Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for New Holland S4L2

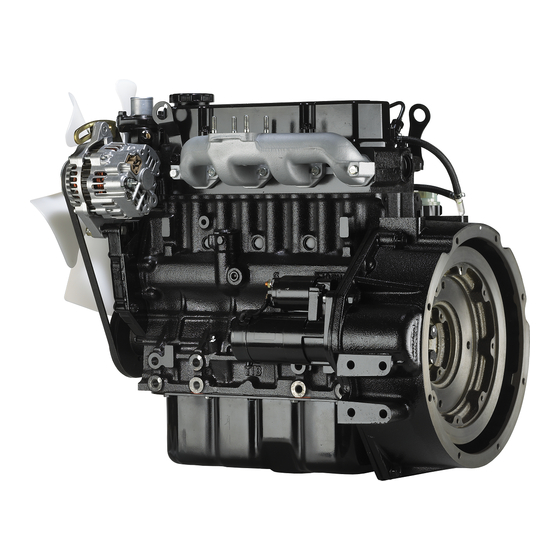

- Page 1 SERVICE MANUAL S4L2, S4L Engine Part number 84373329 English August 2010...

- Page 2 Contents INTRODUCTION HYDRAULIC - PNEUMATIC - ELECTRICAL - ELECTRONIC SYSTEMSA ELECTRICAL POWER SYSTEM ............A.30.A ENGINE AND PTO IN ..............

- Page 3 INTRODUCTION 84373329 09/08/2010 Find manuals at https://best-manuals.com...

- Page 4 General specification ................9 S4L2 Product identification .

- Page 5 INTRODUCTION Foreword This service manual describes the specifications, maintenance and service procedures for Mitsubishi diesel engines. To maintain the performance of the engine for many years and to ensure safe operation, it is important to use the en- gine correctly and conduct regular inspection and maintenance, and also to take necessary measures which involves the disassembly, inspection, repair and reassembly of the engine and engine parts.

- Page 6 INTRODUCTION Safety rules Standard safety precautions Be informed and notify personnel of the laws in force regulating safety, and provide documentation available for consultation. Keep working areas as clean as possible. • Ensure that working areas are provided with emergency boxes. They must be clearly visible and always contain •...

- Page 7 INTRODUCTION Disconnect the batteries prior to performing any work on the equipment. • Disconnect the batteries to place a load on them with a load tester. • After any work is performed, verify that the battery clamp polarity is correct and that the clamps are tight and safe •...

- Page 8 INTRODUCTION Special tools 31A91-00100 Piston pin setting tool For removal and installation of the piston pin • 93101124 ST332340 Camshaft bushing installer For punching and press-fitting of the front camshaft • bushing 93101127 ST332270 Compression gauge adapter For measuring compression •...

- Page 9 INTRODUCTION 31391-12900 Piston ring pliers For removal and installation of the piston rings • 93101123 84373329 09/08/2010 Find manuals at https://best-manuals.com...

- Page 10 INTRODUCTION General specification Refer to the following table for links to the specifications pages. Engine ENGINE - General specification (B.10.A) Lubrication system LUBRICATION SYSTEM - General specification (B.60.A) Fuel and injection system FUEL AND INJECTION SYSTEM - General specification (B.20.A) Engine coolant system ENGINE COOLANT SYSTEM - General specification (B.50.A) Air intake system...

- Page 11 INTRODUCTION General specification S4L2 Refer to the following table for links to the specifications pages. Engine ENGINE - General specification (B.10.A) Lubrication system LUBRICATION SYSTEM - General specification (B.60.A) Fuel and injection system FUEL AND INJECTION SYSTEM - General specification (B.20.A) Engine coolant system ENGINE COOLANT SYSTEM - General specification (B.50.A)

- Page 12 INTRODUCTION Product identification Engine serial number location The engine serial number (1) is stamped on the label of the upper side of the rocker cover. 93101555 84373329 09/08/2010...

- Page 13 SERVICE MANUAL HYDRAULIC - PNEUMATIC - ELECTRICAL - ELECTRONIC SYSTEMS SL Series 84373329 09/08/2010...

- Page 14 Contents HYDRAULIC - PNEUMATIC - ELECTRICAL - ELECTRONIC SYSTEMS - A ELECTRICAL POWER SYSTEM ............A.30.A SL Series 84373329 09/08/2010...

- Page 15 HYDRAULIC - PNEUMATIC - ELECTRICAL - ELECTRONIC SYSTEMS - A ELECTRICAL POWER SYSTEM - 30.A SL Series 84373329 09/08/2010 A.30.A / 1...

