Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

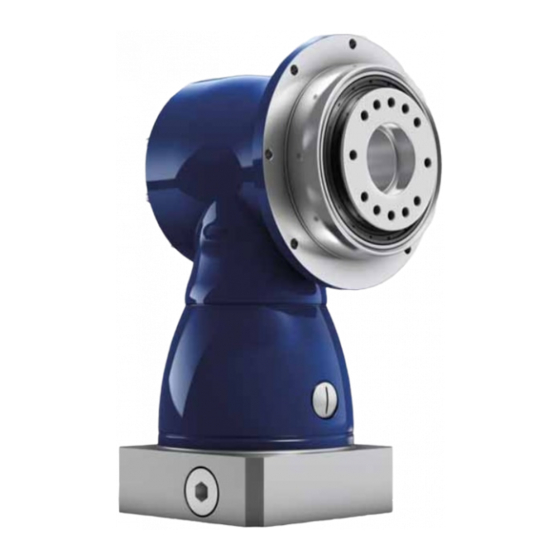

Summary of Contents for Wittenstein Alpha Advanced TK+ Series

- Page 1 alpha Advanced Line ATEX Operating Manual 2022-D034859 Revision: 05...

- Page 2 +41 81 300 10 30 info@wittenstein.tw +886 3 287 0191 WITTENSTEIN Güç Aktarma Türkiye info@wittenstein.com.tr +90 216 709 21 23 Sistemleri Tic. Ltd. Şti. © WITTENSTEIN alpha GmbH 2019 Subject to technical and content changes without notice. 2022-D034859 Revision: 05...

-

Page 3: Table Of Contents

ATEX Table of Contents About this manual ....................3 1.1 Information symbols and cross references ............3 1.2 Scope of delivery ....................3 Safety........................4 2.1 EC/EU Directive ....................4 2.1.1 Machinery Directive..................4 2.1.2 EU directive for devices and protective systems in potentially explosive atmospheres..................4 2.2 Personnel ......................4 2.3 Intended use ......................5 2.4 Reasonably foreseeable misuse ................6... - Page 4 ATEX Maintenance and disposal................23 7.1 Maintenance schedule ..................23 7.1.1 Further maintenance intervals ..............23 7.2 Maintenance work ..................... 23 7.2.1 Visual/Noise inspection................. 23 7.2.2 Checking the tightening torques ..............24 7.2.3 Checking for leakage ..................24 7.2.4 Replacing the gearbox.................. 24 7.3 Startup after maintenance work ................

-

Page 5: About This Manual

A cross reference on a table refers to the table number (e. g. Table "Tbl-15"). Scope of delivery Check the completeness of the delivery against the delivery note. Missing parts or damage must be notified immediately in writing to the carrier, the insurance company, or WITTENSTEIN alpha GmbH. Revision: 05 2022-D034859 en-3... -

Page 6: Safety

Only carry out modifications or reconstructions when these are approved in writing by the WITTENSTEIN alpha GmbH. Personal injuries or material damage, or other claims arising from non-observance of these minimum requirements, are the sole responsibility of the operator. -

Page 7: Intended Use

ATEX Safety Intended use The gearbox serves to convert torques and speeds. It is suitable for all industrial applications. The gearbox can be used in the potentially explosive atmospheres defined in Chapter 3.4 "Ex model". Observe the instructions on the name plate and the appendix on the written ... -

Page 8: Reasonably Foreseeable Misuse

Safety ATEX Reasonably foreseeable misuse Any use that deviates from the approved technical data (e.g. speed, force, torque, temperature, service life) is not use as intended and is therefore not permitted (also see Chapter 3.5 "Dimensions and performance data"). General safety instructions The operation of the gearbox involves residual risks even when adhering to the intended use. -

Page 9: Structure Of Warning Instructions

ATEX Safety Dangers Possible causes Protective measures Hot surfaces Increased friction and dissipated Reduce torques and speeds power because of wear, improper compared to standard gearboxes assembly, overload or leaks. Limit the motor current and maximum speed of the motor Maintenance intervals for wear parts and lubricant according to maintenance schedule... -

Page 10: Safety Symbols

Safety ATEX 2.6.1 Safety symbols The following safety symbols are used to indicate possible hazards, prohibitions, and important information: General hazard Hot surface Suspended loads Entanglement Environmental Information Explosion protection 2.6.2 Signal words The following signal words are used to indicate possible hazards, prohibitions, and important information: This signal word indicates an imminent danger that will cause serious injuries or even death. -

