Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for rayence 1012WCA

- Page 1 1012WCA User manual...

- Page 2 © Copyright 2013, Rayence Co. Ltd. All pages of this document contain proprietary and confidential information of Rayence Corporation and are intended for exclusive use by Rayence Corporation personnel or customers. Copying, disclosure to others or other use is prohibited without the express written authorization from Rayence Corporation.

- Page 3 Attention For improvement of product performance, supplementation, or follow-up of information; the contents of this manual are subject to change without separate prior notice. Please note that our company has neither responsibility for any accidents nor obligation to do free repair service for any damage of the equipment due to user's mistake, which resulted from failure to follow the contents in this manual.

-

Page 4: Table Of Contents

Contents Introduction ..................1 Overview ..................1 Intended use .................. 1 Product features ................2 Product components ..............3 Components Description ............. 5 Warning ..................10 Caution ..................12 Notes for Using the Detector ............15 Preparing ..................15 Handling ..................16 Handle Assembly ................ - Page 5 10. Maintenance ................. 81 Maintenance ................81 Cleaning ..................81 Inspection ..................82 Disposal or Recycling ..............83 Marking and labeling symbols ..........84 Appendix ....................86...

-

Page 6: Introduction

1. Introduction (1) Overview The 1012WCA is a wireless digital X-ray flat panel detector that can generate images of any part of the body. The wireless LAN((IEEE 802.11a/g/n) communication feature improves the operability, and high-speed processing. This X-ray imaging system consists of a scintillator directly coupled to an a-Si TFT sensor. -

Page 7: Product Features

(3) Product features Wi-Fi (802.11a/g/n) Based on a-Si TFT active matrix Compact and light weight Limiting Resolution 14/16-bit digital output Easy integration... -

Page 8: Product Components

(4) Product components Medical Image Processing Unit Photo Item Quantity Detector Handle Battery pack Battery charger Charger adapter... - Page 9 Cables Item Length Quantity Link cable Interface cable cable(A to 1.8m LAN cable AC Power 1.8m cord Trigger cable Installation CD o Manual o Detector Library...

-

Page 10: Components Description

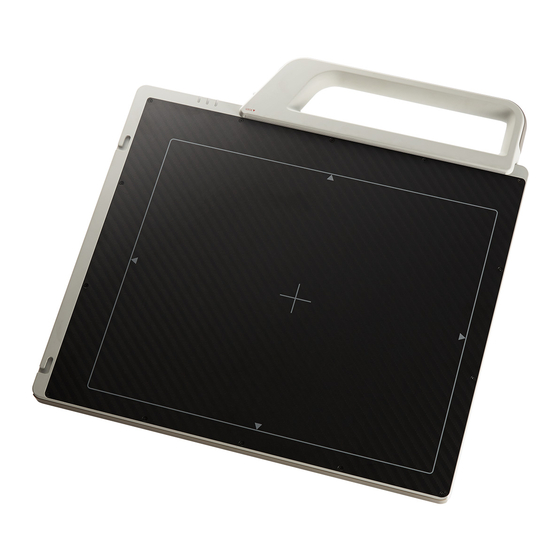

(5) Components Description The detector is designed to capture radiographic images. Captured images are transmitted to PC using the wireless/wired connection. (1) Detector 1. Link Cable Connector : Use for charging battery while detector is in use(Connect between detector and power supply) 2. - Page 11 3. Power & Mode Sleep Button 4. Handle unlock-lever : This is an unlock-lever to remove handle. 5. Handle : Hold this handle when carrying the sensor unit. It is removable. (Horizon/Vertical) 6. CFRP(Carbon Fiber Reinforced Plastic) : The part of the patient’s body to which an image is to be taken should be placed against this plate.

- Page 12 (2) Battery & Charger 1. Battery : Rechargeable Lithium Ion battery(Charging Time-3 hrs) ※ In the diagram above, the box shows where the remaining battery percentage is displayed. 2. Battery Charger : Two port cradle type. 3. LED indicator : Displays battery charging status...

