Table of Contents

Advertisement

Quick Links

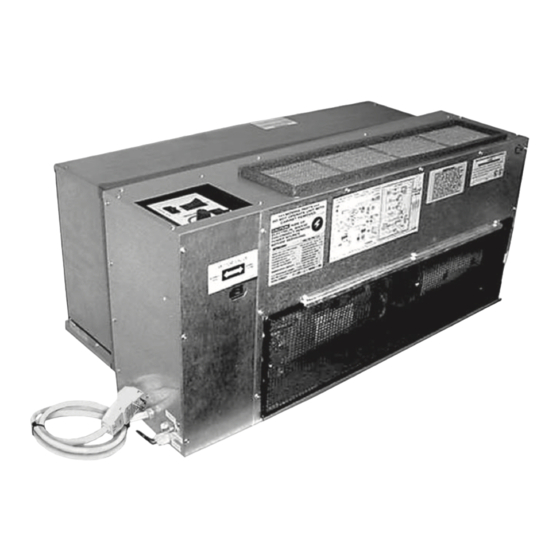

R11C R21C

R22C / H R23C / H R24C / H

Packaged Terminal Air Conditioner (PTAC)

™

The Right Fit for Comfort

Installation, Operation

& Maintenance Manual

ECR International Inc

2201 Dwyer Avenue

Utica, NY 13501

e-mail: info@RetroAire.com

An ISO 9001-2008 Certified Company

P/N 240010329, Rev. A [10/15/2013]

Advertisement

Table of Contents

Summary of Contents for ECR RetroAire R22C

- Page 1 R22C / H R23C / H R24C / H Packaged Terminal Air Conditioner (PTAC) ™ The Right Fit for Comfort Installation, Operation & Maintenance Manual ECR International Inc 2201 Dwyer Avenue Utica, NY 13501 e-mail: info@RetroAire.com An ISO 9001-2008 Certified Company P/N 240010329, Rev. A [10/15/2013]...

-

Page 2: Table Of Contents

AHRI Standards 310/380 UL-484 Information and specifications outlined in this manual in effect at the time of printing of this manual. ECR International reserves the right to discontinue, change specifications or system design at any time without notice and without incurring any obligation, whatsoever. -

Page 3: Receiving Information

RECEIVING INFORMATION Shipping damage MUST be reported to the carrier IMMEDIATELY. Examine exterior. Remove cover and examine compressor and piping for signs of damage. Inspection General Information Check shipment against bill of lading. Installation shall be completed by qualified agency. Retain this manual and warranty for future reference. -

Page 4: Important Safety Information

IMPORTANT SAFETY INFORMATION Safety Information All field wiring shall conform to requirements of authority having jurisdiction or in absence of such requirements: • Installation by qualified personnel. • United States - National Electrical Code, ANSI/NFPA 70 • Turn off electrical supply before servicing unit. •... -

Page 5: Performance Data

PERFORMANCE DATA Table 1 Performance Data - Cooling Outdoor Models Cooling Indoor Air Fresh Air Shipping Sound Sensible Capacity Flow Inlet Flow Weight R11C R21C Level Voltage Heat R22C R23C Ratio Btuh (kW) CFM (L/S) CFM (L/s) lbs (Kg) R24C 9000 (2.7) 440 (207.7) R_ _C 09... -

Page 6: Dimensional/Physical Data

DIMENSIONAL/PHYSICAL DATA Figure 1 R11C Dimensions - Inches (mm) Model Dimension R11C in. (mm) 21.81 (554) 34.44 (875) 13.96 (355) 18.63 (473) 26.00 (660) 18.62 (473) 4.00 (102) 3.60 (91) The Right Fit for Comfort P/N 240010329, Rev. A [10/15/2013]... - Page 7 DIMENSIONAL/PHYSICAL DATA Figure 2 R21C Chassis Model Model Dimension R21C -09 R21C -18 in. (mm) in. (mm) 35.88 (911.2) 35.88 (911.2) 14.78 (375.5) 14.78 (375.5) 7.75 (196.9) 14.40 (365.7) 20.25 (514) 24.34 (618.2) 18.98 (482.1) 28.28 (718.3) 5.66 (143.8) 5.66 (143.8) Made in USA P/N 240010329, Rev.

