Subscribe to Our Youtube Channel

Summary of Contents for Tektronix TDS 520A

- Page 1 sales@artisantg.com artisantg.com (217) 352-9330 | Visit our website - Click HERE...

- Page 2 Service Manual TDS 520A, 524A, 540A, & 544A Digitizing Oscilloscope 070–8713–03 Warning The servicing instructions are for use by qualified personnel only. To avoid personal injury, do not perform any servicing unless you are qualified to do so. Refer to the Safety...

- Page 3 Instrument Serial Numbers Each instrument manufactured by Tektronix has a serial number on a panel insert or tag, or stamped on the chassis. The first letter in the serial number designates the country of manufacture. The last five digits of the serial number are assigned sequentially and are unique to each instrument.

- Page 4 Tektronix, with shipping charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the Tektronix service center is located.

-

Page 6: Table Of Contents

........1 21 TDS 520A, 524A, 540A, & 544A Service Manual... - Page 7 ..........Tektronix Service .

- Page 8 ........Verify the Main and Delayed Trigger Systems ... . . 4 10 Verify the File System (Optional on TDS 520A and 540A) . . . 4 12 Performance Tests .

- Page 9 ......5 19 Brightness and Contrast Adjustment (TDS 520A and 540A - Monochrome - Only) ..5 19...

- Page 10 ........6 64 TDS 520A, 524A, 540A, & 544A Service Manual...

- Page 11 Table of Contents Options Electrical Parts List Diagrams Mechanical Parts List Contents...

- Page 12 Figure 4 17: Measurement of Trigger level Accuracy ....4 47 Figure 4 18: Initial Test Hookup TDS 520A and 524A Only ..4 49 Figure 4 19: Initial Test Hookup TDS 540A and 544A Only .

- Page 13 ......6 13 Figure 6 3: Inner Chassis Modules - TDS 520A or 540A with A20 Display Assembly .

- Page 14 6 52 Figure 6 25: Display Assembly Removal - TDS 524A and 544A . . . 6 55 Figure 6 26: Display Assembly Removal - TDS 520A and 540A . . . 6 56 Figure 6 27: Display Driver Board Removal .

- Page 15 List of Figures Contents...

- Page 16 Table 6 6: No Load Supply Voltages (Measured on J5 and J6 on the A17 Main LV Power Supply Module) ..... 6 68 TDS 520A, 524A, 540A, & 544A Service Manual...

- Page 17 List of Tables Table 7 1: International Power Cords ......Table 7 2: Standard Accessories .

-

Page 18: Safety Summary

DANGER indicates a personal injury hazard immediately accessible as one reads the marking. This symbol appears in manuals: Static Sensitive Devices These symbols appear on equipment: DANGER Protective ATTENTION High Voltage ground (earth) Refer to terminal manual xiii TDS 520A, 524A, 540A, & 544A Service Manual... - Page 19 Disconnect power before removing protective panels, soldering, or replacing components. Power Source The TDS 520A, 524A, 540A, & 544A is intended to operate from a power source that will not apply more than 250 V between the supply conductors or between either supply conductor and ground. A protective ground connec tion, through the grounding conductor in the power cord, is essential for safe system operation.

- Page 20 540A, & 544A in an atmosphere of explosive gasses. Electric Overload Never apply a voltage to a connector on the TDS 520A, 524A, 540A, & 544A that is outside the range specified for that connector. TDS 520A, 524A, 540A, & 544A Service Manual...

- Page 21 Safety Summary Safety...

-

Page 22: Specifications

Specifications Replace this page with the Tab named Specifications... -

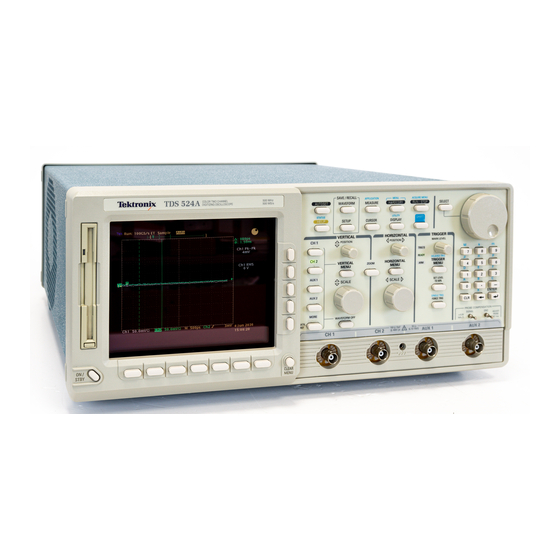

Page 24: General Product Description

Full GPIB software programmability. Hardcopy output using GPIB, RS 232, or Centronics ports (RS 232 and Centronics is standard on the TDS 524A and 544A and optional, as option 13, on the TDS 520A and 540A). Complete measurement and documentation capability. -

Page 25: User Interface

A 1.44 Mbyte, DOS 3.3 or later, floppy disk drive for saving waveforms, color images, and oscilloscope setups (standard on the TDS 524A and 544A and optional, as option 1F, on the TDS 520A and 540A). Also, all TDS 500A have built in NVRAM storage for saving waveforms and setups. -

Page 26: General Purpose Knob

CH1 and CH2 can also have their bandwidth limited (100 MHz or 20 MHz), their vertical coupling specified, and fine gain adjusted. On all TDS 520A, 524A, 540A, & 544A: Besides the four channels, up to three math waveforms and four reference waveforms are available for display. (A math waveform results when dual waveform operations, such as add, are specified on any two channels. -

Page 27: Horizontal System

Specifications Horizontal System There are three horizontal display modes: main only, main intensified, and delayed only. You can select among various horizontal record length settings. A feature called Fit to Screen" allows the user to view entire waveform re cords within the 10 division screen area. In other words, waveforms are compressed to fit on the screen. -

Page 28: Trigger System

10%, 50%, and 90% of pretrigger data in the horizontal menu, or assign the general purpose knob to set pretrigger data to any value within the limits of trigger position resolution. TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 29: Acquisition Control

Specifications Acquisition Control You can specify a mode and manner to acquire and process signals. Select equivalent time sampling on repetitive signals or interpolation of points sampled on non repetitive signals. Both can increase apparent sample rate on the waveform when maximum real time rates are reached. The apparent sample rate can be increased, even further, by using the FastFrame feature. -

Page 30: Measure

Digital Signal Processing (DSP) An important component of the multiprocessor architecture of this Digitizing Oscilloscopes is Tektronix's proprietary digital signal processor, the DSP . This dedicated processor supports advanced analysis of your waveforms when doing such compute intensive tasks as interpolation, waveform math, and signal averaging. -

Page 31: Display

GPIB, RS 232C, or Centronics interfaces. Display The TDS 520A, 524A, 540A, & 544A Digitizing Oscilloscopes offer flexible display options. You can customize the following attributes of your display: Color: Waveforms, readouts, graticule, etc. on the TDS 524A and 544A;... -

Page 32: Nominal Traits

8 bits Input Channels, Number of TDS 540A and 544A: Four, all identical, called CH1 - CH4 TDS 520A and 524A: Two full featured (CH1 and CH2), plus two lim ited, auxiliary inputs (AUX1 and AUX2) Input Coupling DC, AC, or GND... - Page 33 5 Samples/s - 500 MSamples/s 3 or 4 5 Samples/s - 250 MSamples/s Range, Sample Rate Number of Sample Rate TDS 520A, 524A Channels On Range 5 Samples/s - 500 MSamples/s 5 Samples/s - 250 MSamples/s Range, Equivalent Time or Interpolated...