- Page 13 ※Wireless Module and Wireless Antenna Wireless antennas: The module adopts the latest 802.11n Dual-Band technology. DUT does not support simultaneous transmission. The transmitter of the module is powered by host equipment (Detector). The antennas are 2 printed-dipole and correlated antennas. Does not support beamforming.

- Page 14 This device complies with Industry Canada licence-exempt RSS standard(s). Operation is subject to the following two conditions: (1) this device may not cause interference, and (2) this device must accept any interference, including interference that may cause undesired operation of the device. Le present appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio exempts de licence.

-

Page 15: Warning

(6) Warning Make sure to observe Environment of Use and Storage the following right Follow the specified process of operational instructions written in this manual for the safety of the users and patients. Does not use or store the instrument near any flammable chemicals such as thinner, benzene, etc. - Page 16 When Problem Occurs Should any of the following occur, immediately turn OFF the power of each instruments, unplug the power supply cord from the AC outlet, and contact Rayence representative or distributor. When there is smoke, odd smell or abnormal sound.

-

Page 17: Caution

(7) Caution Environment of Use and Storage Do not install the instrument in a location with the conditions listed below. Otherwise, it may result in failure or malfunction, cause fire or injury. Close to facilities where water is used. ... - Page 18 Even when the detector appears to be dry and appears to operate normally, the circuitry could slowly corrode and pose a safety hazard. If the detector and/or battery get wet, have them checked by your service provider or contact Rayence, even if they appear to be working properly.

- Page 19 Use of a non-Rayence-approved battery or charger may present a risk of fire, explosion, leakage, or other hazard. Rayence's warranty does not cover damage to the detector caused by non-Rayence-approved batteries and/or chargers Misuse or use of incompatible batteries and charging...

-

Page 20: Notes For Using The Detector

2. Notes for Using the Detector (1) Preparing Fully charge the battery pack. Charge the battery on the day of examination or on the previous day. Battery slowly discharges even of not in use. The battery pack may have expired if it discharges immediately after being fully charged. -

Page 21: Handling

(2) Handling Handle the instrument carefully, as it may be damaged if something is hit against it, dropped, or receives a strong jolt. (3) Handle Assembly ※ Insert the handle always in the same direction. -

Page 22: Before Exposure

Handle Assembly Type 1 Please confirm lever position. When the handle is locked, the lever should be same position with the right picture. Insert the handle in the same direction If the handle is not locked, the detector can be dropped. -

Page 23: During Exposure

room and in the instrument does not occur, to prevent forming of condensation. (5) During Exposure Do not use the detector near devices generating a strong magnetic field. Doing so may produce image noise or artifacts. Do not apply excessive weight to the sensor unit. Otherwise, the sensor may be damaged. -

Page 24: Limit Of Load

(6) Limit of Load Uniform load: 150 kg over the whole area of sensor window. Local load: 100 kg on an area 40 mm in diameter. -

Page 25: Disinfection And Cleaning

Be sure to use the sensor unit on a flat place so it will not bend. Otherwise, the sensor may be damaged. (7) Disinfection and Cleaning Do not spray the detector directly with disinfectants or detergents. Do not use anything other than neutral detergent for cleaning the cover of the instrument. -

Page 26: Technical Features

3. Technical Features (1) Mechanical Features Size 395 x 337 x 18 mm Weight 2.7 kg (not incl. Handle) Encapsulation Material Window Material Carbon fiber plate with 1.5mm thickness (2) Electrical Features Detector Sensor Type Amorphous Silicon with TFT (Single Panel) X-ray Converter CsI:Tl Total Pixel Number... - Page 27 Capacity Typ. 3400 mAh The number of times 1060 images (@cycle time = 15s) being acquired image The Battery level can be displayed on the LED status of battery. If the battery level goes down under 25%, please charge the battery Battery level Display...

- Page 28 2 printed-dipole antennas. ※Wireless module: The SparkLAN WPEA-121N 802.11 a/b/g/n half mini PCI-e module is implemented. It supports 2T2R (2 transmit 2 receive) MIMO technology, which delivers throughput up to 300Mbps.1012WCA in the RF module does not use DFS band.