- Page 8 DIMENSIONAL/PHYSICAL DATA Figure 3 R22C/R22H Chassis Model Dimension R22C/R22H in. (mm) 35.89 (912) 14.98 (380) .94 (24) 8.98 (228) 19.09 (485) 5.00 (127) 17 (432) 38.04 (966) 25.13 (638) .96 (24) Figure 4 R23C/R23H Chassis Model Dimension R23C/R23H in. (mm) 42.16 (1071) .78 (20) 9.95 (253)

- Page 9 DIMENSIONAL/PHYSICAL DATA Figure 5 R24C/R24H Chassis Model Dimension R24C/R24H in. (mm) 40.02 (1017) 1.19 (30) 19.19 (487) 9.18 (233) 16.87 (429) 42.08 (1069) 25.38 (645) .84 (21) Made in USA P/N 240010329, Rev. A [10/15/2013]...

-

Page 10: Product Description

PRODUCT DESCRIPTION Figure 6 R11C Chassis Speed Switch Fresh Air Switch (FSS) (FAS) System Thermostat Switch (SS) Line Cord Electrical Diagram Control Rating Cycle Plate W/ Jumper Switch (FCS) MTR Valve Hydronic NO/NC Switch Valve Orientation High Switch (VOS) Pressure Switch (HPS) Figure 7... - Page 11 PRODUCT DESCRIPTION Figure 9 R22C | R22H Chassis Speed Fresh Air Switch Switch (FAS) (FSS) System Switch Thermostat (SS) Electrical Diagram Rating Plate Control W/ Jumper Cycle Switch (FCS) Control W/ Jumper High Pressure Line Switch (HPS) Cord MTR Valve Figure 8 R23C | R23H Chassis Speed Fresh Air Switch...

- Page 12 PRODUCT DESCRIPTION Figure 10 R24C | R24H Chassis Speed Fresh Air Switch Switch (FAS) (FSS) System Switch Thermostat (SS) High Pressure Cycle Line Switch Switch Cord (HPS) (FCS) Electrical Diagram Rating Control Plate W/ Jumper MTR Valve The Right Fit for Comfort P/N 240010329, Rev.

- Page 13 PRODUCT DESCRIPTION Product Description Controls • RetroAire Replacement Packaged Terminal Air • Unit-mounted operating controls include thermostat, fan Condition/Heat Pumps units are straight cooling speed control, heat/cool switch, fan cycle switch, fresh (PTAC) or heat pump systems (PTHP). air switch (if equipped). •...

- Page 14 PRODUCT DESCRIPTION Manufacturer Installed Options (Consult Field-Installed Accessories • Hydronic heat — coil assembly is shipped loose for field manufacturer) installation. • 265/277V(12 and 15 only) • Remote wall thermostat — digital 1-stage or 2-stage available. • 115V (09 &12 Models Only) •...

-

Page 15: Ptac/Pthp Installation Preparation

PTAC/PTHP INSTALLATION PREPARATION • For all models, outdoor openings must prevent contact WARNING of all moving parts by means of louvers or grills, with Electrical shock hazard. Before opening existing minor dimension not exceeding 1 in (25.4mm). unit, open power supply disconnect switch. Secure Electrical Power Connection switch in open position during installation. -

Page 16: Installation Instructions - R11C

INSTALLATION INSTRUCTIONS - R11C Installation - R11C Figure 11 Conderser Baffels Verify existing wall thickness — distance from condenser coil to outdoor louver varies with sleeve depth. • Unit(s) ship standard with 1-3/8" (35mm) & 1-1∕8” (38mm) baffles. Figure 16, page •... - Page 17 INSTALLATION INSTRUCTIONS - R11C • Remove 2-position connector assembly from kit Figure 14 Baffle Install bag supplied with unit (2 yellow wires attached). • Connect 2-position connector to 2-position connection located on bottom of control box panel. Field install (optional) Control A.

