Table of Contents

Advertisement

SERVICE MANUAL

Sec. 1: Main Section

I Specifications

I Preparation for Servicing

I Adjustment Procedures

I Schematic Diagrams

I CBA's

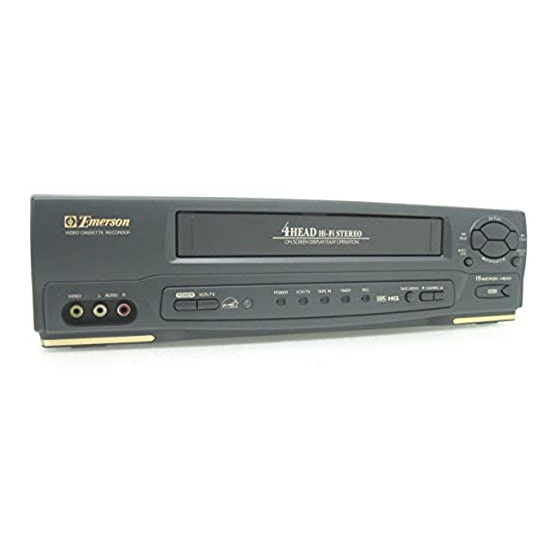

VIDEO CASSETTE RECORDER

EWV601A

VIDEO

L AUDIO R

POWER

VCR/TV

Sec. 2: Deck Mechanism Section

I Standard Maintenance

I Alignment for Mechanism

I Disassembly/Assembly of Mechanism

I Alignment Procedures of Mechanism

REW

REC

OTR

TAPE SPEED

CHANNEL

POWER

VCR/TV

TAPE IN

TIMER

REC

SSV6001A

VIDEO

L

AUDIO

R

PLAY

F.FWD

PAUSE

STILL

VIDEO

L AUDIO R

MENU

POWER

VCR/TV

TAPE IN

TIMER

REC

Sec. 3: Exploded views

and Parts List Section

I Exploded views

I Parts List

KVS600A

POWER

VCR/TV

TAPE IN

TIMER

REC

POWER

VCR/TV

TAPE SPEED

STOP/EJECT

PLAY

REW

F.FWD

REC/OTR

PAUSE/STILL

MENU

PLAY

REW

F.FWD

REC/

PAUSE/

OTR

STILL

STOP/EJECT

CHANNEL

MENU

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Emerson SYLVANIA EWV601A

- Page 1 SERVICE MANUAL Sec. 2: Deck Mechanism Section Sec. 3: Exploded views Sec. 1: Main Section I Standard Maintenance and Parts List Section I Specifications I Preparation for Servicing I Alignment for Mechanism I Exploded views I Disassembly/Assembly of Mechanism I Parts List I Adjustment Procedures I Alignment Procedures of Mechanism I Schematic Diagrams...

- Page 2 IMPORTANT SAFETY NOTICE Proper service and repair is important to the safe, reliable operation of all Funai Equipment. The service procedures recommended by Funai and described in this service manual are effective methods of performing service operations. Some of these service special tools should be used when and as recommended.

-

Page 3: Table Of Contents

MAIN SECTION VIDEO CASSETTE RECORDER EWV601A/KVS600A/SSV6001A Sec. 1: Main Section I Specifications I Preparation for Servicing I Adjustment Procedures I Schematic Diagrams I CBA’s TABLE OF CONTENTS Specifications................1-1-1 Important Safety Precautions. -

Page 4: Specifications

SPECIFICATIONS Description Unit Minimum Nominal Maximum Remark 1. Video 1-1. Video Output (PB) Vp-p SP Mode 1-2. Video Output (R/P) Vp-p SP Mode, 1-3. Video S/N Y (R/P) W/O Burst 1-4. Video Color S/N AM (R/P) SP Mode 1-5. Video Color S/N PM (R/P) SP Mode 1-6. -

Page 5: Important Safety Precautions

IMPORTANT SAFETY PRECAUTIONS Product Safety Notice I. Also check areas surrounding repaired locations. J. Be careful that foreign objects (screws, solder Some electrical and mechanical parts have special droplets, etc.) do not remain inside the set. safety-related characteristics which are often not evi- K. - Page 6 Safety Check after Servicing Examine the area surrounding the repaired location for Chassis or Secondary Conductor damage or deterioration. Observe that screws, parts, and wires have been returned to their original posi- tions. Afterwards, do the following tests and confirm Primary Circuit Terminals the specified values to verify compliance with safety standards.

