove cooling emulsion from the skin immediately. • Do not inhale vapors. Operation with coolant HINT: For more information, refer to the manufacturer's specifications of the coolant. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 66 Support: +49 (0)2831/91021-50 07.03.2022...

-

Page 67: Change Tool

S wi t c h o f f 1. Shut down your computer (Windows 10). 2. Decoupling compressed air connection 3. Turn off the main switch. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 67 Support: +49 (0)2831/91021-50 07.03.2022... -

Page 68: Activities After Use

Inform those responsible at the place of use. Switch off the machine and secure it against reactivation. Clear access roads for emergency vehicles. Instruct emergency vehicles. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 68 Support: +49 (0)2831/91021-50 07.03.2022... -

Page 69: Maintenance

• Before starting the work, switch off the electrical supply and secure it against reactivation. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 69 Support: +49 (0)2831/91021-50 07.03.2022... - Page 70 • Collect oil/grease-containing rags in suitable containers and dispose of them in accordance with the applicable local regulations. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 70 Support: +49 (0)2831/91021-50...

-

Page 71: Spares

Spare parts orders without the above information cannot be considered. In the absence of information about the shipping method, shipping will be at the discretion of the supplier. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 71 Support: +49 (0)2831/91021-50 07.03.2022... -

Page 72: Maintenance Plan

Clean metallic machine parts and rub Operator them with a resin- and acid-free oil/grease Cleaning the air filter of the vacuum Operator pump CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 72 Support: +49 (0)2831/91021-50 07.03.2022... -

Page 73: Maintenance Work

Always wear protective gloves when removing chips. Free recirculating ball screws and linear guides from chips. Clean the entire machine with a slightly oil-soaked cleaning cloth DIN 61650 CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 73 Support: +49 (0)2831/91021-50... -

Page 74: Lubricate Machine

Contact with oil and fat can lead to damage to health. • Avoid skin contact. • Remove oil and fat from the skin immediately. • Do not inhale vapors. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 74 Support: +49 (0)2831/91021-50 07.03.2022... -

Page 75: Measures After Maintenance

Clean the working area and remove any leaked substances such as for example liquids, processing material or the like. Ensure that all safety devices of the machine work properly. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 75 Support: +49 (0)2831/91021-50... -

Page 76: Errors

Wait until all components have come to a standstill. • Wear tight-fitting protective workwear with low tensile strength in the hazardous area. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 76 Support: +49 (0)2831/91021-50 07.03.2022... - Page 77 Depending on the type of fault, have it eliminated by authorized personnel. The following fault table provides information on who is entitled to rectify the fault. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 77 Support: +49 (0)2831/91021-50...

-

Page 78: Tab Of Errors

Machine does not Advance of the Setting the guideline Professionals detect reference reference trip too fast value 50mm/sec in switch software CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 78 Support: +49 (0)2831/91021-50 07.03.2022... -

Page 79: Troubleshooting Work

9 .3 .1 U n l o c k E m e r g e n c y S t o p • Operator Personal: Determine and remedy the cause of the fault. Double unlock 2 emergency stop buttons by turning them. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 79 Support: +49 (0)2831/91021-50 07.03.2022... -

Page 80: Commissioning After Fault Has Been Resolved

Acknowledge fault in the controller. Ensure that there are no people in the danger zone. Start according to the instructions in the chapter "Operation". CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 80 Support: +49 (0)2831/91021-50... -

Page 81: Transport, Packaging And Storage

• Carefully lift the package and see if it tilts. If necessary, change the stop. Improper transport CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 81 Support: +49 (0)2831/91021-50 07.03.2022... -

Page 82: Transportinspektionen

Handling of packaging materials Dispose of packaging material in accordance with the applicable legal provisions and local regulations. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 82 Support: +49 (0)2831/91021-50 07.03.2022... -

Page 83: Packaging

Nothing may be stacked on the marked packages or goods Protect from moisture Protect packages from moisture and keep them dry. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 83 Support: +49 (0)2831/91021-50 07.03.2022... -

Page 84: Transport

• The forklift driver must be entitled to drive industrial trucks with a driver's seat or driver's cab in accordance with national regulations. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 84 Support: +49 (0)2831/91021-50... -

Page 85: Storage

Under certain circumstances, there may be storage instructions on the packages that go beyond the requirements mentioned here. Comply with these accordingly. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 85 Support: +49 (0)2831/91021-50... -

Page 86: Dismantling And Disposal

Subsequently, assemblies and components are professionally cleaned and dismantled in compliance with applicable local occupational health and safety and environmental protection regulations. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 86 Support: +49 (0)2831/91021-50... -

Page 87: Disposal

• In case of doubt, obtain information on environmentally sound disposal from the local authority or special waste management companies. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 87 Support: +49 (0)2831/91021-50 07.03.2022... -

Page 88: Accessories

We will be happy to advise you and send you a corresponding offer. Numerous suggestions and information can also be found on our website. CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 88 Support: +49 (0)2831/91021-50... -

Page 89: Customer Service

If you have any questions, please contact our customer service by e-mail or telephone. We will be happy to advise you. Numerous suggestions and information can also be found on our website: https://www.cnc-step.com/ CNC-STEP GmbH & Co. KG ▪ Siemensstrasse 13-15 ▪ 47608 Geldern ▪ Germany Page 89 Support: +49 (0)2831/91021-50 07.03.2022...

Need help?

Do you have a question about the T-Rex N Series and is the answer not in the manual?

Questions and answers