GEZE TSA 325 NT Installation Instructions Manual

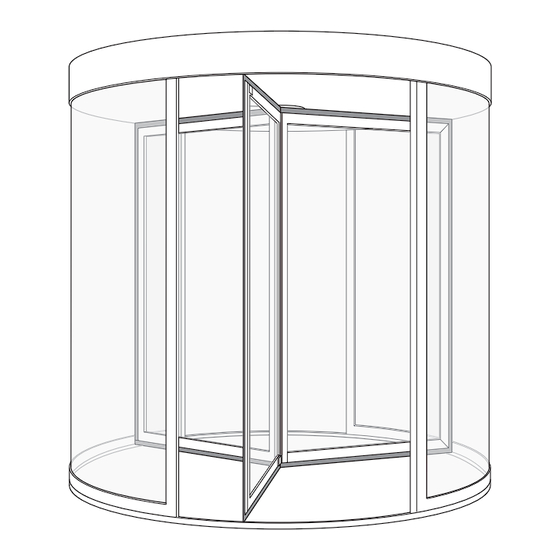

Revolving door

Hide thumbs

Also See for TSA 325 NT:

- Translation of the original instructions (13 pages) ,

- Wiring diagram (68 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for GEZE TSA 325 NT

- Page 1 Revolving door EN Installation instructions TSA 325 NT 131904-05...

-

Page 2: Table Of Contents

Open position monitoring ..................................43 General installation information for NV tooth-belt tension ......................44 Revolving door in all-glass version (TSA 325 NT GG) ........................50 Speed limiter unit for TSA 325 NT ................................61 Revolving door TSA 325 NT RC 2 ........................64 Assemblies and parts .................................... -

Page 3: Symbols And Illustrations

à The revolving door TSA 325 NT may not be used as a fire or smoke proof door drive. à The variants of the revolving door TSA 325 NT with break-out leaves is suitable for use in escape and rescue... -

Page 4: Safety Instructions

à The country-specific laws and regulations are to be observed during safety-related tests. à GEZE is not liable for any injuries or damage whatsoever resulting from unauthorised changes to the system. à GEZE does not accept any warranty for combinations with third-party products. -

Page 5: Inspection Of The Installed System

Revolving door TSA 325 NT Tools and aids à Attach safety stickers to glass door leaves (Mat. no. 136518). à Danger of injury with opened drive. Hair, clothing, cables, etc. can be drawn in by rotating parts. à Danger of injury caused by unsecured crushing, impact, drawing-in or shearing spots! à... -

Page 6: Consumables

Tools and aids Revolving door TSA 325 NT Tool Size/remark Tested lifting tools e.g. Genie Hoist 3.8 or GH 5.6 (min. lifting capacity 160 kg; max. lifting height 3.8 m or 5.6 m) Levelling device Ladder Ceiling lift Hoist unit... -

Page 7: Structure

Revolving door TSA 325 NT Structure Structure Motor Side-hung casement Top bearing Locking bolts Control unit Bolt lock Ceiling canopy Handle Lower ceiling panels Side panels Openings for LED lights (optional) Blocks for side element profiles (optional) Opening for automatic locking system (optional) -

Page 8: Installation

à Evenness of the installation surface. à Cable plan requirements. à Observe installation height/metre level mark at the construction site. Mounting the revolving door TSA 325 NT Secure workplace against unauthorised entry. Always work with a second person. Use a stepladder or step stool. - Page 9 Installation 4.2.2 Aligning the floor ring à In order to ensure trouble-free functioning of the revolving door TSA 325 NT, the floor ring must be aligned perfectly level (±1 mm). Top edge of finished floor level = Top edge of floor ring Align the floor ring every 30–40 cm using a levelling device and underlay it.

- Page 10 à Take the screed height in the floor ring into account. The dimension of 22 mm in the drawing below refers to the standard entrance mats of GEZE. à GEZE recommends sealing the surface of the screed in indoor areas. Fill the floor ring space (1) with screed.

- Page 11 4.2.5 Installation without floor ring The self-supporting drum structure of revolving door TSA 325 NT can be mounted directly on the top edge of the finished floor in certain circumstances. Installation without a floor ring is only permitted if the finished floor level is sufficiently load-bearing and even.