-

Page 7: Standard Notes For Servicing

STANDARD NOTES FOR SERVICING Circuit Board Indications How to Remove / Install Flat Pack-IC a. The output pin of the 3 pin Regulator ICs is indi- 1. Removal cated as shown. With Hot-Air Flat Pack-IC Desoldering Machine:. (1) Prepare the hot-air flat pack-IC desoldering Top View Bottom View machine, then apply hot air to the Flat Pack-IC... - Page 8 With Soldering Iron: (4) Bottom of the flat pack-IC is fixed with glue to the CBA; when removing entire flat pack-IC, first apply (1) Using desoldering braid, remove the solder from all soldering iron to center of the flat pack-IC and heat pins of the flat pack-IC.

- Page 9 Instructions for Handling 2. Installation Semi-conductors (1) Using desoldering braid, remove the solder from the foil of each pin of the flat pack-IC on the CBA Electrostatic breakdown of the semi-conductors may so you can install a replacement flat pack-IC more occur due to a potential difference caused by electro- easily.

-

Page 10: Preparation For Servicing

PREPARATION FOR SERVICING How to Enter the Service Mode About REC-Safety Switch Caution: The REC-Safety Switch is directly mounted on the About Optical Sensors Main CBA. When the Deck Mechanism Assembly is Caution: removed from the Main CBA for servicing, this switch does not work automatically. -

Page 11: Operating Controls And Functions

OPERATING CONTROLS AND FUNCTIONS EWV601A KVS600A DESCRIPTION OF CONTROLS DESCRIPTION OF CONTROLS Front Panel Front Panel 2 3 4 5 6 PLAY PLAY F.FWD F.FWD PAUSE STILL REC/ PAUSE/ POWER VCR/TV TAPE IN TIMER STILL POWER VCR/TV STOP/EJECT TAPE SPEED CHANNEL VIDEO L AUDIO R... - Page 12 SSV6001A DESCRIPTION OF CONTROLS Front Panel 3 4 5 6 PLAY STOP/EJECT F.FWD REC/OTR PAUSE/STILL VIDEO AUDIO TAPE IN TIMER POWER VCR/TV MENU 16 15 1413 1. Cassette Compartment 9. CHANNEL buttons 2. REW button 10. TAPE SPEED button 3. STOP/EJECT button 11.

-

Page 13: Cabinet Disassembly Instructions

CABINET DISASSEMBLY INSTRUCTIONS 1. Disassembly Flowchart (1): Identification (location) No. of parts in the figures (2): Name of the part This flowchart indicates the disassembly steps to gain (3): Figure Number for reference access to item(s) to be serviced. When reassembling, (4): Identification of parts to be removed, unhooked, follow the steps in reverse order. - Page 14 Cylinder FE Head (L-2) Assembly (L-2) AC Head Assembly [5] Deck Assembly [2] Front Assembly (S-3) (L-1) Fig. D2 (S-3) (S-2) (S-2) Desolder [6] Main C.B.A. [3]VCR Desolder Chassis Unit (S-3) [4] Function C.B.A. From From From Capstan Motor From Cylinder AC Head Assembly...

- Page 15 SW507 LD-SW [6]Main C.B.A. [5]Deck Assembly Cam Gear Hole Shaft Hole LD-SW [6]Main C.B.A. Fig. D5 1-6-3 HB300DC...

-

Page 16: Electrical Adjustment Instructions

ELECTRICAL ADJUSTMENT INSTRUCTIONS General Note: "CBA" is an abbreviation for "Circuit Board Assembly." NOTE: Figure 1 1.Electrical adjustments are required after replacing circuit components and certain mechanical parts. It is important to do these adjustments only after EXT. Syncronize Trigger Point all repairs and replacements have been com- V-Sync pleted. -

Page 17: Block Diagrams

BLOCK DIAGRAMS Servo/System Control Block Diagram FUNCTION CBA MAIN CBA IC501 TP502 (SERVO/SYSTEM CONTROL) CL507 CN651 S-INH AL+5V IC301 (Y/C PROCESS) KEY 2 KEY SWITCH CONTROL KEY- 1 SWITCH (DECK ASSEMBLY) TP303 RS501 KEY- 2 D555 23 19 REMOTE S-LED D595 P-ON REMOCON-IN SENSOR... - Page 18 Video Block Diagram NOTE: The Tuner Unit (TU701) is either type A or type B. Wave Form will be different. It depends on the type of tuner used on the unit you are servicing. REC VIDEO SIGNAL PB VIDEO SIGNAL MODE: SP/REC TP751 MAIN CBA...

