Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Reflex Exvoid

- Page 1 21.11.2016 Reflex ex separator Exvoid / Exvoid HC (HiCap) Exdirt / Exdirt HC (HiCap) Extwin /Extwin HC (HiCap) Operating manual Cooke Industries - Phone: +64 9 579 2185 Email: sales@cookeindustries.co.nz Web: www.cookeindustries.co.nz...

- Page 2 Cooke Industries - Phone: +64 9 579 2185 Email: sales@cookeindustries.co.nz Web: www.cookeindustries.co.nz...

-

Page 3: Table Of Contents

Inadmissible operating conditions..............................6 Residual risks ......................................6 Description of the device................................7 Devices........................................7 2.1.1 Exvoid / Exvoid HC ................................7 2.1.2 Exdirt / Exdirt HC ................................7 2.1.3 Extwin / Extwin HC ................................7 Optional equipment ..................................... 7 2.2.1... -

Page 4: Safety

Only specialist personnel or specifically trained personnel may install and operate the equipment. Regional regulations and directives must be adhered to. 4 — English Reflex ex separator — 21.11.2016 Cooke Industries - Phone: +64 9 579 2185 Email: sales@cookeindustries.co.nz Web: www.cookeindustries.co.nz... -

Page 5: Notes To Personnel

• Types of glycol must not be mixed and the concentration is generally to be checked every year (see manufacturer information). Reflex ex separator — 21.11.2016 English — 5 Cooke Industries - Phone: +64 9 579 2185 Email: sales@cookeindustries.co.nz... -

Page 6: Inadmissible Operating Conditions

Ensure proper installation, removal or maintenance work. • Ensure that the system is de-pressurised before performing installation, removal or maintenance work at the connection points. 6 — English Reflex ex separator — 21.11.2016 Cooke Industries - Phone: +64 9 579 2185 Email: sales@cookeindustries.co.nz Web: www.cookeindustries.co.nz... -

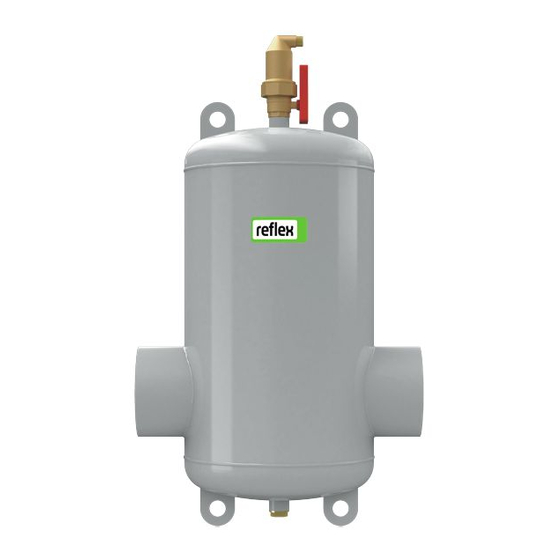

Page 7: Description Of The Device

In general standard separators are used for flow velocities up to 1.5 m/s. In general the HiCap (HC) model is used with flow velocities of 1.5 to 3.0 m/s. Devices 2.1.1 Exvoid / Exvoid HC A gas/air separator with micro bubble separation removing circulating free air and gas bubbles. The device is available in the following variants: Variant... -

Page 8: Identification

Contact the manufacturer to determine the weight of the separator. Note! You can find a detailed listing of all technical data at the end of the complete document. 8 — English Reflex ex separator — 21.11.2016 Cooke Industries - Phone: +64 9 579 2185 Email: sales@cookeindustries.co.nz Web: www.cookeindustries.co.nz... -

Page 9: Installation And Assembly

After attachment of insulation, attach the additional sticker on the outside so that it is readily visible. • Thoroughly rinse the system through after installation of the Reflex Exdirt. Space requirements A: Minimum free space above the top part of the ventilation... -

Page 10: Exvoid

Note! If the separators are equipped with a Reflex Exiso heat insulation unit or another type of heat insulation, then tap extensions must be fitted on the upper or lower side of the connection according to the thickness of the insulation. These are supplied with the insulation or made available on site. -