-

Page 29: Environmental Requirement

(3) Environmental requirement Item Min. Typ. Max. Unit Note Temperature ℃ (Storage) Temperature ℃ (Operation) Humidity (Storage) H.R. Humidity (Operation) H.R. 10-150Hz, Vibrations 10Sweeps, (Wrapping (8G) 1min/Octave, condition) XYZ axis ※ Regularly changed parts : Battery (warranty 6 months) (4) PC Requirements ... -

Page 30: Installation

4. Installation The Detector is composed of sensitive electronic parts and components. It is recommended to use the product in a clean Portable place and to exercise caution to ensure that it is not affected by Imaging processing dust or liquids. It is recommended to Use a dry and soft cloth to unit must be clean the detector housing. -

Page 31: Connection (Manual Trigger)

* In wired mode, the frame ground is necessary. * When you use the detector with wired mode, the WLAN function is automatically off. B. Connect the USB cable from your PC to AGI. ※ Be sure to sure only the dedicated battery pack, RB37WH for 1012WCA. - Page 32 Wireless Communication A. AP Router(Line sharer) setting - SSID : Griffon - Internal network - IP address : 2.2.2.1 - Subnet mask : 255.255.255.0 - Dynamic IP allocation range : 2.2.2.2~2.2.2.254 - Pre-Shared Key(Password) : project302 - Authentication methods : WPAPSK or WPA2PSK - Password methods : TKIP/AES - AP IP : 2.2.2.1 - Channel (Frequency)

- Page 33 C. Checking Link Quality & Battery Remain - After wireless connection is established, perform ‘Get Image’ in ‘Calibration & Acquisition’ tap. - Check the value named ‘Wireless Signal’ in black log screen. Wireless Signal = Link Quality (Max. 100) - Check the value named ‘Battery Remain’ in black log screen. Battery Remain = Battery Remain(Max.

- Page 34 Software Setting (manual trigger) Figure 2: Davinci Setting...

- Page 35 Trigger Connection A. Connect the P-interface cable or trigger cable to the generator X-ray Generator Connection Make A. Mode 1 : P-interface cable mode assurance doubly sure SIGNAL RATING Connect the P-interface cable between the AGI box and X-ray before connection. generator.

- Page 36 The window time can be changed. Refer to the following pictures Exposure Time 500msec is designate to 0.5sec...

- Page 37 B. Mode 2 : Trigger cable mode Connect the Trigger cable between the X-ray enable connector of Make AGI with X-ray generator. assurance doubly sure SIGNAL RATING before connection. Figure 8: <2nd example> wiring for the interface between portable generator & detector Connection description Signal New Label...

- Page 38 Operating description Figure 3 : Timing chart t1: It will be occurred when exposure switch is pushed completely after. t2: Window time of detector is varying 0 sec ~ 5 sec. which can be control by S/W. (Editing parameter: Exposure Time – Refer to the NOTE) ...

-

Page 39: Connection (Auto Trigger)

(3) Connection (Auto Trigger) Power Connection A. Connect the battery pack or power cable to the equipment. * In wired mode, the frame ground is necessary. ※ Be sure to sure only the dedicated battery pack, RB37WH for 1012WCA. - Page 40 Wireless Communication A. AP Router(Line sharer) setting - SSID : Griffon - Internal network - IP address : 2.2.2.1 - Subnet mask : 255.255.255.0 - Dynamic IP allocation range : 2.2.2.2~2.2.2.254 - Pre-Shared Key(Password) : project302 - Authentication methods : WPAPSK or WPA2PSK - Password methods : TKIP/AES - AP IP : 2.2.2.1 - Channel (Frequency)

- Page 41 C. Checking Link Quality & Battery Remain - After wireless connection is established, perform ‘Get Image’ in ‘Calibration & Acquisition’ tap. - Check the value named ‘Wireless Signal’ in black log screen. Wireless Signal = Link Quality (Max. 100) - Check the value named ‘Battery Remain’ in black log screen. Battery Remain = Battery Remain(Max.

- Page 42 Software Setting (Auto trigger) Figure 4: Davinci Setting...