- Page 19 Audio Block Diagram NOTE: The Tuner Unit (TU701) is either type A or type B. Wave Form will be different. It depends on the type of tuner used on the unit you are servicing. PB-AUDIO SIGNAL REC-AUDIO SIGNAL Mode : SP/REC TYPE B TU701 MAIN CBA...

- Page 20 Hi-Fi Audio Block Diagram PB-AUDIO SIGNAL REC-AUDIO SIGNAL Mode : SP/REC MAIN CBA IC451 (MTS/ SAP/ Hi-Fi AUDIO PROCESS/ Hi-Fi HEAD AMP) NOISE Hi-Fi-CS SERIAL FROM/TO Hi-Fi-DATA DATA SERVO/ SYSTEM Hi-Fi-CLK DECODER CONTROL BLOCK ST/SAP DEMOD FILTER DEMOD MATRIX DEMOD STEREO PILOT FILTER...

- Page 21 Power Supply Block Diagram NOTE : CAUTION CAUTION ! The voltage for parts in hot circuit is measured using FOR CONTINUED PROTECTION AGAINST FIRE HAZARD, Fixed voltage power supply circuit is used in this unit. hot GND as a common terminal. REPLACE ONLY WITH THE SAME TYPE FUSE.

-

Page 22: Function Indicator Symbols

FUNCTION INDICATOR SYMBOLS Note: The following symbols will appear on the indicator panel to indicate the current mode or operation of the VCR. On-screen modes will also be momentarily displayed on the tv screen when you press the operation buttons. Display panel Model: EWV601A Model: SSV6001A... -

Page 23: Power Supply Trouble Shooting Guide

Power Supply Trouble Shooting Guide It is highly recommended that a variable isolation If the tester does not indicate any low resistance value transformer which can monitor current be used. (around 0 ohm), no load is short-circuited and there is (Alternatively a variable AC source which moni- no problem. -

Page 24: Schematic Diagrams / Cba's And Test Points

SCHEMATIC DIAGRAMS / CBA’S AND TEST POINTS Standard Notes Notes: WARNING 1. Do not use the part number shown on these draw- ings for ordering. The correct part number is Many electrical and mechanical parts in this chassis shown in the parts list, and may be slightly different have special characteristics. - Page 25 LIST OF CAUTION, NOTES, AND SYMBOLS USED IN THE SCHEMATIC DIAGRAMS ON THE FOLLOWING PAGES: 1. CAUTION: FOR CONTINUED PROTECTION AGAINST FIRE HAZARD, REPLACE ONLY WITH THE SAME TYPE FUSE. ATTENTION: POUR UNE PROTECTION CONTINUE LES RISQES D'INCELE N'UTILISER QUE DES FUSIBLE DE MEMO TYPE.

- Page 26 Main 1/4 Schematic Diagram Main 1/4 Schematic Diagram REC Video Signal PB Video Signal Note: When it is necessary to replace one or more of the following Diodes, Ref. NO Position all five should be replaced: D595, D596, D597, D598, D599. REC Audio Signal PB Audio Signal IC501...

- Page 27 Main 2/4 Schematic Diagram Note: The Tuner Unit ( TU701 ) is either type A or type B. These two types are exchangeable and can be equally used REC Video Signal PB Video Signal whichever the model is. The difference between type A and type B is shown in the table below.

- Page 28 Main 3/4 Schematic Diagram Main 3/4 Schematic Diagram Ref.NO Position CAUTION ! CAUTION Fixed voltage power supply circuit is used in this unit. FOR CONTINUED PROTECTION AGAINST FIRE HAZARD, If Main Fuse (F001) is blown, check to see that all components in the power supply IC001 REPLACE ONLY WITH THE SAME TYPE FUSE.

- Page 29 Main 4/4 Schematic Diagram REC Video Signal PB Video Signal REC Audio Signal PB Audio Signal 1-9-11 1-9-12 HB4J0SCM4...

- Page 30 Function Schematic Diagram ( EWV601A ) Function Schematic Diagram ( SSV6001A ) HB4J0SCF HB4L0SCF Function Schematic Diagram ( KVS600A ) HB431SCF 1-9-13 1-9-14...

