Table of Contents

Advertisement

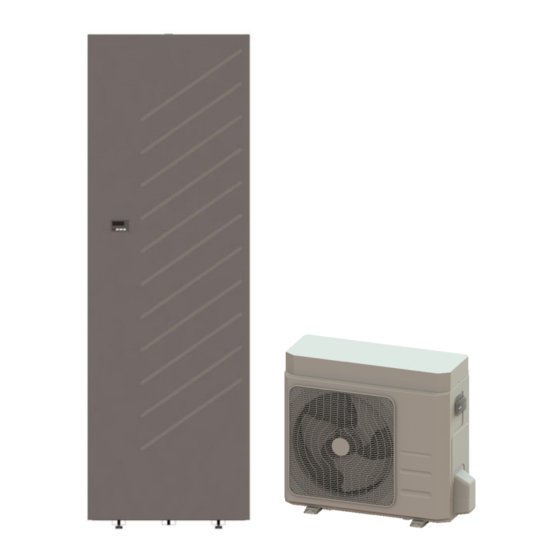

INVERTER AIR/WATER CHILLERS AND HEAT PUMPS

WITH FLOOR‐STANDING INDOOR UNIT AND REMOTE CONDENSING

Indoor unit Mod. MAR/MARP

This manual has been created for informative purpose. The company declines any responsibility for the results of any projecting or any installation based on the explanations and/or on the technical specifications

provided in this manual. It is besides forbidden the reproduction under any form of the texts and of the figures contained in this manual.

"This manual is a translation from the official italian language version. For reasons of environmental respect the Company will not provide the hard copy in the original language which could be directly requested or

downloaded from the Company website at any time. In case of any dispute, the original language manual will be the trusted one".

OUTDOOR UNIT

USER'S AND INSTALLER'S MANUAL

Models

i‐SHWAK V4 06 / i‐SHWAK V4 08

i‐SHWAK V4 10 / i‐SHWAK V4 12

i‐SHWAK V4 14 / i‐SHWAK V4 14T

i‐SHWAK V4 16 / i‐SHWAK V4 16T

Outdoor unit i‐SHWAK V4

Advertisement

Table of Contents

Summary of Contents for MAXA i-SHWAK V4 06

- Page 1 INVERTER AIR/WATER CHILLERS AND HEAT PUMPS WITH FLOOR‐STANDING INDOOR UNIT AND REMOTE CONDENSING OUTDOOR UNIT USER’S AND INSTALLER’S MANUAL Models i‐SHWAK V4 06 / i‐SHWAK V4 08 i‐SHWAK V4 10 / i‐SHWAK V4 12 i‐SHWAK V4 14 / i‐SHWAK V4 14T i‐SHWAK V4 16 / i‐SHWAK V4 16T Indoor unit Mod. MAR/MARP Outdoor unit i‐SHWAK V4 This manual has been created for informative purpose. The company declines any responsibility for the results of any projecting or any installation based on the explanations and/or on the technical specifications provided in this manual. It is besides forbidden the reproduction under any form of the texts and of the figures contained in this manual. "This manual is a translation from the official italian language version. For reasons of environmental respect the Company will not provide the hard copy in the original language which could be directly requested or downloaded from the Company website at any time. In case of any dispute, the original language manual will be the trusted one". ...

- Page 2 Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 07 09‐2020 AL.B A.R. Update of diagrams circuits 06 05‐2020 A.P. A.R. Varied pipes “HP counter‐ current”. Correction of performance data 05 12‐2019 A.R. A.R. Update of paragraph 8.6 – Refrigerant piping connections 04 07‐2008 AL.B. A.R. Update of technical data and characteristics 03 05‐2018 AL.B. A.R. Update of solar specifications and DHW‐R kit 02 10‐17 AL‐B P.F ...

- Page 3 Minichiller Inverter Duo i‐SHWAK V4 CE CONFORMITY DECLARATION DICHIARAZIONE DI CONFORMITÁ CE THE COMPANY ADVANTIX S.P.A – VIA SAN GIUSEPPE LAVORATORE, 24 – LOC. LA MACIA Z.A.I. – 37040 – ARCOLE ‐ VERONA ‐ ITALY LA SOCIETÀ ADVANTIX S.P.A – VIA SAN GIUSEPPE LAVORATORE, 24 – LOC. LA MACIA Z.A.I. – 37040 – ARCOLE ‐ VERONA ‐ ITALY DECLARES DICHIARA that the unit: che la macchina: Air to water reversible heat pump with remote condenser unit / Definition Pompa di calore aria‐acqua reversibile con unità condensante remota Definizione: i‐SHWAK/V4 06 / 08 / 10 / 12 / 14 / 16 Model N°: MAR / MARS / MARP / MARPS N° modello: Serie N°: N° di serie: MEETS THE REQUIREMENTS OF DIRECTIVE 2006/42/CE È CONFORME AI REQUISITI DELLA DIRETTIVA 2006/42/CE 1. The unit is in CAT. I, so it’s free from the application of Directive 2014/68/UE (Reference to Art. I, paragraph 2, point f) L’attrezzatura a pressione rientra nella CAT. I. L’unità è quindi esente dall’applicazione della normativa PED 2014/68/UE (Riferimento Art. I, paragrafo 2 punto f). 2. Harmonized standards applied to designing and manufacture : UNI EN 378‐1, UNI EN378‐2, UNI EN 12735‐1 Norme armonizzate applicate alla progettazione ed alla costruzione : UNI EN 378‐1, UNI EN378‐2, UNI EN 12735‐1 ...

-

Page 4: Table Of Contents

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 INDEX PURPOSES AND CONTENTS OF THE MANUAL .................. 5 CONSERVATION MANUAL ............................... 5 GRAPHIC SYMBOLS .................................... 5 SAFETY LAWS ............................ 5 PERMITTED USES ............................ 5 GENERAL SAFETY GUIDELINES ........................ 6 HEALTH SAFETY WORKERS .............................. ... - Page 5 Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 START UP.............................. 32 INDICATIONS FOR THE USER ......................... 32 SHUTDOWNS FOR LONG PERIODS ...................... 33 MAINTENANCE AND PERIODIC CHECKS .................... 33 12.1 ENVIRONMENTAL PROTECTION ................................ 3 4 DISPOSAL ............................. 34 TECHNICAL DATA .......................... 3 5 14.1 PERFORMANCE DATA .................................. 3 5 ...