Page 11: Description Of The Gearbox

ATEX Description of the gearbox Description of the gearbox The gearbox is a single- or multi-stage low-backlash gearbox. Certain product types may be used only in a defined mounting position. Various types of motors can be accommodated using an adapter plate and, where necessary, a bushing. -

Page 12: Name Plate

SN: 1234567 DMF: 07/16 Made in Germany T : 480 Nm / n : 2500rpm 1max WITTENSTEIN alpha GmbH - Walter-Wittenstein-Str.1 - 97999 Igersheim Ordering code Production date CW/YY (see Chapter 3.3 "Ordering code") Maximum permitted gear output torque Ratio i... -

Page 13: Atex Marking For Use In Potentially Explosive Dust Atmospheres

ATEX Description of the gearbox 3.2.2 ATEX marking for use in potentially explosive dust atmospheres Designation Equipment category "Ex h: non- electrical” II 2D Ex h IIIC T150 °C Db X Equipment group "III: Explosive dust atmospheres" Subgroup "C: suitable for combustible suspended solids, non-conductive and conductive dust"... -

Page 14: Ex Model

Description of the gearbox ATEX Ex model The gearbox can be used in potentially explosive atmosphere group II, zones 1 and 2 as well as group III, zones 21 and 22. The gearbox can be operated in a gas atmosphere in temperature class T3. In a dust atmosphere, a maximum surface temperature of 150 °C is possible. -

Page 15: Dimensioning

- Use sealing plates between motor flange and adapter plate to seal the through-holes of the adapter plate. Sealing plates are available upon request from WITTENSTEIN alpha GmbH. Information about the lubricant All gearboxes are filled by the manufacturer with synthetic gear oil (polyglycols) (see name plate). -

Page 16: Transport And Storage

Transport and storage ATEX Transport and storage Packaging The gearbox is delivered packed in foil and cardboard boxes. Dispose of the packaging materials at the recycling sites intended for this purpose. Observe the applicable national regulations concerning disposal. Transport Suspended loads can fall and can cause serious injuries and even death. -

Page 17: Assembly

ATEX Assembly Assembly Read the general safety instructions before beginning to work (see Chapter 2.5 "General safety instructions"). If you have questions about correct mounting, consult our Customer Service department. Preparations Pressurized air can damage the gearbox seals. Do not use pressurized air to clean the gearbox. -

Page 18: Installation Conditions

Place an appropriate sealing ring between adapter plate and motor for gearboxes in Hygienic Design to avoid leaks. In addition, WITTENSTEIN alpha GmbH offers a suitable sealing plate. The tightening torque value [TA] of the clamping bolt [H] can be found on the clamping hub [C]. -

Page 19: Mounting The Gearbox On A Machine

ATEX Assembly If the clamping bolt [H ] is loosened too far or removed, the clamping ring [I] can rotate on the clamping hub. Align it so that the clamping bolt [H ] is in the keyway of the clamping hub (see table "Tbl-9"). -

Page 20: Mounting With Through-Holes

(doc. no. 2022–D063351) applies for this. The manual will be provided by our Sales / Customer Service department on request. Please always provide the serial number. WITTENSTEIN alpha GmbH offers corresponding mounting kits for gearboxes in Hygienic Design. The separate instructions "Hygienic Design Instruction Sheet, Mounting Kit" (Doc. no. -

Page 21: Mounting With Threaded Bores

ATEX Assembly Slide the washers onto the fastening screws. Fasten the gearbox to the machine with the fastening screws through the slotted holes [M]. Pinning the mounted and aligned gearbox (optional) Optionally, there are two bore holes [N] on the gear housing for pinning the gearbox to the machine. -

Page 22: Mounting With Shrink Disk

WITTENSTEIN alpha GmbH offers corresponding mounting kits for gearboxes in Hygienic Design. The separate instructions "Hygienic Design Instruction Sheet, Mounting Kit" (Doc. no. 2022–D062618) are valid for this. The manual will be provided by our Sales / Customer Service department on request. -

Page 23: Startup And Operation

ATEX Startup and operation Startup and operation Read the general safety instructions before beginning to work (see Chapter 2.5 "General safety instructions"). Operating the gearbox in areas for which it is not approved can lead to explosions that may cause serious injuries and even death. Ensure that the gearbox is only used in those areas for which it is ... -

Page 24: Checking Run-In Behavior

Startup and operation ATEX Checking run-in behavior Make sure there is no explosive atmosphere during the test. After 4 running hours in maximum operating conditions, check the gearbox for leakage between gear and motor and on the output shaft seal. Measure the surface temperature at two points on the gear housing (on near the drive ... -

