Table of Contents

Advertisement

Quick Links

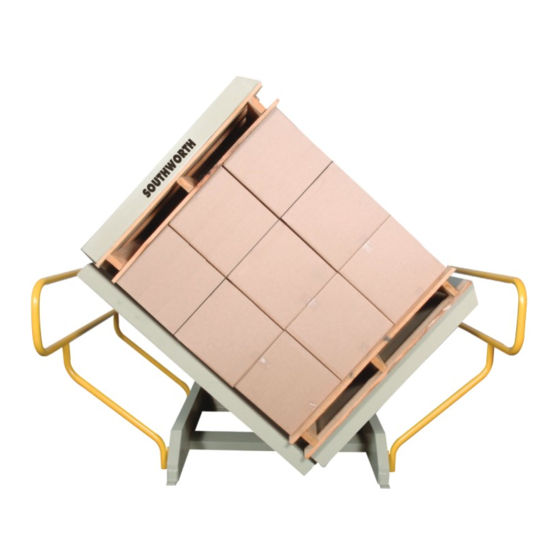

PalletPal Pallet Rotator

Owner's Manual

Model:

Serial Number:

Date placed in

service:

SOUTHWORTH PRODUCTS CORP.

P.O. Box 1380, Portland, ME 04104-1380

Telephone: 800-743-1000 • 207-878-0700

www.SouthworthProducts.com

SR-44

__________________________

__________________________

Fax: 207-797-4734

December 9, 2020

Advertisement

Table of Contents

Summary of Contents for Southworth SR-44 Series

- Page 1 PalletPal Pallet Rotator Owner’s Manual Model: SR-44 Serial Number: __________________________ Date placed in __________________________ service: SOUTHWORTH PRODUCTS CORP. P.O. Box 1380, Portland, ME 04104-1380 Telephone: 800-743-1000 • 207-878-0700 Fax: 207-797-4734 www.SouthworthProducts.com December 9, 2020...

-

Page 2: Table Of Contents

Wiring Schematics ......................20 8.2.1 Single Phase Wiring Schematic ................20 8.2.2 Three Phase Wiring Diagram ..................21 Hydraulics ......................22 Hydraulic Power Unit ......................22 Hydraulic Schematic ......................23 Warranty & Contact Information ............... 24 Southworth Products SR-44 Manual... - Page 3 This label (part # 10095524) is required by California law. For more information visit www.65Warnings.ca.gov. This label (part # 10095524) is required by California law. For more information visit www.P65Warnings.ca.gov. Southworth Products SR-44 Manual...

-

Page 4: Introduction

3. Retrained, if necessary, based on the owners/user’s observation and evaluation of the operator. Modifications and additions shall not be performed without the manufacturer’s prior written approval. Where such authorization is granted, capacity, operation, and maintenance instruction plates, tags, or decals shall be changed accordingly. Southworth Products SR-44 Manual... -

Page 5: Responsibilities Of Operators

Before Operations - The operator shall: 1. Read and understand the manufacturer’s operating instruction(s) and user’s safety rules or have them explained. 2. Understand all labels, warnings, and instructions displayed on the machine or have them explained. Southworth Products SR-44 Manual... - Page 6 13. Problems or malfunctions - Any problem(s) or malfunction(s) that affect the safety of operations shall be repaired prior to the use of the machine. Southworth Products SR-44 Manual...

-

Page 7: Safety

Maintenance Chains: Used to secure the rotating mechanism against movement during maintenance and repair. Guard Rails: Protects the operator, and nearby personnel, from access during operation. Emergency Stop Located on the control station. Press this button to immediately stop the machine during an emergency. Southworth Products SR-44 Manual... -

Page 8: Labeling

BK-LD TAG 2.00X10.0 LD DCL 2.00X3.00 SO BK-LD DCL 1.50X5.50 BK-LD DCL 3.00X1.50 BK-LD DCL 1.25X1.75 BK-LD DCL 1.25X1.75 LD DCL 4.50X8.00 CL LD DCL 1.25X2.75 CA LD DCL 2.00X11.00 N LD DCL 2.00X9.00 STA ITEM Southworth Products SR-44 Manual... - Page 9 BK-LD DCL 2.50X12.75 (ENGLISH AND SPANIS 10021381 TWO PLACES LD DCL 1.50X6.00 FORK ENTRY - LIFT HERE 10039033 BK-LD TAG 2.00X10.00 SOUTHWORTH 5900158 LD DCL 2.00X3.00 SOUTHWORTH SERIAL ID BL 10079929 POWER DECALS BK-LD DCL 1.50X5.50 TANK TO BE FULL ONLY 2986997 VOLTAGE ITEM NO.