- Page 34 Waveform Display Colors/Grey Scale TDS 524A and 544A: Sixteen colors in infinite persistence or variable persistence display with color coding. TDS 520A and 540A: Sixteen levels in infinite persistence and vari able persistence display styles. 1 11 TDS 520A, 524A, 540A, & 544A Service Manual...

- Page 35 GPIB interface complies with IEEE Std 488-1987 Interface, RS 232 RS 232 interface complies with EIA/TIA 574 (talk only) (optional, as option 13, on TDS 520A and 540A) Interface, Centronics Centronics interface complies with Centronics interface standard C332 44 Feb 1977, REV A...

- Page 36 Construction Material Chassis parts constructed of aluminum alloy; front panel constructed of plastic laminate; circuit boards constructed of glass laminate. Cab inet is aluminum and is clad in Tektronix Blue vinyl material. Finish Type Tektronix Blue vinyl clad aluminum cabinet...

- Page 37 Nominal Traits 1 14 Specifications...

-

Page 38: Warranted Characteristics

Warranted Characteristics This subsection lists the electrical and environmental warranted characteristics that describe the TDS 520A, 524A, 540A, & 544A Digitizing Oscilloscopes. Warranted characteristics are described in terms of quantifiable performance limits which are warranted. NOTE In these tables, those warranted characteristics that are checked in the procedure Performance Verification, found in Section 4, appear in boldface type under the column Name. - Page 39 Warranted Characteristics Table 1 8: Warranted Characteristics Signal Acquisition System (Cont.) Name Description Analog Bandwidth, DC 50 W Coupled Volts/Div Bandwidth or DC 1 MW Coupled 5 mV/div - 10 V/div DC - 500 MHz 2 mV/div - 4.98 mV/div DC - 350 MHz 1 mV/div - 1.99 mV/div DC - 250 MHz...

- Page 40 The TRIG'D LED stays constantly lighted when the SEC/DIV setting is 2 ms or faster but may flash when the SEC/DIV setting is 10 ms or slower. 1 17 TDS 520A, 524A, 540A, & 544A Service Manual...

- Page 41 Warranted Characteristics Table 1 11: Warranted Characteristics Interfaces, Output Ports and Power Requirements Name Description Logic Levels, Main and Delayed Characteristic Limits Trigger Outputs Vout (HI) w2.5 V open circuit; w1.0 V into a 50 W load to ground v0.7 V into a load of v4 mA; Vout (LO) v0.25 V into a 50 W load to ground Output Voltage and Frequency,...

- Page 42 Operating: 0_ C to +50_ C; Non operating: -40_ C to +60_ C Relative humidity with floppy disk (optional on TDS 520A and 540A): Operating: To 80%, at or below +29_ C; Operating: To 20%, at or below +50_ C Non operating: To 90%, at or below +40_ C;...

- Page 43 Warranted Characteristics 1 20 Specifications...

-

Page 44: Typical Characteristics

Typical Characteristics The tables in this subsection list the typical characteristics that describe the TDS 520A, 524A, 540A, & 544A Digitizing Oscilloscopes. Typical characteristics are described in terms of typical or average performance. Typical characteristics are not warranted. Table 1 13: Typical Characteristics... - Page 45 Name Description Step Response Settling Errors Volts/Div Setting Step Settling Error (%) TDS 540A and 544A, all channels, Amplitude TDS 520A and 524A, CH1, CH2 only 20 ns 100 ns 20 ms 1 mV/div-99.5 mV/div v2 V v0.5 v0.2 v0.1...

- Page 46 25 divisions/ms at the trigger level or the threshold crossing. Sensitivities, Pulse Type Runt Trigger 1.0 division, from DC to 200 MHz with a minimum slew rate of 25 divisions/ms at the trigger level or the threshold crossing. 1 23 TDS 520A, 524A, 540A, & 544A Service Manual...

- Page 47 3.5 inch, 720 K or 1.44 Mbyte, DOS 3.3 or later compatible Standard on TDS 540A, 544A Option 1F on TDS 520A, 524A 1 The time that reference waveforms, stored setups, and calibration constants are retained when there is no power to the oscillo scope.

-

Page 48: Operating Information

Operating Replace this page with the tab named Operating Information Information... -

Page 50: Using This Manual

Before Servicing This manual is for servicing the TDS 520A, 524A, 540A, & 544A Digitizing Oscilloscopes. To prevent injury to yourself or damage to the oscilloscope, do the following before you attempt service: Be sure you are a qualified service person;... -

Page 51: Manual Structure

The following is a brief description of each manual section. Specifications contains a product description of the TDS 520A, 524A, 540A, & 544A Digitizing Oscilloscopes and tables of the characteristics and descriptions that apply to it. -

Page 52: Manual Conventions

Various icons such as the example icon at the left are used in proce dures to help identify certain readouts and menu functions on screen. TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 53: Tektronix Service

Of these services, the annual maintenance agreement offers a particularly cost effective approach to service for many owners of the TDS 520A, 524A, 540A, & 544A Digitizing Oscilloscopes. Such agreements can be purchased to span several years. -

Page 54: Self Service

Information TDS 520A, 524A, 540A, & 544A User Manual contains a tutorial to quickly show you how to operate the TDS 520A, 524A, 540A, & 544A Digitizing Oscilloscopes and an in depth discussion of how to more completely use its features. - Page 55 Using This Manual Operating Information...

-

Page 56: General Information

250 volts. Before making connection to the power source, be sure the TDS 520A, 524A, 540A, or 544A has a suitable two pole, three terminal grounding type plug. GROUNDING. This instrument is safety Class 1 equipment (IEC designation). -

Page 57: Power Cord Information

Power Cord Information A power cord with appropriate plug configuration is supplied with each TDS 520A, 524A, 540A, & 544A Digitizing Oscilloscope. Table 2 1 gives the color coding of the conductors in the power cord. If you require a power cord other than the one supplied, refer to Figure 2 1 Power Cord and Plug Identification. -

Page 58: Figure 2 1: Power Cord Plug Identification

North American American 230V 115V/High Power 3 Phase 230V * Canadian Standards Association certification includes these power plugs for use in the North American power network Figure 2 1: Power Cord Plug Identification TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 59: Operating Environment

Environment Operating Temperature The TDS 520A, 524A, 540A, & 544A Digitizing Oscilloscopes can be operated where the ambient air temperature is between +4_ (0_ without the floppy disk) and +50_ C and can be stored in ambient temperatures from -22_ (-40_ without the floppy disk) to +60_ C. -

Page 60: Applying And Interrupting Power

A voltage reference adjustment is re quired (Section 5). Frequency Response A frequency response adjustment is re quired (Section 5). Error Log Errors logged are lost. Reference Waveforms Waveform Lost. Saved Setups Setup Lost. 2 11 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 61: Repackaging Instructions

275 pounds and with an inside dimension at least six inches greater than the Instructions instrument dimensions. If the instrument is being shipped to a Tektronix Service Center, enclose the following information: the owners address, name and phone number of a contact person, type and serial number of the instrument, reason for returning, and a complete description of the service required. -

Page 62: General Operating Instructions

General Operating Instructions This subsection contains general operating instructions for the TDS 520A, 524A, 540A, & 544A Digitizing Oscilloscopes. The complete operators in structions are found in the User Manual. Additional instructions are integrated into the service procedures found in later sections of this manual. -

Page 63: How To Use Help

General Operating Instructions Position of waveform General purpose record relative to knob readout. the screen and display. Brief status information. Graticule and waveforms Waveform reference symbols: ground levels and waveform sources. Vertical scale, horizontal scale, and trigger level readouts. Pop up menu Side menu area. -

Page 64: How To Set Functions

Special Function Controls: Access all functions except vertical, horizontal, and trigger functions from this front panel control block. CH 1 CH 2 MORE CH 1 CH 2 2 15 TDS 520A, 524A, 540A, & 544A Service Manual... - Page 65 General Operating Instructions 2. Select the waveform source(s). Position, scale, and set trigger level for waveform source(s) directly from the front panel. (Examples of possible control selections are given in the steps that follow.) CH 1 CH 2 MORE CH 1 CH 2 a.

