Summary of Contents for IBCcontrol VariMax50M

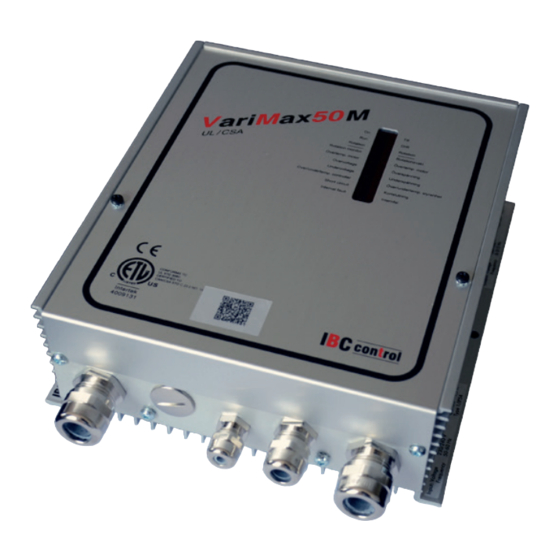

- Page 1 MANUAL Ska vara 25 mm i diameter på höjden CONTROL UNIT FOR ROTATING HEAT EXCHANGER WITH MODBUS VariMax50M UL/CSA Article no. F21050304 control...

-

Page 3: Table Of Contents

TABLE OF CONTENTS Installation instructions Modbus Mounting Technical data, Modbus Safety instructions Connection Manufacturer's declaration Function settings, Modbus Description of functions Operational indications, Modbus Technical data, control unit Timeout Technical data, motor DIP switch Functions Modbus Register Folder - DIP switch Coil - Operational indications Discrete input... -

Page 4: Installation Instructions

INSTALLATION INSTRUCTIONS Warning indication The control unit must only be used in perfect technical condition. Any damage that may affect safety must be dealt with immediately. Maintenance/Repairs The function of the control unit should be checked regularly. Troubleshooting and repairs must only be performed by trained personnel. -

Page 5: Safety Instructions

SAFETY INSTRUCTIONS The following symbols and references will be used in this description. These instructions are important; they apply to personal and technical safety during operation. This safety instruction refers to instructions whose specific intent is to avoid the risk of personal injury and to prevent damage to equipment. -

Page 6: Manufacturer's Declaration

Manufacturer IBC control AB Brännerigatan 5 A, SE-263 37 Höganäs, Sweden Product Control unit for rotating heat exchanger Type designation VariMax50M EU Directive The manufacturer's declaration of conformity with the requirements of the applicable to the EMC Directive 2004/108/EC. product... -

Page 7: Description Of Functions

All control units have an input signal of 0-10 V. • The VariMax50M is designed for rotors up to 2500 mm with a rotor speed of max. 12 rpm. If the rotor requires a faster rotor speed, the rotor diameter should be reduced. -

Page 8: Technical Data, Control Unit

TECHNICAL DATA, CONTROL UNIT External power supply 1x230-240 V +/-15 % Output frequency 0-312 Hz 50/60 Hz Acceleration and 30 sec Power input, max. 240 W retardation time Ambient temperature, Input current, max. 1,9 A -30 - +45 non condensing -40 - +45 C ***) External fuse, max. -

Page 9: Dip Switch

DIP SWITCH Cleaning function Cleaning function connected in ON position. When the rotor has stopped for 10 minutes, the cleaning function is activated and the rotor starts to rotate. As a warning, the rotor first rotates for 6 seconds at a motor speed of 5 rpm, the rotor is then stationary for 3 seconds. -

Page 10: Settings Via Potentiometer

Continued from previous page Probable fault cause - Magnet turned the wrong way during installation - Magnet transmitter incorrectly connected (wrong polarity), refer to "connections" on page 9 - Gap too wide between the magnetic sensor and magnet; max 15 mm Probable fault cause in - Broken belt operation... -

Page 11: Connection Diagram

CONNECTION DIAGRAM (Max 2 A / 50 V AC) 11 12 14 15 A1 A2 9 10 Reset 1 x 230 V Alarm relay Manual Input Rotation Thermal Stepping motor 3-phase speed signal monitor contact 0 - 10 V CONNECTIONS The voltage must be switched off before undertaking any work on the equipment. -

Page 12: Input Signal/Rotation Speed

INPUT SIGNAL/ROTATION SPEED Rotation speed (%) Input signal - rotation speed The input signal is directly proportional to the efficacy of the rotor, which implies that input signal and rotation speed are as per the adjacent diagram. Input signal 0-10 V CHECKS BEFORE POWERING UP THE CONTROL UNIT Check that the control unit is connected as per instructions on page 9. -

