Subscribe to Our Youtube Channel

Summary of Contents for Westermann Cleanmeleon ll

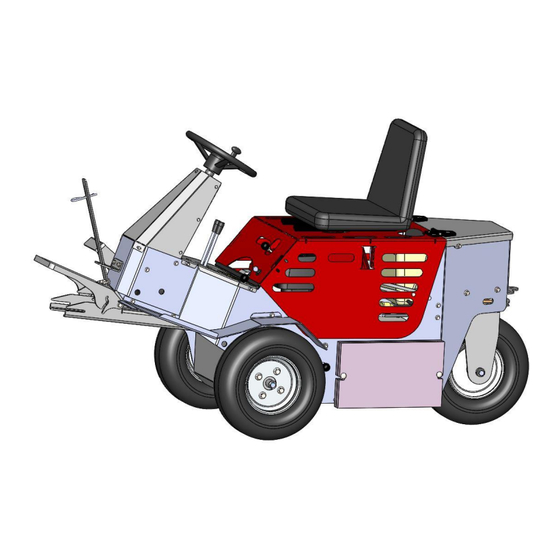

- Page 1 Westermann Cleanmeleon II Westermann GmbH & Co .KG Westermann Cleanmeleon ll Operating instructions and spare parts list...

- Page 2 Westermann Cleanmeleon II Westermann GmbH & Co .KG Foreword Dear customer, By purchasing the Westermann Cleanmeleon ll, you are now in possession of a product that has been manufactured to the highest quality standards. These operating instructions contain useful and important infor- mation relating to the operational safety, reliability and value reten- tion of your Westermann Cleanmeleon ll.

-

Page 3: Table Of Contents

Westermann Cleanmeleon II Westermann GmbH & Co .KG Index General information ............... 1 1.1. Purpose ..................1 1.2. Product information ..............1 1.2.1 Manufacturer ................1 1.2.2 Type plate ................. 2 1.2.3 Ordering spare parts ..............2 1.2.4 Intended use ................3 1.2.5. - Page 4 Westermann Cleanmeleon II Westermann GmbH & Co .KG 5.1. Hydraulic oil quantity (standard) ..........29 Optional component: ..............30 6.1. Large oil sump ................ 30 6.2. Large hydraulic pump ............. 30 6.3. Oil cooler/hydraulic oil filter ............. 31 6.4. Electrical system ..............31 Maintenance and repair ...............

-

Page 5: General Information

Westermann GmbH & Co .KG 1. General information Please observe the operating instructions provided by the manufacturer for the Cleanmeleon ll and for the motor, as this is essential for problem-free use. Only proper operation, observation of the safety information and appropriate maintenance and care guarantee the long- term use of your recently purchased machine. -

Page 6: Type Plate

Westermann Cleanmeleon II Westermann GmbH & Co. KG 1.2.2 Type plate The type plate is located on the right-hand side of the steering col- umn (in the direction of travel). Type plate 1.2.3 Ordering spare parts When ordering spare parts or accessories, the type designation, machine number and year of construction should be stated. -

Page 7: Intended Use

Westermann GmbH & Co. KG 1.2.4 Intended use The Westermann Cleanmeleon ll has been constructed exclusively for general use to clean slatted floors, sweep paved areas such as yards, streets, car parks, silo plates and barns, to shift snow, scat- ter feed, litter down barns, and other similar work. -

Page 8: Technical Datasheet

Westermann Cleanmeleon II Westermann GmbH & Co. KG 1.2.5. Technical datasheet Westermann Cleanmeleon Specifications GXV 160 / GXV 340 / B&S engine 4-stroke petrol engine GXV 160 starter Hand start Honda GXV 340 starter E-Start / Hand start Briggs & Stratton starter... -

Page 9: Safety

Westermann Cleanmeleon II Westermann GmbH & Co. KG 2. Safety These operating instructions include basic information that must be observed during operation, maintenance and servicing. Staff must read these operating instructions prior to start-up and use of the machine, and they must remain accessible to staff at all times. -