- Page 66 Example: Push Coupling (13). e. Select the setting for the function from the side menu (9) using the side menu buttons (11). Example: Push AC (10). 2 17 TDS 520A, 524A, 540A, & 544A Service Manual...

-

Page 67: How To Set Complex Functions

General Operating Instructions How to Set Complex Functions A few functions require more than just two levels (main and side) of menus to completely specify their settings. In such cases, either the main menu, the side menu, or both are modified to supply additional choices. The proce dures that follow show both schemes. - Page 68 The general purpose knob can also be assigned to control the following functions: Cursor positioning Display intensities Delay time Number of events Trigger position Holdoff 2 19 TDS 520A, 524A, 540A, & 544A Service Manual...

- Page 69 General Operating Instructions Offset Variable persistence In all cases, the menus are used to select the function to which the general purpose knob is assigned. The following attributes apply to this knob: Depending on the function it is assigned to control, the general purpose knob may vary numerical readouts, position objects (cursors) on screen, or select between icon label settings that show up in side menu labels.

- Page 70 From the Utility menu, you can configure the GPIB port (talk/listen, address, etc.) and access internal routines for self diagnostics and self compensation. Instructions for setting up communication over the GPIB are found in Sec tion 5, Adjustment Procedures. 2 21 TDS 520A, 524A, 540A, & 544A Service Manual...

- Page 71 General Operating Instructions 2 22 Operating Information...

-

Page 72: Theory Of Operation

Theory of Replace this page with the Tab named Theory of Operation Operation... -

Page 74: Circuit Description

Circuit Description This section describes the electrical operation of the TDS 520A, 524A, 540A, & 544A Digitizing Oscilloscopes using the major circuit blocks or modules. This section has two main parts: Logic Conventions describes how logic functions are discussed and represented in this manual. - Page 75 Circuit Description Attenuators Circuitry in the attenuator selects the input coupling, termi nation, and the attenuation factor. The processor system, by way of the acquisition system, controls the attenuators. For example, if 50 W input termi nation is selected and the input is overloaded, the processor system switches the input to the 1 MW position.

- Page 76 Tube Assembly All information (waveforms, text, graticules, and pictographs) is displayed by the A20 (for the TDS 520A and 540A) or the A30/31/32 (for the TDS 524A and 544A) Display system. The Display system generates the high voltages necessary to drive the display tube. It also contains the video amplifier, hori zontal oscillator, and the vertical and horizontal yoke driver circuitry.

- Page 77 Circuit Description Theory of Operation...

-

Page 78: Performance Verification

Performance Replace this page with the Tab named Performance Verification Verification... -

Page 80: Brief Procedures

If you are not familiar with operating this oscilloscope, read the TDS 520A, 524A, 540A, 544A, & 644A Reference or the TDS 520A, 524A, 540A, & 544A User manual. These contain instructions that acquaint you with the use of the front panel controls and the menu system. -

Page 81: Conventions

Brief Procedures Conventions Throughout these procedures the following conventions apply: Each test procedure uses the following general format: Title of Test Equipment Required Prerequisites Procedure Each procedure consists of as many steps, substeps, and subparts as required to do the test. Steps, substeps, and subparts are sequenced as follows: 1. -

Page 82: Figure 4 1: Map Of Display Functions

Pop up Menu measurements move here when CLEAR MENU is pressed. Main menu display area. Readouts in lower graticule area move here when CLEAR MENU is pressed. Figure 4 1: Map of Display Functions TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 83: Self Tests

Brief Procedures Self Tests This procedure uses internal routines to verify that this oscilloscope functions and was adjusted properly. No test equipment or hookups are required. Verify Internal Adjustment, Self Compensation, and Diagnostics Equipment Required: None. Prerequisites: Power on the Digitizing Oscilloscopes and allow a 20 minute warm up before doing this procedure. -

Page 84: Figure 4 2: Verifying Adjustments And Signal Path Compensation

Confirm signal path compensation returns passed status: Verify the word Pass appears under Signal Path in the main menu. (See Fig ure 4 2.) 2. Return to regular service: Press CLEAR MENU to exit the system menus. TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 85: Functional Tests

Brief Procedures Functional Tests The purpose of these procedures is to confirm that this oscilloscope functions properly. The only equipment required is one of the standard accessory probes and, to check the file system, a 3.5 inch. 720 K or 1.44 Mbyte floppy disk. - Page 86 (Note that there is noise present on the peaks of the square wave.) Peak Detect mode displays an actively acquiring waveform on screen with the noise present in Sample mode peak de tected." TDS 520A, 524A, 540A, & 544A Service Manual...

- Page 87 Be sure to check only CH 1 and CH 2 when testing the TDS 520A or 524A. (Step 3 will test the AUX 1 and AUX 2 inputs.) When testing the TDS 540A or 544A, test all four channels, CH 1 through CH 4.)

-

Page 88: Verify The Time Base

The horizontal POSITION knob positions the signal left and right on screen when rotated. 3. Remove the test hookup: Disconnect the probe from the channel input and the probe compensation terminals. TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 89: Verify The Main And Delayed Trigger Systems

Brief Procedures Verify the Main and Delayed Trigger Systems Equipment Required: One P6139A probe. Prerequisites: None. Procedure: 1. Install the test hookup and preset the oscilloscope controls: a. Hook up the signal source: Install the probe on CH 1. Connect the probe tip to PROBE COMPENSATION SIGNAL on the front panel;... - Page 90 4. Remove the test hookup: Disconnect the standard accessory probe from the channel input and the probe compensation terminals. 4 11 TDS 520A, 524A, 540A, & 544A Service Manual...

-

Page 91: Verify The File System (Optional On Tds 520A And 540A)

Brief Procedures Verify the File System (Optional on TDS 520A and 540A) Equipment Required: One P6139A probe and one 720 K or 1.44 Mbyte, 3.5 inch DOS compatible disk. You can use a disk of your own or you can use the Programming Examples Software 3.5 inch disk (Tektronix part number... - Page 92 Disconnect the standard accessory probe from the channel input and the probe compensation terminals. Remove the disk from the disk drive. Do this by pushing in the tab at the bottom of the disk drive. 4 13 TDS 520A, 524A, 540A, & 544A Service Manual...

- Page 93 Brief Procedures 4 14 Performance Verification...