- Page 43 Important Note In AUTO TRIGGER MODE, the trigger will be forced not to acquire images when detector senses vibration or shock. In READY mode, Detector will automatically switch to WAIT mode when detector senses vibration or shock, so that user won’t acquire images in WAIT mode although X-ray exposure applies.

-

Page 44: Ip Set Up

(5) IP set up [My Network Places] → [Properties] → [Local Area Connection] → [Properties] → [Internet Protocol (TCP/IP)] → [Use the following IP address] IP address: Obtain an IP address automatically IP address : Obtain an IP address automatically... -

Page 45: Using Fpd_Manager (Ip, Ssid Change / Upgrade Fw)

(6) Using FPD_Manager (IP, SSID Change / Upgrade FW) Change IP Address of Detector A. Turn on Detector and connect to PC (wired connection is recommended) B. After detector boot up, Launch FPD_Manager.exe... - Page 46 C. Check the “IP Change” and type current IP address as below D. Type IP address to set...

- Page 47 E. Click “Start Setting” button F. Click “예 (Y) ” button G. Click “확인” button H. Restart detector(Turn Off then On)

- Page 48 Change SSID and PSK(Pre-Shared Key) A. Turn on Detector and connect to PC (wired connection is recommended) B. After detector boot up, Launch FPD_Manager.exe...

- Page 49 C. Check the “SSID change” and write current IP address as below D. Type SSID and PSK to set...

- Page 50 E. Click “Start Setting” button I. Click “예 (Y) ” button F. Click “확인” button G. Restart detector(Turn Off then On)

- Page 51 Upgrade Firmware A. Turn on Detector and connect to PC (wired connection is recommended) B. After detector boot up, Launch FPD_Manager.exe...

- Page 52 C. Check the “SSID change” and write current IP address as below D. Select firmware or FPGA file by click “select” button...

- Page 53 E. Click “Start Setting” button F. Click “예 (Y) ” button G. Click “확인” button H. Restart detector(Turn Off then On)

-

Page 54: Calibration

5. Calibration (1) General Principle X-ray detector Notation should be used at stable state within driving Calibration can be done by image acquisition S/W. The gain- temperature range. offset correction (under calibration) will be done with one dark, at Acquire the X-ray images after power least one bright and object frame. - Page 55 Bright Calibration Point calibration To gain correction, bright frame and dark frame should be range of acquired. The dark frame is needed only one frame. The bright bright is can be frame is recommended to be acquired more than 2 different select by which exposure level is levels of median values of bright frames.

-

Page 56: Calibration (Manual Mode)

(2) Calibration (Manual mode) Describe the calibration step by step. 1st Step A. Push “Calibration” button B. Push “Manual Mode” button... - Page 57 C. Click on the “Calibration” button. The acquired dark frame “dark.raw” will be generated in the “\cal\” folder. Figure 1: Get dark...

- Page 58 2nd Step Click button [Get Push “Get Bright” button at different four of X-ray condition. The Bright]. It will produce frame X-ray condition should be set or tested before, same as the level with name %CAL% of ‘1.2’. Push “Get Bright” button at least 2 times at same xNNNNNA.raw condition, and then the offset subtracted bright (gain) is where...

- Page 59 3rd step step, the “Generate” button will be activated. Click the After 2 button “Generate”, and then calibration point will be generated which of file name is “A ‘# of point’_ ‘median value of generated point’” like file of bright frame. The acquired bright frames within tolerance value which is variance of median level of acquired bright frames will be averaged and generated to a calibration point.

- Page 60 4th step After 3rd step, Change Bad Pixels Removal Tab, Click the button “Generate Auto BPM”, and then Defect Map will be generated which of file name is “BPM.raw “ at the “\cal\” folder. Figure 4: Bad pixels removal...

- Page 61 5th step For additional Defect correction, if “BPMM.raw” is existed at the install CD, copy to the “\cal\” folder. 6th step On Acquisition Tab. Check the box “Offset Calibration”, “Gain Calibration”, “Bad Pix Map” for activate to each calibration and Bad Pixels Removal.