- Page 12 Installation Revolving door TSA 325 NT Determine the mounting points for the side panels for 4-leaf door systems Determine the mounting points for the side panels based on the system axis (1) and the passage axis (2) according to the sketch.

- Page 13 Revolving door TSA 325 NT Installation 4.2.6 Mounting the ceiling ring When mounting the ceiling canopy use supports (2). Connect the 2 half-shells (1) of the ceiling canopy. Screw the 2 half-shells (1) (see arrows). Check the radius of the ceiling construction.

- Page 14 Installation Revolving door TSA 325 NT 4.2.7 Mounting the drive unit The drive unit (1) can be supplied premounted or separately. Mount the drive unit (1) parallel to the system axis (4). Outside Inside The system axis often also corresponds to the façade axis.

- Page 15 Revolving door TSA 325 NT Installation 4.2.8 Lifting the ceiling canopy WARNING! The ceiling canopy is very heavy (approx. 200 kg). Risk of injury due to falling ceiling canopy. Only lift the ceiling canopy by means of suitable aids (e.g. pneumatic press).

- Page 16 Installation Revolving door TSA 325 NT Secure the inserted side elements against falling over by using a strap in the upper third. Spray soap water or silicone spray onto the upper rubber of the side elements and ceiling canopy. Lower the ceiling canopy carefully onto the side element profiles.

- Page 17 Revolving door TSA 325 NT Installation Tighten the screws (3) of the clamping ring on the chain wheel crosswise to 16.5 Nm. 4.2. 1 1 Inserting the floor bearing Screw the bearing ring (2) to the bearing plate (3) using the 4 screws (1).

- Page 18 Installation Revolving door TSA 325 NT 4.2. 1 2 Mounting the collector ring Screw the collector ring (1) to the bearing shaft (2) of the turnstile. Screw the circuit board DCU602 (4) to the chain View from below: wheel using the 2 screws (3).

- Page 19 Revolving door TSA 325 NT Installation 4.2. 1 4 Drilling a cable guide for post safety Drill a hole for the post safety sensor cable rout- ing at each post (2) through the ceiling canopy (1). Thread the post safety sensor (3) cable through the ceiling canopy.

- Page 20 Installation Revolving door TSA 325 NT The chain lock must be inserted from above. Insert the drive chain (1). Check whether the drive pinion (3) and the chain wheel (2) are flush. 4.2. 1 7 Mounting the side-hung casements Insert the side-hung casement (1).

- Page 21 Revolving door TSA 325 NT Installation 4.2. 1 8 Fastening the side-hung casements Screw the side-hung casements at the top and bottom with 2 screws each (2) onto the turnstile. Insert the 2 cover caps (3) (accessories). The centre rod (1) can be turned to cover existing drill holes.

-

Page 22: Mounting Switch Contact Strips On The Leaves

Installation Revolving door TSA 325 NT 4.2. 1 9 Adjusting the chain tensioner Loosen the 2 screws (1) at the chain tensioner (4). Tighten the drive chain (2). The indicator (3) must be positioned in the green area. Place the chain tensioner between the chain wheels and vertically to the chain. -

Page 23: Connect The Geze St220 Diagnostic Device/Use Gezeconnects

ST 220 can also be inserted onto the back of the keypad programme switch. Start up the system with control element GEZE ST220 (serial no. 087261) or GEZEconnects (serial no. 133367). Information on commissioning the system is available in the DCU6 wiring diagram. -

Page 24: Mount The Ceiling Panel

Installation Revolving door TSA 325 NT Mount the ceiling panel 4.5. 1 Placing the cover Lay the cover (1) (wooden panel or aluminium sheet) on the ceiling ring. Screw the cover on tight (1). Bond the sheeting (4). Mount the weather guard with water gutter (5). - Page 25 Revolving door TSA 325 NT Installation 4.5.2 Inserting and screwing on the segment sheeting For doors with a turnstile brace, the ceiling panel with hole must first be inserted into the ceiling. Drill the holes for the locking bolts of the manual and automatic locking system (optional).