Page 10: Staff Training And Instruction

The Usage under influence of tiredness, illness, alcohol or drug influence is forbidden. The Westermann Cleanmeleon ll may only be used, maintained and repaired by staff who are familiar with it and who have been informed of the associated risks. -

Page 11: Risk Of Non-Compliance With The Safety Instructions

The safety information provided by the vehicle manufacturer must also be followed. Operation on public roads is NOT per- mitted because the Cleanmeleon ll does not meet the applicable legal regulations (the StVZO and StVO in the Federal Republic of Germany). -

Page 12: Safety Instructions For The Operator/User

Westermann Cleanmeleon II Westermann GmbH & Co. KG 2.5. Safety instructions for the operator/user Only operate device well- ventilated areas. NEVER use in closed spaces as poisonous carbon monoxide is generated during petrol combustion. Danger of poisoning! The oil level must be checked at regu-... - Page 13 Westermann Cleanmeleon II Westermann GmbH & Co. KG Users must always wear close-fitting clothing. Avoid wearing loose clothing. Shoes shall not be slippery Familiarise yourself with how to operate the engine. Take note of how to switch off the engine in an emergency.

- Page 14 Westermann Cleanmeleon II Westermann GmbH & Co. KG The travelling speed should be adapted to the applicable road and traffic conditions. Avoid any sudden turning ma- noeuvres when travelling uphill, downhill, or across an in- cline. the forces that are exerted on the Remember to account for handling, steering and braking ability.

-

Page 15: Safety Notice For Maintenance, Inspection And Installation Work

Leaks are a danger to the environment and must be fixed immediately. Use suitable tools when looking for leaks in order to avoid risk of injury. Only operate the Westermann Cleanmeleon II in well- ventilated areas. 2.6. Safety notice for maintenance, inspection and instal- lation work... -

Page 16: Unauthorised Modifications And Production Of Spare Parts

Westermann Cleanmeleon II Westermann GmbH & Co. KG All safety and protective devices should be reinstalled and put back into operation immediately after completing the work. The points listed in section “4 Starting up the machine” must be observed before restarting. -

Page 17: Warning Symbols On The Machine According To Iso 11684

Westermann Cleanmeleon II Westermann GmbH & Co. KG 2.9. Warning symbols on the machine according to ISO 11684 Article-Nr. . 94456 Read and follow the operating instructions and safety notic- es before start-up. Never reach into the crushing or danger zone when there is a chance that parts may move. -

Page 18: Westermann Cleanmeleon Ii

Westermann Cleanmeleon II Westermann GmbH & Co. KG 3. Westermann Cleanmeleon II 3.1. Typeplate (identification) Type: Year of construc- tion: Serial no.: The type plate is an official certificate Notice and must not be modified or otherwise concealed. -

Page 19: Storage

Westermann Cleanmeleon ll is positioned securely and cannot roll away. Check the vehicle for any damage. Caution Clean the Westermann Cleanmeleon ll thoroughly as re- quired. Dirt attracts damp and causes rust. Patch paint scratches if necessary... -

Page 20: Description Of Product And Accessories

The Cleanmeleon ll can be driven forwards and backwards using the right foot pedal. It is also possible to rotate the Cleanmeleon ll 360° on the spot by configuring the three wheels. This is particular- ly useful for remaining mobile on narrow slatted floors (alleyways). -

Page 21: Attachments

Westermann Cleanmeleon II Westermann GmbH & Co. KG 3.4. Attachments The attachments listed below can be installed on the Westermann Cleanmeleon ll. This provides a range of potential uses. Attachments with standard swing arm: ASS 900 (double column slides) ... -

Page 22: Installing The Attachments

Ensure that the Westermann Cleanmeleon ll is positioned securely and cannot roll away. If ballast weights are prescribed, these must be attached to the fixing points provided on the Cleanmeleon ll, in accordance with the instructions. Special caution is required when attaching or coupling. -

Page 23: Attachment To Swing Arm With Attachment Shoe

Westermann Cleanmeleon II Westermann GmbH & Co. KG 3.5.2. Attachment to swing arm with attachment shoe The attachment shoe is screwed directly onto the attachment. The attachment shoe is then hooked into the swing arm with the at- tachment and secured using a locking device. -