-

Page 62: Calibration (Auto Mode)

(3) Calibration (Auto mode) Describe the calibration step by step. 1st Step A. Push “Calibration” button Figure 1: Calibration... - Page 63 B. Click “Start” button to acquire a dark frame then “dark.raw” will be generated in the “\cal\” folder. Figure 2: Auto calibration start C. When after the dark frame is acquired the pop up will be comes up as ‘figure 3’ Figure 3: Bright acquisition...

- Page 64 D. When ‘Bright acquiring bright frame’ is shown, Exposure X-ray to create Bright points as RED box on ‘Figure 4’ Suitability of the acquired bright frames are shown at the message bright point made box as ‘figure 5’, please check the message box for each steps. If by average value of 4 bright frames in calibration is successful, the pop up will appeared as ‘figure 6’...

- Page 65 Figure 5 Bright acquisition message Figure 6 Calibration complete...

- Page 66 2nd step For additional Defect correction, if “BPMM.raw” is existed at the install CD, copy to the “\cal\” folder. 3rd step On Acquisition Tab. Check the box “Offset Calibration”, “Gain Calibration”, “Bad Pix Map” for activate to each calibration and Bad Pixels Removal.

-

Page 67: Image Acquisition Test

6. Image Acquisition Test (1) Get Image On Acquisition tab, click the “Get Image” button to get image. After click the button, you can see pop-up window, which is display window time and process of acquiring image. -

Page 68: View Images

(2) View Images Frame- and image-files have extension “raw” and contain pixel data in signed 16-bits little-endian format. One could view those files in Photoshop or another image editor. - Page 69 Common controls and displayed statistics Pixel_Min – minimum pixel value in frame- or image- data Pixel_Max – maximum pixel value Pixel_Black – if a pixel ≤ Pixel_Black then it is displayed as black (RGB 0, 0, 0) ...

- Page 70 Histogram’s presentation Relative Histogram Scale [H]=1000 means that that the distance depicted as “H” on the drawing matches 1% of total number of pixels. Respectively [H]=100 means that “H” matches 0.1% of pixels and [H]=500 means that “H” matches 0.5% of pixels.

- Page 71 Marker type “S” Displays local surround of selected location Marker type “R” Display profile chart of a row.

- Page 72 Marker type “C” Display profile chart of a column.

-

Page 73: Get Recent Frame

(3) Get Recent Frame If the image is not transferred to the PC after exposure because of connection fail (wire or wireless). You can get a recent frame again. -

Page 74: Operation

7. Operation (1) Recommend X-ray detector should be used at stable state within driving temperature range. Acquire the X-ray images after power on and 5 minutes warming up to obtain high quality images. The calibration should be performed every 6 months (2) Switching power on / off ... -

Page 75: Safety Information

8. Safety Information (1) Safety standard Do not This equipment has been tested and found to comply with the touch signal limits for medical devices in IEC 60601-1-2:1994. These limits input, signal output are designed to provide reasonable protection against harmful or other connectors, and the patient interference in a typical medical installation. - Page 76 Type of protection against electric shock: Class I equipment Classification according to the degree of protection against ingress of water as detailed in the current edition of IEC 529: IPX0, ordinary equipment This equipment is not suitable for use in the presence of flammable anesthetic s or oxygen.

-

Page 77: Electromagnetic Compatibility Information

(2) Electromagnetic Compatibility Information Guidance and manufacturer’s declaration - electromagnetic emissions The EUT is intended for use in the electromagnetic environment specified below. The customer or the user of the EUT should assure that it is used in such an environment. Immunity Test Compliance Electromagnetic Environment - Guidance... - Page 78 Guidance and manufacturer’s declaration - electromagnetic immunity The EUT is intended for use in the electromagnetic environment specified below. The customer or the user of the EUT should assure that it is used in such an environment. The EUT is intended for use in the electromagnetic environment specified below. The customer or the user of the EUT should assure that it is used in such an environment.

- Page 79 Guidance and manufacturer’s declaration - electromagnetic immunity The EUT is intended for use in the electromagnetic environment specified below. The customer or the user of the EUT should assure that it is used in such an environment. Immunity test Compliance Electromagnetic environment - guidance 60601-1-2 level...