-

Page 94: Performance Tests

+4_ C and +50_ C. (The warm up require ment is usually met in the course of meeting the first prerequisite listed above.) Related Information Read General Instructions and Conventions that start on page 4 1. 4 15 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 95: Equipment Required

Female BNC to dual banana Tektronix part number Various Accuracy Banana (two 103-0090-00 Tests required) Connector, BNC Male BNC to dual female BNC Tektronix part number Checking Trigger T" 103-0030-00 Sensitivity Coupler, Dual Female BNC to dual male Tektronix part number... - Page 96 Option 05 Equipped Instruments Only 20 Termination, Impedance 75 W; connectors: Tektronix part number Used to Test Video 75 W female BNC input, male BNC 011-0102-01 Option 05 Equipped output Instruments Only 4 17 TDS 520A, 524A, 540A, & 544A Service Manual...

- Page 97 Performance Tests 4 18 Performance Verification...

-

Page 98: Test Record

5 mV Vert scale setting, + 1.0355 V __________ __________ + 1.0445 V -5 Div position setting 5 mV Vert scale setting, - 1.0445 V __________ __________ - 1.0355 V +5 Div position setting 4 19 TDS 520A, 524A, 540A, & 544A Service Manual... - Page 99 Performance Tests TDS 500A Test Record (Cont.) Instrument Serial Number: Certificate Number: Temperature: RH %: Date of Calibration: Technician: Performance Test Minimum Incoming Outgoing Maximum 200 mV Vert scale setting, + 11.525 V __________ __________ + 11.675 V -5 Div position setting 200 mV Vert scale setting, - 11.675 V __________...

- Page 100 CH 3 SIGNAL OUTPUT, 1 M W Pk Pk 90 mV __________ __________ Pk Pk 110 mV CH 3 SIGNAL OUTPUT, 50 W Pk Pk 45 mV __________ __________ Pk Pk 55 mV 4 21 TDS 520A, 524A, 540A, & 544A Service Manual...

- Page 101 Performance Tests TDS 500A Test Record (Cont.) Instrument Serial Number: Certificate Number: Temperature: RH %: Date of Calibration: Technician: Performance Test Minimum Incoming Outgoing Maximum Probe Compensator Output Signal Frequency (CH1 Freq.) 950 Hz __________ __________ 1050 Hz Voltage (difference) 495 mV __________ __________...

-

Page 102: Signal Acquisition System Checks

Select an unchecked channel: Press WAVEFORM OFF to remove the channel just confirmed from the display. Then, press the front panel button that corresponds to the channel you are to confirm. 4 23 TDS 520A, 524A, 540A, & 544A Service Manual... - Page 103 CH 1 CH 4; ignore the columns for AUX 1 & AUX 2 settings and limits. Model TDS 520A, 524A Only Use Table 4 2 to test input channels; use the columns for CH 1 CH 4 when testing CH 1 and CH 2; use the columns for AUX 1 and AUX 2 when testing those channels.

-

Page 104: Check Dc Gain And Voltage Measurement Accuracy

Equipment Required: Two dual banana connectors (Item 5), one BNC T connector (Item 6), one DC calibration generator (Item 8), and two precision coaxial cables (Item 4). Prerequisites: The oscilloscope must meet the prerequisites listed on page 4 15. 4 25 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 105: Figure 4 5: Initial Test Hookup

Performance Tests Procedure: 1. Install the test hookup and preset the instrument controls (see Figure 4 5): DC Calibrator Output Sense Dual Banana to BNC Adapters 50 W Coaxial Cables BNC T Connector Figure 4 5: Initial Test Hookup a. Hook up the test signal source: Set the output of a DC calibration generator to 0 volts. - Page 106 (D:) readout, not the absolute (@:) readout. See Figure 4 6 on page 4 28. d. Check against limits: CHECK that the D: readout on screen is within 485 mV to 515 mV (see Figure 4 6). 4 27 TDS 520A, 524A, 540A, & 544A Service Manual...

-

Page 107: Figure 4 6: Measurement Of The Dc Accuracy For Delta

Performance Tests First align a cursor to the DC baseline (no input). Second align the second cursor to the DC test level that you input. Third read the results of the measurement here. Figure 4 6: Measurement of the DC Accuracy for Delta Measurements e. - Page 108 Set its vertical scale: Set the vertical SCALE to one of the settings listed in Table 4 3 (and Table 4 4 for the TDS 520A and 524A) that is not yet checked. (Start with the first setting listed.)

- Page 109 Performance Tests Table 4 4: DC Accuracy: AUX 1-AUX 2 Scale Position Offset Generator Accuracy Setting Setting Setting Setting Limits (Divs) 100 mV +0.5 V +1.3 V +1.271 V to +1.329 V -0.5 V -1.3 V -1.271 V to -1.329 V +5 V +13 V +12.710 V to +13.290 V...

-

Page 110: Figure 4 7: Measurement Of Dc Accuracy At Maximum Offset And Position

Repeat substeps c through f until all vertical scale settings set tings listed in Table 4 3 (and Table 4 4 for the TDS 520A and 524A) are checked for the channel under test. g. Test all channels: Repeat substeps a through f for all four channels. -

Page 111: Check Analog Bandwidth

Performance Tests Check Analog Bandwidth Equipment Required: One high frequency leveled sine wave generator and its leveling head (Item 11), plus two10X attenuators (Item 1). Prerequisites: See page 4 15. Procedure: 1. Install the test hookup and preset the instrument controls: a. - Page 112 1 ns 500 MHz w42 mV 5 mV 30 mV (6 divisions) 1 ns 500 MHz w21 mV 2 mV 12 mV (6 divisions) 2 ns 350 MHz w8.48 mV 4 33 TDS 520A, 524A, 540A, & 544A Service Manual...

-

Page 113: Figure 4 9: Measurement Of Analog Bandwidth

Performance Tests e. Display the test signal: Do the following subparts to first display the reference signal and then the test signal. Press MEASURE; then press the main menu button Select Measrmnt for CHx. Now press the side menu button more until the menu label Pk Pk appears in the side menu (its icon is shown at the left). - Page 114 Test all channels: Repeat substeps a through g for all four channels. 3. Disconnect the hookup: Disconnect the test hook up from the input connector of the channel last tested. 4 35 TDS 520A, 524A, 540A, & 544A Service Manual...

-

Page 115: Check Delay Between Channels

Performance Tests Check Delay Between Channels Equipment Required: One medium frequency leveled sine wave generator (Item 10), one precision, 50 W, coaxial cable (Item 4), one 50 W terminator (Item 3), and a dual input coupler (Item 7). Prerequisites: See page 4 15. Procedure: DO NOT use the vertical position knob to reposition any channel while doing this check. - Page 116 TO 50% frequently to speed up the updating of the waveform ampli tude on screen. TDS 520A and 524A only: Press CH 2; then skip to substep e and continue this check. If testing a TDS 540A or 544A model, continue with the next substep, b.

-

Page 117: Figure 4 11: Measurement Of Channel Delay

Performance Tests Read the measurement results at the D: cursor readout, not the @: readout on screen. First, display the live/reference waveforms for channels. Note their overlapping ground reference indicators. Second, identify the time reference points of those waveforms. Third, turn on the cursor and align the V bar cursors to the time reference points. -

Page 118: Time Base System Checks

Press VERTICAL MENU; then press the main menu button Coupling. Press the side menu W button to 50 W. Press SET LEVEL TO 50%. Use the vertical POSITION knob to center the test signal on screen. 4 39 TDS 520A, 524A, 540A, & 544A Service Manual... - Page 119 Performance Tests Set the horizontal SCALE of the Main time base to 1 ms. Press TRIGGER MENU; then press the main menu button Mode & Holdoff. Now press the side menu button Normal. Press SET LEVEL TO 50%. Press horizontal MENU. Press the main menu button Record Length;...