Page 24: Device Start-Up

Danger of accident! Ensure that the Westermann Cleanmeleon ll is positioned securely and cannot roll away. Please read the Cleanmeleon ll and engine op- erating instructions with the associated setting instructions carefully before startup! Ensure that the operating instructions have also been understood! The safety regulations from Chapter 2.5... -

Page 25: Seating Adjustment

Westermann Cleanmeleon II Westermann GmbH & Co. KG 4.1. Seating adjustment The lever for the seating adjustment (to push the seat further for- wards or backwards) is on the left under the seat when facing the direction of travel. Lever... -

Page 26: Checking The Engine Before Start-Up

Westermann Cleanmeleon II Westermann GmbH & Co. KG 4.2. Checking the engine before start-up Read the enclosed engine operating instructions for how to main- tain and care for the engine. They include all the necessary maintenance steps such as changing the oil, changing the spark plugs, and engine inspection intervals. -

Page 27: Handbrake

Westermann Cleanmeleon II Westermann GmbH & Co. KG 4.3. Handbrake To prevent the device moving out of neutral, the handbrake can be applied for safety. Handbrake lever To apply the brake, pull the handbrake lever up and hook it into place. -

Page 28: Starting / Stopping Cleanmeleon Ii

Westermann Cleanmeleon II Westermann GmbH & Co. KG 4.5. Starting / stopping Cleanmeleon II Gear activation lever Ensure that the gear activation has been set Caution correctly for operation. Push the lever in and engage (drive mode). Has the fuel tap on the engine been opened? - Page 29 Westermann Cleanmeleon II Westermann GmbH & Co. KG 4.5.2. Handstart GXV 340 engine Cold start (Choke) Standing/Stop Within cold start the reward nut needs to be Igni- in front of the lead-in panel. tion Start the engine by turning the ignition key.

-

Page 30: Transportation

Westermann Cleanmeleon II Westermann GmbH & Co. KG 4.6. Transportation The safety regulations from Chapter 2.5 apply. Perforated profile Holder Foot pedal Safety catch During transportation, lift the tool with the left foot pedal until the safety catch clicks. Also secure it against unintended lowering with a splint in the perforated profile. -

Page 31: Working With The Vehicle

Westermann Cleanmeleon II Westermann GmbH & Co. KG 4.7. Working with the vehicle Remove the safety splint from the perforated profile and lower the tool using the foot pedal or by hand using the spool valve until it touches the ground. You can now begin working with the vehicle. -

Page 32: Dismantling The Tool

Westermann Cleanmeleon II Westermann GmbH & Co. KG 4.8. Dismantling the tool Only for tools with attachment shoe. Danger of accident! Check attachment is positioned se- curely. The safety regulations from Chapter 2.5 apply. Set the attachment on the floor, unlock the locking device and pull out the attachment from the swing arm. -

Page 33: Hydraulic Controls

Westermann Cleanmeleon II Westermann GmbH & Co. KG 5. Hydraulic controls Needle valve: Optional: Right lever Left lever Needle valve for regulating the oil flow through the hydraulic lifting mechanism. Left lever: Push the lever forward = brush rotates right... -

Page 34: Optional Component

Westermann Cleanmeleon II Westermann GmbH & Co. KG 6. Optional component: The Cleanmeleon II can be optionally equipped with a larger oil sump, a larger hydraulic pump, an oil cooler and a hydraulic oil filter. 6.1. Large oil sump Dipstick max. -

Page 35: Oil Cooler/Hydraulic Oil Filter

Westermann Cleanmeleon II Westermann GmbH & Co. KG 6.3. Oil cooler/hydraulic oil filter If the Cleanmeleon II is equipped with the large hydraulic pump (6 l) and large oil sump (17 l), an oil cooler and a hydraulic oil filter can also be mounted. -

Page 36: Maintenance And Repair

All maintenance, repair and alteration work can only be carried the Westermann Cleanmeleon ll when stopped and with the en- gine switched off. The procedure for stopping the unit described in the operating instructions must be observed. Danger of accident! Ensure that the Westermann Cleanmeleon ll is positioned securely and cannot roll away. - Page 37 Westermann Cleanmeleon II Westermann GmbH & Co. KG Fuel feed lines should be replaced after a maximum service period of six years (including storage time of max. two years). Replace damaged and aged fuel feed lines. The replacement lines must correspond to the manufactur- er’s technical requirements.

