Summary of Contents for CNH Cursor 9

- Page 1 SERVICE MANUAL Cursor ® Tier 4A (interim) and Stage IIIB Engine See the following page for engine model numbers Part number 48076828 edition English November 2016 Replaces part numbers 84394558, 84394568, 84394551, 84394547...

- Page 2 SERVICE MANUAL F2CFE613A*A, F2CFE613C*A, F2CFE613E*A, F2CFE613F*A, F2CFE613H*A, F2CFE613J*A, F2CFE613L*A026, F2CFE613L*A, F2CFE613N*A, F2CFE613P*A, F2CFE613R*A, F2CFE614A*A, F2CFE614B*A, F2CFE614C*A, F2CFE614D*A, F2CFE614E*A 48076828 09/11/2016 Find manuals at https://best-manuals.com...

- Page 3 Contents INTRODUCTION Engine..................10 [10.001] Engine and crankcase ............. 10.1 [10.120] Engine brake .

- Page 4 [55.988] Selective Catalytic Reduction (SCR) electrical system ......55.6 [55.012] Engine cooling system ............. 55.7 [55.013] Engine oil system .

- Page 5 48076828 09/11/2016 Find manuals at https://best-manuals.com...

- Page 6 INTRODUCTION 48076828 09/11/2016 Find manuals at https://best-manuals.com...

-

Page 7: Table Of Contents

Contents INTRODUCTION Foreword ..................3 Safety rules . -

Page 8: Foreword

Improper disposal of batteries can contaminate the soil, groundwater, and waterways. CNH strongly recommends that you return all used batteries to a CNH dealer, who will dispose of the used batteries or recycle the used batteries properly. In some countries, this is a legal requirement. - Page 9 INTRODUCTION • Store the returned batteries in a suitable location • Send the returned batteries to the battery manufacturer for recycling 48076828 09/11/2016 Find manuals at https://best-manuals.com...

-

Page 10: Safety Rules

INTRODUCTION Safety rules Personal safety This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that follow this symbol to avoid possible death or injury. Throughout this manual and on machine decals, you will find the signal words DANGER, WARNING, and CAUTION followed by special instructions. -

Page 11: Basic Instructions - Important Notice Regarding Equipment Servicing

Some information could not be updated due to modifications of a technical or commercial type, or changes to the laws and regulations of different countries. In case of questions, refer to your CNH Sales and Service Networks. 48076828 09/11/2016... -

Page 12: Basic Instructions - Shop And Assembly

Only use "CNH Original Parts" or " CNH Parts". Only genuine spare parts guarantee the same quality, duration and safety as original parts, as they are the same parts that are assembled during standard production. Only "CNH Original Parts" or " CNH Parts" can offer this guarantee. - Page 13 84-110 TOOLS The tools that CNH suggests and illustrate in this manual have been: • specifically researched and designed for use with CNH machines • essential for reliable repair operations • accurately built and rigorously tested so as to offer efficient and long-lasting operation By using these tools, repair personnel will benefit from: •...

-

Page 14: Torque - Minimum Tightening Torques For Normal Assembly

INTRODUCTION Torque - Minimum tightening torques for normal assembly METRIC NON-FLANGED HARDWARE NOM. LOCKNUT LOCKNUT SIZE CL.8 CL.10 CLASS 8.8 BOLT and CLASS 10.9 BOLT and W/CL8.8 W/CL10.9 CLASS 8 NUT CLASS 10 NUT BOLT BOLT PLATED PLATED UNPLATED UNPLATED W/ZnCr W/ZnCr 2.2 N·m (19 lb... - Page 15 INTRODUCTION METRIC FLANGED HARDWARE NOM. CLASS 8.8 BOLT and CLASS 10.9 BOLT and LOCKNUT LOCKNUT SIZE CLASS 8 NUT CLASS 10 NUT CL.8 CL.10 W/CL8.8 W/CL10.9 BOLT BOLT PLATED PLATED UNPLATED UNPLATED W/ZnCr W/ZnCr 2.4 N·m (21 lb 3.2 N·m (28 lb 3.5 N·m (31 lb 4.6 N·m (41 lb 2.2 N·m (19 lb...

- Page 16 INTRODUCTION 1. Manufacturer's Identification 2. Property Class 3. Clock Marking of Property Class and Manufacturer's Identification (Optional), i.e. marks 60 ° apart indicate Class 10 properties, and marks 120 ° apart indicate Class 8. INCH NON-FLANGED HARDWARE LOCKNUT LOCKNUT NOMINAL SAE GRADE 5 BOLT SAE GRADE 8 BOLT GrB W/ Gr5...

- Page 17 INTRODUCTION INCH FLANGED HARDWARE NOM- LOCKNUT LOCKNUT SAE GRADE 5 BOLT and SAE GRADE 8 BOLT and INAL GrF W/ Gr5 GrG W/ Gr8 SIZE BOLT BOLT UNPLATED PLATED UNPLATED PLATED or PLATED W/ZnCr or PLATED W/ZnCr SILVER GOLD SILVER GOLD 12 N·m (106 lb 13 N·m (115 lb...

- Page 18 INTRODUCTION Inch Lock Nuts, All Metal (Three optional methods) 20090268 Grade Identification Grade Corner Marking Method (1) Flats Marking Method (2) Clock Marking Method (3) Grade A No Notches No Mark No Marks Grade B One Circumferential Notch Letter B Three Marks Grade C Two Circumferential Notches...