- Page 31 Function CBA Top View Function CBA Bottom View Function CBA Top View Function CBA Bottom View NOTE : Either BHB400F01013, BHB400F01014 is used for the Function CBA in this S/M. BHB400F01013-B BHB400F01014-B 1-9-15 1-9-16...

- Page 32 Main CBA Top View CAUTION FOR CONTINUED PROTECTION AGAINST FIRE HAZARD, REPLACE ONLY WITH THE SAME TYPE FUSE. CAUTION ! ATTENTION : POUR UNE PROTECTION CONTINUE LES RISQES BECAUSE A HOT CHASSIS GROUND IS PRESENT IN THE POWER Fixed voltage power supply circuit is used in this unit. D'INCELE N'UTILISER QUE DES FUSIBLE DE MEMO TYPE.

- Page 33 Main CBA Bottom View CAUTION FOR CONTINUED PROTECTION AGAINST FIRE HAZARD, REPLACE ONLY WITH THE SAME TYPE FUSE. CAUTION ! ATTENTION : POUR UNE PROTECTION CONTINUE LES RISQES BECAUSE A HOT CHASSIS GROUND IS PRESENT IN THE POWER Fixed voltage power supply circuit is used in this unit. D'INCELE N'UTILISER QUE DES FUSIBLE DE MEMO TYPE.

- Page 34 Main CBA Top View CAUTION FOR CONTINUED PROTECTION AGAINST FIRE HAZARD, REPLACE ONLY WITH THE SAME TYPE FUSE. CAUTION ! ATTENTION : POUR UNE PROTECTION CONTINUE LES RISQES BECAUSE A HOT CHASSIS GROUND IS PRESENT IN THE POWER Fixed voltage power supply circuit is used in this unit. D'INCELE N'UTILISER QUE DES FUSIBLE DE MEMO TYPE.

- Page 35 Main CBA Bottom View CAUTION FOR CONTINUED PROTECTION AGAINST FIRE HAZARD, REPLACE ONLY WITH THE SAME TYPE FUSE. CAUTION ! ATTENTION : POUR UNE PROTECTION CONTINUE LES RISQES BECAUSE A HOT CHASSIS GROUND IS PRESENT IN THE POWER Fixed voltage power supply circuit is used in this unit. D'INCELE N'UTILISER QUE DES FUSIBLE DE MEMO TYPE.

-

Page 36: Waveforms

WAVEFORMS NOTE: The Tuner Unit (TU701) is either type A or type B. Wave Form will be different. It depends on the type of tuner used on the unit you are servicing. WF 1 V-OUT E-E 10usec 50mV x 10 MOD-V 20mV x 10 2msec... -

Page 37: Wiring Diagrams

WIRING DIAGRAM AC CORD FRONT REAR (DECK ASSEMBLY) VIDEO AUDIO AUDIO VIDEO AUDIO AUDIO VIDEO AUDIO AUDIO IN (R) IN (L) IN (R) IN (L) OUT (R) OUT (L) ANT-IN ANT-OUT AC HEAD ASSEMBLY CL504 AUDIO AE-H ERASE HEAD AE-H/FE-H A-COM AUDIO HEAD A-PB/REC... -

Page 38: System Control Timing Charts

SYSTEM CONTROL TIMING CHARTS Mode SW : LD-SW LD-SW Position detection A/D Input voltage Limit Symbol (Calculated voltage) 3.76V~4.50V (4.12V) 4.51V~5.00V (5.00V) 0.00V~0.25V (0.00V) 1.06V~1.50V (1.21V) 0.66V~1.05V (0.91V) 1.99V~2.60V (2.17V) 1.51V~1.98V (1.80V) 3.20V~3.75V (3.40V) 0.26V~0.65V (0.44V) 4.51V~5.00V (5.00V) 2.61V~3.19V (2.97V) Note: Note : RS: Loading FWD (LM-FWD “H”, LM-REV “L”) - Page 39 13 RF-SW The first rise of RF-SW after a rise in F-AD signal F-AD (Internal Signal) "H" "H" "Z" 5 C-DRIVE "L" "L" Stop detection (T2) Acceleration Detection (T1) Slow Tracking Value 37 PB CTL Reversal Limit Value 10 C-F/R 11 H-A-SW 12 ROTA STILL...