Page 25: Maintenance And Disposal

20,000 operating hours. Tbl-11: Maintenance schedule 7.1.1 Further maintenance intervals Send the gearbox to WITTENSTEIN alpha GmbH for the following types of maintenance: - The radial shaft seal on the drive must be replaced and an oil change is required every 5,000 operating hours. -

Page 26: Checking The Tightening Torques

" design). - At the latest after a total of 20,000 operating hours. Alternatively, the gearbox can be checked by WITTENSTEIN alpha GmbH and if necessary, approved for further operation. For removal of the gearbox, please also refer to the Chapter 8 "Disassembly". -

Page 27: Disassembly

ATEX Disassembly Disassembly If you need to remove the gearbox for maintenance or replacement, complete the steps in this chapter. Read the general safety instructions before beginning to work (see Chapter 2.5 "General safety instructions"). Secure the higher-level machine against restarting and unintentional movements during ... -

Page 28: Disassembling The Gearbox With The Motor From The Machine

Disassembly ATEX Disassembling the gearbox with the motor from the machine Disconnect the electrical connections of the motor. Secure the gearbox and the motor so it cannot fall. Loosen the screws [S] connecting the gearbox to the whole ... -

Page 29: Malfunctions

ATEX Malfunctions Malfunctions Changed operational behavior can be an indication of existing damage to the gearbox or can cause damage to the gearbox. Do not put the gearbox back into operation until the cause of the malfunction has been rectified. Rectifying of malfunctions may only be done by specially trained technicians. -

Page 30: Appendix

Appendix ATEX Appendix 10.1 Specifications for mounting to a motor Designation Clamping bolt, eccentrical Tbl-14: Arrangement of motor shaft, clamping bolt and bushing Tightening torque for clamping bolt (H Ordering code: xxxxxxxx-xxx-xxxxx-x(.)*x-xx (see Chapter 3.2 "Name plate") Clamping hub (.)* Code Width Tightening torque [Nm] Ø... -

Page 31: Specifications For Mounting To A Machine

ATEX Appendix 10.2 Specifications for mounting to a machine The gearbox may only be operated in the approved mounting position. Further information on the mounting position can be found in chapters 10.4.1 "Mounting position" and 10.4.2 "Impermissible operating conditions". 10.2.1 Specifications for mounting with through-holes Ordering code: TK..xxxx-xFx-xxxxx-xxx-xx;... -

Page 32: Specifications For Startup And Operation

Appendix ATEX 10.4 Specifications for startup and operation Ambient temperature Product type Minimum temperature Maximum temperature [°C] [°C] Operating temperature Product type Max. permissible housing temperature [°C] Tbl-19: Ambient temperature / Operating temperature 10.4.1 Mounting position Improper use can cause damage to the gearbox and cause ignition hazards. Ensure that the gearbox is mounted in the mounting positions depicted below to ... -

Page 33: 2Impermissible Operating Conditions

/ hollow shaft interface. If necessary, install external bearing points for the load shaft. In case of unclear installation situations, contact WITTENSTEIN alpha GmbH. - Co-riding the gearbox on the drive axle is prohibited. Exceptions require a written approval and technical statement from WITTENSTEIN alpha GmbH. -

Page 34: Technical Specifications

Appendix ATEX 10.6 Technical specifications 10.6.1 Technical specifications for TK 004 for use in areas with explosion hazards Technical specifications for TK 004, 1-stage Ratio i Max. acceleration torque T [Nm] (max. 1000 cycles per hour) Nominal output torque T [Nm] 17.5 17.5... - Page 35 ATEX Appendix Technical specifications for TK 004, 2-stage Ratio i Max. acceleration torque [Nm] (max. 1000 cycles per hour) Nominal output torque T 17.5 17.5 17.5 17.5 17.5 17.5 17.5 17.5 [Nm] (At n Emergency stop torque [Nm] 2Not (1000 times possible during the service life of the gearbox) Permissible average input...

-

Page 36: 2Technical Specifications For Tk + 010 For Use In Areas With Explosion Hazards

Appendix ATEX Technical specifications for TK 004, 2-stage Ratio i Direction of rotation In- and output opposite directions Mass moment of inertia J 0.09 0.09 0.08 0.07 0.06 0.06 0.06 0.06 0.06 0.06 [kgcm Refers to the drive; Bore diameter of the clamping hub: 11 mm Mass moment of inertia J 0.21 0.20 0.19 0.19 0.18 0.18 0.17 0.17 0.17 0.17... - Page 37 ATEX Appendix Technical specifications for TK 010, 1-stage Ratio i Ambient temperature [°C] See Chapter 10.4 "Specifications for startup and operation" Lubrication synthetic gear oil (see also Chapter 7.1 "Maintenance schedule") Direction of rotation In- and output opposite directions Mass moment of inertia J [kgcm 1.81 1.39...

