ipf electronic OY32 Instruction Manual

Safety light curtain

Hide thumbs

Also See for OY32:

- Original instruction manual (57 pages) ,

- Quick instruction manual (9 pages)

Table of Contents

Advertisement

Quick Links

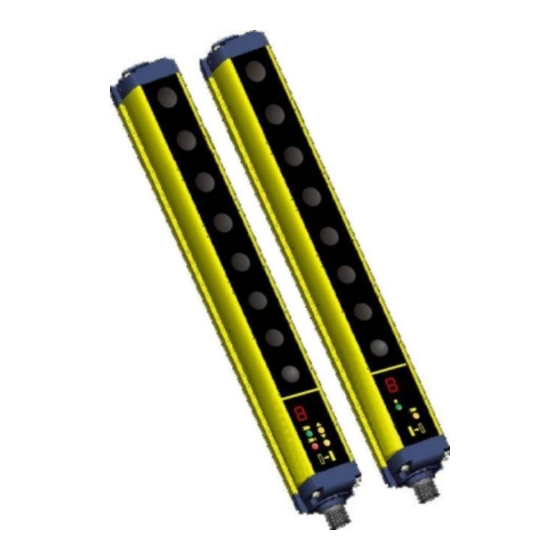

Original Instruction Manual Safety Light Curtain OY32

Devices for finger- and handprotection

Safety Category Type 4

simple installation and configuration

Diagnostics inside

compact profile (32,3x36,9xlength)

Short response time

self testing

Connection with M12-Connector

ipf electronic gmbh

Kalver Str. 25-27

fon +49 (0) 2351/9365-0

D-58515 Lüdenscheid

fax +49 (0) 2351/9365-19

Instruction Manual

Safety Light Curtain OY32

www.ipf.de

Subject to Alteration!

e-mail:

info@ipf.de

August 2012

1

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for ipf electronic OY32

- Page 1 Instruction Manual Safety Light Curtain OY32 Original Instruction Manual Safety Light Curtain OY32 Devices for finger- and handprotection Safety Category Type 4 simple installation and configuration Diagnostics inside compact profile (32,3x36,9xlength) Short response time self testing Connection with M12-Connector ipf electronic gmbh Kalver Str.

-

Page 2: Table Of Contents

Instruction Manual Safety Light Curtain OY32 INDEX GENERAL INFORMATION ..................1 1.1. General Description of the safety light curtains ............3 1.1.1. Package contents ..................... 4 1.2. How to choose the device ..................5 1.2.1. Resolution ........................ 5 1.2.2. Controlled height ...................... 6 1.2.3. -

Page 3: General Information

The light curtains of the OY32 series are Type 4 intrinsic safety systems used as accident- prevention protection devices and are manufactured in accordance with the international... -

Page 4: Package Contents

OY32 light curtains and the safety rules that regulate the correct installation. 1.1.1. Package contents Package contains the following objects: •... -

Page 5: How To Choose The Device

Instruction Manual Safety Light Curtain OY32 1.2. How to choose the device There are at least three different main characteristics that should be considered when choosing a safety light curtain, after having evaluated the risk assessment: 1.2.1. Resolution The resolution of the device is the minimum dimension that an opaque object must have in order to obscure at least one of the beams that constitute the sensitive area. -

Page 6: Controlled Height

The controlled height is the height protected by the safety light curtain (Hp). Fig. 2 The OY32 controlled height is delimited by the yellow line padprinted on the front glass and by the dimensions listed in the table: Controlled height... -

Page 7: Minimum Installation Distance

Instruction Manual Safety Light Curtain OY32 1.2.3. Minimum Installation Distance The safety device must be positioned at a specific safety distance (Fig. 3). This distance must ensure that the dangerous area cannot be reached before the dangerous motion of the machine has been stopped by the ESPE. - Page 8 Instruction Manual Safety Light Curtain OY32 If the safety light curtain must be mounted in a horizontal position (Fig.4), the distance be- tween the dangerous area and the most distant optical beam must be equal to the value cal- culated using the following formula: S = 1600 mm/s (t ) + 1200 –...

-

Page 9: Typical Applications

Safety Light Curtain OY32 1.3. Typical applications The safety light curtains of the OY32-series provide soulutions in all atomation fields where the access to dangerous areas has to be controlled. In particular, the safety curtains can be used in stopping moving parts in: - Automatic machines;... - Page 10 Instruction Manual Safety Light Curtain OY32 Example 3: Paper cutting machines These machines typically cut paper to a specific size for newspa- pers or spezial applications. The operator must be protected against abrasion or cuts by cutter blades. Solution: OY32010x safety light curtain is especially suitable for this kind of application, which requires the installation of the de- vice directly on the machine.