-

Page 18: Installation Instructions - R21C

INSTALLATION INSTRUCTIONS — R21C Installation - R21C Figure 15 Direction Of Baffles Verify existing wall thickness — distance from Baffles condenser coil to outdoor louver varies with sleeve depth. 09/12K • Chassis includes standard air baffles to accommodate most common condenser coil to outdoor louver requirements •... - Page 19 INSTALLATION INSTRUCTIONS — R21C Field install (optional) Control Figure 18 Front View Of Chassis A. Remove black jumper wire located on bottom panel of control box (also terminated with 2-position connector). B. Cut jumper wire in middle and splice control to jumper.

-

Page 20: Installation Instructions - R22C | R22H

INSTALLATION INSTRUCTIONS — R22C | R22H Installation - R22C/R22H Figure 19 Baffles Verify existing wall thickness — distance from condenser coil to outdoor louver varies with sleeve depth. • Units are shipped with baffles factory installed Apply 1/2” x 3/4” open-cell foam strips around supply air duct to ensure all conditioned air is delivered into room (see Figure 25, page 22.) Failure to do so results in recirculation of conditioned air through cabinet... - Page 21 INSTALLATION INSTRUCTIONS — R22C | R22H Hard-wired units — If unit is hard wired, follow in- Figure 22 Foam Installation Weather Seal structions on pages 40-44 to verify existing wiring and over current protection. A. Remove line cord wires from PTAC/PTHP power entrance terminals.

-

Page 22: Installation Instructions - R23C | R23H

INSTALLATION INSTRUCTIONS — R23C | R23H Installation - R23C/R23H Figure 23 Direction Of Baffles And Foam Verify existing wall thickness — distance from Installation condenser coil to outdoor louver varies with sleeve depth. • Chassis includes standard air baffles to accommodate most common condenser coil to outdoor louver requirements •... - Page 23 INSTALLATION INSTRUCTIONS — R23C | R23H • Remove 2-position connector assembly from kit Figure 26 Foam Tape Installation Against bag supplied with unit (2 yellow wires attached). Wall Sleeves • Connect 2-position connector to 2-position connection located on bottom of control box panel.

-

Page 24: Installation Instructions - R24C | R24H

INSTALLATION INSTRUCTIONS — R24C | R24H Installation - R24C/R24H Figure 27 Baffle Locations Verify existing wall thickness — distance from condenser coil to outdoor louver varies with sleeve depth. • Chassis includes standard air baffles to accommodate most common condenser coil to outdoor louver requirements •... - Page 25 INSTALLATION INSTRUCTIONS — R24C | R24H B. Coil with old unit can be located in subbase, under Figure 30 Foam Tape Installation Against chassis in special attachment. It is necessary to Wall Sleeves know where coil is to be located and physical size of coil if ordered for replacement.

-

Page 26: Sequence Of Operation

SEQUENCE OF OPERATION General Figure 31 Control Board R_ _C units are straight cool, single stage air conditioners available with electric or hydronic heat. R_ _H units are limited range, single stage heat pump. Mechanical compression heating (heat pump mode) is locked out at outdoor temperatures of approximately 35ºF (1.7ºC) and below. - Page 27 SEQUENCE OF OPERATION R_ _C / R_ _H; Cooling Operation R_ _C / R_ _ H; Heating Operation System Switch [SS] set to “Heat”, and Fan Cycle ( For unit mount controls) Switch [FCS] set to “On” (Continuous Fan Operation), System Switch [SS] set to “Cool”, and Fan Cycle indoor fan motor starts.

- Page 28 SEQUENCE OF OPERATION • R_ _H; Auxiliary Heating “Electric” or “Hydronic” • “Remote Wall Thermostat Controls” A. Cooling and Heating operate identical to unit Outdoor coil temperature falls to 25ºF (-4ºC) or mount controls. below for 180 seconds at anytime during heating call, compressor and outdoor fan motor are de-energized B.

-

Page 29: Inspection & Start-Up

INSPECTION & START-UP Before Operating Unit Any obstruction of supply air, including use of deflector baffles, may cause condensate to form on louver or cabinet ☐ Read and understand contents of this manual. (see Figure 38, page 31). ☐ Install unit per instructions outlined in this manual and all applicable local and national codes. - Page 30 INSPECTION & START-UP Electrical Connections Figure 34 TEST Jumper (selects heat pump or straight cooling) WARNING Electrical shock hazard. Disconnect all power Straight Heat Pump before removing chassis, performing any cleaning, Cool Mode Mode Mode servicing, or maintenance. Failure to do so could (jumper center (jumper center &...