-

Page 38: 3Technical Specifications For Tk + 025 For Use In Areas With Explosion Hazards

Appendix ATEX Technical specifications for TK 010, 2-stage Ratio i Service life L See Chapter 7.2.4 "Replacing the gearbox" Weight incl. standard adapter plate m [kg] Operating noise L ≤ 66 [dB(A)] (For n = 3000 min w/o load) Max. permissible housing temperature [°C] Ambient temperature [°C] See Chapter 10.4 "Specifications for startup and operation"... - Page 39 ATEX Appendix Technical specifications for TK 025, 1-stage Ratio i Torsional rigidity C [Nm/arcmin] Max. axial force F 3950 2AMax Max. tilting moment M [Nm] 2KMax Service life L See Chapter 7.2.4 "Replacing the gearbox" Weight incl. standard adapter plate m [kg] Operating noise L [dB(A)] ≤...

- Page 40 Appendix ATEX Technical specifications for TK 025, 2-stage Ratio i Average no-load running torque T [Nm] (For n =3000 min gearbox temperature 20 °C) Max. backlash j [arcmin] ≤ 4 Torsional rigidity C 13.0 13.0 13.0 13.0 13.0 13.0 13.0 16.0 16.0 16.0 [Nm/arcmin] Max.

-

Page 41: 4Technical Specifications For Tk + 050 For Use In Areas With Explosion Hazards

ATEX Appendix 10.6.4 Technical specifications for TK 050 for use in areas with explosion hazards Technical specifications for TK 050, 1-stage Ratio i Max. acceleration torque T [Nm] (max. 1000 cycles per hour) Nominal output torque T [Nm] (At n Emergency stop torque T [Nm] 2Not... - Page 42 Appendix ATEX Technical specifications for TK 050, 2-stage Ratio i Max. acceleration torque [Nm] (max. 1000 cycles per hour) Nominal output torque T [Nm] (At n Emergency stop torque [Nm] 2Not (1000 times possible during the service life of the gearbox) Permissible average input 2600 2600 2600 2600 2600 2600 2600 2800 2800 3500...

-

Page 43: 5Technical Specifications For Tk + 110 For Use In Areas With Explosion Hazards

ATEX Appendix Technical specifications for TK 050, 2-stage Ratio i Direction of rotation In- and output opposite directions Mass moment of inertia J 4.43 3.97 3.36 3.22 2.82 2.75 2.50 2.47 2.44 2.42 [kgcm Refers to the drive; Bore diameter of the clamping hub: 24 mm Mass moment of inertia J 11.3 10.9 10.3 10.1 9.74 9.66 9.41 9.38 9.35 9.33... - Page 44 Appendix ATEX Technical specifications for TK 110, 1-stage Ratio i Ambient temperature [°C] See Chapter 10.4 "Specifications for startup and operation" Lubrication synthetic gear oil (see also Chapter 7.1 "Maintenance schedule") Direction of rotation In- and output opposite directions Mass moment of inertia J [kgcm 96.5 64.6...

- Page 45 ATEX Appendix Technical specifications for TK 110, 2-stage Ratio i Operating noise L ≤ 68 [dB(A)] (For n = 3000 min w/o load) Max. permissible housing temperature [°C] Ambient temperature [°C] See Chapter 10.4 "Specifications for startup and operation" Lubrication synthetic gear oil (see also Chapter 7.1 "Maintenance schedule") Direction of rotation In- and output opposite directions...

-

Page 46: Declaration Of Conformity

Appendix ATEX 10.7 Declaration of Conformity en-44 2022-D034859 Revision: 05... - Page 47 ATEX Revision history Revision Date Comment Chapter 18.12.2009 New version 31.08.2010 2-stage design 1, 3, 5, 7, 9 27.05.2015 Lubricant 3.1, 9.6 10.03.2016 2014/34/EU 2.1, 2.4, 3.1, 3.2, 3.4.1, 19.12.2019 EN ISO 80079 Revision: 05 2022-D034859...

- Page 48 WITTENSTEIN alpha GmbH · Walter-Wittenstein-Straße 1 · 97999 Igersheim · Germany Tel. +49 7931 493-0 · info@wittenstein.de WITTENSTEIN ‒ with the future www.wittenstein-alpha.de AC: XXXXXXXX 2022-D034859 Revision: 05...

Need help?

Do you have a question about the Advanced TK+ Series and is the answer not in the manual?

Questions and answers