-

Page 11: Serial Number

N = December 1.5. Safety Information The following points must be observed for a correct and safe use of the OY32 safety de- vice: • The stopping system of the machine must be electrically controlled. • This control system must be able to stop the dangerous movement of the machine with- in the total machine stopping time T as per paragraph 1.3.3, and during all working cy-... -

Page 12: Installation Mode

2.1. Precautions to be observed for the choice and installation Make sure that the protection level assured by the OY32 device (Type 4) is compatible with the real danger level of the machine to be controlled, according to EN 954-1 and EN 13849- •... -

Page 13: General Information On Device Positioning

Instruction Manual Safety Light Curtain OY32 2.2. General information on device positioning The safety light curtain should be carefully positioned, in order to reach a very high protec- tion standard. Access to the dangerous area must only be possible by passing through the protecting safety light beams. -

Page 14: Minimum Installation Distance

Instruction Manual Safety Light Curtain OY32 When the installation of the safety light curtain near to the dangerous area is not possible, a second light curtain must be mounted in a horizontal position in order to prevent any lateral access, as shown in Fig.6b. - Page 15 Instruction Manual Safety Light Curtain OY32 2.2.2. Minimum distance from reflecting surfaces Reflecting surfaces placed near the light beams of the safety device (over, under or lateral- ly) can cause passive reflections. These reflections can affect the recognition of an object inside the controlled area.

- Page 16 Instruction Manual Safety Light Curtain OY32 Fig. 8 The formula to get D is the following (m) = 0,15 for operating distances < 3m (m) = 0,5 x operating distance (m) x tan 2 for operating distances α ≥ ipf electronic gmbh Kalver Str.

- Page 17 Instruction Manual Safety Light Curtain OY32 2.2.3. Distance between homologous devices If different safety devices have to be installed in adjacent areas, the emitter of one device must not interfere dangerously with the receiver of the other device. The TX...

- Page 18 Instruction Manual Safety Light Curtain OY32 WARNING: the interfering device (TX ) must be positioned at the same D distance, calcu- lated as shown above, even if closer to TX respect to RX Installation precautions have to be taken to avoid interference between homologous devices.

-

Page 19: Emitter And Receiver Orientation

Instruction Manual Safety Light Curtain OY32 2.2.4. Emitter and receiver orientation The two units shall be assembled parallel each other, with the beams arranged at right an- gles with the emission and receiving surface, and with the connectors orientated towards the same direction. - Page 20 Instruction Manual Safety Light Curtain OY32 The operator must respect the following precautions when using the deviating mirrors: • The alignment of the emitter and the receiver can be a very critical operation when deviating mirrors are used. Even very small displacement of the mirror is enough to lose alignment. The use of laser pointer accessory is recommended under these conditions.

-

Page 21: Controls After First Installation

Instruction Manual Safety Light Curtain OY32 2.2.6. Controls after first installation The control operations to carry-out after the first installation and before machine start-up are listed hereinafter. The controls must be carried-out by qualified personnel, either directly or under the strict supervision of the person in charge of machinery Safety. -

Page 22: Mechanical Mounting

Two types of brackets can be used to fix the two units. Angled fixing brackets Angled fixing brackets are supplied with all OY32 models (Fig.15). Adjustable supports for correcting unit inclination on the axes are available on request (see section 14 “Accessories”). - Page 23 Instruction Manual Safety Light Curtain OY32 In case of applications with particularly strong vibrations, vibration dampers together with mounting brackets are recommended to reduce the impact of the vibrations. Fig. 17 The recommended mounting positions according to the light curtain length are shown in Fig.18 and in the following table.

-

Page 24: Electrical Connections

Instruction Manual Safety Light Curtain OY32 ELECTRICAL CONNECTIONS All electrical connections to the emitting and receiving units are made through a male M12 connector, located on the lower part of the two units. For receiver a M12 8-pole connector is used, while for emitter a M12 4-pole connector is used. -

Page 25: Notes On Connections

4.1. Notes on connections For the correct functioning of the OY32 safety light curtains, the following precautions re- garding the electrical connections have to be respected. • Do not place connection cables in contact with or near high-voltage cables and/or cable undergoing high current variations (e.g. - Page 26 Instruction Manual Safety Light Curtain OY32 • If one of these configurations is erroneously used, the device enters into the output failure condition (see section 7 “Diagnostic functions”). • Connect both OSSDs to the activating device. Failure to connect an OSSD to the activating device jeopardises the system safety degree that the light curtain has to control.