- Page 26 Installation Revolving door TSA 325 NT 4.5.3 Installing the entrance mat Install the entrance mat (1) according to the installation plan (see below). Installation plan X division Installation plan Y division...

-

Page 27: Check List For Commissioning And Service

Revolving door TSA 325 NT Installation 4.5.4 Façade connection (optional) The façade connection is an equipment option, and can be included in the scope of delivery if requested by the customer. The façade connection consists of the following components: à 10 mm flat material; to compensate between the drum wall and canopy à... -

Page 28: Options

~ 9 5 m 5. 1 .3 Mounting the locking ramps at the TSA 325 NT BO Mount the locking ramps at the two moving leaves that are positioned inside in the night position at the pre drilled positions (approx. 95 mm from the leaf outer edge (2)). - Page 29 Revolving door TSA 325 NT Options 5. 1 .4 Installation positions Installation position TSA 325 NT, 3-leaf: Outside Inside Side-hung casement Locking Installation position TSA 325 NT, 3-leaf, Variant BO: Outside Inside Side-hung casement Locking...

- Page 30 Options Revolving door TSA 325 NT Installation position TSA 325 NT, 4-leaf: Outside Inside Side-hung casement Locking Installation position TSA 325 NT BO, 4-leaf: Outside Inside Side-hung casement Locking...

- Page 31 Revolving door TSA 325 NT Options 5. 1 .5 Setting the position of the locking systems The locking system has to be set so that it is as close as possible to the ceiling panel without touching it. Ceiling panel...

- Page 32 Options Revolving door TSA 325 NT Adjust the turnstile so that the leaves are not positioned under the locking systems. Use the manual unlocking (hexagon size 6) (see section 5.1.1 Components on page 28, Item 7) to position both locking systems completely at the bottom.

-

Page 33: Revolving Doors With Breakout Function

Revolving door TSA 325 NT Options Revolving doors with breakout function 5.2. 1 Installing the central spin axis Remove the protective panel (1). Pre-mount the floor bearing (2). Place the lower disk (2) on the floor bearing. Unscrew the 4 screws (4) from the upper break-... - Page 34 Options Revolving door TSA 325 NT Lift the bearing plate of the upper break out mechanism (3). Insert the steel tube (5) of the swivelling axis onto the lower disk (2) and into the upper break-out mechanism. Ensure that the disk and the upper break-out...

- Page 35 Revolving door TSA 325 NT Options Secure the steel tube against twisting and slipping at the top and bottom with 2 fitting keys (6) each. Secure the fitting keys with M3 screws. Secure M3 screws with thread lock. Removing fitting keys: Screw the M3 screws out of the fitting screws.

- Page 36 Options Revolving door TSA 325 NT Turn the central spin axis (9) so that the hole of the BO axis of the leaf (7) that is to be mounted points side- wards to the middle of the side elements (11), i.e. in the direction of the swivel axis (10) shown below.

- Page 37 Revolving door TSA 325 NT Options Insert the lower BO axis into the disk (2). Swivel in the upper BO flange (8) and screw tight with four screws (15).

- Page 38 Options Revolving door TSA 325 NT Remove the stress from the locking pin by turning the adjustment screw (16) counterclockwise. The adjustment screw (16) has to contact lightly. The leaf latches into the BO lock. Turn the adjustment screw (16) ¼ of a rotation clockwise.

- Page 39 Revolving door TSA 325 NT Options 5.2.3 Checking the switching disk Mount the switching disk (2) on the upper BO flange so that the roller (3) of the switch is located in the recess of the switching disk in the leaf zero setting.

- Page 40 Options Revolving door TSA 325 NT Measuring the break-out force Measuring devices: à Force measuring tool à Spring scale Mark the measuring point (4) in accordance with the adjacent drawing. Measure the break-out force of the individual BO leaf at the measuring point (4).