-

Page 6: Purposes And Contents Of The Manual

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 This manual collects all the necessary information for the better use of the equipment under safety conditions for the operator thus meeting the requirements listed in the 2006/42/CE Equipment Directive and following amendments. Note: All the pictures in this manual are for explanation purpose only. They may be slightly different from the unit you purchased. The actual shape shall prevail. 1 PURPOSES AND CONTENTS OF THE MANUAL This manual provides basic information as for the selection, installation, operation and maintenance of the “i‐SHWAK V4” units. It is addressed to the installer and the user of the unit: it allows this equipment to operate efficiently, even if the user does not have any previous specific knowledge of it. This manual describes the characteristics of the equipment when it was being put on the market; therefore, it may not capture later technological improvements introduced by the company as part of its constant endeavour to enhance the performance, ergonomics, safety and functionality. The company introduces also technological improvements and is not constrained to update the manuals for previous versions of appliances that could not be compatible. So make sure to use, for the installed unit, the supplied manual. It’s recommended that, the user must follow the instructions contained in this booklet, especially those concerning the safety and routine maintenance. 1.1 CONSERVATION OF THE MANUAL The manual has to be always kept by the user for future references. It has to be stored in a safe place, away from the dust and moisture. It has to be accessible to all users who shall consult it any time they are in doubt on how to operate the equipment. The company reserves the right to modify its products and related manuals without necessarily updating previous versions of the reference ... -

Page 7: General Safety Guidelines

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 4 GENERAL SAFETY GUIDELINES Before beginning to operate on i‐SHWAK V4 units every user has to be perfectly knowledgeable about the functions of the equipment and its controls and has to have read and understood the information listed in this manual. It’s strictly forbidden to remove and/or tamper with any safety device. Children or unassisted disabled persons are not allowed to use the appliance. Do not touch the appliance when barefoot or parts of the body are wet or damp. Do not clean the unit when the power supply is ‘ON’. Do not pull, remove or twist the electrical cables coming out from the unit, even if it is disconnected from the main power supply. Do not step with your feet on the appliance, sit down and/or place any type of object. Do not spray or pour water directly on the unit. Do not dispose of, abandon or leave within reach of children packaging materials (cardboard, staples, plastic bags, etc) as they may represent an environmental and life hazard. Any routine and/or not‐routine maintenance operation shall be carried out when the equipment has been shut down, disconnected from electric and pneumatic power sources and after its pneumatic system has been discharged. Do not put neither your hands nor insert screwdrivers, spanners or other tools into moving parts of the equipment. The equipment supervisor and the maintenance man have to receive suitable training for the performance of their ... -

Page 8: Safety Symbols

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 4.3 SAFETY SYMBOLS The safety signs indicated on the unit which should be respected: General hazard. Electric shock hazard. Presence of moving organs. Presence of surfaces that may cause injures. Presence of hot surfaces which can cause burns. 4.4 REFRIGERANT SAFETY DATA SHEET Name: R410A (50% Difluoromethane (R32); 50% Pentafluoroethane (R125). RISKS INDICATIONS Major risks: Asphyxia Specific risks: The rapid evaporation can cause freezing. FIRST AID General information: Never give anything by mouth to an unconscious person. Inhalation: Outdoors opens transport. Use oxygen or artificial respiration if necessary. Do not give adrenaline or similar drugs Eyes contact: Rinse carefully with water for at least 15 minutes and consult a doctor. Contact with skin: Wash immediately with plenty of water. Take off immediately the contaminated clothes. FIRE PREVENTION Extinguishing Media: ... -

Page 9: General Characteristics

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 5 GENERAL CHARACTERISTICS 5.1 AVAILABLE MODELS Model MAR1, 1‐phase FLOOR STANDING version with technical water puffer of 250 lt for DHW. Model MARS1, 1‐phase FLOOR STANDING version with technical water puffer for DHW of 250 lt equipped with solar coil. Model MARP1, 1‐phase floor standing version, with technical water puffer tank of 190 lt for DHW and technical water puffer tank of 40 lt for plant side. Model MARPS1, 1‐phase floor standing unit, with technical water puffer tank of 190 lt for DHW equipped with solar coil and technical water puffer tank of 40 lt for plant side. Model MAR3, 3‐phase floor standing version with technical water puffer tank of 250 lt for DHW. Model MARS3, 3‐phase floor standing version, with technical water puffer tank of 250 lt for DHW equipped with solar coil. Model MARP3, 3‐phase floor standing version, with technical water puffer tank of 190 lt for DHW and technical water puffer tank of 40 lt for plant side. Model MARPS3, 3‐phase floor standing version, with technical water puffer tank of 190 lt for DHW equipped with solar coil and technical water puffer tank of 40 lt for plant side. 5.2 MAR As standard: 1) Technical water puffer tank in 250 lt for DHW, coated with a 50 mm thick polyurethane. 2) Pump circulator and rapid preparer of high efficiency according to ErP up to the values EEI ≤ 0,21. 3) Exchangers of the heat pump and of the DHW rapid producer in stainless steel AISI 304. 4) An included Y‐filter with impurities discharge valve. 5) Tap of water loading/unloading on DHW technical side. 6) Automatic air vent valves mounted on DHW technic side. ... -

Page 10: Mars/Marps

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 15) Integrated climatic system for plant. 16) Controller logic for plant remote temperature sensor. 17) Integrated controller logic for double set‐point of plant side. 18) Integrated controller logic for intelligent energy resources. Accessories: 1) Single and three phase electric heaters of 2 ‐ 3 ‐ 4,5 kW, common to the plant and DHW technical sides (if the optional diverter valve kit is present), managed in integration and/or substitution mode. Double safety level with automatic and manual reset thermostat for protecting the system and the user (optional kit, factory‐fitted mod. RExxxx). 2) Mixer’s controller logic for plant side in both heating and cooling operations. Controller logic for solar integration. Controller logic for relaunching circulator (secondary) plant side (optional kit, installed in the factory mod. GI2). 3) Boiler kit on DHW technical side: allows connecting the unit with additional energy source (boiler or others similar) to manage in integration and/or substitution of the heat pump (KCACS kit). ... -

Page 11: Fans

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 6.5 FANS The fans are axial type with aluminium aerofoil blades. They are statically and dynamically balanced and supplied complete of the safety fan guard according to the CE EN 60335‐2‐80 rule (safety for electrical apparatus of domestic and similar use). They are mounted on the unit frame by interposition of rubber vibration dampers. The electric motors are all brushless DC type with 8 poles (about 200/1000 rpm). The motors are directly driven with an integrated thermal overload protection. The protection class ... -