-

Page 27: Ground Connection

Safety Light Curtain OY32 Ground Connection OY32 safety light curtain units are preset for easy ground connection. A special compart- ment, positioned onto caps and marked with the special symbol shown in Figure 24, allows connection with ground cable by means of an additional screw coming with the equipment. -

Page 28: Alignment Procedure

Instruction Manual Safety Light Curtain OY32 5. ALIGNMENT PROCEDURE The alignment between the emitting and the receiving units is necessary to obtain the correct functioning of the light curtain. A good alignment prevents outputs instability caused by dust or vibrations. -

Page 29: Correct Alignment Procedure

Instruction Manual Safety Light Curtain OY32 5.1. Correct Alignment Procedure The light curtain alignment can be effected only after having completed the mechanical in- stallation and the electrical connections as described above. Compare alignment results with those given in the following table. - Page 30 Instruction Manual Safety Light Curtain OY32 Keep the receiver in a steady position and set the emitter until the yellow LED ( SYNC) is OFF. This condition shows the alignment of the first synchronisation beam. Rotate the emitter, pivoting on the lower optics axis, until the yellow LED ( LAST) is off.

-

Page 31: Functioning Mode

Instruction Manual Safety Light Curtain OY32 FUNCTIONING MODE 6.1. Restart Mode The interruption of a beam due to an opaque object causes the opening of OSSD outputs and the stop of the safety light curtain, SAFE (BREAK) condition ESPE standard operation can be reset (OSSD safety contact closing = NORMAL OP. condi-... -

Page 32: Test Function

Instruction Manual Safety Light Curtain OY32 6.2. Test Function The TEST function can be activated by keeping a normally open external contact (TEST push-button), closed for at least 0.5 seconds. The TEST signal is active high. Fig. 28 6.3. Reset Function The RX light curtain has a RESET function which is activated after an internal error. -

Page 33: Edm-Function

Instruction Manual Safety Light Curtain OY32 6.4. EDM Function The light curtain has a function for monitoring actuation external devices (EDM). This function can bie enabled or deactivated. The function controls a normally closed contact switch on OSSD status change. -

Page 34: Alignment And Function

Safety Light Curtain OY32 Alignment aid function OY32 light curtain is fitted with a system which informs the user about reached alignment degree. The alignment function can be selected on device starting by keeping closed RESET/RESTART N.O. contact for at least 0.5 seconds (Fig.32). -

Page 35: Diagnostic Functions

Curtain operating status is visualised through an one-digit display present on both the re- ceiver and emitter units. OY32 also has four LEDs on the receiver and two LEDs on the emitter. Fig. 33 shows all LEDs signalling modes: OFF, ON and BLINKING. -

Page 36: Diagnostic Messages

Instruction Manual Safety Light Curtain OY32 7.2. Diagnostic Messages The operator can evaluate the main causes of the system Stopp or failure though the display and signalling LEDs. For Receiver: Function Status Meaning DIGIT Alignment See section 5 Light curtain being tested. - Page 37 Instruction Manual Safety Light Curtain OY32 Function Type Check and repair DIGIT Check OSSD connections. Make sure that they are not in contact with one OSSD error another or with the supply cables, then (red ON) Reset. If the failure continues contact ipf electronic.

- Page 38 Instruction Manual Safety Light Curtain OY32 For emitter: Function Status Meaning DIGIT Light curtain being tested. TEST OSSD status on the receiver (green ON) must be OFF Normal operation Emission Light curtain in normal operat- ing condition. (green ON, yellow ON)

-

Page 39: Periodical Checks

Instruction Manual Safety Light Curtain OY32 PERIODICAL CHECKS The following is a list of recommended check and maintenance operations that should be pe- riodically carried-out by qualified personnel (section 2.2.6 “Controls after first installation”). Verify, that: • the ESPE stays locked ( ) during beam interruption along the entire protected area, using the suitable “test piece”... -

Page 40: General Information And Usefull Data

24 (twenty four) months from the date of manufacturing. ipf electronic will not be liable for any damages to persons and things caused by failure to stick to the correct installation modes and device use. -

Page 41: Device Maintenance

• paper or other abrasive materials 9.1. Procuct disposal Under current Italian and European laws, ipf electronic is not obliged to take care of product disposal at the end of its life. ipf electronic recommends to dispose of the product in compliance with local laws or contact authorised waste collection centres. -

Page 42: Technical Data

Instruction Manual Safety Light Curtain OY32 TECHNICAL DATA ELEKTRICAL DATA Power Supply (Vdd) : 24V DC ± 20% Consumption (TX): 2,5W max. Consumption (RX): 3,5W max (without load) OSSD Outputs: 2 PNP Short-circuit protection: 1,4A max Output current: 0,5A max. each output Output voltage –... -

Page 43: List Of Available Models

Instruction Manual Safety Light Curtain OY32 11. LIST OF AVAILABLE MODELS Controlled Response Number of Resolution Article-No. height time Beams (mm) (mm) (ms) OY320130 OY320131 OY320132 OY320133 OY320134 OY320135 1050 OY320136 OY320137 1200 OY320138 1350 1500 OY320139 OY32013A 1650 OY32013C... - Page 44 Instruction Manual Safety Light Curtain OY32 PFHd MTTFd Article-No. CAT SIL SIL CL (1/h) (years) (years) OY320130 2,64E-09 98,80% 99,30% 2,64E-09 98,80% 99,30% OY320131 2,64E-09 98,80% 99,30% OY320132 2,64E-09 98,80% 99,30% OY320133 2,64E-09 98,80% 99,30% OY320134 2,64E-09 98,80% 99,30% OY320135...