- Page 40 13 RF-SW The first rise of RF-SW after a rise in F-AD signal F-AD (Internal Signal) "H" "H" "Z" 5 C-DRIVE "L" "L" Stop detection (T2) Acceleration Detection (T1) Slow Tracking Value 37 PB CTL Reversal Limit Value 10 C-F/R 11 H-A-SW 12 ROTA STILL...

- Page 41 EJECT ST-S,/ END-S "OFF" CASS.LOAD LD-FWD 0.2S LD-REV 0.7S LD-FWD 0.2S LD-REV 0.2S LD-FWD 0.5S LD-REV STOP(A) PLAY LD-FWD PLAY LD-FWD 0.4S LD-FWD LD-REV 0.2S LD-FWD PLAY PLAY PAUSE (SLOW) LD-FWD STILL(SLOW) PLAY LD-REV 0.2S LD-FWD PLAY STOP /EJECT LD-REV STOP(A) Fig.

- Page 42 STOP(A) STOP LD-REV 0.2S LD-FWD STOP /EJECT LD-REV 1.0S LD-FWD 0.5S LD-REV STOP(A) LD-REV 0.2S LD-FWD STOP /EJECT LD-REV 1.0S LD-FWD 0.5S LD-REV STOP(A) LD-FWD PAUSE LD-FWD 0.2S 2.0S Short REV LD-REV 0.2S LD-FWD REC PAUSE REC or PAUSE STOP /EJECT LD-FWD 0.2S...

-

Page 43: Ic Pin Function Descriptions

IC PIN FUNCTION DESCRIPTIONS IC501( SERVO / SYSTEM CONTROL IC ) Signal Active Function Name Level “H” ≥ 4.5V, “L” ≤ 1.0V C-VIDEO- Composite Video Pins that have * in the Pin No. section on table below Signal Input (Slicer) are not used. - Page 44 Signal Active Signal Active Function Function Name Level Name Level Playback Control N.U. Not Used PB-CTL PULSE Signal N.U. Not Used Capstan Motor N.U. Not Used 55 OUT C-CONT Control Signal CAS- IN “CASSETTE” LED 88 OUT Drum Motor Control Signal Output 56 OUT D-CONT Signal...

-

Page 45: Lead Identifications

LEAD IDENTIFICATIONS BN1F4M-T 2SC1815-BL(TPE2) BA1F4M-T 2SC1815-Y(TPE2) KTA1266(GR) 2SC1815-GR(TPE2) KTC3193(Y) 2SC3331(T,U) KTC3199(Y,GR,BL) 2SC2120-Y(TPE2) 2SC2785(J.H.F.K) KTC3203(Y) 2SA1015-GR(TPE2) KTA1267(Y,GR) KTC3198(Y,GR) KRC103M KRA103M 2SA1175(J,H,F) E C B E C B LTV-817(B.C)-F QSZAA0RMB108 2SC536NF(NG)-NPA-AT EL817(A.B.C) LA71091M MID-32A22 2SK3374 72000M PT204-6B-12 2SK3472 2SK2599 Note: A: Anode K: Cathode E: Emitter C: Collector... - Page 46 DECK MECHANISM SECTION VIDEO CASSETTE RECORDER EWV601A/KVS600A/SSV6001A Sec. 2: Deck Mechanism Section I Standard Maintenance I Alignment for Mechanism I Disassembly/Assembly of Mechanism I Alignment Procedures of Mechanism TABLE OF CONTENTS Standard Maintenance..............2-1-1 Service Fixtures and Tools .

- Page 47 STANDARD MAINTENANCE Service Schedule of Components H: Hours : Check I: Change Deck Periodic Service Schedule Ref.No. Part Name 1,000 H 2,000 H 3,000 H 4,000 H Cylinder Assembly Loading Motor Assembly Pulley Assembly Tension Lever Sub Assembly AC Head Assembly B573,B574 Reel S, Reel T Capstan Motor...

- Page 48 Cleaning Cleaning of Audio Control Head Clean the head with a cotton swab. Cleaning of Video Head Procedure Clean the head with a head cleaning stick or chamois 1.Remove the top cabinet. cloth. 2.Dip the cotton swab in 90% isopropyl alcohol and Procedure clean the audio control head.

- Page 49 SERVICE FIXTURE AND TOOLS J-1-1, J-1-2 Ref. No. Name Part No. Adjustment J-1-1 Alignment Tape FL8A Head Adjustment of Audio Control Head J-1-2 Alignment Tape FL8N Azimuth and X Value Adjustment of Audio Control (2Head only) Head / Adjustment of Envelope Waveform FL8NW (4Head only) Guide Roller Adj.Screwdriver...