- Page 120 CHECK that the readout for CH 1 Per is within 19.760 ns to 20.240 ns. 3. Disconnect the hookup: Disconnect the cable from the generator output at the input connector of CH 1. 4 41 TDS 520A, 524A, 540A, & 544A Service Manual...

-

Page 121: Trigger System Checks

Performance Tests Trigger System These procedures check those characteristics that relate to the Main and Delayed trigger systems and are listed as checked under Warranted Charac Checks teristics in Section 1, Specifications. Check Accuracy (Time) for Pulse Glitch or Pulse Width Triggering Equipment Required: One medium frequency leveled sine wave generator (Item 10), one 10X attenuator (Item 1), and one precision, 50 W, coaxial cable... - Page 122 Press the side menu button Upper Limit; then use the general purpose knob to slowly decrease the the Upper Limit readout until triggering is lost. CHECK that the Upper Limit readout is within 2.5 ns to 7.5 ns, inclusive. 4 43 TDS 520A, 524A, 540A, & 544A Service Manual...

-

Page 123: Figure 4 15: Measurement Of Time Accuracy For Pulse And Glitch

Performance Tests First, the upper and lower limits are set so the test waveform triggers within limits. Second, a limit (here, the lower limit) is increased until triggering stops. Figure 4 15: Measurement of Time Accuracy for Pulse and Glitch Triggering 3. -

Page 124: Check Accuracy, Trigger Level Or Threshold, Dc Coupled

BNC T connector to CH 1. See Figure 4 16. DC Calibrator Output Sense Dual Banana to BNC Adapter 50 W Coaxial Cables BNC T Connector Figure 4 16: Initial Test Hookup 4 45 TDS 520A, 524A, 540A, & 544A Service Manual... - Page 125 Performance Tests b. Initialize the oscilloscope: Press save/recall Setup. Press the main menu button Recall Factory Setup. Press the side menu button OK Confirm Factory Init. c. Select Delayed Triggerable: Press HORIZONTAL MENU. Press the main menu button Time Base. Press the side menu button Delayed Triggerable.

-

Page 126: Figure 4 17: Measurement Of Trigger Level Accuracy

10.060 V, inclusive. Press the main menu button Slope; then press the side menu button for negative slope. (See icon at left.) Press the main menu button Level. Repeat substep c. 4 47 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 127: Sensitivity, Edge Trigger, Dc Coupled

Performance Tests CHECK that the Level readout in the side menu is within 9.940 V to 10.060 V, inclusive. 4. Disconnect the hookup: a. First set the output of the DC calibration generator to 0 volts. b. Then disconnect the cable from the generator output at the input connector of CH 1. -

Page 128: Figure 4 18: Initial Test Hookup Tds 520A And 524A Only

Generator Output 50 W Coaxial Cables Figure 4 18: Initial Test Hookup TDS 520A and 524A Only TDS 520A and 524A only: Connect, through a 50 W precision coaxial cable, the signal output of a medium frequency sine wave generator to CH 1. See Figure 4 18. - Page 129 Performance Tests Press MEASURE. Press the main menu button High Low Setup; then press the side menu button Min Max. Press the main menu button Select Measrmnt for Ch1. Press the side menu button -more- until Amplitude appears in the side menu (its icon is shown at the left). Press the side menu button Amplitude.

-

Page 130: Figure 4 20: Measurement Of Trigger Sensitivity

Time Base. Now press the side menu button Main Only. TDS 520A and 524A only: Skip to step 4 since the TDS 520A and 524A are not equipped with an AUX Trigger input. If testing the TDS 540A or 544A, continue with step 3. - Page 131 Performance Tests 3. Confirm the AUX Trigger input: a. Display the test signal: Remove the 10X attenuator and reconnect the cable to CH 1. Set the test signal amplitude for about 2.5 divisions on screen. Now fine adjust the generator output until the CH 1 Amplitude readout indicates the amplitude is 250 mV.

- Page 132 (See definition of a stable trigger earlier in this procedure.) 6. Disconnect the hookup: Disconnect the cable from the generator output at the input connector of the channel last tested. 4 53 TDS 520A, 524A, 540A, & 544A Service Manual...

-

Page 133: Output Signal Checks

Performance Tests Output Signal The procedure that follows checks those characteristics of the output signals that are listed as checked under Warranted Characteristics in Section 1, Checks Specifications. The oscilloscope outputs these signals at its front and rear panels. Check Outputs CH 3 and Main and Delayed Trigger (TDS 540A and 544A only) Equipment Required: Two 50 W precision cables (Item 4), and one calibra... -

Page 134: Figure 4 22: Measurement Of Main Trigger Out Limits

Press both side menu buttons High and Low. See Figure 4 22. First, turn on the measurements high and low. Second, read the measurement results here. Figure 4 22: Measurement of Main Trigger Out Limits 4 55 TDS 520A, 524A, 540A, & 544A Service Manual... - Page 135 Performance Tests c. Check Main Trigger output against limits: CHECK that the Ch2 High readout is w2.5 volts and that the Ch2 Low readout is v700 mV. Press VERTICAL MENU; then press the main menu button Coupling. Now press the side menu button W to toggle it to the 50 W setting.

-

Page 136: Check Probe Compensator Outputs

50 W Coaxial Cable Female BNC to Clip Adapter Figure 4 23: Initial Test Hookup b. Initialize the oscilloscope: Press save/recall SETUP . Press the main menu button Recall Factory Setup. 4 57 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 137: Figure 4 24: Measurement Of Probe Compensator Frequency

Performance Tests Press the side menu button OK Confirm Factory Init. c. Modify the initialized front panel control settings: Set the vertical SCALE to 100 mV as required. Set the horizontal SCALE to 200 ms. Press Set Level to 50% and use the VERTICAL POSITION knob to center the display on screen. -

Page 138: Figure 4 25: Subsequent Test Hookup

Figure 4 25: Subsequent Test Hookup c. Measure amplitude of the probe compensation signal: Press SHIFT; then ACQUIRE MENU. Then use the keypad to set AVERAGE to 16 in the side menu. 4 59 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 139: Figure 4 26: Measurement Of Probe Compensator Amplitude

Performance Tests Adjust the output of DC calibration generator until it precisely overlaps the top (upper) level of the stored probe compensation signal. (This value will be near 500 mV.) Record the setting of the DC generator. Adjust the output of DC calibration generator until it precisely overlaps the base (lower) level of the stored probe compensation signal. -

Page 140: Option 05 Video Trigger Checks

ENTER). k. Press HORIZONTAL MENU. Press the main menu Horiz Scale. m. Use the keypad to set the horizontal scale to 200 ns (press 200, SHIFT, n, then ENTER). 4 61 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 141: Figure 4 27: Jitter Test Hookup

Performance Tests 3. Check Jitter vs. Signal Amplitude a. Setup equipment for Jitter Test (See Figure 4 27). Connect one of the rear panel composite outputs marked COMPST on the TSG121 through a 75 W cable and a 75 W terminator to the oscilloscope CH1 input. - Page 142 If not successful, the oscilloscope bell will ring. When the word Run in the top left corner of the display changes to STOP , the test is complete (See Figure 4 29). 4 63 TDS 520A, 524A, 540A, & 544A Service Manual...