-

Page 38: Tighten V-Belt

Westermann Cleanmeleon II Westermann GmbH & Co. KG 7.2. Tighten V-belt Loosen the nuts on the engine holding plate on both sides of the device and push back via the groove in the frame Groove using a screwdriver. The V-belt must be able to press in another 0.5 - 1 cm 7.3. -

Page 39: Faults, Causes And Solution

Westermann Cleanmeleon II Westermann GmbH & Co. KG 7.4. Faults, causes and solution Fault Cause Solution No fuel in the tank Fill with fuel Spark plug faulty Replace spark plug Air filter dirty Clean or replace Vehicle does not start... - Page 40 Westermann Cleanmeleon II Westermann GmbH & Co. KG Fault Cause Solution Hydraulic Check connections connections incorrect Insufficient hydraulic Refill with oil oil in the oil tank Spool valve faulty Visit workshop Attachment does not spin Pressure or volume Visit workshop...

-

Page 41: Ec Declaration Of Conformity

Westermann Cleanmeleon II Westermann GmbH & Co. KG 8. EC Declaration of Conformity In accordance with EC Directive 89/392/EEC The company Westermann GmbH & Co. KG Schützenhof 23 D-49716 Meppen (Emsl.) declares under sole responsibility that its product, the Westermann Cleanmeleon ll,... -

Page 42: Warranty Guidelines

The following guidelines are valid from 01/01/2002 for Westermann warranty claims. 1) For Westermann products in the consumer goods sector (pri- vate use) which were purchased from specialist Westermann retailers, the warranty period lasts for a period of 2 years from the date of sale to the end customer. - Page 43 Westermann Cleanmeleon II Westermann GmbH & Co. KG by Westermann GmbH & Co. KG cannot be accepted under the warranty. Please ensure that only original Westermann spare parts and Westermann accessories purchased from a specialist Wester- mann retailer are used. Using spare parts or accessories other than original Westermann spare parts or accessories can cause subsequent damage and increase the risk of accident.

- Page 44 13) To ensure fast processing, the warranty claim must be submit- ted to Westermann customer service at the latest 5 days after repairs have been carried out. Warranty claims submitted 3 months after repairs have been carried out can no longer be processed.

-

Page 45: Spare Parts List

Westermann Cleanmeleon II Westermann GmbH & Co. KG Spare parts list Westermann Cleanmeleon ll... -

Page 46: Exploded Drawing Of Rear Wheel Bearing

Westermann Cleanmeleon II Westermann GmbH & Co. KG 10.1. Exploded drawing of rear wheel bearing 10.2. Parts list of rear wheel bearing Quantity Item Article no. Description UNM005L Bearing plate Compression ball bearings DK-LS 289439 UNM144B Rear suspension chain guide disk... -

Page 47: Exploded Drawing Of Throttle Handle

Westermann Cleanmeleon II Westermann GmbH & Co. KG 10.3. Exploded drawing of throttle handle Honda GXV 340 Only Honda GXV 160 and B&S 10.4. Parts list of throttle handle Artikel-Nr. Bezeichnung Menge UNM032 Throttle handle UNM033 Holder throttle handle 842040... -

Page 48: Exploded View Of Foot Lifting Mechanism

Westermann Cleanmeleon II Westermann GmbH & Co. KG 10.5. Exploded view of foot lifting mechanism 10.6. Parts list of foot lifting mechanism Quantity Item Article no. Description UNM060D Pedal axle UNM065A Socket UNM042B Left pedal 7096907 Adjusting ring A20 UNM040A... -

Page 49: Exploded View Of Covering Hood

Westermann Cleanmeleon II Westermann GmbH & Co. KG 10.7. Exploded view of covering hood 10.8. Parts list of covering hood Menge POS Artikel- Nr. Bezeichnung UNM007K Spool valve unit (RAL 3000) 0703287 Hexagonal head screw M8x20 039408 Nut M8 ratchet... -