- Page 50 MECHANICAL ALIGNMENT PROCEDURES Explanation of alignment for the tape to correctly run B. Method to place the Cassette Holder in the tape- starts on the next page. Refer to the information below loaded position without a cassette tape on this page if a tape gets stuck, for example, in the 1.

- Page 51 1.Tape Interchangeability Algnment Note: To do these alignment procedures, make sure that the Tracking Control Circuit is set to the center position every time a tape is loaded or unloaded. (Refer to page 2-3-4, procedure 1-C, step 2.) Equipment required: Dual Trace Oscilloscope VHS Alignment Tape (FL8NW) Guide Roller Adj.

- Page 52 1-A. Preliminary/Final Checking and 3. Check to see that the tape runs without creasing at Alignment of Tape Path Take-up Guide Post [4] or without snaking between Guide Roller [3] and AC Head. (Fig. M3 and M5) Purpose: 4. If creasing or snaking is apparent, adjust the Tilt To make sure that the tape path is well stabilized.

- Page 53 6. Press CH DOWN button on the unit until the CTL 1-D. Azimuth Alignment of Audio/Control/ waveform has shifted from its original position (not Erase Head the position achieved in step 5, but the position of Purpose: CTL waveform in step 4) by approximately -2msec. To correct the Azimuth alignment so that the Audio/ Make sure that the envelope is simply attenuated Control/Erase Head meets tape tracks properly.

- Page 54 DISASSEMBLY/ASSEMBLY PROCEDURES OF DECK MECHANISM Before following the procedures described below, be sure to remove the deck assembly from the cabinet. (Refer to CABINET DISASSEMBLY INSTRUCTIONS on page 1-6-1.) All the following procedures, including those for adjustment and replacement of parts, should be done in Eject mode;...

- Page 55 REMOVAL INSTALLATION STEP START- REMOVE/*UNHOOK/ /LOC. PART ADJUSTMENT Fig. No. UNLOCK/RELEASE/ CONDITION UNPLUG/DESOLDER [33] [2],[25] M Brake T Assembly DM1,DM16 *(P-6) [34] [2],[25] M Brake S Assembly DM1,DM16 *(P-7) Tension Lever Sub [35] [34] DM1,DM16 Assembly [36] [35] T Lever Holder DM1,DM16 *(L-6) [37] [33]...

- Page 56 Top View [41] [42] [46] [43] [14] [13] [11] [15] [35] [36] [10] [12] [34] [33] [40] [29] [38] [37] [39] Fig. DM1 Bottom View [19] [32] [31] [24] [26] [27] [25] [23] [28] [22] [20] [21] [30] Fig. DM2 2-4-3 U25NDA...

- Page 57 (S-1) (S-1) (S-2) (P-1) (S-3) (S-4) Fig. DM5 Fig. DM3 [46] Pin D Pin C Pull up Slide (L-8) Pin A Pin B Slot A (S-5) Slots B Slot A First, while pushing the locking tab as shown in the right, slide and pull up the right side on [2] to release Pin A and Pin B from the slots A.

- Page 58 (S-7) (S-8) [14] (S-9) [15] Desolder from bottom (S-6) Lead with White Stripe Belt View for A Fig. DM7 Fig. DM9 Adj. Screw [17] After removing the Screw (S-10), [11] while pressing the Locking Tab (L-1) (L-3) (L-2) (L-3), remove [16]. (P-3) [16] [13]...

- Page 59 Cap Belt Portions A on [21] must be set in the slot on [20] as shown. (C-1) [19] [20] Portions A Portions A View for A [21] Fig. DM12 (S-11) Fig. DM11 2-4-6 U25NDA...

- Page 60 [25] (C-2) (C-5) (C-3) [22] [23] (S-12) (P-4) [27] (L-4) (C-4) [26] [28] [24] (P-4) [28] When installing [23], install the spring (P-4) to [28] as Position of Mode Lever when installed shown in the left figure, and then install [23] while Pin on Pin of [34] Pin of [30]...

- Page 61 Refer to the Alignment Section, Page 2-4-9. [42] [41] [43] (P-5) [30] (L-7) [32] [29] [31] (L-5) Fig. DM17 Fig. DM15 [35] (C-7) [38] (C-6) (P-7) [40] [37] turn (L-6) [39] [44] [45] Slide (P-6) [34] turn [33] [36] Fig. DM18 turn Fig.