-

Page 143: Figure 4 29: Jitter Test When Completed

Performance Tests STOP shows the test is complete Figure 4 29: Jitter Test When Completed w. Press the main menu Limit Test Setup. x. Toggle the side menu Ring Bell if Condition Met to OFF. y. Toggle the side menu Limit Test to OFF. 4. -

Page 144: Figure 4 30: Triggered Signal Range Test - 300

Also, CONFIRM that the waveform on the screen has one positive pulse and a number of negative pulses (See Figure 4 31). 4 65 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 145: Figure 4 31: Triggered Signal Range Test - 75

Performance Tests Positive pulse Negative pulses Figure 4 31: Triggered Signal Range Test - 75 mV p. Disconnect all test equipment (TSG121) from the digitizing oscillo scope. 5. Check 60 Hz Rejection. a. Setup oscilloscope for 60 Hz Rejection Test. Use the keypad to set the Ch1 Fine Scale to 282 mV (press 282, SHIFT m, then ENTER). -

Page 146: Figure 4 32: 60 Hz Rejection Test Hookup

COMPST on the TSG 121) to a 75 W cable and a 75 W terminator. Connect both signals to the CH1 input through a BNC T (See Figure 4 34). 4 67 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 147: Figure 4 34: Subsequent 60 Hz Rejection Test Hookup

Performance Tests Press VERTICAL MENU. If needed, press the main menu Fine Scale. Use the keypad to set fine scale to 500 mV (press 500, SHIFT, m, then ENTER). Connect another the PAL signal source's composite signal con nector (labelled COMPST on the TSG 121) through a 75 W cable and a 75 W terminator to the CH2 input (See Figure 4 34). -

Page 148: Figure 4 35: 60 Hz Rejection Test Result

(on the TSG 121 this refers to the signal at the rear labelled COMPST) to the CH1 input through a 75 W cable and a 75 W terminator (See Figure 4 36). 4 69 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 149: Figure 4 36: Line Count Accuracy Test Hookup

Performance Tests PAL Signal Source TSG121 COMPST 75 W Cable 75 W Terminator Figure 4 36: Line Count Accuracy Test Hookup Press the main menu Trigger Position. Press the side menu to Set to 50%. Press the main menu Horiz Pos. Press the side menu to Set to 50%. -

Page 150: Figure 4 38: Line Count Accuracy Correct Result Waveform

Setup digitizing oscilloscope for Sync Duty Cycle Test. Press TRIGGER MENU. Press the Standard pop up to select FlexFmt. (Trigger Type should already be set to Video) Press the main menu Setup. 4 71 TDS 520A, 524A, 540A, & 544A Service Manual... - Page 151 Performance Tests Press the side menu Field Rate. Use the keypad to set the field rate to 60.05 Hz (press 60.05, then ENTER). Press the side menu Lines. Use the keypad to set the field rate to 793 lines (press 793, then ENTER).

-

Page 152: Figure 4 39: Pg502 Setup For Sync Duty Cycle Test

(See Figure 4 40). NOTE You may need to adjust the trigger level control to obtain a stable trigger. 4 73 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 153: Figure 4 40: Sync Duty Cycle Test: One Div Neg Pulse Waveform

Performance Tests Figure 4 40: Sync Duty Cycle Test: One Div Neg Pulse Waveform Turn the pulse generator PULSE DURATION variable control to adjust the negative pulse so the oscilloscope CH1 - Width measurement displays 400ns +/-10 ns. Turn the HORIZONTAL SCALE knob to set the oscilloscope time base to 5 ms/div. -

Page 154: Figure 4 41: Sync Duty Cycle Test: Critically Adjusted Pulse

CONFIRM that the TRIG'D LED is on and the waveform is stable. Disconnect all test equipment (TSG 121) from the oscilloscope. Press save/recall SETUP , press the main menu button Recall Factory Setup, and the side menu OK Confirm Factory Init. 4 75 TDS 520A, 524A, 540A, & 544A Service Manual... - Page 155 Performance Tests 4 76 Performance Verification...

-

Page 156: Adjustment Procedures

Adjustment Replace this page with the Tab named Adjustment Procedures Procedures... -

Page 158: General Information

Adjustment Procedures This section contains information needed to adjust TDS 520A, 524A, 540A, & 544A Digitizing Oscilloscopes to bring them to conformance with the War ranted Characteristics as listed in the Specifications section of this manual. The Adjustment Procedures are divided into seven subsections as follows: General Information gives basic start up information. -

Page 159: Equipment Requirements And Options

A GPIB board National InstrumentsR GPIB PCII, GPIB PCIIA or GPIB PCII/IIA. (A PC GPIB Package that includes the PCII/IIA is available Tektronix part number S3FG210). Suitable keyboard and monitor. Optional Peripherals Installation of a math coprocessor integrated circuit (IC) in your system is not required, but is strongly recommended to decrease the time required to adjust the oscilloscope. -

Page 160: Complete Adjustment

Written procedures for these adjustments begin on page 5 11. Complete Adjustment A complete adjustment, is defined as the performance of all adjustments on the TDS 520A, 524A, 540A, & 544A Adjustment Software, in sequence, plus the Probe Adjustment (see page 5 11). Individual Adjustments The adjustment software contains three classes of adjustments. -

Page 161: Adjustment After Repair

Adjustment Procedures Adjustment After Repair After the removal and replacement of a module due to electrical failure, you must either do a complete adjustment or no adjustment is required, depend ing on the module replaced (see Table 5 1). Table 5 1: Adjustments Required for Module Replaced Module Replaced Adjustment Required Acquisition Board... -

Page 162: Equipment Required

Adjustment Procedures Equipment Required The following test equipment is required to adjust the TDS 520A, 524A, 540A, & 544A Digitizing Oscilloscopes. Table 5 3: Test Equipment, Fixtures, and Supplies Item Number and Minimum Requirements Example Purpose Description Adapter, BNC Fe... - Page 163 Variable amplitude from Sine Wave Generator with its Adjustments Frequency 5 mV to 4 V into 50 W; leveling head or a Tektronix 6 MHz reference; SG 5030 Programmable Lev harmonic content: 2 eled Sine Wave Generator with harmonic down -30 dB its leveling head from fundamental;...

-

Page 164: Adjustment Instructions

1. Create a working disk: Using the proper DOS commands, copy the TDS 520A, 524A, 540A, & 544A Adjustment Software disk to a working disk. TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 165: Software Based Adjustments

Adjustment Procedures 2. Install the software to hard disk: a. Install your working disk in a floppy drive then type install. You will be asked to specify the hard disk on which to install the adjustment software. You will also be prompted to specify several GPIB card configuration parameters. -

Page 166: Figure 5 1: Accessing The Protection Switch

5. 5. Start the adjustment software: a. Change the drive to the hard drive. b. Change directories to TDS500.ADJ. c. Type ADJ500. d. Follow the instructions as prompted on your computer screen. TDS 520A, 524A, 540A, & 544A Service Manual... - Page 167 Adjustment Procedures 6. When adjustment has been completed: CAUTION Be sure to disable the NVRAM protection switch as instructed below to protect the adjustment constants against alteration. a. Locate the two small access holes on the right side of the oscillo scope cabinet near the front.