-

Page 16: Table Of Contents

General specification ............... 3 S4L, S4L2 Torque . -

Page 17: Electrical Power System

HYDRAULIC - PNEUMATIC - ELECTRICAL - ELECTRONIC SYSTEMS - ELECTRICAL POWER SYSTEM ELECTRICAL POWER SYSTEM - General specification S4L, S4L2 Engine model S4L, S4L2 Voltage - polarity 12 V- negative (-) ground Starter - Type M008T70471A - Manufacturer Mitsubishi Electric Corporation... -

Page 18: Remove - Stop Solenoid

HYDRAULIC - PNEUMATIC - ELECTRICAL - ELECTRONIC SYSTEMS - ELECTRICAL POWER SYSTEM ELECTRICAL POWER SYSTEM - Remove - Stop solenoid 93101324 Removing sequence Stop solenoid Rubber cap 84373329 09/08/2010 A.30.A / 4... - Page 19 HYDRAULIC - PNEUMATIC - ELECTRICAL - ELECTRONIC SYSTEMS - ELECTRICAL POWER SYSTEM 84373329 09/08/2010 A.30.A / 5...

-

Page 20: Remove - Glow Plugs

HYDRAULIC - PNEUMATIC - ELECTRICAL - ELECTRONIC SYSTEMS - ELECTRICAL POWER SYSTEM ELECTRICAL POWER SYSTEM - Remove - Glow plugs 93101320 Glow plug Glow plug plate 84373329 09/08/2010 A.30.A / 6... -

Page 21: Inspect - Glow Plugs

HYDRAULIC - PNEUMATIC - ELECTRICAL - ELECTRONIC SYSTEMS - ELECTRICAL POWER SYSTEM ELECTRICAL POWER SYSTEM - Inspect - Glow plugs Check continuity between the terminal and the body as shown in the illustration. If no continuity is indi- cated, or the resistance is large, replace the glow plug with a new one. -

Page 22: Install - Glow Plugs

HYDRAULIC - PNEUMATIC - ELECTRICAL - ELECTRONIC SYSTEMS - ELECTRICAL POWER SYSTEM ELECTRICAL POWER SYSTEM - Install - Glow plugs 93101320 Torque glow plugs (1) to 14.7 - 19.6 N·m (10.8 - 14.5 lb ft). 84373329 09/08/2010 A.30.A / 8... - Page 23 HYDRAULIC - PNEUMATIC - ELECTRICAL - ELECTRONIC SYSTEMS - ELECTRICAL POWER SYSTEM Installing stop solenoid 93101324 Torque the stop solenoid retaining nuts (1)of the ETS type (2)and ETR type (3)stop solenoids to 39.2 - 49.0 N·m (28.9 - 36.2 lb ft). 84373329 09/08/2010 A.30.A / 9...

- Page 24 HYDRAULIC - PNEUMATIC - ELECTRICAL - ELECTRONIC SYSTEMS - ELECTRICAL POWER SYSTEM Installing stop solenoid (ETR type) 93101328 Procedure for installing stop solenoid (ETR type) Apply Threebond 1212 or 1211 sealant to the threaded portion (1) of the stop solenoid (2). NOTE: Apply the sealant up to the position where the stop solenoid is screwed into the governor case.

-

Page 25: Inspect

HYDRAULIC - PNEUMATIC - ELECTRICAL - ELECTRONIC SYSTEMS - ELECTRICAL POWER SYSTEM Alternator - Inspect Inspecting alternator operation Locate the cause of faulty charging from malfunctions de- scribed below. Do not remove the alternator for inspection and repair unless inspection cannot be performed with the alternator installed on the engine. - Page 26 HYDRAULIC - PNEUMATIC - ELECTRICAL - ELECTRONIC SYSTEMS - ELECTRICAL POWER SYSTEM Inspecting regulated voltage (IC regulator integral type) Disconnect (+) battery terminal (1) and connect an ammeter (2) across the line. Connect a voltmeter (3) between terminal L and ground.

- Page 27 HYDRAULIC - PNEUMATIC - ELECTRICAL - ELECTRONIC SYSTEMS - ELECTRICAL POWER SYSTEM 84373329 09/08/2010 A.30.A / 13...

-

Page 28: Remove

HYDRAULIC - PNEUMATIC - ELECTRICAL - ELECTRONIC SYSTEMS - ELECTRICAL POWER SYSTEM Alternator - Remove 93101321 Removing sequence Harness Flange bolt Generator brace Bolt Alternator 84373329 09/08/2010 A.30.A / 14... - Page 29 HYDRAULIC - PNEUMATIC - ELECTRICAL - ELECTRONIC SYSTEMS - ELECTRICAL POWER SYSTEM 84373329 09/08/2010 A.30.A / 15...

-

Page 30: Disassemble

HYDRAULIC - PNEUMATIC - ELECTRICAL - ELECTRONIC SYSTEMS - ELECTRICAL POWER SYSTEM Alternator - Disassemble 79103817 Disassembling sequence Pulley, spacer, check for deformation and damage Through bolt Front bracket, bearing, check for rotation Rotor, bearing, check for dirt, damage and seizure of slip ring and coil resistance and rotation of bearing Stator, check for broken wire and ground of coil Rear bracket, check for crack or damage... - Page 31 This as a preview PDF file from best-manuals.com Download full PDF manual at best-manuals.com...

Need help?

Do you have a question about the S4L2 and is the answer not in the manual?

Questions and answers