Summary of Contents for Wittenstein Alpha V-Drive Advanced VT+

- Page 1 V-Drive Advanced / Value / Basic , VH , VS / NVH, NVS / CVH, CVS Operating Manual 2022-D059517 Revision: 05...

- Page 2 +41 81 300 10 30 info@wittenstein.tw +886 3 287 0191 WITTENSTEIN Güç Aktarma Türkiye info@wittenstein.com.tr +90 216 709 21 23 Sistemleri Tic. Ltd. Şti. © WITTENSTEIN alpha GmbH 2020 Subject to technical and content changes without notice. 2022-D059517 Revision: 05...

-

Page 3: Table Of Contents

V.. / NV.. / CV.. Table of Contents About this manual ....................3 1.1 Information symbols and cross references ............3 1.2 Scope of delivery ....................3 Safety........................4 2.1 EC/EU Directive ....................4 2.1.1 Machinery Directive..................4 2.2 Personnel ......................4 2.3 Intended use ......................4 2.4 Reasonably foreseeable misuse ................5 2.5 General safety instructions ..................5 2.6 Structure of warning instructions................6 2.6.1 Safety symbols ....................6... - Page 4 V.. / NV.. / CV.. Malfunctions ...................... 22 Appendix ......................23 9.1 Specifications for mounting to a motor .............. 23 9.2 Specifications for mounting to a machine............24 9.2.1 Specifications for mounting with threaded holes .......... 24 9.2.2 Specifications for mounting with through-holes ..........25 9.3 Specifications for mounting to the output side...........

-

Page 5: About This Manual

A cross reference on a table refers to the table number (e. g. Table "Tbl-15"). Scope of delivery Check the completeness of the delivery against the delivery note. Missing parts or damage must be notified immediately in writing to the carrier, the insurance company, or WITTENSTEIN alpha GmbH. Revision: 05 2022-D059517 en-3... -

Page 6: Safety

Only carry out modifications or reconstructions when these are approved in writing by the WITTENSTEIN alpha GmbH. Personal injuries or material damage, or other claims arising from non-observance of these minimum requirements, are the sole responsibility of the operator. -

Page 7: Reasonably Foreseeable Misuse

V.. / NV.. / CV.. Safety The gearbox is intended for installation on motors that: - correspond to the design B5 (in the event of deviations, consult our Customer Service department [Technical Customer Service department]). - have a radial and axial runout tolerance according to DIN EN 50347. - have a cylindrical shaft end with tolerance class h6 to k6. -

Page 8: Structure Of Warning Instructions

Safety V.. / NV.. / CV.. A damaged gearbox can cause accidents and injury: Immediately shut down a gearbox that has been overloaded due to misuse or a machine crash (see Chapter 2.4 "Reasonably foreseeable misuse"). Replace the damaged gearbox, even if no external damage is visible. ... -

Page 9: Signal Words

V.. / NV.. / CV.. Safety 2.6.2 Signal words The following signal words are used to indicate possible hazards, prohibitions, and important information: This signal word indicates an imminent danger that will cause serious injuries or even death. This signal word indicates a potential hazard that could cause serious injuries and even death. -

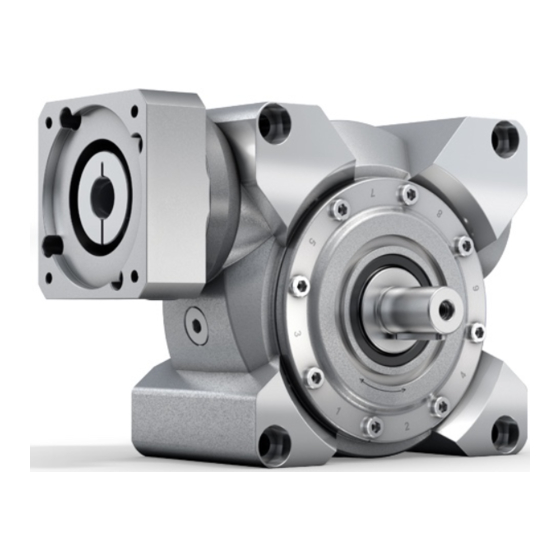

Page 10: Description Of The Gearbox

Description of the gearbox V.. / NV.. / CV.. Description of the gearbox The gearbox is a single- or multi-stage low-backlash servo worm gearbox. The gearbox must only be operated in mounting position as specified in the order. Various types of motors can be accommodated using an adapter plate and, where necessary, a bushing. -