Page 50: Exploded Drawing Of Frame

Westermann Cleanmeleon II Westermann GmbH & Co. KG 10.9. Exploded drawing of frame... -

Page 51: Parts List Of Frame

Westermann Cleanmeleon II Westermann GmbH & Co. KG 10.10. Parts list of frame Quantity Item Article no. Description GXV 160 GXV 340 UNM006E Engine plating UNM001W Right support UNM002V Left support UNM004C Adjustment lever UNM017C Cover UNM054E Left tread UNM055E... -

Page 52: Exploded Drawing Of Frame

Westermann Cleanmeleon II Westermann GmbH & Co. KG 10.11. Exploded drawing of frame... -

Page 53: Parts List Of Frame

Westermann Cleanmeleon II Westermann GmbH & Co. KG 10.12. Parts list of frame Quantity Item Article no. Description GXV 160 GXV 340 0704246 Disk 21 mm DIN 125 7095288 Hexagonal head screw 8x30 ratchet 7051499 Coach bolt M10x25 0394010 Nut M10 ratchet... -

Page 54: Exploded View Of Drive / Steering

Westermann Cleanmeleon II Westermann GmbH & Co. KG 10.13. Exploded view of drive / steering... -

Page 55: Drive/Steering Parts List

Westermann Cleanmeleon II Westermann GmbH & Co. KG 10.14. Drive/steering parts list Quantity Article no. Description GXV 160 GXV 340 UNM5016 Spool valve unit GXV160UH2-N1-5- GXV160 GXV340T2 GXV 340 2000-031 Gear transmission incl. hydrostat 751-0818C Tank 751-0603 GC300 filler cap A027.5... -

Page 56: Exploded View Of Drive/Steering

Westermann Cleanmeleon II Westermann GmbH & Co. KG 10.15. Exploded view of drive/steering... -

Page 57: Drive/Steering Parts List

Westermann Cleanmeleon II Westermann GmbH & Co. KG 10.16. Drive/steering parts list Quantity Item Article no. Description GXV 160 GXV 340 UNM5010 Sheet strap unit for declutching UNM5007 Parking brake unit UNM5006 Gear activation unit UNM5011 Angle joint unit UNM5012... -

Page 58: Exploded View Of Steering Console

Westermann Cleanmeleon II Westermann GmbH & Co. KG 10.17. Exploded view of steering console 10.18. Parts list of steering console Quantity Article no. Description UNM034B Steering console UNM051A Steering shaft Plain bearings 20 x 25 x 15 008200300002 white SE3816-DMR-20... -

Page 59: Exploded View Of Foot Lifting Mechanism

Westermann Cleanmeleon II Westermann GmbH & Co. KG 10.19. Exploded view of foot lifting mechanism 10.20. Parts list of foot lifting mechanism Quantity Item Article no. Description UNM060D Pedal axle UNM065A Socket UNM042B Left pedal 7096907 Adjusting ring A20 UNM040A... -

Page 60: Exploded View Of Steering Wheel

Westermann Cleanmeleon II Westermann GmbH & Co. KG 10.21. Exploded view of steering wheel 10.22. Parts list of steering wheel Quantity Item Article no. Description GXV 160 GXV 340 VOL1930C2P Steering wheel Cheese-head screw with hexagon 0703618 socket M8x20 0704035... -

Page 61: Hydraulic Diagram

Westermann Cleanmeleon II Westermann GmbH & Co. KG 10.23. Hydraulic diagram 10.23.1 Cleanmeleon II without hydraulic lifting mechanism Hydraulic connections Spool valve / direction rotation Oil sump Pump... -

Page 62: Cleanmeleon Ii With Hydraulic Lifting Mechanism

Westermann Cleanmeleon II Westermann GmbH & Co. KG 10.23.2 Cleanmeleon II with hydraulic lifting mechanism...

Need help?

Do you have a question about the Cleanmeleon ll and is the answer not in the manual?

Questions and answers