-

Page 41: External Night Time Closer (Automatic And Manual)

Revolving door TSA 325 NT Options External night time closer (automatic and manual) WARNING! Danger of injury due to broken glass! Always mount the door leaf together with another person. Hang the door leaf (2). Use the adjusting screw (1) to adjust the door leaf to the correct height. - Page 42 Options Revolving door TSA 325 NT Mount the emergency stop switch (option) (2). 5.3.2 Mounting the manual night-time closer Mount the rosettes (2) for the lock. Mount the emergency stop switch (option) (1). 5.3.3 Mount the emergency stop switch tappet contact...

-

Page 43: Open Position Monitoring

Revolving door TSA 325 NT Options Open position monitoring à The leaf part of the tappet contact must be mounted on the roller carriage before installing the leaf. Subse- quent installation on the roller carriage is not possible. à The leaf part tappet contacts can only be mounted on an RC 2 roller carriage. -

Page 44: General Installation Information For Nv Tooth-Belt Tension

Options Revolving door TSA 325 NT General installation information for NV tooth-belt tension 5.5. 1 Position the driver in relation to the pulley holders The distances indicated in the drawing below between the driver in open position (1) and the deflection or motor gear unit, as well as between the two interior pulley holders (2) may not be exceeded. - Page 45 Revolving door TSA 325 NT Options 5.5.2 Distributing the pulley holders If the pulley holders are distributed unevenly, the tooth belt tension will fluctuate greatly. This can cause the following problems: à System cannot be taught correctly à System does not close completely à...

- Page 46 Options Revolving door TSA 325 NT 5.5.3 Set the adjustable pulley on the pulley holder The more the tooth belt (3) lifts up from the pulleys on the pulley holder, the more the tooth belt tension will fluctuate. Because of this, the adjustable pulley (1) must be set with the smallest possible distance (5) from the passing driver (4) after installing the leaves on all pulley holders.

- Page 47 Revolving door TSA 325 NT Options Tooth belt turning on the motor gear unit and deflection pulley To ensure the transmission of force and ensure the locking feature functions correctly, the tooth belt must be turned by 180° between the outermost pulley holder and the motor gear unit or deflector (see arrow).

- Page 48 Options Revolving door TSA 325 NT Tooth belt crossing with outside-running night-time closer Tandem rollers (3) must be used for an outside-running night-time closer. The recesses in the canopy panel must be placed accordingly. Belt 1 Belt 2 Tandem roller...

- Page 49 Revolving door TSA 325 NT Options 5.5.5 Using a tooth-belt tensioner The smaller the system, the greater the tooth belt tension will fluctuate as the leaf moves. The tooth belt tensioner (mat. no. 140538) ensures that the tooth-belt tension is more even.

-

Page 50: Revolving Door In All-Glass Version (Tsa 325 Nt Gg)

Building shell recess 1500 × 1000 × 300 Optional: 900 × 900 × 280 Revolving door TSA 325 NT GG with drive box and exter- nally mounted control box Building shell recess 1000 × 1000 × 300 A depth of at least 60 mm for the cavity is sufficient at manual doors since no drive box is installed. - Page 51 Revolving door TSA 325 NT Options Determine the position of the floor ring. Specify the position of the drive box and align it correctly. Drive box dimensions 1404 1444* *) with angle frame...

- Page 52 Options Revolving door TSA 325 NT 5.6.3 Aligning the floor ring Align the floor ring and drive box every 30–40 cm using a levelling device and underlay it. Align the drive box correctly. The top edge of the drive box is 24 mm lower than the top edge of the floor ring.

- Page 53 Take the screed height in the floor ring into account. The dimension of 22 mm in the drawing below refers to the standard floor entrance mats of GEZE. à GEZE recommends sealing the surface of the screed in indoor areas.

- Page 54 Options Revolving door TSA 325 NT Support the side elements (1) in the H profile with glazing packers (2) at the joint. Ensure that the gap (x) is a minimum of 2–3 mm wide on the inside in order to ensure sufficient sealing.

- Page 55 Revolving door TSA 325 NT Options Loosely screw in the bracket holders (6). 4–6 bracket holders are mounted per ceiling glass (see below). Seal the gap between the side panel and drum wall with clear silicone (7). Screw the ceiling bearing shells (8) into the...