- Page 62 ALIGNMENT PROCEDURES OF MECHANISM The following procedures describe how to align the Alignment 1 individual gears and levers that make up the tape Loading Arm, S and T Assembly loading/unloading mechanism. Since information about the state of the mechanism is provided to the Install Loading Arm S and T Assembly so that their System Control Circuit only through the Mode Switch, triangle marks point to each other as shown in Fig.

- Page 63 Alignment 3 Cam Gear (A), Rack Assembly Install the Rack Assembly so that the first tooth on the gear of the Rack Assembly meets the first groove on the Cam Gear (A) as shown in Fig. AL4. Top View Cam Gear (A) Alignment 3 First tooth First groove...

- Page 64 EXPLODED VIEWS AND PARTS LIST SECTION VIDEO CASSETTE RECORDER EWV601A/KVS600A/SSV6001A Sec. 3: Exploded views and Parts List Section I Exploded views I Parts List TABLE OF CONTENTS Exploded Views ............... . 3-1-1 Mechanical Parts List.

-

Page 65: Exploded Views

EXPLODED VIEWS Front Panel EWV601A KVS600A SSV6001A 3-1-1 HB4J0FEX... - Page 66 Cabinet 2L011 See Electrical Parts List for parts with this mark. 2L011 Some Ref. Numbers are not in sequence. 2L011 2L021 2L021 2L021 2L021 2L021 SENSOR CBA 2B34 2L031 SENSOR CBA MAIN CBA RS501 2L031 2L031 FUNCTION CBA AC001 3-1-2 HB400CEX...

- Page 67 Packing Some Ref. Numbers are not in sequence. Unit 2B36 [ KVS600A ] 3-1-3 HB4J0PEX...

- Page 68 DECK EXPLODED VIEWS Deck Mechanism View 1 Mark Description Part No. (Blue grease) Floil G-374G 0VZZ00109 SLIDUS OIL #150 0VZZ00226 L1467 B494 B553 L1191 B411 B567 L1053 B410 L1051 Chassis Assembly Top View (Lubricating Point) B501 B560 L1450 B426 L1466 B121 B126 L1468...

- Page 69 Deck Mechanism View 2 Mark Description Part No. Floil G-374G (Blue grease) 0VZZ00109 B574 B508 B148 B573 B487 L1406 B522 B518 B520 B521 B414 B564 B499 B558 B585 B557 B416 B572 B565 B525 L1151 B417 B568 B569 B133 B551 B505 B488 B491 Bottom Side...

- Page 70 Deck Mechanism View 3 Mark Description Part No. Floil G-374G (Blue grease) 0VZZ00109 L1321 B347 L1321 B355 B354 B483 B529 B425 L1461 B360 L1341 B359 B482 B562 L1341 B300 B563 B555 B303 Some Ref. Numbers are not in sequence. B514 3-1-6 U25NDEX...

-

Page 71: Mechanical Parts List

LABEL, BAR CODE HB4J0UD 0VM412836 LABEL, BAR CODE HB431UD 0VM412845 LABEL, BAR CODE HB4L0UD 0VM412926 LABEL, TELEPHONE NUMBER 0VM411684 H7931UD(EMERSON) LABEL, TELEPHONE NUMBER 0VM410320 H5730UD(SYLVANIA) AC001# AC CORD A0A0280-007 or (See Electrical Parts List) AC CORD PB8K9F9110A-057 (See Electrical Parts List) -

Page 72: Electrical Parts List

ELECTRICAL PARTS LIST PRODUCT SAFETY NOTE: Products marked with a Ref. No. Mark Description Part No. # have special characteristics important to safety. C024 CERAMIC CAP. SL J 390pF/50V CCD1JJSSL391 Before replacing any of these components, read care- C026 ELECTROLYTIC CAP. 2.2µF/250V M or CA2E2R2S6009 fully the product safety notice in this service manual. - Page 73 Ref. No. Mark Description Part No. Ref. No. Mark Description Part No. C312 ELECTROLYTIC CAP. 1µF/50V M H7 CE1JMAVSL1R0 CHIP CERAMIC CAP. B K 0.047µF/50V or CHD1JK30B473 C314 CHIP CERAMIC CAP.(MELF) SL J 100pF/ CZM1JJBSL101 CHIP CERAMIC CAP. B K 0.047µF/25V CHD1EK30B473 50V or C351...