Page 11: Name Plate

1234567 DMF: 10/18 Lubrication: xxx Made in Germany Lubricant WITTENSTEIN alpha GmbH-Walter-Wittenstein-Str.1-97999 Igersheim Production date Data matrix code (optional) Tbl-5: Identification plate (sample values) Ordering code xxxxxxx x - x x x - xxxxx - x x x - x x xx x... -

Page 12: Dimensions And Performance Data

Description of the gearbox V.. / NV.. / CV.. Dimensions and performance data The dimensions, the maximum permissible speeds and torques, and information on the service life can be found - in our catalog, - at www.wittenstein-alpha.de, ® - in the specification software cymex - in the respective customized performance data (X093–D...). -

Page 13: Transport And Storage

V.. / NV.. / CV.. Transport and storage Transport and storage Packaging The gearbox is delivered packed in foil and cardboard boxes. Dispose of the packaging materials at the recycling sites intended for this purpose. Observe the applicable national regulations concerning disposal. Transport Suspended loads can fall and can cause serious injuries and even death. -

Page 14: Transport Of Gearboxes Size 080 And Up

Transport and storage V.. / NV.. / CV.. 4.2.2 Transport of gearboxes size 080 and up For gearboxes size 080 and up, we recommend M (12x) the use of hoisting equipment. You can screw in eye bolts (e.g. acc. to DIN 580) into the threaded bores [M] in the housing. -

Page 15: Assembly

Operation without an adapter plate might lead to damage. Only install your own adapter plate or replace an adapter plate according to the specifications of WITTENSTEIN alpha GmbH. Our Customer Service department will provide you with disassembly instructions for this purpose. -

Page 16: Mounting The Motor To The Gearbox

Place an appropriate sealing ring between adapter plate and motor for gearboxes in Hygienic Design to avoid leaks. In addition, WITTENSTEIN alpha GmbH offers a suitable sealing plate. The tightening torque value [TA] of the clamping bolt [H] can be found on the clamping hub [C]. - Page 17 V.. / NV.. / CV.. Assembly Preferably, the motor should be mounted in a vertical orientation. Remove the locking screw / stopper plug [A] from the mounting bore in the adapter plate [B]. Rotate the clamping hub [C] until the clamping bolt [H] can ...

-

Page 18: Mounting The Gearbox On A Machine

(doc. no. 2022–D063351) applies for this. The manual will be provided by our Sales / Customer Service department on request. Please always provide the serial number. WITTENSTEIN alpha GmbH offers corresponding mounting kits for gearboxes in Hygienic Design. The separate instructions "Hygienic Design Instruction Sheet, Mounting Kit" (Doc. no. -

Page 19: Mounting With Slotted Holes

V.. / NV.. / CV.. Assembly 5.3.2 Mounting with slotted holes Use only the washers included with the delivery for fastening the gearbox to the machine (see Chapter 9.2 "Specifications for mounting to a machine"). The gearbox can be optionally equipped with an output pinion [P ]. -

Page 20: Mounting With Threaded Bores

WITTENSTEIN alpha GmbH offers corresponding mounting kits for gearboxes in Hygienic Design. The separate instructions "Hygienic Design Instruction Sheet, Mounting Kit" (Doc. no. 2022–D062618) are valid for this. The manual will be provided by our Sales / Customer Service department on request. -

Page 21: Mounting With Shrink Disk

V.. / NV.. / CV.. Assembly 5.4.1 Mounting with shrink disk The slip-on shaft / hollow shaft / hollow shaft interface [Q] is axially secured to the load shaft by means of a shrink disk connection. If a gearbox with shrink disk [P] was ordered, then it is already mounted. If a different shrink disk is used, observe the instructions of the ... -