- Page 56 Options Revolving door TSA 325 NT 5.6.9 Mounting the pivot bearing and turnstile below Screw the bearing ring (2) to the bearing plate (3) using the 4 screws (1). Grease the bearing housings of the bearing ring well. Mount the turnstile (4) on the pivot bearing.

- Page 57 Revolving door TSA 325 NT Options 5.6. 1 0 Inserting the door leaves WARNING! Danger of injury through falling top turnstile! Secure the upper turnstile against falling down before inserting the first door leaf. Slide the door leaf (1) onto the bars of the turnstile and screw them on.

- Page 58 Options Revolving door TSA 325 NT 5.6. 1 1 Place the chain and set the chain tensioner Loosen the 2 screws (1) at the chain tensioner (4). Tighten the drive chain (2). The indicator (3) must be positioned in the green area.

- Page 59 Revolving door TSA 325 NT Options 5.6. 1 3 Cabling and fastening the sensor equipment The cables (3) of the radar movement detector and of the sensor (4) for the anterior post safety can be hidden in the mounted profile (2) of the ceiling glasses (1) and threaded downwards through the post.

- Page 60 Options Revolving door TSA 325 NT 5.6. 1 5 Mounting the manual night-time closer outdoors When equipped with a night-time closer, the ceiling glass is cut larger on the outside and has holes so that the guide rail can be screwed on at the top.

-

Page 61: Speed Limiter Unit For Tsa 325 Nt

Revolving door TSA 325 NT Options Speed limiter unit for TSA 325 NT The speed limiter unit (mat. no. 157585) is pre-mounted as shown below. The chain wheel and chain are placed loosely. Speed limiter with chain, chain wheel and mounting plate... - Page 62 Options Revolving door TSA 325 NT Setting the speed limiter Install the chain wheel and chain. Loosen the screws (1) and roughly position the speed limiter. Loosen the clamping screws (2). Tension the chain slightly using the tensioning screw (3).

- Page 63 Revolving door TSA 325 NT Options Turn the base plate motor (2) and chain tensioner (3). Screw the motor gear unit (4) with speed limiter to the base plate (2). Place the chain (5) and set the speed limiter (see previous page).

-

Page 64: Revolving Door Tsa 325 Nt Rc 2

Revolving door TSA 325 NT RC 2 Revolving door TSA 325 NT Revolving door TSA 325 NT RC 2 6. 1 Assemblies and parts Burglar-resistant doors are complete elements and require careful installation. The connecting walls/façades must have a structure that conforms to at least DIN EN 1627. -

Page 65: Revolving Door Tsa 325 Nt Rc 2

Revolving door TSA 325 NT Revolving door TSA 325 NT RC 2 Revolving door TSA 325 NT RC 2 6.2. 1 Night-time closer drive (AINV) Connecting bracket Earthing connection Stop buffer DCU 1 motor gear unit Façade bracket Control unit... - Page 66 Revolving door TSA 325 NT RC 2 Revolving door TSA 325 NT 6.2.2 Safety sensor activation device – LV drive Sensor package for interior LV systems Rain cover to protect the light curtain outdoors (optional) GC 339 Light curtain to protect the main closing edge for automatic night-time closers...

- Page 67 Revolving door TSA 325 NT Revolving door TSA 325 NT RC 2 6.2.3 Portals 2 types of portals can be installed on the revolving door TSA 325 NT RC2: à Box portal à Sandwich portal Box portal Sandwich portal...

-

Page 68: Installing Revolving Door Tsa 325 Nt Rc 2

Installing revolving door TSA 325 NT RC 2 The installation of revolving door TSA 325 NT RC 2 is the same in many respects as the installation of revolving door TSA 325 NT. This section describes the installation steps that differ from installation of revolving door TSA 325 NT. - Page 69 Revolving door TSA 325 NT Revolving door TSA 325 NT RC 2 6.3.5 Removing the sickle plates 6.3.6 Mounting the ceiling canopy see section 4.2.5 Installation without floor ring on page 11 6.3.7 Mounting the drive unit see section 4.2.7 Mounting the drive unit on page 14 6.3.8 Placing blocks for side element profiles...