-

Page 168: Probe Adjustment

Modify the initialized front panel control settings: Press AUTOSET. Set the horizontal SCALE to 200 ms. Press SHIFT. Then press ACQUIRE MENU. Press the main menu button Mode. Then press the side menu button Hi Res. 5 11 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 169: Compensate The Probe

Adjustment Procedures Figure 5 3: Performing Probe Compensation 2. Compensate the Probe: a. Locate the probe compensation hole in the side of the probe body (see Figure 5 3). b. Using the adjustment tool, adjust the probe for best square wave compensation (flat as possible across its across its top). -

Page 170: Measure Probe Bandwidth

Second, unscrew the ribbed ferrule tip cover and pull forward to remove. First, pull forward remove the retract able hook tip. Figure 5 5: Exposing the Inner Probe Tip 5 13 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 171: Figure 5 6: Initial Test Hookup

Adjustment Procedures High Frequency Sine Wave Generator Output BNC Female BNC to Probe to Female Tip Adapter Leveling Head BNC Adapter Figure 5 6: Initial Test Hookup b. Hook up test signal source: Connect the output of a high frequency sine wave generator, through its leveling head, to a female to female adapter (see Figure 5 6). -

Page 172: Adjust The Probe High Frequency Response

The probe tip should be exposed from the procedure Measure Probe Bandwidth. If not, follow the instructions in Figure 5 5 on page 5 13 to expose the probe tip. 5 15 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 173: Figure 5 7: Exposing The Probe Body

Adjustment Procedures Follow the instructions in Figure 5 7 to remove the probe body covers. Use a small standard screw driver to pry between the cover and metal cord connector to pop off cover. Repeat for lower cover. Figure 5 7: Exposing the Probe Body b. - Page 174 Plug the probe tip from the probe into the BNC to probe tip adapter. Press the main menu button Coupling. Then press the side me nu button W to toggle to 1 MW coupling. Press HORIZONTAL MENU. 5 17 TDS 520A, 524A, 540A, & 544A Service Manual...

-

Page 175: Figure 5 9: Locations Of Probe Adjustments

Adjustment Procedures Press the main menu button Trigger Position; and press the side menu button 50%. c. Make the adjustments: Locate the various adjustments in Figure 5 9. Not Used LF Comp Figure 5 9: Locations of Probe Adjustments Manually adjust the front corner response of the probe to best match the response of the Ref 1 waveform. -

Page 176: Display Assembly Adjustment

Brightness and Contrast Adjustment (TDS 520A and 540A - Monochrome - Only) Equipment Required: One 6X magnifier (Item 14) and one J16 Photometer with a J6503 Luminance Probe (Item 15). -

Page 177: Figure 5 11: Tds 520A/540A Five And Ten Percent Luminance

10% Patch 5% Patch Figure 5 11: TDS 520A/540A Five and Ten Percent Luminance Patches 3. Adjust the display contrast: a. Display the White Field test pattern: Press the center main menu button to display the main menu. - Page 178 Restore the dip switch to the settings that follow: Switch No. Open Closed b. Power off the oscilloscope. c. See Removal and Installation Procedures in Section 6 to reinstall the cabinet and other modules removed in step 1. 5 21 TDS 520A, 524A, 540A, & 544A Service Manual...

-

Page 179: Rotation, Brightness, And Contrast Adjustment (Tds 524A And 544A - Color - Only)

Adjustment Procedures Rotation, Brightness, and Contrast Adjustment (TDS 524A and 544A - Color - Only) Equipment Required: One 6X magnifier (Item 14) and one J16 Photometer with a J6503 Luminance Probe (Item 15). Procedure: 1. Access the inside of the oscilloscope: See Removal and Installation Procedures in Section 6 to remove the cabinet. -

Page 180: Figure 5 12: Tds 524A/544A Five And Ten Percent Luminance

Locate R404. It is one of the adjustments on the left side of the instrument located just ahead of the fan. It is the fifth adjustment from the fan. Monitor the luminance at center screen using a J16 photometer and a luminance probe. 5 23 TDS 520A, 524A, 540A, & 544A Service Manual... - Page 181 Adjustment Procedures Adjust R404 (CONTRAST) for a reading of 40 foot lamberts. NOTE The adjustments for contrast and brightness interact with each other. 5. Restore the oscilloscope to normal operation: a. Restore the dip switch to the settings that follow: Switch No.

-

Page 182: Maintenance

Maintenance Replace this page with the Tab named Maintenance... -

Page 184: Maintenance Information

Maintenance Information This section contains the information needed to do periodic and corrective maintenance on the TDS 520A, 524A, 540A, & 544A Digitizing Oscilloscopes. Specifically, the following subsections are included: Maintenance Information Includes this introduction plus general information on preventing damage to internal modules when doing maintenance. -

Page 185: Preventing Electrostatic Discharge (Esd)

Maintenance Information Preventing Electrostatic CAUTION Discharge (ESD) Electrostatic discharge can damage any semiconductor component in this oscilloscope. Precautions When performing any service which requires internal access to the oscillo scope, adhere to the following precautions to avoid damaging internal mod ules and their components due to electrostatic discharge (ESD). - Page 186 2 = 200 to 500 V 7 = 400 to 1000 V (est.) 3 = 250 V 8 = 900 V 4 = 500 V 9 = 1200 V 5 = 400 to 600 V TDS 520A, 524A, 540A, & 544A Service Manual...

- Page 187 Maintenance Information Maintenance...

-

Page 188: Inspection And Cleaning

Inspection and Cleaning Inspection and Cleaning describes how to inspect for dirt and damage on, and how to clean the exterior and interior of, the TDS 520A, 524A, 540A, & 544A Digitizing Oscilloscopes. Inspection and cleaning are done as preven tive maintenance. -

Page 189: Inspection Exterior

Inspection and Cleaning Inspection Exterior Inspect the outside of the oscilloscope for damage, wear, and missing parts, using Table 6 2 as a guide. Oscilloscopes that appear to have been dropped or otherwise abused should be checked thoroughly to verify correct operation and performance. -

Page 190: Inspection Interior

Loose plugs or connectors. Burned, bro Firmly seat connectors. Repair or replace ken, or frayed wiring. modules with defective wires or cables. Chassis Dents, deformations, and damaged hard Straighten, repair, or replace defective ware. hardware. TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 191: Cleaning Procedure Interior

Inspection and Cleaning Cleaning Procedure Interior If, after doing steps 1 and 2, a module is clean upon inspection, skip the remaining steps. 1. Blow off dust with dry, low pressure, deionized air (approximately 9 psi). 2. Remove any remaining dust with a lint free cloth dampened in isopropyl alcohol (75% solution) and rinse with a warm deionized water. -

Page 192: Removal And Installation Procedures

Discharge on page 6 2. WARNING Before doing any procedure in this subsection, disconnect the power cord from the line voltage source. Failure to do so could cause serious injury or death. TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 193: List Of Modules

Removal and Installation Procedures List of Modules Section 10, Mechanical Parts List lists all modules. General Instructions READ THESE GENERAL INSTRUCTIONS BEFORE REMOVING A MODULE. First read the following Summary of Procedures to understand how the procedures are grouped. Then read Equipment Required for a list of the tools needed to remove and install modules in this oscillo scope. - Page 194 Phillips head screws Needle Nose Pliers Standard tool Nutdriver, 1/4 inch Standard tool Retaining Ring Pliers Standard tool; 1 1/8 inch minimum throw Angle Tip Tweezers Standard tool Pliers Standard tool 6 11 TDS 520A, 524A, 540A, & 544A Service Manual...