Page 11: Maintenance

During a hydraulic pressure test, the pressure must not exceed 1½ times the maximum working pressure. • During a compressed air test of the system, the large vent valve of the separators Exvoid and Extwin must be closed for this period by a site-provided suitable closing cap. -

Page 12: Sludge Separator With Removable Floor Flange

4. Screw the magnet into the immersion sleeve. Note! If no magnetic insert is fitted, steps 1 and 4 are not needed. 12 — English Reflex ex separator — 21.11.2016 Cooke Industries - Phone: +64 9 579 2185 Email: sales@cookeindustries.co.nz Web: www.cookeindustries.co.nz... -

Page 13: Annex

This declaration of conformity is issued under the sole responsibility of the manufacturer. Air and Dirt Ex-Separators Exvoid, Exvoid T, T Solar, Solar, HiCap / Exdirt, Exdirt M, HiCap / Extwin, Extwin M universally applicable in heating, solar and cooling systems type according to name plate of vessel Serial no. - Page 14 Cooke Industries - Phone: +64 9 579 2185 Email: sales@cookeindustries.co.nz Web: www.cookeindustries.co.nz...

- Page 15 Exvoid Ø1 Ø2 (mm) (mm) (mm) (mm) (mm) A 60.3 60.3 12.5 A 76.1 76.1 A 88.9 88.9 A 114.3 114.3 A 139.7 22.0 139.7 A 168.3 24.0 168.3 A 219.1 44.0 219.1 1125 A 273.0 70.0 273.0 1402 A 323.9 112.0...

- Page 16 Exdirt Ø1 Ø (mm) (mm) (mm) (mm) (mm) D 60.3 60.3 12.5 D 76.1 76.1 D 88.9 88.9 D 114.3 114.3 D 139.7 22.0 139.7 D 168.3 24.0 168.3 D 219.1 44.0 219.1 1021 D 273.0 70.0 273.0 1324 D 323.9 112.0 323.9 1535...

- Page 17 Exdirt-HiCap Ø1 Ø (mm) (mm) (mm) (mm) (mm) D 60.3 HC 60.3 D 76.1 HC 76.1 D 88.9 HC 88.9 D 114.3 HC 114.3 D 139.7 HC 139.7 1121 D 168.3 HC 168.3 1121 D 219.1 HC 219.1 1391 D 273.0 HC 273.0 1532 D 323.9 HC...

- Page 18 Extwin Ø1 Ø (mm) (mm) (mm) (mm) (mm) (mm) TW 60.3 60.3 12.5 TW 76.1 76.1 TW 88.9 12.0 88.9 TW 114.3 14.0 114.3 TW 139.7 34.0 139.7 1200 TW 168.3 31.0 168.3 1200 TW 219.1 113.0 219.1 1470 TW 273.0 215.0 273.0 1916...

- Page 19 Extwin-HiCap Ø1 Ø2 (mm) (mm) (mm) (mm) (mm) (mm) TW 60.3 HC 60.3 1050 TW 76.1 HC 76.1 1050 TW 88.9 HC 88.9 1285 TW 114.3 HC 114.3 1285 TW 139.7 HC 139.7 1710 TW 168.3 HC 168.3 1710 TW 219.1 HC 219.1 2035 1075...

- Page 20 Exdirt / Extwin 82521xx / 82523xx / 82531xx / 82533xx - [mm] HiCap [mm] DN 50 / DN 65 / 60.3 76.1 88.9 - DN 80 / DN 100 114.3 DN 125 / DN 150 / 139.7 / 168.3 / DN 200 219.1 DN 250 / DN 300...

- Page 21 Cooke Industries - Phone: +64 9 579 2185 Email: sales@cookeindustries.co.nz Web: www.cookeindustries.co.nz...

- Page 22 Reflex Winkelmann GmbH Gersteinstraße 19 59227 Ahlen, Germany Telephone: +49 (0)2382 7069-0 Fax: +49 (0)2382 7069-588 www.reflex.de Cooke Industries - Phone: +64 9 579 2185 Email: sales@cookeindustries.co.nz Web: www.cookeindustries.co.nz...

Need help?

Do you have a question about the Exvoid and is the answer not in the manual?

Questions and answers