- Page 70 Revolving door TSA 325 NT RC 2 Revolving door TSA 325 NT 6.3. 1 0 Attaching the floor strips from the RC 2 outside side panels to the outside of the floor ring M5 × 20 countersunk head screw Upper floor strip M5 ×...

- Page 71 Revolving door TSA 325 NT Revolving door TSA 325 NT RC 2 6.3. 1 1 Loosening the floor strips and blocks from the inside RC 2 side panel Optionally, cylinder head screws with a head diameter of 10 mm (M6 DIN 912) can be used instead of the blocks.

- Page 72 Revolving door TSA 325 NT RC 2 Revolving door TSA 325 NT 6.3. 1 3 Lifting the ceiling canopy WARNING! The ceiling canopy is very heavy (approx. 200 kg). Risk of injury due to falling ceiling canopy. Only lift the ceiling canopy by means of suitable aids (e.g. pneumatic press).

- Page 73 Revolving door TSA 325 NT Revolving door TSA 325 NT RC 2 Lift the canopy approx. 40 mm higher than the passage height.

- Page 74 Revolving door TSA 325 NT RC 2 Revolving door TSA 325 NT 6.3. 1 4 Inserting the portal side panels in the floor ring (with bolts, mounted at the factory) Hold the portal side elements (1) in place.

- Page 75 Revolving door TSA 325 NT Revolving door TSA 325 NT RC 2 6.3. 1 5 Inserting the portal side elements into the mullion and transom façade 6.3. 1 6 Inserting the portal side elements into the floor ring A - A...

- Page 76 Revolving door TSA 325 NT RC 2 Revolving door TSA 325 NT 6.3. 1 7 Insert the side panel Further information see section 4.2.9 Inserting the side panel on page 15...

- Page 77 Revolving door TSA 325 NT Revolving door TSA 325 NT RC 2 Secure the inserted side elements against falling over in the upper third. Spray soap water or silicone spray onto the upper rubber of the side elements and ceiling canopy.

- Page 78 Revolving door TSA 325 NT RC 2 Revolving door TSA 325 NT 6.3. 1 8 Inserting the ceiling construction into the mullion and transom façade The ceiling canopy has to lie evenly on all the side element profiles. Lower the ceiling canopy carefully onto the side element profiles.

- Page 79 Revolving door TSA 325 NT Revolving door TSA 325 NT RC 2 6.3.20 Inserting the portal head element into the mullion and transom façade Loosen the façade mullion profile. Remove the cover (4), cover profile (3), square profile (2) and 2 rubber profile (1).

- Page 80 Revolving door TSA 325 NT RC 2 Revolving door TSA 325 NT Screw the portal head element into the mullion and transom façade Screw the portal head element (5) on the right and left into the portal side elements with 2 screws (6) on each side.

- Page 81 Revolving door TSA 325 NT Revolving door TSA 325 NT RC 2 6.3.21 Screwing the portal side element into the mullion and transom façade Remove the cover (1), cover profile (2), square profile (3) and retaining rubber profile (4). Drill through the portal side element (5) and the façade transom profile (6).

- Page 82 Revolving door TSA 325 NT RC 2 Revolving door TSA 325 NT 6.3.22 Mounting the LV door leaf Set the markings (arrows) at the positions of the fixing screws (1). Insert the door leaf into the floor guide. Unscrew the suspension bolt (5) from the roller carriage (3).

- Page 83 Revolving door TSA 325 NT Revolving door TSA 325 NT RC 2 Screw the hanger bracket with 2 screws (2) each at the marked positions into the sliding blocks. Screw the M8 roller carriage screw (4) into the roller carriage to determine the height position of the door leaf.

- Page 84 Revolving door TSA 325 NT RC 2 Revolving door TSA 325 NT Lay the right-hand sickle plate (5) in the middle of the floor ring and slide it under the right-hand door leaf. Place the middle sickle plate (6) on the floor ring.

- Page 85 Revolving door TSA 325 NT Revolving door TSA 325 NT RC 2 6.3.24 Installing stop buffers Align the door stop (1) to the outer roller carriage. Tighten the screw (2). 6.3.25 Adjusting the LV door leaves Observe the applicable standards and guidelines on crushing, shearing and drawing-in spots.