- Page 80 Recommended separation distances between portable mobile communications equipment and the EUT There is intended for use in an electromagnetic environment in which radiated RF disturbances are controlled. The customer or the user of the EUT can help Prevent electromagnetic interference by maintaining a minimum distance between portable and mobile RF communications equipment (transmitters) and the EUT as recommended below, according to the maximum output power of the communications equipment.

- Page 81 Immunity and Compliance Level Immunity test IEC 60601-1-2 Actual Immunity Level Compliance Level Test Level Conducted RF 3Vrms 3Vrms 3Vrms IEC 61000-4-6 150kHz to 80MHz Radiated RF 3Vrms 3V/m 3V/m IEC 61000-4-3 80MHz to 2.5GHz Guidance and manufacturer’s declaration - electromagnetic immunity The EUT is intended for use in the electromagnetic environment specified below.

-

Page 82: Radio Frequency Compliance

9. Radio Frequency compliance (1) FCC Notice (U.S.A) Test standards - 47CFR Part 15.107 (b) / 47CFR Part 15.109 (g) Class A. FCC Part 15 C Section 15.247, Operation within the bands 902–928 MHz, 2400–2483.5 MHz, and 5725–5850 MHz - FCC Part 15 C Section 15.407, Operation within the bands 902–928 MHz, 2400–2483.5 MHz, and 5725–5850 MHz ... - Page 83 FCC CAUTION Changes or modifications not expressly approved by the party responsible for compliance could void the user’s authority to operate the equipment. This transmitter must not be co-located or operated in conjunction with any other antenna or transmitter. When installing it in a mobile equipment This equipment complies with FCC radiation exposure limits set forth for an uncontrolled environment and meets the FCC radio frequency (RF) Exposure Guidelines in Supplement C to OET65.

-

Page 84: Ic Notice (Canada)

- IC RSS-210 Issue 7, Operation within the bands 902–928 MHz, 2400–2483.5 MHz, and 5725–5850 MHz IC: 10742A-1012WCA This Class A digital apparatus complies with Canadian ICES-003 Host device of the approved module shall be marked with the following... -

Page 85: R&Tte Notice (European Union)

(3) R&TTE Notice (European Union) Test standards - EN 62311 - ETSI EN 301 489-1 - ETSI EN 301 489-17 - ETSI EN 300 328 - ETSI EN 301 893... -

Page 86: Maintenance

Maintenance (1) Maintenance Maintenance of the detector should be done by an authorized service provider safety reasons, be If the Detector Panel is defective, the detector will be sure to turn OFF the returned as is to the manufacturer for repair power of the detector when the ... -

Page 87: Inspection

If problem still cannot be corrected, please contact Rayence representative or distributor. It is recommended that a record of the inspection be kept by making copies of the check lists in this section, or making a separate check list. -

Page 88: Disposal Or Recycling

(4) Disposal or Recycling Follow local governing ordinances and recycling plans regarding the disposal or recycling of device components. Disposal of old Electrical & Electronic Equipment (Application in the European Union and other European countries with separate collection system.) This symbol indicates that this product shall not be treated as household waste. -

Page 89: Marking And Labeling Symbols

(5) Marking and labeling symbols Symbols Meaning Refer to instruction manual/ booklet Alternate current Protective earth (Ground) Off (power : disconnect from the main switch) On (power : connect to the main switch) Warning Caution Read carefully Manufacturer Date of manufacture Serial number... - Page 90 non-ionizing radiation WEEE : Waste Electrical and Electronic Equipment Authorized representative in the European Community CE symbol grants the product compliance to the European Directive for Medical Devices 93/42/EEC as a class Ⅱa device. Authorized by Notified Body SGS (code no.:0120) of British Recognized Component Mark for Canada and the United States CE symbol for wireless...

-

Page 91: Appendix

Appendix Dimension [unit : mm]... - Page 92 Rayence Co., Ltd. 14, Samsung 1-ro 1-gil, Hwaseong-si, Gyeonggi-do, Korea www.rayence.com...

Need help?

Do you have a question about the 1012WCA and is the answer not in the manual?

Questions and answers