- Page 31 INSPECTION & START-UP Start Up Figure 36 Circuit Board Verify unit is secure and level. TEST JUMPER Heat pump units only — Verify thermostatic drain pan valve is operating correctly. Valve should be closed if temperature is above 60°F and open if temperature is below 60°F.

- Page 32 INSPECTION & START-UP Heating Cycle — Electric Option NOTICE Place thermostat or system switch in HEAT position. DO NOT rotate thermostat knob back and forth Adjust thermostat for warmer temperature until from heating to cooling. This causes compressor to indoor fan starts running and electric heater coil starts cycle on and off rapidly and will cause damage to emitting heat.

- Page 33 INSPECTION & START-UP After unit starts running and area is warmer, adjust Warmer room temperature desired, adjust thermostat thermostat to cooler temperature, hydronic valve will to a warmer temperature. The cooling mode will cease close and indoor fan will switch off after sixty-second and the compressor and outdoor fan will stop.

- Page 34 INSPECTION & START-UP Auxiliary Heating Operation — Heat Pump Units – After unit starts running and space gets — Outdoor Temperature Below 40°F (4C°) — warmer, hydronic valve closes and indoor fan Electric Option switches off after sixty-second purge time has elapsed.

-

Page 35: Maintenance

MAINTENANCE Monthly Inspection And Maintenance To manually reset limit switch; – Remove control box cover. WARNING – Locate limit switch. Electrical shock hazard — disconnect power to – Push reset button in. See Figure 44, page 37). replacement PTAC/PTHP before servicing or accessing control compartment. - Page 36 MAINTENANCE • Check fan motors and blower assemblies. Some units Heat Pump Units — Temporary Emergency Heating Mode may require drop of light oil to motors and/or bearing assemblies (look for oil cups). Verify set-screws and Heat pump failure, control board can be forced into electric motor mounting hardware are secure.

-

Page 37: Troubleshooting

TROUBLESHOOTING Troubleshooting WARNING Fire, explosion, and electrical shock hazard. Troubleshooting procedures shall be conducted by a qualified technician. Improper installation could result in death or serious injury. Symptom Suggestion • Verify unit has power and thermostat is satisfied. If thermostat is not satisfied, No heat or cooling call your installing contractor or service contractor. -

Page 38: Electrical Specifications

ELECTRICAL SPECIFICATIONS Table 5 R11, R21, R22, R23, R24 - 9,000 BTU Electrical Specifications Power Indoor Outdoor Supply Compressor Electric Heat Unit Electrical Ratings Fan Motor Volt 1–60 Motor Volt Volt MOCP Plug 0.09 0.125 10.5 12.4 5-15P 115V 45.6 0.09 0.125 13.0... - Page 39 ELECTRICAL SPECIFICATIONS Table 7 R11, R21, R22, R23, R24 - Cooling Capacity 15 Electrical Specifications Power Indoor Outdoor Supply Electric Heat Unit Electrical Ratings Compressor Volt Motor Motor 1–60 Volt Volt MCA MOCP Plug 10.6 6–15P 1636 10.4 6–15P 2000 11.5 2454 11.8...

- Page 40 ELECTRICAL SPECIFICATIONS Table 9 Electrical Plug (Rating) The Right Fit for Comfort P/N 240010329, Rev. A [10/15/2013]...

- Page 41 HYDRONIC HEAT PERFORMANCE Table 10 R21C/H Hydronic Heat * — Performance 104-101 (Single Row Coil) Air Entering Dry Air Entering Air Entering Flow Hydronic Coil Code Water Flow Water Entering Capacity Pressure Drop Water Leaving Water Delta Model Bulb Wet Bulb Rate Part Number ºF...

- Page 42 NOTES The Right Fit for Comfort P/N 240010329, Rev. A [10/15/2013]...

-

Page 44: Warranty

Warranty ECR International Inc 2201 Dwyer Avenue Utica, NY 13501 e-mail: info@RetroAire.com An ISO 9001-2008 Certified Company...

Need help?

Do you have a question about the RetroAire R22C and is the answer not in the manual?

Questions and answers