-

Page 86: Installation Information For Nv Tooth Belt Tension Rc2

Revolving door TSA 325 NT RC 2 Revolving door TSA 325 NT 6.3.26 Shortening the tooth belt cut protection If the toothed belt collides with the cut protection: Shorten the cut protection (2) so that the toothed belt (1) passes the cut protection without contact. -

Page 87: Mounting The Turnstile

Revolving door TSA 325 NT Revolving door TSA 325 NT RC 2 Mounting the turnstile see section 4.2.5 Installation without floor ring on page 11 6.5. 1 Inserting the floor bearing see section 4.2.5 Installation without floor ring on page 11 6.5.2... - Page 88 Revolving door TSA 325 NT RC 2 Revolving door TSA 325 NT 6.7.2 Mount the outside Preparations Remove the transom cover (1) from the mullion and transom façade. Stick the GYSO sealing tape (2) to the gutter profile.

- Page 89 Revolving door TSA 325 NT Revolving door TSA 325 NT RC 2 Mount the clamping plate (1)

- Page 90 Revolving door TSA 325 NT RC 2 Revolving door TSA 325 NT Set the ceiling panel in place and screw in Variant: Waterproof roof 2 Burglar-protection screw 3 High-resistance, sealing thread lock...

- Page 91 Revolving door TSA 325 NT Revolving door TSA 325 NT RC 2 Mounting to the box portal and façade Mounting to the sandwich portal and mullion (example) and transom façade Portal profile Ceiling panel Burglar-protection screws Mullion and transom façade...

- Page 92 Revolving door TSA 325 NT RC 2 Revolving door TSA 325 NT 6.7.3 Mount inside Mount the clamping plate Push in the ceiling panel...

- Page 93 Revolving door TSA 325 NT Revolving door TSA 325 NT RC 2 Screw the façade kick plate to the interior ceiling panel 6.7.4 Insert and screw in the segment panels and sickle plates Mount the segment panels Insert 8 segment panels (2) and screw each one in with 2 screws (1).

-

Page 94: Check List For Commissioning And Service

Revolving door TSA 325 NT RC 2 Revolving door TSA 325 NT Mount the sickle plates outside inside Screw the sickle plates (4) with screws (3) and align them to one another. Mount the sickle plate (5) in the inside entry area. -

Page 95: Revolving Door Tsa 325 Nt, 3-Leaf

Revolving door TSA 325 NT Revolving door TSA 325 NT, 3-leaf Revolving door TSA 325 NT, 3-leaf Burglar-resistant doors are complete elements and require careful installation. The connecting walls/façades must have a structure that conforms to at least DIN EN 1627. -

Page 96: Night-Time Closer Drive (Ainv)

Revolving door TSA 325 NT, 3-leaf Revolving door TSA 325 NT Night-time closer drive (AINV) Connecting bracket Earthing connection Stop buffer DCU 1 motor gear unit Façade bracket Control unit Frame tube, inside Rechargeable battery Fastening tube Transformer Reinforcing brace ceiling... -

Page 97: Mounting The Tsa 325 Nt Revolving Door, 3-Leaf

Many of the steps for mounting the TSA 325 3-leaf revolving door are the same as those for mounting the TSA 325 NT revolving door and the TSA 325 NT RC 2 revolving door. This section describes the installation steps that differ from installation of revolving door TSA 325 NT or revolving door TSA 325 NT RC 2. - Page 98 Revolving door TSA 325 NT, 3-leaf Revolving door TSA 325 NT 7.3. 1 1 Loosening the floor strips and blocks from the inside side panel see section 6.3.11 Loosening the floor strips and blocks from the inside RC 2 side panel on page 71 7.3.

- Page 99 Revolving door TSA 325 NT Revolving door TSA 325 NT, 3-leaf 7.3.26 Installing opening position monitoring See section 5.4 7.3.27 Mounting the protective leaf Preparing the protective leaf Position for locking (X) Position for lower floor-mounted pivot bearing (Y) Position for upper floor-mounted pivot bearing (Z)

- Page 100 Revolving door TSA 325 NT, 3-leaf Revolving door TSA 325 NT Place the protective leaves on blocks so that the centre of the glass pane is elevated. The straight glass edges must be freely accessible. Mounting the brush strip Spread suitable synthetic glass glue into the long groove for the brush strip (1).