Page 12: Description Of The Indoor Unit Code

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 7 DESCRIPTION OF THE INDOOR UNIT CODE The “i‐SHWAK V4” system is composed of a moto‐condensing outdoor unit and of a floor‐standing indoor unit. The code of the unit consists of: no. 7 fixed digits. The symbol # as separator. no. 10 variable digits (fields) which identify the sizes, power supply and factory‐fitted accessories (the field RE is composed of two digits). no. 1 fixed digit equal to 0, for now is not used. no. 2 variable digits (field MC) which identifies the i‐SHWAK V4 series in its customizations (the field MC is composed of two digits) 0110918#(CI)(CT)(AE)(DHW)(CAL)(SUN)(GI)(KI)(RE)0(MC) FATHER CODE CONFIGURATION SIZE POWER SUPPLY FACTORY‐FITTED ACCESSORIES 0110918# CI CT1 AE DHW* CAL SUN GI** KI*** RE Hydronic configuration 4 Single puffer (DHW) Thermal capacity 5 Double puffer (DHW + plant) ... - Page 13 Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 Warning: The selection of the DHW electric heater kit is related also related to the absence of the expansion vessel kit for MAR/MARS models. CI – Hydronic configuration 4 5 00 Without electric heater 11 DHW electric heater of 2 kW 00 Without electric heater 13 DHW electric heater 4,5 kW 16 Plant side heater of 4,5 kW 0 12 DHW electric heater of 3 kW 11 DHW heater of 2 kW 14 Plant side Electric heater of 2 kW 17 DHW heater 2 kW + plant side heater 2 kW 13 DHW electric heater of 4,5 kW 12 DHW heater of 3 kW 15 Plant system Electric heater of 3 kW DHW heater 1,2 kW + plant side heater 1.2 kW DHW electric heater of 1,2 kW Plant electric heater of 1, kW DHW electric heater of 1,2 kW ...

- Page 14 Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 Field Variant Description 4 Unit supplied with 250 litre technical puffer tank for instantaneous DHW production. Unit supplied with 190 litre technical puffer tank of instantaneous DHW production and 40 litres puffer tank for plant side technical CI 5 water. 16 ÷21 Nominal thermal capacity of the unit. CT 0 1‐phase electric power supply. AE 1 3‐phase electric power supply. 1 Unit supplied with DHW instantaneous production kit. DHW 0 Boiler without kit. CAL 1 With kit for management of additional energy source for DHW technical side (boiler or others similar). 0 Without solar kit. SUN 1 With kit for integrated management of the solar system 0 Unit not supplied with plant management module. The GI additional module implements some useful functions for managing the plant, such as: the mixer’s controller logic for plant GI 1 side in both heating and cooling operations, controller logic for solar integration. Controller logic for relaunching (secondary) circulator plant side. ...

- Page 15 Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 Refer to the following table for the codes of the standard configuration of the various (e.g. for the models i‐SHWAK V4 06 and 16) models (for selecting the accessories, just set the corresponding variant to the desired value according to the TABLE FIELDS/ VARIANTS described above): Indoor unit Model Description Standard configuration code MAR1 1‐phase puffer tank floor‐standing unit 0110918#416010000000XX MARS1 1‐phase puffer tank floor‐standing unit with solar kit 0110918#416010100080XX MARP1 1‐phase double puffer tank floor‐standing unit 0110918#516010001000XX MARPS1 1‐phase double puffer tank floor‐standing unit with solar kit 0110918#516010102080XX ...

-

Page 16: Optional Accessories

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 Herein below is represented the correspondence between the RE variants and the name of its electric heaters, depending on the electric power supply of the unit. When ordering you must specify the electric heaters of both DHW the technical puffer tank and plant side puffer tank. Name 1‐phase 3‐phase Filed Variant Description DHW Plant DHW Plant 00 Without electric heater / / / / 11 DHW electric heater of 2 kW RE2.0M2 / RE2.0T / 12 DHW electric heater of 3 kW RE3.0M2 / RE3.0T / 13 DHW electric heater of 4,5 kW RE4.0M2 / RE4.0T / 14 ... -

Page 17: Installation

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 8 INSTALLATION WARNING: All the operation described below MUST BE DONE BY TRAINED PEOPLE ONLY. Before any operation on the unit, be sure that the electric power supply is disconnected. 8.1 GENERALITY When installing or servicing the unit, it is necessary to strictly follow the rules listed in this manual, to comply with all the specifications of the labels on the unit, and to take any possible precautions. Not observing the rules reported on this manual can create dangerous situations. After receiving the unit, immediately check its integrity. The unit left the factory in perfect condition; any eventual damage has to be questioned to the carrier and recorded on the Delivery Note before signing it. ... -

Page 18: Outdoor Unit

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 8.2.2 Outdoor unit It is recommended to unpack the unit only with equipment positioned near the installation place, otherwise take special care not to damage the unit when handling it. Removal of the packing box: Cut the strap fasteners. Remove the apparatus by lifting the packing upward. Remove the corner pieces of polystyrene foam. Remove the unit from the pallet by unscrewing the screws that hold the feet to the pallet itself. When unloading and installing the unit, it is highly recommended to avoid any sudden move in order to protect the inner components. The units can be lifted by means of a forklift or, in alternative, of belts, being sure not to damage the lateral panels and the cover. It ... -

Page 19: Hydraulic Connections

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 Positioning on the floor Provide lifting from the floor of the unit: 20 mm without conveying the condensate drain 90 ÷ 100 mm to allow the conveying of the condensate drain In case of installation in areas subjected to extreme cold or heavy snow, where there is the possibility of freezing, it’s recommended to provide suitable frost protection systems. (A) Level (1) condensate drain pipe Suspended positioning In the case of suspended installation, adequate brackets must be used to support the weight of the unit and also depending also on the type of the wall to which should be fixed. Make sure that the section of the wall doesn’t overlap to ... -