-

Page 10: Installation

If necessary, the machine may be anchored so that it remains in position. Anchors to be provided by the installer. Southworth Products SR-44 Manual... -

Page 11: Positioning The Machine

7. Insert and tighten the lag bolts according to the lag bolt manufacturer’s specification. 8. Install the guardrails using the supplied hardware (both sides of machine). ANCHOR POINT (BOTH ENDS OF OUTRIGGER, BOTH SIDES OF MACHINE) USE SUPPLIED HARDWARE IN THESE LOCATIONS TO ATTACH GUARD RAILS Southworth Products SR-44 Manual... -

Page 12: Electrical Connections

Allow the machine to rest for one minute. The machine should hold its position. 9. Press and hold the “Unclamp” button until mechanism is fully opened. Immediately release the button once the mechanism is fully opened. Southworth Products SR-44 Manual... - Page 13 14. Press and hold “Rotate CCW” button until the load reaches its end of travel. Immediately release the button once the end of travel is reached. 15. Rotate the load to the original position. Unclamp and remove the load. The machine is now ready for normal operation. Southworth Products SR-44 Manual...

-

Page 14: Operation

The machine must only be loaded and unloaded when the side panel is vertical. 5.2.1. Load Restrictions Model Min Load Height Max Load Height Max Load Weight SR44-60 30” 60” 4,400 lb SR44-72 42” 72” 4,400 lb SR44-84 54” 84” 4,400 lb Southworth Products SR-44 Manual... -

Page 15: Operation Instructions

Make necessary adjustments to the load. 6. Press and hold the “Clamp” button until the load is securely held by the clamping mechanism. 7. Rotate the load back to the original orientation. 8. Release the clamp and remove the load. Southworth Products SR-44 Manual... -

Page 16: Maintenance & Repair

Always secure with maintenance chains before relieving hydraulic pressure. Once maintenance/repair is complete and if hydraulic system pressure has been relieved, the hydraulic system will need to be re-pressurized before maintenance chains can be removed. Southworth Products SR-44 Manual... -

Page 17: Periodic Maintenance

Replace hydraulic fluid and fluid filter. See section 9. Hydraulics. CLAMPING CYLINDERS PIVOT ASSEMBLY GREASE FITTINGS REMOVE PANEL TO ACCESS CYLINDERS APPROXIMATE CONTROL ROUTING OF PANEL GREASE LINES ROLLERS/ROLLER TRACKS (BOTH SIDES OF CLAMP MECHANISM) HYDRAULIC PIVOT ASSEMBLY POWER UNIT ROTATION CYLINDER Southworth Products SR-44 Manual... -

Page 18: Troubleshooting

(motor does not run) voltage. Supply voltage must be within 10% of the The machine may not be receiving power rated voltage for three phase machines or 5% of the rated voltage for single phase machines. Southworth Products SR-44 Manual... -

Page 19: Electrical Information

Nominal Supply Power Full Load Amps Required Breaker 115/1/60 208/1/60 14.3 230/1/60 13.5 208/3/60 230/3/60 460/3/60 190/3/50 380/3/50 Ensure the motor overload relay is set for the correct full load amps for the given primary voltage. Southworth Products SR-44 Manual... -

Page 20: Wiring Schematics

8.2.1. Single Phase Wiring Schematic 115/208/230V E-STOP CLAMP MOTOR STARTER UNCLAMP ROTATE CW ROTATE CCW NOTES: • SUPPLY POWER CONNECTS TO 1L1,3L2 AT TOP OF MOTOR CONTACTOR. • SUPPLY GROUND CONNECTS TO GROUNDING TERMINAL IN CONTROL PANEL Southworth Products SR-44 Manual... -

Page 21: Three Phase Wiring Diagram

8.2.2. Three Phase Wiring Diagram NOTES: • SUPPLY PHASES CONNECT TO 1L1, 3L2,5L3 AT TOP OF MOTOR CONTACTOR • SUPPLY GROUND CONNECTS TO GROUNDING TERMINAL IN CONTROL PANEL Southworth Products SR-44 Manual... -

Page 22: Hydraulics

Repeat until fluid level is consistently one inch from the top of the tank. Hydraulic Power Unit ROTATION VALVE STACK (VALVE STACK “A”) CLAMP VALVE STACK (VALVE STACK “B”) PUMP MOTOR FLUID FILTER BREATHER/ FILL PORT TANK SUCTION ASSEMBLY Southworth Products SR-44 Manual... -

Page 23: Hydraulic Schematic

Hydraulic Schematic Southworth Products SR-44 Manual... -

Page 24: Warranty & Contact Information

For specific warranty information, contact Southworth Products with the machine’s serial number. Any claim for breach of this warranty must be received in writing by Southworth within the warranty period. Warranties shall not cover failure or defective operation, caused by misuse, misapplication, negligence or accident, exceeding recommended capacities, or any alteration or repair of the item purchased which has not been authorized by Southworth.

Need help?

Do you have a question about the SR-44 Series and is the answer not in the manual?

Questions and answers