Table of Contents

Advertisement

—

ASSEMBLY INSTRUCTIONS

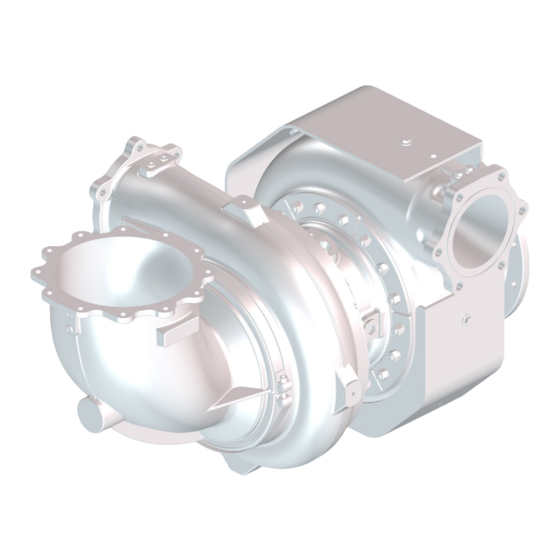

Turbocharger / A200-H

Original assembly instructions – English

This document is valid for:

A238-H.., A240-H..

Purpose

The assembly instructions explain how the ABB

turbocharger is fitted to the engine correctly and

without any health and safety risks.

Target group

The assembly instructions are intended for

engineers and mechanics responsible for fitting

the turbocharger on the engine.

A200-H turbocharger

More power, less fuel

Advertisement

Table of Contents

Summary of Contents for ABB A238-H Series

- Page 1 Original assembly instructions – English This document is valid for: A238-H.., A240-H.. Purpose A200-H turbocharger The assembly instructions explain how the ABB More power, less fuel turbocharger is fitted to the engine correctly and without any health and safety risks. Target group...

-

Page 3: Table Of Contents

Fastening the turbocharger with a clamping nut ..........14 Fastening the turbocharger with a standard nut ..........16 Connecting the turbocharger..................17 Storage of new turbochargers and spare parts ..........18 Further information..................... 20 © Copyright 2021 ABB. All rights reserved. HZTL455311P0042_EN Rev.A September 2021... -

Page 4: Introduction

Introduction Purpose of the assembly instructions The assembly instructions explain how the ABB turbocharger is fitted to the engine correctly and without any health and safety risks. This element of the documentation is supplied with the product, as is required for partly completed machinery in accordance with machinery dir- ective 2006/42EC. -

Page 5: Definition Of Warning, Caution, Note

ABB Switzerland Ltd, Turbocharging is identified as ABB Turbocharging in this document. Official service stations of ABB Turbocharging Official service stations are regularly audited and certified by ABB Turbocharging. See "Con- tact Information" on our website at www.abb.com/turbocharging. Definition of warning, caution, note... -

Page 6: Definition Of Mandatory Signs

Apply other paste in accord- Dispose of in an environmentally ance with specifications compatible, professional way and in compliance with locally Oil free, grease free and dry applicable regulations. Table 3: Definition of pictograms © Copyright 2021 ABB. All rights reserved. HZTL455311P0042_EN Rev.A September 2021... -

Page 7: Safety

Introduction State of the art Turbochargers manufactured by ABB Turbocharging are state of the art and comply with the respective health and safety standards in effect at the time the turbocharger was built. This ensures safe operation of the turbocharger. -

Page 8: Lifting Of Loads

Use a suitable edge guard if there are sharp edges. The assembly devices must be completely screwed in and must not unscrew during use. Use assembly devices only for the described applications. © Copyright 2021 ABB. All rights reserved. HZTL455311P0042_EN Rev.A... -

Page 9: Occupational Safety

When performing welding work in the vicinity of the turbocharger, always cover the filter silencer to prevent the filter mat from being damaged. Keep flammable objects and substances out of the vicinity of flying sparks. © Copyright 2021 ABB. All rights reserved. HZTL455311P0042_EN Rev.A... - Page 10 Observe the information in the material safety data sheet for the operat- ing materials and supplies. Comply with local legislation. Wear safety goggles. Wear safety gloves to protect against mechanical hazards. Wear a respiratory mask to protect against gases. © Copyright 2021 ABB. All rights reserved. HZTL455311P0042_EN Rev.A September 2021...