Page 20: Plant's Water Characteristics

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 8.4.1 Plant’s water characteristics In order to ensure the correct operation of the unit, the water should be properly filtered (as indicated in the beginning of this paragraph) and the amounts of dissolved substances should be minimal. The maximum permitted values are given in the below table. MAXIMUM PHYSICAL AND CHEMICAL CHARACTERISTICS ALLOWED BY THE WATER OF THE PLANT CIRCUIT PH 7,5 ‐ 9 Electrical conductivity 100 ‐ 500 μS/cm Total hardness 4,5 – 8,5 dH Temperature ˂ 65°C Oxygen content ˂ 0,1 ppm Maximum glycol content 50 % Phosphates (PO4) ˂ 2ppm Manganese (Mn) < 0,05 ppm Iron (Fe) < 0,3 ppm Alkalinity (HCO3) 70 – 300 ppm Chloride ions (Cl‐) < 50 ppm sulfate ions (SO4) < 50 ppm Sulfide ion (S) None Ammonium ions (NH4) None Silica (SiO2) < 30 ppm 8.4.2 Hydraulic circuit Circulator pump ... -

Page 21: Connections' Positions

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 8.4.3 Connections’ positions 8.4.3.1 Indoor unit From the plant (1”M) To the plant (1”M) Water supply inlet (3/4”M) The user DHW‐R (3/4”M) Liquid line (see Paragraph 14.3) Gas line (see Paragraph 14.3) To the solar plant (3/4”M) From the solar plant (3/4”M) To the boiler (3/4”M) From the boiler (3/4”M) For DHW‐R user, it means the point(s) of using of domestic hot water produced by the instantaneous preparer DHW. The DHW‐R means “rapid” production of the domestic hot water. 8.4.3.2 Outdoor unit ‐ Units 06, 08, 10 and 12 A. Power supply cover (terminal block) B. Gas connections cover C. Gas connections Model Liquid pipe Gas pipe 06 3/8 SAE 5/8 SAE 08 3/8 SAE 5/8 SAE 10 ... -

Page 22: Connection Of The Relief Valve's Discharge

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 8.4.4.2 Outdoor unit The outdoor units have been designed in a way to use their own basement as a drain pan. • Locate the hole at the basement of the unit between the finned coil and fan, A. • Connect to the hole the provided fitting joint, B. • Connect a hose to the nozzle of the supplied fitting joint. • Direct the hose into the disposal place for condensate water. • Keep a sufficient slope to ensure the smooth flow of condensate water. 8.4.5 Connection of the relief valve’s discharge A drain pipe in PVC material is situated on the rear side of the indoor unit, it is internally ... -

Page 23: Plant Circuit Unloading

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 During the operations of loading/topping up, the plugs of the air vent valves must be partially unscrewed to allow air to flow freely out of the valves. The MAR/MARS models are equipped with two air vent valves; one is installed on the single puffer in correspondence to the three‐way valve. The MARP/MARPS models are equipped with three air vent valves, one for the DHW technical side puffer, one on the plant side, and the other near the three‐way valve. Refer to position 2 of the Paragraph 25.1 and the Paragraph 25.2. (2) Stopper of the air vent valve When it’s necessary to top up the circuit of the plant or to adjust the title of glycol (in the cases described in Chapter 22), you can use the service valves. Unscrew the cap of the service valve and connect to joint connector a hose pipe of 14 mm (inner diameter) ... -

Page 24: Schematic Diagram Of The Plant With Dhw Recirculation

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 All the components included inside the dashed line "CONNECTIONS THAT SHOULD BE DONE BY THE INSTALLER" are only indicated but not supplied. WARNING: It is recommended to install a 3 bar relief valve (not supplied) as shown in the plant diagram. It is necessary to install an automatic air vent at the highest point of the plant circuit. An additional expansion vessel is required (not supplied) for absorbing the volume changes in the plant circuit side and domestic hot water side, when it’s necessary. Note that, the models MAR/MARS do not include an integrated expansion vessel for plant side; therefore the installation of an additional expansion vessel is required for these models. The integrated expansion vessel of 8 litres is expected only in the model “MAR” without VE8AT kit and in ... -

Page 25: Refrigerant Connections

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 REFRIGERANT CONNECTIONS The refrigerant connections are equipped with shut off valves on the outdoor unit and designed for flare connections. How to make the connection: Place the refrigerant pipes; (place the refrigerant pipes, the number of curves should be as low as possible and avoid throttling of the pipes) Bring together the flared ends to their connection located on the indoor and outdoor units; Tighten the connections by using the method of ”key against key”; Perform a proper evacuation of the refrigerant pipes using the taps of the moto‐condensing unit (similarly to household split). Check if the work was being done well by evaluating the rise time by mean of pressure gauge that integrated in the ... - Page 26 Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 Refrigerant piping i‐SHWAK V4 Models 6 8 10 12 Liquid connections/Minimum thikness of piping inch SAE/mm 3/8”/ 0,8 3/8”/ 0,8 3/8”/ 0,8 3/8”/ 0,8 Gas connections /Minimum thickness of piping inch SAE 5/8”/ 0,8 5/8”/ 0,8 5/8”/ 0,8 5/8”/ 0,8 A – Minimum required equivalent length (1) m 3 3 3 3 A – Maximum required equivalent length (1) m 20 30 40 40 B – Maximum dislevel (outdoor up and indoor down m 15 15 25 25 (as in the figure above) B – Maximum dislevel indoor up and outdoor down ...

-

Page 27: Refrigerant Diagram I-Shwak V4 06, 08

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 Do not put both pipes in the same protecting sheath, in order to ensure the correct operation of the plant. Do not carry out the connections by using ordinary hydraulic pipes that might contain inside themselves residues of chips, dirt, or water which can damage the components of the unit and alterate the correct operation of the equipment. Use only specific refrigeration copper pipes that should be provided clean and sealed at the ends. Use only pipes with correct dimensions of diameters; refer to the table of the technical data in the chapter 14. Cut the pipes with wheel pipes cutter, clutch slowly paying attention for not to crush the pipes when using the tool. Never use an ordinary hacksaw because shavings could go into the pipe and then circulate in the system which can seriously damage the components. After cutting the pipe, please seal immediately the opening on both ends of the roll and cut pipe. The equipment does not require any additional refrigerant. The refrigerant pipes should be straight as possible and the necessary bends must have radius more than 300mm. Plug the opening on the ends of the pipes before inserting them through the hole in the wall. The refrigerant piping and joints must be thermally insulated to prevent heat losses. You should avoid the introduction of non‐condensable gases (air) into the circuit, otherwise, the pressure becomes high during operation with the risk of system breakage. 8.6.1 Refrigerant diagram i‐SHWAK V4 06, 08 COMPRESSOR C ... -