Page 13: Emc Installation

EMC INSTALLATION NCY-HAR/UL/CSA 7G0,75 Incoming EKK 3G1.5 Unshielded Shielded Input signal, LiYCY 2x0,34, UL recognized, LiYCY 2x0,34/0,5 UL recognized Shielded Shielded EMC glands must be used for shielded cables. The above cables or equivalent must be used to comply with the EMC Directive. EMC GLAND NOTE! When connecting the shielding to the EMC gland, it is important to connect as shown above. -

Page 17: Modbus

TECHNICAL DATA, MODBUS Communication MODBUS RTU protocol Interface RS485, half-duplex Data rate 9 600, 19 200, 38 400, 56 000 bits per second Bit format 8 databits, 1 stop bit, even parity 8 databits, 1 stop bit, no parity 8 databits, 2 stop bits, no parity 8 databits, 1 stop bit, odd parity Address 8 unique addresses, refer to the table "Addressing"... -

Page 18: Function Settings, Modbus

A green LED starts flashing if there is data traffic present in the bus. Settings made via Modbus are not saved in VariMax50M. When VariMax50M is restarted the setting from the DUC has to be re-transmitted. -

Page 19: Operational Indications, Modbus

- No reference value received from host system *VariMax has received a reference value for the past 90 seconds. TIMEOUT If messages with reference values stop coming, VariMax50M will continue using the latest received reference value. After 90 seconds the red LED will activate. -

Page 20: Dip Switch

DIP SWITCH Modbus communication On Addressing Hexadecimal Decimal Rate 9 600 19 200 38 400 56 000 Package 1 stop bit, even parity 1 stop bit, no parity 2 stop bits, no parity 1 stop bit, odd parity Termination To... -

Page 21: Modbus Register Folder

MODBUS REGISTER FOLDER VariMax50M supports the following Modbus functions: ◆ Coil (digital Read/Write) ◆ Discrete input (digital Read) ◆ Input register (analogue Read) ◆ Holding register (analogue Read/Write) COIL 1-bit register (Read/Write). Modbus function 01 "Read Coil Status" is used for reading. -

Page 22: Discrete Input

DISCRETE INPUT 1-bit status register (Read). Modbus function 02 "Read Input Status" is used for reading. Reads 1 if a fault has occurred. 0 = normal 1 = alarm Address Name Designation Data Read/ Factor Unit form Write Error Error regardless of which fault Single bit Read has occurred. - Page 23 Continued from previous page Address Name Designation Data Read/ Factor Unit form Write Short circuit Short circuit Single bit Read Short circuit Imbalance between phases Single bit Read Short circuit Phase 1 missing Single bit Read Short circuit Phase 2 missing Single bit Read Short circuit Phase 3 missing...

-

Page 24: Input Register 16-Bits

INPUT REGISTER 16-bit register (Read). Modbus function 04 "Read Input Registries" is used for reading. Address Name Designation Data Read/ Factor Unit form Write Program version UINT 16 Read Program version UINT 16 Read VariMax model Reads 50 for VariMax50 etc. UINT 16 Read Temperature Temperature in the control unit INT 16... - Page 25 Continued from previous page Address Name Designation Data Read/ Factor Unit form Write Current rotor Only calculated if the speed UINT 16 Read speed reference value remains constant between two pulses on the rotation monitor. Displays 0 if no value is available. To ensure the correctness of the measured value the speed reference value should be...

-

Page 26: Input Register 32-Bit

INPUT REGISTER 32-bit register (Read). Modbus function 04 "Read Input Registries" is used for reading. Address Name Designation Data Read/ Factor Unit form Write Motor speed RPM Number of rotations UINT 32 Read Motor starts Number of motor starts UINT 32 Read Restarts Number of faults causing restarts UINT 32 Read Surge... - Page 27 Continued from previous page Address Name Designation Data Read/ Factor Unit form Write Stop time, Time with stopped motor, UINT 32 Read normal temp. 0-40 °C Stop time, Time with stopped motor, UINT 32 Read cold temp. below 0 °C Running time, Time with motor running, in UINT 32 Read...

-

Page 28: Holding Register

HOLDING REGISTER 16-bit register (Read/Write). Modbus function 03 "Read Holding Registries" is used for Reading. Modbus function 06 "Write” Singles Registries" is used for Writing. Address Name Designation Data Read/ Factor Unit form Write Reference value, 1000 = 100 % of set max rpm UINT 16 Read/ relative speed speed. -

Page 29: Personal Notes

PERSONAL NOTES... - Page 30 PERSONAL NOTES...

- Page 31 PERSONAL NOTES...

- Page 32 IBC control AB Brännerigatan 5 A SE-263 37 Höganäs Sweden Tel. +46 42 33 00 10 www.ibccontrol.se info@ibccontrol.se...

Need help?

Do you have a question about the VariMax50M and is the answer not in the manual?

Questions and answers