- Page 74 Ref. No. Mark Description Part No. Ref. No. Mark Description Part No. CHIP CERAMIC CAP. B K 0.022µF/50V or CHD1JK30B223 CHIP CERAMIC CAP.(MELF) F Z 0.01µF/ CZM1CZ30F103 CHIP CERAMIC CAP. B K 0.022µF/25V CHD1EK30B223 C495 CHIP CERAMIC CAP.(MELF) F Z 0.01µF/ CZM1CZB0F103 C451 ELECTROLYTIC CAP.

- Page 75 Ref. No. Mark Description Part No. Ref. No. Mark Description Part No. CHIP CERAMIC CAP. CG J 27pF/50V or CHD1JJBCG270 D016 SCHOTTKY BARRIER DIODE SB140 or NDQZ000SB140 CHIP CERAMIC CAP. CH J 27pF/50V or CHD1JJ3CH270 SCHOTTKY BARRIER DIODE ERB81-004 AERB81004*** CHIP CERAMIC CAP.

- Page 76 Ref. No. Mark Description Part No. Ref. No. Mark Description Part No. CARBON RES. 1/4W J 2.7M Ω L501 PCB JUMPER D0.6-P5.0 JW5.0T RCX4JATZ0275 CARBON RES. 1/6W J 2.7M Ω or L502 INDUCTOR 100µH-K-26T LLAXKATTU101 R005 RCX6JATZ0275 CARBON RES. 1/4W J 2.7M Ω L503 CHOKE COIL 47µH-K LLBD00PKV007...

- Page 77 Ref. No. Mark Description Part No. Ref. No. Mark Description Part No. CHIP RES.(1608) 1/10W J 47k Ω CHIP RES.(1608) 1/10W J 2.2M Ω or RRXAJR5Z0473 R407 RRXAJB5Z0225 CHIP RES.(1608) 1/10W J 47k Ω or CHIP RES.(1608) 1/10W J 2.2M Ω R305 RRXAJB5Z0473 RRXAJR5Z0225...

- Page 78 Ref. No. Mark Description Part No. Ref. No. Mark Description Part No. CHIP RES.(1608) 1/10W J 8.2k Ω CARBON RES. 1/4W J 270 Ω RRXAJR5Z0822 R535 RCX4JATZ0271 CHIP RES.(1608) 1/10W J 47k Ω or CHIP RES.(1608) 1/10W J 4.7k Ω or R461 RRXAJB5Z0473 R537...

- Page 79 Ref. No. Mark Description Part No. Ref. No. Mark Description Part No. CHIP RES.(1608) 1/10W J 1k Ω RRXAJR5Z0102 X'TAL 32.768kHz(20PPM) FXC323LDS002 CHIP RES.(1608) 1/10W J 1M Ω or R854 RRXAJB5Z0105 TUNER EXCLUSIVE(A) CN2510/B400/ 0VDM11101 SANYO CHIP RES.(1608) 1/10W J 1M Ω RRXAJR5Z0105 TU701 TUNER UNIT VD045AQ...

- Page 80 Ref. No. Mark Description Part No. TACT SWITCH SKQSAF001A SST0101AL041 SW665 TACT SWITCH KSM0614B or SST0101HH013 TACT SWITCH SKQSAF001A SST0101AL041 SW676 TACT SWITCH KSM0614B or SST0101HH013 TACT SWITCH SKQSAF001A SST0101AL041 SW677 TACT SWITCH KSM0614B or SST0101HH013 TACT SWITCH SKQSAF001A SST0101AL041 SW683 TACT SWITCH KSM0614B or SST0101HH013...

-

Page 81: Deck Parts List

DECK PARTS LIST Ref. No. Description Part No. B520 T BRAKE SPRING MK10 0VM411123 Ref. No. Description Part No. B521 SOFT SPRING MK10 0VM411122 CYLINDER ASSEMBLY MK11 NTSC 4HD HIFI N1468CYL B522 TG POST ASSEMBLY MK11 0VSA12080 CYLINDER ASSEMBLY(V) MK11 NTSC 4HD N1469CYL HIFI B525... - Page 82 Printed in Japan 2002-02-10 HO...

Need help?

Do you have a question about the SYLVANIA EWV601A and is the answer not in the manual?

Questions and answers