Page 28: Refrigerant Diagram I-Shwak V4 14, 14T And 16T

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 8.6.3 Refrigerant diagram i‐SHWAK V4 14, 14T and 16T COMPRESSOR C COMPRESSOR LIQUID SEPARATOR CLS OIL SEPARATOR OS COMPRESSOR INLET TEMPERATURE ST COMPRESSOR OUTLET TEMPERATURE DT HIGH PRESSURE TRANSDUCER HP HIGH PRESSURE FLOW SWITCH Pr LOW PRESSURE TRANSDUCER LP VALVE FO INVERTING CYCLE 4WV LIQUID RECEIVER LR ELECTRONIC EXPANSION VALVE EEV FILTER FL AXIAL FAN M OUTDOOR AIR TEMPERATURE SE CIRCULATOR ON BOARD UNIT P WATER INLET TEMPERATURE IN WATER OUTLET TEMPERATURE OUT CAPILLARY CP ... -

Page 29: Indoor Unit

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 the value to be set contact please our office. The company excludes any contractual and extra contractual liabilities for damages caused to persons, animals or objects, by incorrect installation, setting and maintenance, improper use of the equipment, and the partial or superficial reading of the information contained in this manual. It’s forbidden to open the electrical board by unauthorized persons. Do not carry out any work on the equipment under voltage. Do not touch the equipment if you are not authorized. Direct contact with the pipes must be avoided. Requirements before performing electrical work on the control board: Turn off the unit from the control panel ("OFF" displayed) Put the switch “QF” general differential on OFF position. Wait for 15 seconds before getting access to the electric board. Check the ground connection before beginning any operation. Be sure that you are well insulated from the ground, with dry hands and feet, or by using insulating platforms and gloves. Check that there is no foreign material near the system. 8.7.1 Indoor unit Electric cables entry The power supply and signal cables should pass along the space between the metal sheets in the top part of the unit and use the fixing clamps for fastening. Follow along the suggested path cable reported in the image. ... -

Page 30: Connection Terminals

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 Remove the mounting screws. Remove the cover plate of the electric box. Connect the cable to the terminals inside the electric box. Please refer to the wiring diagrams given in the manual of wiring diagrams of the unit. (A) Power cable hole (B) Auxiliary connections WARNING: For allowing the power supply and communication cables to cross easily, it is recommended to remove the side panels. Prepare then all the connections before any concealed installation. Note: All the pictures in this manual are for explanation purpose only. They may be slightly different from the unit you purchased. The actual shape shall prevail. 8.7.1.1 Connection terminals For getting information on the legend and location of the terminal blocks in the electric box, please see the wiring diagrams in the Chapter 27. Power supply terminal block Power supply board Single phase system 1‐Ph_230Vac + N +PE Three‐phase system 3‐Ph _230Vac + N +PE Terminal block Terminal Description Terminal block Terminal Description PE Grounding conductor PE Grounding conductor M1 L ... -

Page 31: Outdoor Unit

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 DO4 Phase conductor for auxiliary DHW electric heater (230Vac) DO4N Neutral conductor for auxiliary DHW electric heater DO5 Phase conductor for boiler enablement (230Vac) DO5N Neutral conductor for boiler enablement NO2 Normally open changeover contact for double set‐point valve (Phase 230Vac) NC2 Normally closed changeover contact for double set‐point valve (Phase 230Vac) KCS Phase conductor for solar circulator (230Vac) KN Neutral conductor for solar circulator KMO N.A. contact for mixer valve (230Vac) KMC N.C. contact for mixer valve (230Vac) KDO Relaunching circulator phase KDON Phase conductor for relaunching circulator (230Vac) *M5 K1 Mixing valve outlet sensor KS1 Solar panel collector sensor KS2 Solar panel storage tank sensor K2 Water recirculation sensor KPWM Digital input for ambient thermostat KN2 Neutral conductor for solar discharge valve KCS2 Phase conductor for solar discharge valve ... -

Page 32: Wiring Between Indoor And Outdoor Units

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 Outdoor unit terminal block Terminals Description GND Grounding N1 Neutral L1 Phase 1 L2 Phase 2 (only for three‐phase systems) L3 Phase 3 (only for three‐phase systems) NO Power supply (230V AC) general alarm (closed if the alarm is on) N Neutral NC Power supply (230V AC) general alarm (closed if the alarm is off) Modbus Slave I+ / I‐ Wiring with indoor unit Modbus Master R+ / R‐ Wiring with indoor unit GND reference signals GNDR (Modbus reference mass for connection with indoor unit) It’s recommended to use a shielded twisted‐pair multipolar cable 5x0.75mm for connecting the I‐, I+ and GNDR terminals. 8.7.3 Wiring between indoor and outdoor units The indoor unit must be connected to the outdoor unit respecting the below table. Indoor unit terminal block Outdoor unit terminal block I+ I+ ... -

Page 33: Start Up

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 A. Manual reset thermostat: Opening 90±5°C; Manual rest: follow the procedure in the Paragraph 24.1 to remove the front panel, unscrew the plug casing on the on thermostats box, push the red button with a suitable tool, and replace the plug. B. Automatic reset thermostat: Factory setting to 70°C, opening 70±4°C; Differential 5±3.5°C (WARNING: Adjustment knob of the intervention threshold of the automatic thermostat with factory setting at 70°C, (check the correct positioning of the graduated knob) other values can ensure the proper operation of the unit) ... -