Page 22: Startup And Operation

Startup and operation V.. / NV.. / CV.. Startup and operation Read the general safety instructions before beginning to work (see Chapter 2.5 "General safety instructions"). Improper use can cause damage to the gearbox. Ensure that - the ambient temperature is in the permissible range (see Chapter 9.4 "Specifications for startup and operation") and - the operating temperature does not exceed +90 °C. -

Page 23: Maintenance And Disposal

V.. / NV.. / CV.. Maintenance and disposal Maintenance and disposal Read the general safety instructions before beginning to work (see Chapter 2.5 "General safety instructions"). Maintenance schedule Maintenance work At startup For the first time after 500 Every 3 operating hours or 3 months months Visual inspection... -

Page 24: Malfunctions

Malfunctions V.. / NV.. / CV.. Malfunctions Changed operational behavior can be an indication of existing damage to the gearbox or can cause damage to the gearbox. Do not put the gearbox back into operation until the cause of the ... -

Page 25: Appendix

V.. / NV.. / CV.. Appendix Appendix Specifications for mounting to a motor Designation Clamping bolt, eccentrical Tbl-12: Arrangement of motor shaft, clamping bolt and bushing Tightening torque for clamping bolt (H Ordering code: xxxxxxxx-xxx-xxxxx-x(.)*x-xx (see Chapter 3.2 "Name plate") Clamping hub (.)* Code Width... -

Page 26: Specifications For Mounting To A Machine

Appendix V.. / NV.. / CV.. Specifications for mounting to a machine The gearbox must only be operated in mounting position as specified in the order. For further information on the mounting position, please refer to Chapter 9.4.1 "Mounting position". 9.2.1 Specifications for mounting with threaded holes Gearbox size Quantity x thread x... -

Page 27: Specifications For Mounting With Through-Holes

V.. / NV.. / CV.. Appendix 9.2.2 Specifications for mounting with through-holes Gearbox size Screw size / Tightening torque V-Drive Property class [Nm] M8 / 8.8 21.5 M10 / 8.8 42.5 M10 / 8.8 42.5 M10 / 8.8 42.5 M12 / 8.8 73.5 Tbl-17: Specifications for mounting to a machine Specifications for mounting to the output side... -

Page 28: Mounting On The Keyed Hollow Shaft

Appendix V.. / NV.. / CV.. 9.3.1 Mounting on the keyed hollow shaft The shaft end (load shaft) of the machine must be equipped with a DIN 6885 Part 1, Form A shaft key and must have a DIN 332 Form DS centering (with thread) on the front side. Incorrectly aligned shafts can lead to damage. -

Page 29: Mounting Position

V.. / NV.. / CV.. Appendix 9.4.1 Mounting position The gearbox must only be operated in mounting position as specified in the order. The mounting position can be found on the name plate (see Chapter 3.2 "Name plate"). Output side Ordering code: xxxxxxx-xxx-xxx-xxx-xx-AXx View of the motor connection, output... -

Page 30: Continuous Operation

The bleed screw is not included in the scope of delivery. WITTENSTEIN alpha GmbH offers suitable bleed screws to this end (see Table "Tbl-24"). If you would like to order a bleed screw, contact our sales department. - Page 31 V.. / NV.. / CV.. Revision history Revision Date Comment Chapter 22.03.17 New version 02.05.17 Bleed screw 15.11.17 Bleed screw material number 06.12.17 Tightening torques 08.01.20 Layout Revision: 05 2022-D059517...

- Page 32 WITTENSTEIN alpha GmbH ꞏ Walter-Wittenstein-Straße 1 ꞏ 97999 Igersheim ꞏ Germany Tel. +49 7931 493-0 ꞏ info@wittenstein.de WITTENSTEIN ‒ with the future www.wittenstein-alpha.de AC: XXXXXXXX 2022-D059517Revision: 05...

Need help?

Do you have a question about the V-Drive Advanced VT+ and is the answer not in the manual?

Questions and answers