Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Data Aire DARC 03

- Page 2 NOTE: This manual is intended to assist trained service personnel by providing neces- sary guidelines for this particular equipment. Service to Data Aire units should be done by qualified individuals with an adequate background in areas such as HVAC, electrical, plumbing and electronics, as applicable.

-

Page 3: Table Of Contents

TABLE OF CONTENT 1.0 INTRODUCTION ....................5 1.1 Model Identification ..................5 1.2 Inspection ....................... 5 1.3 Paperwork ...................... 5 1.4 Storage......................6 1.5 Locating the Remote Heat Exchanger ............6 1.6 Leg Assembly ....................7 1.7 Rigging ......................7 1.8 Installation ...................... - Page 4 6.2 Electronically commutated (EC) Fan Trouble Shooting ....... 20 6.3 Coil Cleaning ....................20 6.3.1 When to Clean ..................20 6.3.2 What to Use ..................... 20 6.3.3 How to Clean ................... 21 7.0 LINE SIZES ....................... 21 8.0 CONTACT DATA AIRE ..................22...

-

Page 5: Introduction

Model Identification Inspection This Data Aire unit has been factory run tested and has passed a comprehensive inspection prior to packaging and shipment ensuring it arrives in excellent condition. However, shipping damage can occur and a visual inspection of the outer crating immediately upon delivery should be performed. -

Page 6: Storage

NOTE: It is the responsibility of the installing contractor to return the start-up sheet and warranty registration card to Data Aire for proper activation of the unit warranty. Failure to do so may cause delays and in some cases void the warranty. -

Page 7: Leg Assembly

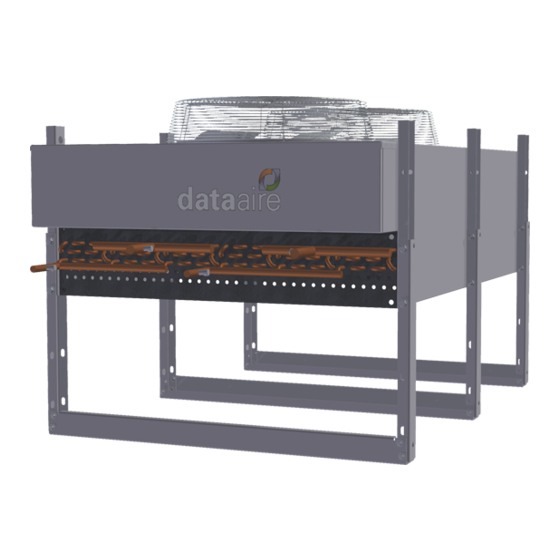

Condensers should not be closer than 36 inches from a wall or any obstruction. With proper clear- ance on all other sides units can be placed side by side. Additional units should be placed no closer than 48 inches apart, see Figure 1. Avoid air recirculation conditions that could be caused by walls, screening, etc. -

Page 8: Installation

Figure 2 Installation NOTE: There is no intent on the part of Data Aire, Inc. to define local codes or statutes which may supersede common trade practices. The manufacturer assumes no respon- sibility for their interpretation. Consult local building codes and the National Electrical Code (NEC) for special installation requirements. - Page 9 Only qualified and experienced service technicians should perform installation and maintenance on this product. Equipment damage and personal injury can result from improper piping installation, leak checking and improper handling. This equipment is designed to operate properly and produce rated capacities when installed in ac- cordance with industry standards.

-

Page 10: Piping

Refer to the Line Size chart (7.0 LINE SIZES) for a guideline to sizing refrigerant lines. The ultimate responsibility for line size selection is that of the installing contractor or project engineer. Data Aire does not assume this responsibility. The chart covers distances up to 200 equivalent feet. For in- stallations greater than this distance refer to ASHRAE or similar references. -

Page 11: Field Piping, Remote Condenser Above Evaporator

Field Piping, Remote Condenser Above Evaporator Figure 3 Field Piping, Remote Condenser Below Evaporator Air Cooled Condenser User Manual •... -

Page 12: Condenser Connection Sizes

CONDENSER CONNECTION SIZES – Single Circuit Standard Discharge Liquid Discharge Liquid Fans (Hot Gas) Line Line EC Fans (Hot Gas) Line Line DARC 03 1/2” 1/2” GHRC 011 1/2” 1/2” DARC 05 1/2” 1/2” GHRC 018 1/2” 1/2” DARC 07 1-1/8”... -