Page 34: Shutdowns For Long Periods

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 11 SHUTDOWNS FOR LONG PERIODS The types of shutdown depend on the weather of the site where the unit is installed and on the period of the stop. The antifreeze system, if it’s installed, stay on work also with the on‐board control unit in “OFF” position. If the time of stop is long and the temperature is low, we recommend you to drain the hydraulic circuits or use a mixture of water and glycol. Discharge the hydraulic circuits and shutdown the unit following the below steps: Turn off the units from control panel (displayed “OFF”). Close the water faucet (tap). Place the general differential QF switch in “OFF” state (if it is installed upstream of the system). If the indoor unit is installed in areas of the building subject to low temperatures (attics, basements, etc.) and the temperature drops below 0°C there is serious danger of frost: provide please a mixture of water and glycol in the plant system, otherwise drain the water system and the hydraulic circuits of the heat pump. If it is necessary to add glycol to the hydraulic circuit of the plant, provide a T‐fitting with tap downstream of the non‐return valve on the charging/topping up pipe (see Paragraph 8.5), in order to adapt the glycol concentration. WARNING: even the transient operation, with water temperatures below +5°C is not guaranteed on the basis of the limits set out in Paragraph 21.4 . Before you turn the unit on after a long off period, make sure that the temperature of the mixture of water and glycol is higher than or at least equal to +5°C. 12 MAINTENANCE AND PERIODIC CHECKS WARNING: All the operations described in this chapter HAVE TO BE CARRIED OUT BY TRAINED STAFF ONLY. Before any operation or before acceding to the inner components of the unit, be sure that the power supply is not connected. The compressor’s heads and discharge piping are usually at high temperature levels. Be very careful when operating in their surroundings. Aluminium coil fins are very sharp and can cause serious wounds. Be very careful when operating near them. After servicing operations, re‐ install the cover panels, and fix them by means of screws. The refrigerant circuits must not be filled with refrigerant gas other than that indicated on the nameplate. The use of a different refrigerant can cause severe damage to the compressor. It is forbidden to use refrigerant oils other than those specified in this manual. The use of different oil can cause serious damage to the compressor. The top part and discharge pipes of the compressor operate at high temperatures. Be sure to let the unit to become cool before beginning any maintenance work. Be careful when working near the condensing coils. ... -

Page 35: Environmental Protection

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 It is a good rule to carry out periodic checks in order to verify the proper operation of the unit. OPERATION 1 month 4 month 6 month Charging of the water circuit. x Presence of bubbles in the water circuit. x Check the proper working of the safety and control devices (indoor and outdoor units) x Check if there is a possible oil leakage from compressor (outdoor unit). x Check if there is a possible water leakage from the hydraulic circuit (indoor unit). x Check the proper working of the flow switches (outdoor unit). x Check out if the crankcase resistances are supplied and working properly (outdoor unit). x Clean the metallic filters of the hydraulic circuit. x Clean the finned coil by means of compressed air (outdoor unit). x ... -

Page 36: Technical Data

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 14 TECHNICAL DATA 14.1 PERFORMANCE DATA Models i‐SHWAK V4 PERFORMANCE DATA Units 06 08 10 Cooling capacity (1) min/nom/max kW 2,32 / 5,07 / 5,58* 2,95 / 6,12 / 6,73* 3,27 / 7,56 / 8,83* Input power (1) kW 1,74 2,11 2,43 EER (1) W/W 2,91 2,90 3,11 Cooling Cooling capacity (2) min/nom/max kW 3,65 / 6,87 / 7,56* 4,65 / 8,52 / 9,12* 5,4 / 10 / 11,35* Input power (2) kW 1,69 2,18 2,26 EER (2) W/W ... -

Page 37: Outdoor Units

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 14.2 OUTDOOR UNITS Model i‐SHWAK V4 TECHNICAL DATA Unit 06 08 10 12 Twin Rotary Twin Rotary Twin Rotary Twin Rotary Type DC Inverter DC Inverter DC Inverter DC Inverter Compressor Number 1 1 1 1 ESTER OIL VG74, ESTER OIL VG74, ESTER OIL VG74, ESTER OIL VG74, Refrigerant oil (type, quantity) ml 670 670 1000 1000 Type R410A R410A ... -

Page 38: Indoor Units

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 14.3 INDOOR UNITS 14.3.1 Models MAR/MARS Model i‐SHWAK V4 TECHNICAL CHARACTERISTICS Unit MAR/MARS Indoor unit coupled with a moto‐condensing unit size: 06 08 10 12 Water flow (3) /h 1,13 1,38 1,72 2,08 Available head pressure (3) kPa 52 39 31,0 30,1 Nominal input power of water pump (3) kW 0,075 0,09 Circulator Max. input power of water pump kW 0,075 0,09 Max. input current of water pump A 0,60 ... -

Page 39: Models Marp/Marps

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 14.3.2 Models MARP/MARPS Model i‐SHWAK V4 TECHNICAL CHARACTERISTICS Unit MARP/MARPS 06 08 10 12 Indoor unit coupled with a moto‐condensing unit size: Water flow (3) /h 1,13 1,38 1,72 2,08 Available head pressure (3) kPa 52 39 31 30 Nominal capacity (3) kW 0,075 0,09 Circulator Max. input power kW 0,075 0,09 Max. input current A 0,60 0,70 Energy Efficiency Index (EEI) ... -

Page 40: Electric Data

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 15 ELECTRIC DATA Power supply of circulator and V/~/Hz 230/1/50*‐400/3/50** V/~/Hz 230/1/50 Power supply of the unit diverting valve (indoor unit) V/~/Hz 12/1/50 Outdoor fans power supply V/~/Hz 230/1/50 Outdoor unit control board circuit Check the power V/~/Hz 12/1/50 Electric heaters power supply V/~/Hz Indoor unit control board circuit supply of the unit * For the single‐phase indoor units and for outdoor units namely: i‐SHWAK 06, 08, 10, 12, 14 and 16. ** For the three‐phase indoor units and for the outdoor units namely: i‐SHWAK 14T and 16T. Note: Electric data may change for updating the manual. It is therefore necessary to refer always to the technical data label attached on the right‐side panel of the unit. ... -

Page 41: Maximum Power Consumption / Maximum Input Current Of The Indoor Units 10-12

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 15.1 MAXIMUM POWER CONSUMPTION / MAXIMUM INPUT CURRENT OF THE INDOOR UNITS 10‐12 Model MAR1 10‐12 MAR3 10‐12 MARS1 10‐12 MARS3 10‐12 Electric heater NOT PRESENT 0,14 kW 1,16 A 0,14 kW 1,16 A 0,22 kW 1,76 A 0,22 kW 1,76 A DHW electric heater of 1,2 kW 1,40 kW 6,64 A 1,47 kW 7,14 A ... -

Page 42: Maximum Power Consumption/Maximum Input Current Of The Indoor Units 14-16

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 15.2 MAXIMUM POWER CONSUMPTION/MAXIMUM INPUT CURRENT OF THE INDOOR UNITS 14‐16 Model MAR1 14‐16 MAR3 14‐16 MARS1 14‐16 MARS3 14‐16 Electric heater NOT PRESENT 0,19 kW 1,51 A 0,19 kW 1,51 A 0,27 kW 2,11 A 0,27 kW 2,11 A DHW heater of 1,2 kW 1,45 kW 6,99 A 1,53 kW 7,59 A ... -

Page 43: Plant Side Hydraulic Circuit Available Head Pressures

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 16 PLANT SIDE HYDRAULIC CIRCUIT AVAILABLE HEAD PRESSURES The characteristic curves corresponding to prevalence‐water flow rate without head losses of the hydronic kit, which is composed of the components described in Paragraph 6.10 are shown below. The optimal operating points of the different models are shown on the following curve according to the conditions indicated in the apex 3 of the paragraph 14.3. The plant must be designed so as to ensure the nominal water flow rate corresponding to the operating points indicated below. Herein below also the range of the available head pressures that the unit can provide during the circulator’s modulation period. 42 Note: All the pictures in this manual are for explanation purpose only. They may be slightly different from the unit you purchased. The actual shape shall prevail. ... - Page 44 Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 43 ...