- Page 19 CONSUMABLES INDEX Consumable Reference PAGE Loctite RTV 598 Basic instructions - Shop and Assembly Loctite® Instant Gasket 587 Basic instructions - Shop and Assembly Blue 48076828 09/11/2016...

- Page 20 SERVICE MANUAL Engine F2CFE613A*A, F2CFE613C*A, F2CFE613E*A, F2CFE613F*A, F2CFE613H*A, F2CFE613J*A, F2CFE613L*A026, F2CFE613L*A, F2CFE613N*A, F2CFE613P*A, F2CFE613R*A, F2CFE614A*A, F2CFE614B*A, F2CFE614C*A, F2CFE614D*A, F2CFE614E*A 48076828 09/11/2016...

- Page 21 Contents Engine - 10 [10.001] Engine and crankcase ............. . . 10.1 [10.120] Engine brake .

- Page 22 [10.408] Oil cooler and lines ..............10.19 48076828 09/11/2016...

- Page 23 CONSUMABLES INDEX Consumable Reference PAGE Engine oil pan - Install Loctite® 5970™ 10.3 / 6 Loctite® 5970™ Engine oil pan - Install 10.3 / 6 Loctite® 5970™ Engine block cover Front - Install 10.3 / 10 Loctite® SI 598™ Black Engine block cover Rear - Install 10.3 / 12 Loctite®...

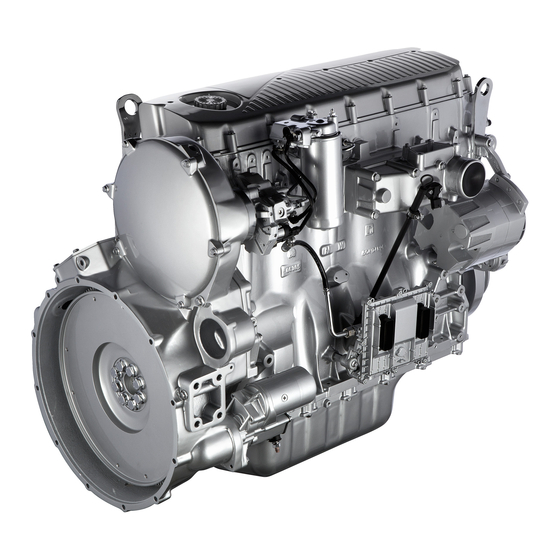

- Page 24 Engine - 10 Engine and crankcase - 001 F2CFE613A*A, F2CFE613C*A, F2CFE613E*A, F2CFE613F*A, F2CFE613H*A, F2CFE613J*A, F2CFE613L*A026, F2CFE613L*A, F2CFE613N*A, F2CFE613P*A, F2CFE613R*A, F2CFE614A*A, F2CFE614B*A, F2CFE614C*A, F2CFE614D*A, F2CFE614E*A 48076828 09/11/2016 10.1 [10.001] / 1...

- Page 25 Contents Engine - 10 Engine and crankcase - 001 TECHNICAL DATA Engine Service limits ................3 FUNCTIONAL DATA Engine Detailed view .

- Page 26 Engine - Engine and crankcase Engine - Service limits Engine specifications Compression ratio 15.9:1 Bore 117 mm (4.6 in) Stroke 135 mm (5.3 in) Cylinder spacing 138 mm (5.4 in) Displacement 8710 cm³ Turbocharging Inter-cooled, Direct injection Lubrication Forced by gear pump, relief valve single action oil filter Oil pressure (Warm engine) - Idling 4 bar (58 psi)

- Page 27 Engine - Engine and crankcase Piston pin OD - pin bore 0.016 - 0.028 mm (0.0006 - 0.0011 in) Piston ring grooves - Top 2.582 - 2.716 mm (0.102 - 0.107 in) - Middle 2.550 - 2.570 mm (0.100 - 0.101 in) - Bottom 4.02 - 4.04 mm (0.158 - 0.159 in) Piston rings...

- Page 28 Engine - Engine and crankcase Big end bearing shells - Red 1.994 - 2.002 mm (0.079 - 0.079 in) - Green 2.002 - 2.010 mm (0.079 - 0.079 in) - Yellow 2.010 - 2.018 mm (0.079 - 0.079 in) Main bearing housings - Rated value 99.000 - 99.030 mm (3.8976 - 3.8988 in) - Class 1...

- Page 29 Engine - Engine and crankcase Camshaft bearing journals 64.924 - 64.940 mm (2.556 - 2.557 in) O.D. of the camshaft bushings 69.090 - 69.130 mm (2.720 - 2.722 in) I.D. of the camshaft bushings 65.080 - 65.116 mm (2.562 - 2.564 in) Clearance between bushings and housings in 0.060 - 0.115 mm (0.002 - 0.005 in) the cylinder head...

- Page 30 Engine - Engine and crankcase Engine - Detailed view NHIL13ENG1011FA Left-hand side view NHIL13ENG1019FA Right-hand side view 48076828 09/11/2016 10.1 [10.001] / 7...

- Page 31 This as a preview PDF file from best-manuals.com Download full PDF manual at best-manuals.com...

Need help?

Do you have a question about the Cursor 9 and is the answer not in the manual?

Questions and answers

Моменты затяжки болтов головки блока курсор 9 ивеко

The torque specifications for the head bolts on the CNH Cursor 9 engine are not provided in the available context.

This answer is automatically generated

Какой зазор должен быть между гильзой и поршнем курсор 9

ДОБРЫЙ ДЕНЬ ДАЙТЕ ПОЖАЛУСТА РАЗМЕРЫ ЗАЗОРОВ КЛАПАНОВ CURSOR 9 IVECO CNG