-

Page 11: Turbocharger Weight And Transportation

Depending on the specification, the weight specified on the rating plate may be lower than the standard value specified here. Swivel lifting eyes to be used Swivel lifting eyes are required for the safe lifting of loads, which are not supplied by ABB. Fig. 3: Swivel lifting eye (example) Product... -

Page 12: Installing The Turbocharger

The oil is supplied (02) and drained (03) through the bracket (01). The necessary gaskets (05) must be integrated in the support plate. A suggestion for the slot shape (04) is shown below. The gaskets are not included in the ABB scope of delivery and must be provided by the enginebuilder. -

Page 13: Fixing Elements

Fixing elements The standard nuts (01), washers (02), threaded rods (03) and centering bushes (04) are not supplied by ABB. The clamping nut (42201) can be ordered as an option. This enables the re- quired pre-tension to be achieved with a commercially available torque spanner. -

Page 14: Placing And Aligning The Turbocharger On The Bracket

Screw the centering bush (04) flush onto the threaded rod from below. Clean the surface of the bracket, the bearing casing, the centering bush and the centering holes in the bracket. © Copyright 2021 ABB. All rights reserved. HZTL455311P0042_EN Rev.A September 2021... - Page 15 Step 1. Comply with the steps for fastening the turbocharger: ¡ Fastening the turbocharger with a clamping nut →14 ¡ Fastening the turbocharger with a standard nut →16 © Copyright 2021 ABB. All rights reserved. HZTL455311P0042_EN Rev.A September 2021...

-

Page 16: Fastening The Turbocharger With A Clamping Nut

4. Tighten clamping nut (03) by hand. 5. Unscrew clamping nut (03) by ¼ of a turn (90°). The distance between the thrust washer and the clamping nut is now about 1 mm. © Copyright 2021 ABB. All rights reserved. HZTL455311P0042_EN Rev.A... - Page 17 4. Work in a circle to tighten all pressure screws to 100 % of the tightening torque specified in the table. 5. Tighten pressure screws to 100 % in 5 … 7 rounds until the required residual tightening angle of < 20° is achieved. © Copyright 2021 ABB. All rights reserved. HZTL455311P0042_EN Rev.A September 2021...

-

Page 18: Fastening The Turbocharger With A Standard Nut

**) When the turbocharger is mounted on the engine support, the bolt threads and screw heads must be lightly oiled (assumed friction coefficient µ = 0.12 for tightening torque) Remove the lifting gear. © Copyright 2021 ABB. All rights reserved. HZTL455311P0042_EN Rev.A... -

Page 19: Connecting The Turbocharger

Make sure there is an uninterrupted supply of cooling air during opera- tion. Fig. 13: Connecting the compressor cooling air Remove the lock from the connection for the compressor wheel cooling (01) and fit the cooling air line. © Copyright 2021 ABB. All rights reserved. HZTL455311P0042_EN Rev.A September 2021... -

Page 20: Storage Of New Turbochargers And Spare Parts

Old VCI corrosion protection emitters must be disposed of in an environmentally compat- ible, professional way and in compliance with locally applicable regulations. Close package. The more tightly the package is sealed, the longer the protection dura- tion. © Copyright 2021 ABB. All rights reserved. HZTL455311P0042_EN Rev.A September 2021... - Page 21 Inspect the package for damage. If the package is damaged, the turbocharger must be in- spected by an ABB Turbocharging Service Station and repacked. After every 3 years the following work steps must be performed by an ABB Turbocharging Service Station: ¡...

-

Page 22: Further Information

Operation Manual The Operation Manual for the turbocharger with the relevant serial number is available online on our website www.abb.com/turbocharging. Fig. 16: Serial number of the turbocharger on the rating plate One rating plate (01) each is attached on the left and the right side of the turbocharger bear- ing casing. - Page 23 Assembly Instructions / A200-H 6 Further information / Fig. 17: Finding the Operation Manual online © Copyright 2021 ABB. All rights reserved. HZTL455311P0042_EN Rev.A September 2021...

- Page 24 Phone: +41 58 585 7777 Station”). Fax: +41 58 585 5144 Find and download the Operation Manual of E-mail: turbocharging@ch.abb.com your product on our website (see “Operation Manuals“). www.abb.com/turbocharging © Copyright 2019 ABB. All rights reserved. Visit our website by scanning the QR code.

Need help?

Do you have a question about the A238-H Series and is the answer not in the manual?

Questions and answers