Table of Contents

Advertisement

Quick Links

PRINCIPLES OF ULTRASONIC CLEANING

Ultrasonics is defined as a mechanical vibration above the

range of human hearing (i.e., above 18,000 Hz.). Ultrasonic

cleaning refers to the use of ultrasonic energy to assist in

the cleaning of soiled objects while they are immersed in a

cleaning fluid. Typical frequencies used in ultrasonic cleaning

are 20kHz, 25 kHz, 40 kHz, and 80 kHz.

Every ultrasonic cleaning system consists of three basic

components:

• An Ultrasonic Generator that converts 50 or 60 Hz electric

power form the electric utility supply to a high frequency

electric signal in the ultrasonic range.

• Ultrasonic Transducers to convert the ultrasonic electrical

signal into mechanical vibrations.

• A Tank with the ultrasonic transducers bonded to its exterior

and that contains the cleaning fluid and work pieces.

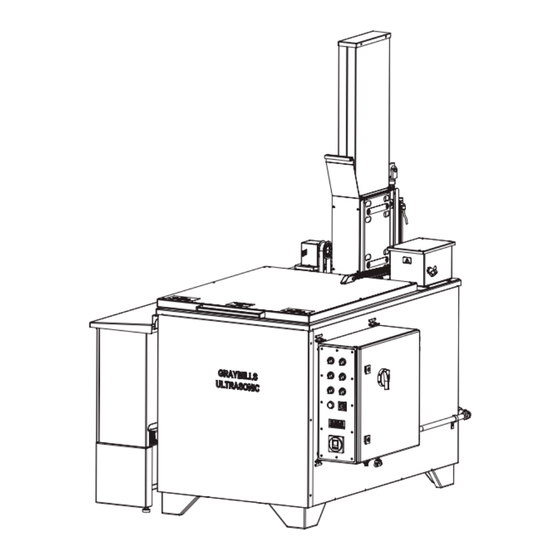

Maintenance Instructions

For units manufactured after January 2015

TUSR24/36 SERIES

LIFTKLEEN

ULTRASONIC

HEATED/AQUEOUS

PARTS WASHER

Read all of the SAFETY INSTRUCTIONS in this

manual BEFORE installing or using this equipment.

Keep this manual handy for reference/training.

The tank is filled with a fluid suitable for the cleaning

application. When the ultrasonic generator is activated, the

transducers begin to vibrate at their natural frequency and

couple the ultrasonic energy into the cleaning fluid. If sufficient

energy is produced, the fluid molecules are pulled apart,

creating microscopic "voids" or bubbles. This phenomenon is

called cavitation. These cavitation bubbles increase and shrink

in size in step with the ultrasonic frequency. Above a certain

energy threshold, the bubbles will grow to an unstable size

and then suddenly collapse, releasing a tremendous amount of

energy into the fluid. If a soiled work piece is immersed in the

fluid, the cavitation bubbles will tend to collapse on the surfaces

of the parts. This creates a scrubbing action that literally

"blasts" away the contaminants from the parts.

795-93077-0115 TUSR24/36

Operation and

®

Advertisement

Table of Contents

Summary of Contents for Graymills LIFTKLEEN TUSR24 Series

- Page 1 795-93077-0115 TUSR24/36 Operation and Maintenance Instructions For units manufactured after January 2015 TUSR24/36 SERIES LIFTKLEEN ® ULTRASONIC HEATED/AQUEOUS PARTS WASHER Read all of the SAFETY INSTRUCTIONS in this manual BEFORE installing or using this equipment. Keep this manual handy for reference/training. PRINCIPLES OF ULTRASONIC CLEANING Ultrasonics is defined as a mechanical vibration above the The tank is filled with a fluid suitable for the cleaning...

-

Page 2: Safety Warnings

Provide sufficient clearance around the machine for fluid changeovers and servicing. If you have any questions regarding the recommended fluids to use in this unit, call Graymills at (773) 248-6825 and ask for Customer Service. Electrical Hazards Before performing any maintenance, be sure to disconnect all electrical power going to unit. -

Page 3: Installation

If you have any questions regarding the recommended fluids to Since operator safety at all times is a priority, we strongly use in this unit, call Graymills at (773) 248-6825 and ask for recommend that—whether or not required by local code—... -

Page 4: Applying Power

APPLYING POWER change in the pitch and volume of the sound of the unit that indicates de-gassing is taking place. At the end of the cycle the ultrasonics will turn off and the platform will rise. Run this cycle to de-gas the fluid. DO NOT RUN THIS UNIT WITHOUT FLUID IN TANk. -

Page 5: Operation

Do NOT exceed weight limit (TUSR24: 150lb, TUSR36: 200lb). Failure to keep coil immersed can cause heater to burn out. Make sure that parts do not extend beyond height of curved 2. The tank should be filled to approximately 6” below the lift bar. -

Page 6: Maintenance

Disconnect all power before servicing the ultrasonic generators surfaces. or tank heaters. As Necessary If in doubt about any servicing procedures, contact Graymills’ customer service department at 773-248-6825. • To prevent damage to painted surfaces, wipe up any cleaning fluid spills immediately. • When the cleaning action of the detergent solution Before performing any repairs or internal maintenance on diminishes, drain the tank and recharge with fresh fluid. - Page 7 V-Groove rollers (5A). The duration units displayed in the upper window of CYCLE 7. Inspect roller bearing, grease rollers at this time. Graymills TIMER control can be adjusted to any one of six intervals: rcommends the use of a marine grade grease for this 1 or 10 seconds, 1 or 10 minutes, 1 or 10 hours.

-

Page 8: Buttons And Functions

24/7 HEATER TIMER 4. Minutes will blink. Select minutes (+/-) and confirm with OK. 5. Day will blink. Select today’s day (+/-) and confirm with OK. 6. Program 01 will display with preset ON settings To select as The connection and installation is, press OK. -

Page 9: Troubleshooting Guide

Air pressure may be too low to lift load Increase air pressure to 100 psig lifting and lid If your problem is not listed above or problems persist, please contact Graymills for further assistance.1-888-472-9645 795-93077_0115 TUSR24/36 Operation and Maintenance Instructions 9... - Page 10 Figure 1 Figure 2 Control Function Control Box Main Power Turns the control power on or off. Green light illuminates when on. UP/DOWN platform switch Sends platform up or down. Sending platform down starts timed cycle Ultrasonic ON/OFF Turns ultrasonics on or off Heater ON/OFF Turns heater on.

-

Page 11: Specifications

KIT ASSEMBlY TUSR2420 TUSR3626 AVAILAbLE OPTIONS AND ACCESSORIES Part Number Part Number Description OAp-25 To extend life of heated fluids, order Graymills 746-92612 746-92515 Air Cylinder Oil Absorbent Pads (Part No. OAP-25) which are 729-90678 729-90678 1/4” Polyethylene Tubing ideal for surface oil removal. -

Page 12: Warranty

Buyer’s remedies thereunder (except to title) are within ninety days of any defect or failure and satisfactory solely and exclusively stated herein. In no case will Graymills proof thereof. be liable for consequential damages, loss of production or any other loss incurred due to interruption of service.

Need help?

Do you have a question about the LIFTKLEEN TUSR24 Series and is the answer not in the manual?

Questions and answers