-

Page 45: Reading Of The Indoor Unit Manometers

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 17 READING OF THE INDOOR UNIT MANOMETERS Each indoor unit is equipped with two manometers. The difference between the manometers (1 and 2) reading can be used as approximate value for verifying the water flow rate/pressure head when the unit works on the plant. To the difference of manometers value you should subtract the pressure drop of the 3‐way valve for getting an approximate value of the available pressure head of the plant. The characteristic curve corresponding to the Head pressure versus Water flow rate of the three‐ way diverter valve, whose values should be deducted at the manometry for verifying with sufficient accuracy the available static pressure of the plant system at the nominal operating points marked in the curves of Chapter 16. For certainty raisons, it is recommended to remove 5% from the obtained values. 18 DHW INSTANTANEOUS PREPARER Here below are indicated the operating regions of the instantaneous DHW preparer versus the temperature of the primary circuit (DHW temperature of technic side) and the water flow rate of the secondary circuit (DHW withdrawal rate), for different values of the set temperature of domestic hot water (T"_Set_DHW). The region of operation corresponding only to the optional electric heater is indicated with red dashed lines. WARNING: It is necessary to install on the DHW line between the instantaneous preparer and the mixers of domestic hot water, an anti‐scald thermostatic valve calibrated at 45°C. Otherwise there is a serious risk of burning and severe scalding. WARNING: ... -

Page 46: Secondary Circuit Load Losses ( To Dhw

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 T”_Set_DHW=45°C T”_Set_DHW=50°C 18.1 Secondary circuit load losses (to DHW-R) The load losses diagram for the user‐side domestic hot water circuit is shown below. 19 SOLAR GROUP (MODELS: MARS/MARPS) WARNING: It is recommended after doing the filling/topping up/washing to replace the supplied hose connector with the respective plugs. This can minimize the risk of water dripping and boiling glycol. Keep the supplied hose connectors for future operations of topping up and cleaning. WARNING: The Solar plant design should be performed by qualified personnel in the field of thermotechnical engineering. Read carefully the paragraph 19.4 for the correct setting of the water flow rate. ... -

Page 47: Circulator Curves

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 The models MARS and MARPS include the kit for managing the solar energy source composed of the inlet (return from the plant circuit) and outlet pipes and group for forced circulation with high efficiency circulator consisting of: safety group, manometer, integrated check and ball valves and a flow regulator (2 ÷ 12 L/min). This group allows the filling/washing/maintenance of the circulator without necessity of evacuating the plant circuit, through the closing of the outlet side ball valve. Main components of the Solar Group: 1) Thermometer 2) Knob ... -

Page 48: Maintenance Of The Circulator

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 19.3 MAINTENANCE OF THE CIRCULATOR For removing and/or working on the circulator pump, there is no need to evacuate the plant circuit, just stop the fluid to flow from both upstream and downstream sides by closing the ball valve (1) (by rotating the knob clockwise) and closing the flow regulator valve (2) (horizontal calibration pin). ... -

Page 49: Optional Dhw Technical Side Boiler Kit

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 Filter with extractable cartridge NTC temp. sensor for immersion Loading group with pressure Expansion vessel reducer device Discharge valve Air vent valve Shut‐off valve 3‐way anti‐scalding thermostatic valve Check valve Domestic water mixer To the domestic utilities 3 bar relief valve Dial thermometer Electronic timer Manometer 0‐6 bar... -

Page 50: Hot Water Production (Winter Operation)

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 21.3 Hot water production (winter operation) Once the system is working at the right temperature, the inlet hot water temperature should not to be lower than 25°C; the lowest values that are not related to transitional or start‐up stages may cause incorrect working operation to the system with the possible breakdown of the compressor. The maximum outlet water temperature should not exceed 58°C. At this temperature, the power consumption and the performances in terms of COP are enhanced when the outdoor temperature is higher than 5°C, even if the unit is still able to work up to the limit reported in the envelope. For higher temperatures than those pointed out, especially if have a concomitant with the reduction of the water flow rate, it may cause abnormalities to the normal operating of the unit, or the safety devices act in critical cases. 21.4 Ambient air temperature The ... -

Page 51: Correction Factors For Operation With Glycol

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 DOMESTIC HOT WATER MODE 22 CORRECTION FACTORS FOR OPERATION WITH GLYCOL The following correction factors are to be used only if the indoor unit is installed in any internal area of the building subject to low temperatures and with the judgment of adding a certain quantity of glycol for protecting the hydraulic circuit. Glycol % (°C) CCF IPCF WFCF PDCF Freezing point 10 0,985 1 1,02 1,08 ‐3,2 20 0,98 0,99 1,05 1,12 ‐7,8 30 0,97 0,98 1,10 1,22 ‐14,1 40 0,965 0,97 1,14 1,25 ‐22,3 50 0,955 0,965 ... -

Page 52: Outdoor Units

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 23.2 OUTDOOR UNITS 23.2.1 Models: i‐SHWAK V4 06/08 23.2.2 Models: i‐SHWAK V4 10/12 23.2.3 Models: i‐SHWAK V4 14/14T/16/16T 51 ... -