- Page 101 Revolving door TSA 325 NT Revolving door TSA 325 NT, 3-leaf Screw the mounted upper part of the locking mechanism (3) onto the glass leaf: Push the bushing (6) into the drill hole in the glass leaf. Screw the upper part onto the glass leaf with a screw (9), metal plate (8) and intermediate plate (7).

- Page 102 Revolving door TSA 325 NT, 3-leaf Revolving door TSA 325 NT Screw the mounted upper part pivot bearing (1) onto the glass leaf: Push the bushing (6) into the drill hole in the glass leaf. Screw the upper pivot bearing (1) onto the glass leaf with a screw (8), metal plate (7) and intermedi- ate plate (5).

- Page 103 Revolving door TSA 325 NT Revolving door TSA 325 NT, 3-leaf Screw the mounted upper part of the lower pivot bearing (1) onto the glass leaf: Push the bushing (4) into the drill hole in the glass leaf. Screw the mounted upper part of the lower pivot...

- Page 104 Revolving door TSA 325 NT, 3-leaf Revolving door TSA 325 NT Mounting the upper pivot bearing on the track side Mount the upper pivot bearing according to the drawing: Screw the counterplate (2) onto the bear- ing plate (3) with 2 screws (1).

- Page 105 Revolving door TSA 325 NT Revolving door TSA 325 NT, 3-leaf 7.3.28 Installing the protective leaf Push the LV leaf towards the closed position.

- Page 106 Revolving door TSA 325 NT, 3-leaf Revolving door TSA 325 NT Tip the protective leaf (1) and install it in revolving door TSA 325. Tip the protective leaf (1) and insert it into the floor bearing (2). Loosen the nut (5).

- Page 107 Revolving door TSA 325 NT Revolving door TSA 325 NT, 3-leaf 7.3.29 Adjusting the protective leaf Adjust the height position Adjust the height position of the thread- ed rod (1) on the upper pivot bearing and threaded rod (4) on the lower pivot bearing.

-

Page 108: Installation Information For Nv Tooth-Belt Tension

Revolving door TSA 325 NT, 3-leaf Revolving door TSA 325 NT Mount stop bolts Screw the stop bolts (2) into the upper pivot bearing (1). 7.3.30 Shortening the tooth belt cut protection If the toothed belt collides with the cut protection: Shorten the cut protection so that the toothed belt passes the cut protection without contact. -

Page 109: Mounting Contact Strips On The Leaves

Revolving door TSA 325 NT Revolving door TSA 325 NT, 3-leaf 7.5.7 Fastening the side-hung casements see section 4.2.18 Fastening the side-hung casements on page 21 7.5.8 Adjusting the chain tensioner see section 4.2.19 Adjusting the chain tensioner on page 22 Mounting contact strips on the leaves see section 4.3 Mounting switch contact strips on the leaves on page 22... - Page 110 Revolving door TSA 325 NT...

- Page 111 Revolving door TSA 325 NT...

- Page 112 E-Mail: leonberg.de@geze.com Baltic States – Iberia Scandinavia – Norway Lithuania / Latvia / Estonia GEZE Iberia S.R.L. GEZE Scandinavia AB avd. Norge GEZE GmbH E-Mail: norge.se@geze.com E-Mail: baltic-states@geze.com E-Mail: info.es@geze.com Niederlassung Süd-Ost www.geze.no www.geze.es Tel. +49 (0) 7152 203 6440 E-Mail: muenchen.de@geze.com...

Need help?

Do you have a question about the TSA 325 NT and is the answer not in the manual?

Questions and answers

Подскажите как разблокируется дверь во время пожара.

The GEZE TSA 325 NT revolving door is not designed to be used as a fire or smoke-proof door drive. However, the variant with break-out leaves is suitable for use in escape and rescue routes. In case of an emergency, including fire, the break-out leaves can be used to facilitate escape.

This answer is automatically generated