-

Page 45: Overall Dimensions

Instruction Manual Safety Light Curtain OY32 OVERALL DIMENSIONS Article-No. OY3201x0 233.3 153.3 OY3201x1 383.2 303.2 OY3201x2 533.2 453.3 OY3201x3 683.2 603.2 OY3201x4 833.2 753.3 OY3201x5 983.2 903.2 OY3201x6 1133.2 1053.2 OY3201x7 1283.3 1203.3 OY3201x8 1433.2 1353.2 OY3201x9 1583.3 1503.3 OY3201xA 1733.3... -

Page 46: Outfit

Instruction Manual Safety Light Curtain OY32 OUTFIT Angled fixing bracket ipf electronic gmbh Kalver Str. 25-27 fon +49 (0) 2351/9365-0 www.ipf.de Subject to Alteration! D-58515 Lüdenscheid fax +49 (0) 2351/9365-19 e-mail: info@ipf.de August 2012... -

Page 47: Angled Fixing Bracket Mounting

Instruction Manual Safety Light Curtain OY32 13.1. Angled fixing bracket mounting MOUNTING A MOUNTING B Angled fixing bracket Angled fixing bracket + adjustable support Angled fixing bracket + anitvibration support Angled fixing bracket + adjustable support + anitvibration support Article-No. -

Page 48: Accessoires

Instruction Manual Safety Light Curtain OY32 14. ACCESSOIRES Rotating fixing bracket Article-No. Description Rotating fixing bracket (4 pc kit) AO000243 ipf electronic gmbh Kalver Str. 25-27 fon +49 (0) 2351/9365-0 www.ipf.de Subject to Alteration! D-58515 Lüdenscheid fax +49 (0) 2351/9365-19 e-mail: info@ipf.de... - Page 49 (floor stand). The latter is composed of two plates mounted together using 3 load springs. The special profile, available in different lengths, ensures that the protective stand can contain the models of the OY32 and the OY35 series and even the deviating mirrors shown on the next page. Article-No.

- Page 50 Instruction Manual Safety Light Curtain OY32 Deviating Mirrors (drawing including stand alone bracket mounting kit) Article-No. Description AO000236 Deviating Mirror 150mm Article-No. Description L1 (mm) L2 (mm) L3 (mm) AO000237 Deviating Mirror H = 600mm AO000238 Deviating Mirror H = 900mm...

- Page 51 Instruction Manual Safety Light Curtain OY32 Laser pointer The laser pointer AO000219 is a helping accessory for installation and alignment of safety light curtains. For testing the complete adjustment of a safety light curtain the pointer is movable along the light barrier profile (upward and downward ipf electronic gmbh Kalver Str.

- Page 52 Instruction Manual Safety Light Curtain OY32 Lens Shield This accessory for safety light curtains, composed of a PMMA Altuglas plate that can be mounted on the front glass, ensures an effective protection against dust, chips and incandescent drops, de- riving from material working near the safety light curtain. The accessory can be easily installed thanks to the fixing brackets supplied in the package that exploit the side groove of the safety light curtain.

- Page 53 This special housing is a PMMA acrylic tube used to protect and seal the safety light curtains of the OY32- and OY35-series. Thanks to this accessory the IP protection of the safety light curtain is increased from IP65 to IP67, IP68 and IP69K.

-

Page 54: Glossary

Instruction Manual Safety Light Curtain OY32 15. GLOSSARY ACTIVE OPTOELECTRONIC PROTECTIVE DEVICE (AOPD) Its detection function is achieved thanks to the use of optoelectronic receivers and emitters detect- ing the optical beams interruptions inside the device caused by an opaque object present inside the specified detecting area. - Page 55 Instruction Manual Safety Light Curtain OY32 FINAL SWITCHING DEVICE (FSD) Part of the control system involving machine safety conditions. It breaks the circuit to the machine primary control element (MPCE) when the output signal switching device (OSSD) becomes inac- tive.

- Page 56 Instruction Manual Safety Light Curtain OY32 RECEIVER Unit receiving infrared beams, consisting of a set of optically-synchronised phototransistors. The receiving unit, combined with the emitting unit (installed in the opposite position), generates an op- tical “curtain”, i.e. the detecting area.

Need help?

Do you have a question about the OY32 and is the answer not in the manual?

Questions and answers