Page 53: Access Procedure To Internal Parts

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 24 ACCESS PROCEDURE TO INTERNAL PARTS 24.1 INDOOR UNIT 1) Remove the two fixing screws in the top part of the unit. 2) Remove the front panel paying attention to the locking system: to remove the front panel, it is sufficient to lift it with 10mm and to pull it in front side turning it slightly towards you. 3) The same procedure should be repeated on the opposite way for repositioning the front panel. 24.2 OUTDOOR UNIT 24.2.1 Models: i‐SHWAK V4 06 / 08 1) Remove the top cover 2) Twist off the screws (number 2; 3; 4) of the user interface cover plate and the screw (1) from the side panel for separating the side panel from the front panel (Detail A). 3) Sequentially, twist off the screws (number 5; 6; 7) in order to move shift slightly the front panel and gain access to the screw (number 8) visible in detail B. 4) Twist off the screws (number 8; 9 visible in detail B) and those positioned on the battery side of the unit. To remove the side panel, pull it up (in order to free the tab of the base coupling which is indicated as C in detail B) and remove it. 52 Note: All the pictures in this manual are for explanation purpose only. They may be slightly different from the unit you purchased. The actual shape shall prevail. ... -

Page 54: Models: I-Shwak V4 10 / 12

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 24.2.2 Models: i‐SHWAK V4 10 / 12 1) Remove the cover twisting off the screws (number 1; 2; 3; 4; 5; 6; 7; 8). 2) Twist off the screws (number 9; 10) of the front panel and then push the panel downward to remove the interlocking tab (Detail A); pull the panel forward to remove it. 3) Twist off the screws (number 11; 12; 13) and those places on the battery side of the unit. To remove the side panel, pull the panel forward to remove it (in order to loose the hooking tab on the basement indicated as C in the detail B) and remove it. 24.2.3 Models: i‐SHWAK V4 14 / 14T / 16 / 16T 1) Remove the cover twisting off the screws (number 1; 2; 3; 4; 5; 6; 7; 8;9). 2) Twist off the screws (number 10; 11) of the front panel and then push the panel downward to remove the interlocking tab (Detail A); pull the panel forward to remove it. 3) Twist off the screw number 12 and those placed of the battery side of the unit. To remove the side panel, pull it upward (in order to loose the hooking tab on the basement indicated as C in the detail B) and remove it. 53 ... -

Page 55: Components Of Indoor And Outdoor Units

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 25 COMPONENTS OF INDOOR AND OUTDOOR UNITS 25.1 INDOOR UNIT MODELS MAR / MARS and additional kit Model MAR Automatic air vent valve included on DHW technical side DHW technical side expansion vessel Flowmeter DHW‐R Circulator DHW‐R Plate heat exchanger DHW – R Relief valve of 3 bar Plate heat exchanger Automatic air vent valve for DHW technical side Safety flow switch 10) Circulator 11) Y‐filter with integrated discharge 12) Plant side/DHW technical side reverse valve 13) User interface 14) Main electric panel 15) DHW technical puffer tank (250 L) 16) Expansion vessel plant side (VE8AT kit optional – available only for versions without electric heater or boiler kits) MODEL MAR equipped with electric heaters kit Safety thermostats boxes Electric heaters ... -

Page 56: Indoor Unit Models Marp/Marps And Additional Kit

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 MODEL MARS equipped with electric heaters kit Safety thermostats boxes Electric heaters Wells thermostat sensors Additional electric board 25.2 Indoor unit models MARP/MARPS and additional kit MODEL MARP Automatic air vent valve for plant side Expansion vessel for DHW technical side (10‐liters) Flowmeter DHW ‐ R Circulator DHW ‐ R Automatic air vent for DHW side Plate heat exchanger DHW – R Automatic air vent for DHW side Technical puffer tank for DHW (190 L) 3 bar relief valve 10) Plate heat exchanger 11) Circulator 12) Safety flow switch 13) Y filter 14) Plant side/DHW technical side reverse valve 15) User’s interface 16) Main electric panel 17) Technical puffer tank for plant side (40 L) ... - Page 57 Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 MODEL MARPS Solar group Solar side circulator Solar plant outlet pipe (label "to the solar plant") Solar plant return pipe (label “from the solar plant”) Additional electric board Pant side expansion vessel of 8 litres DHW side expansion vessel of 10 litres The model MARPS equipped with electric heaters kit Relief thermostats boxes Electric heaters (One only for DHW side and one for plant side) Wells thermostat sensors Additional electric board Pant side expansion vessel of 8 litres DHW side expansion vessel of 10 litres 56 Note: All the pictures in this manual are for explanation purpose only. They may be slightly different from the unit you purchased. The actual shape shall prevail. ...

-

Page 58: Indoor Unit Temperature Sensors

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 25.3 Indoor unit temperature sensors Model MAR Model MARS Position of temperature sensor Heat exchanger inlet Heat exchanger outlet DHW technic side DHW‐R primary circuit inlet DHW‐R secondary circuit inlet DHW‐R secondary circuit outlet Solar coil Model MARP Model MARPS Position of temperature sensor Heat exchanger inlet Heat exchanger outlet DHW technical side DHW‐R primary circuit inlet DHW‐R secondary circuit inlet DHW‐R secondary outlet Solar coil 26 FILTER CLEANING Remove the discharge pipe from the fitting of the relief valve (1) ... -

Page 59: Wiring Diagrams

Inverter air/water chillers and heat pumps with floor‐standing and remote condensing units i‐SHWAK V4 27 WIRING DIAGRAMS 27.1 INDOOR UNIT ELECTRIC BOX LAYOUT 1) [TF1]: Electric transformer 240V‐12V‐30VA 2) [M1]: Power supply terminal block 3) [CB1]: User interface controller 4) [AB1]: Support board 5) [F3*]: Fuses for electric heater protection 6) [M2]: Auxiliary power supply terminal block 7) [M3; M4**]: User terminal block * Present only with the optional electric heater RExxxx kit ** Present only with the optional Gi2 kit There exist a second electrical board in case of presence of the optional Gi2 kit and/or the RExxxx optional electric heater. 8) 4 pole contactor coil 230V, 20A for DHW electric heater side [K1*]; 9) 4 pole contactor coil 230V, 20A for plant system electric heater [K2*]; 10) [SL2**] controller. - Page 60 37040 Arcole Verona - Italy Tel. +39 - 045.76.36.585 r.a. Fax +39 - 045.76.36.551 r.a. www.maxa.it e-mail: info@advantixspa.it The data indicated in this manual is purely indicative. The manufacturer reserves the right to modify the data whenever it is considered necessary.

Need help?

Do you have a question about the i-SHWAK V4 06 and is the answer not in the manual?

Questions and answers