Page 13: Leak Testing

Leak Testing NOTE: With any connection there is risk of leakage. Leakage could result in damage. Leakage can be a result from improper installation and/or practices. No installation is complete until the entire system has been thoroughly checked for leaks. This includes checking the refrigerant tubing, flare fittings, pressure controls, Schrader fittings and com- pressor Rotalock service valves. -

Page 14: Electrical Connections

ELECTRICAL CONNECTIONS WARNING: The Data Aire cooling unit must be connected by a licensed and qualified electrician. Risk of electrical shock could result in injury or death. Disconnect all remote electrical power supplies prior to working on the unit. NOTE: Disconnect switches are optional. The disconnect switch when turned OFF will de-energize the high voltage. -

Page 15: Phase

DAP-II controller, the terminals are #42 and #43. On most remote heat exchangers the terminals will be #39 and #40. All control wiring on Data Aire equipment is 24 VAC or less. Refer to the wiring diagrams. WARNING: Check the wiring connections in the unit control panel to ensure they are tight. -

Page 16: Charging

CHARGING Fan Speed Control/Fan Cycling Data Aire air-cooled condensers (DARC) is equipped with the latest upgrade to control the high side pressure of the refrigeration system. The Fan Speed Control (FSC) is a single-phase condenser fan speed controller that is compact, weather-resistant, and durable speed control for single-phase, permanent-split capacitor (PSC) motors used in a wide variety of low-ambient refrigeration and air conditioning condenser applications. -

Page 17: Charging With Fan Speed Control

Charging with Fan Speed Control As previously noted, the standard Data Aire air-cooled condenser (DARC) comes equipped with fan speed control on the lead motor (motor number 1, nearest the header). After field refrigerant pip- ing is properly completed, connect a refrigerant drum to the low side of the system and charge with vapor (refer to Section 2.5 Leak Testing and Section 2.6 Evacuation prior to charging the system). -

Page 18: R-410A - Charging/Installation Work Procedures

Data Aire units with optional receivers are either provided within the evaporator section (depending on the unit size) or shipped loose for field installation. The receiver includes heaters and thermostat. -

Page 19: Refrigerant Handling

EPA certification card. Condenser with EC Motor Axial Fan(s) (Option) Data Aire air-cooled condensers (GHRC) provided with optional axial Electronically Commutated (EC) fan(s) provide variable speed control based on head pressure. The EC motor has all the re- quired components to run at variable speeds. -

Page 20: Warranty

WARRANTY NOTE: See separate warranty certificate and registration card that is supplied with each unit as part of the paperwork package. PREVENTIVE MAINTENANCE The operating life of the condenser can be extended by following a simple preventive maintenance schedule. This schedule will reduce the possibility of failure of components and unnecessary mal- function of the system. -

Page 21: How To Clean

WARNING: If a pressure washer is used, make sure the equipment is set to a lower pressure setting and that the nozzle is set to the fan spray, not stream. Otherwise, dam- age to the fins could result. If a chemical cleaner is required, a non-acidic type cleaner is recommended. WARNING: Acid-type cleaners can be aggressive to the coil fins as well as surrounding areas. -

Page 22: Contact Data Aire

714-921-6011 Engineering 714-921-6022 Parts Sales E-mail: Service@dataaire.com Engineering@dataaire.com Sales@dataaire.com Web Site: http://www.dataaire.com Job/Unit Information: ________________________________ Data Aire Job Number: ________________________________ Evaporator Serial Number: ________________________________ Evaporator Model Number: ________________________________ Condenser Serial Number: ________________________________ Condenser Model Number: ________________________________ Installing Contractor: ________________________________ Date installed:... - Page 23 INDEX Clearance ....................8 Coil ....................7, 8, 21 Concrete pads .....................8 Controller ....................16 Electronic Expansion Valves (EEV) ............18 Electronically Commutated (EC) ............20, 21 External damage ..................6 Fan Speed Control ................17, 18 Freezing ......................7 Inspect ....................6, 7, 21 Installation ....................9 Internal damage ..................6 Leakage ....................13 Micron gauge ....................14 Modulate ....................17...

- Page 24 Air Cooled Condenser User Manual •...

- Page 25 Air Cooled Condenser User Manual •...

- Page 26 Air Cooled Condenser User Manual •...

- Page 27 Air Cooled Condenser User Manual •...

- Page 28 02/2021 Air Cooled Condenser User Manual •...

Need help?

Do you have a question about the DARC 03 and is the answer not in the manual?

Questions and answers