-

Page 195: Figure 6 1: External Modules

Removal and Installation Procedures Rear Cover Cabinet Fuse Cap Line Fuse Line Cord Handle EMI Gasket Handle Cap Foot Display EMI Gasket Foot Pad Frame Flip Stand Front Panel Knobs Menu Buttons Attenuator Cover A12 Front Panel Assembly Trim Ring Front Cover Figure 6 1: External Modules 6 12... -

Page 196: Figure 6 2: Outer Chassis Modules

A11 DRAM Processor/Display Board Rear Chassis Top Cover A23 SerPar Board Board Bracket A14 D1 Bus Analog and Digital Attenuator Power Cables Assembly Acquisition Board Figure 6 2: Outer Chassis Modules 6 13 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 197: Figure 6 3: Inner Chassis Modules - Tds 520A Or 540A With A20 Display Assembly

Removal and Installation Procedures A20 Display Assembly A16 Power Supply Main Chassis Front Subpanel Figure 6 3: Inner Chassis Modules - TDS 520A or 540A with A20 Display Assembly 6 14 Maintenance... -

Page 198: Figure 6 4: Inner Chassis Modules - Tds 524A Or 544A With A30 Display Assembly

Removal and Installation Procedures A30 Display Assembly A16 Power Supply Main Chassis Front Subpanel Figure 6 4: Inner Chassis Modules - TDS 524A or 544A with A30 Display Assembly 6 15 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 199: Access Procedure

Removal and Installation Procedures Access Procedure Begin with this procedure when you have identified a module to be removed for service and have read General Instructions found earlier in this section. 1. Locate module to be removed: a. Find the module to be removed in the module locator diagrams, Figures 6 1 through 6 4. -

Page 200: Procedures For External Modules

4. Reinstallation: To reinstall the knob, align it to the shaft and push it in until it snaps. 6 17 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 201: Line Fuse And Line Cord

Removal and Installation Procedures When reinstalling the knobs, note there are three sizes. Be sure to reinstall the proper size knob in the proper location. Figure 6 5: Knob Removal Line Fuse and Line Cord 1. Assemble equipment and locate modules to be removed: Have handy a flat bladed screwdriver (Item 5). -

Page 202: Emi Gaskets

(1) Unplug (2) Rotate (3) Pull Line Fuse Fuse Cap Figure 6 6: Line Fuse and Line Cord Removal EMI Gaskets See Rear Cover and Cabinet procedure on page 6 20. 6 19 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 203: Rear Cover And Cabinet

Removal and Installation Procedures Rear Cover and Cabinet 1. Assemble equipment and locate modules to be removed: a. Have handy a screwdriver with a size T 20 TorxR tip (Items 1 and 3). b. Make sure the oscilloscopes front cover is installed; if it's not, install it by snapping its edges over the trim ring. - Page 204 When reinstalling the four screws at the rear panel, tighten them to 16 inch lbs torque. See the procedure Line Fuse and Line Cord to reinstall the line cord. This completes the oscilloscope reassembly. 6 21 TDS 520A, 524A, 540A, & 544A Service Manual...

-

Page 205: Figure 6 7: Rear Cover And Cabinet Removal

Removal and Installation Procedures Figure 6 7: Rear Cover and Cabinet Removal 6 22 Maintenance... -

Page 206: Front Cover, Trim Ring, Menu Buttons, And Attenuator Panel

DO NOT touch the carbon contact points on the menu buttons in stalled in the trim ring. Also, do not touch the contacts on the flex circuit exposed when you remove the trim ring. 6 23 TDS 520A, 524A, 540A, & 544A Service Manual... - Page 207 Removal and Installation Procedures 4. Remove the trim ring: Grasp the trim ring by its top edge and pry it up and lift it forward to snap it off of the front subpanel. If servicing the menu buttons, lift them out of the trim ring. (When reinstalling, reinsert the menu buttons, align the trim ring to the front subpanel and press it back on.) 5.

-

Page 208: A12 Front Panel Assembly

P3 of the front panel assembly. (The flex board is part of the display frame assembly.) c. Finally, lift the front panel assembly out of the front subpanel to complete the removal. 6 25 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 209: Figure 6 9: A12 Front Panel Assembly

Removal and Installation Procedures Front Panel Assembly To J2 of A11 DRAMA Processor /Display Board Figure 6 9: A12 Front Panel Assembly 4. Further disassembly of front panel assembly: If the front panel or the front panel buttons are to be serviced, do the following substeps: a. -

Page 210: Display Frame Assembly

6 13. 2. Orient the oscilloscope: Set the oscilloscope so its bottom is down on the work surface and its front is facing you. 3. Remove the display frame assembly: 6 27 TDS 520A, 524A, 540A, & 544A Service Manual... - Page 211 Removal and Installation Procedures a. Do the procedure Front Cover, Trim Ring, Menu Buttons, and Attenua tor Panel (page 6 23) to remove the front cover and trim ring. b. Lift the front panel assembly out of the front subpanel until you can reach J2 on the front panel assembly.

-

Page 212: Cabinet Modules

6c; then see Rear Cover and Cabinet (page 6 20) to reinstall the rear cover and cabinet. Do in reverse order steps 3 and 5, reversing each step, to reinstall the flip stand, then the handle caps (if removed), then the handle. 6 29 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 213: Figure 6 11: Cabinet Modules Removal

Removal and Installation Procedures Push down to flex handle and flatten against cabinet; then pull it out. Handle Cap Removal Handle Removal Flip Stand Removal Foot Removal Figure 6 11: Cabinet Modules Removal 6 30 Maintenance... -

Page 214: Procedures For Outer Chassis Modules

4. Reinstallation: Do in reverse order substeps 3a-3d, reversing the removal instructions in each substep to reinstall the assembly. Then see the following procedures, in the order listed, to complete reassembly of the oscilloscope. 6 31 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 215: Fan

Removal and Installation Procedures Front Cover, Trim Ring, Menu Buttons, and Attenuator Panel (page 6 17) J1200 J1100 J1300 J1400 Figure 6 12: Attenuator Interconnect Cable Routing and Jack Locations Rear Cover and Cabinet (page 6 20) 1. Assemble equipment and locate module to be removed: Have handy a screwdriver with a size T 20 TorxR tip (Items 1 and 3). -

Page 216: A14 D1 Bus And Power Cables

Unplug the digital power cable at J27 on the display processor board, at J6 on the low voltage power supply, and at J101 on the acquisition board. 6 33 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 217: Figure 6 13: A14 D1 Bus And Power Cables Removal

Removal and Installation Procedures Analog and Digital Power Cables (Interchangeable) A14 D1 Bus Figure 6 13: A14 D1 Bus and Power Cables Removal 5. Reinstallation: a. Do in reverse order steps 3 and 4, reversing the procedure outlined in each step to reinstall the assembly. b. -

Page 218: A23 Serpar Board: Rs232/Centronics Hardcopy Interface

Disconnect the cable connector (number 2) from the processor dis play circuit board connector (number 1). c. Pull out the A23 SerPar Board assembly (number 3). Figure 6 14: Remove Circuit Board Assembly From Oscilloscope 6 35 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 219: Figure 6 15: Remove Circuit Board From Assembly

Removal and Installation Procedures 2. Remove circuit board from assembly: a. Using a 3/16 inch nutdriver, remove the four lock connectors (number 3 in Figure 6 14) securing the circuit board to the rear plate. b. Separate the circuit board with attached cable (number 1), from the rear plate with attached brackets (number 2). -

Page 220: A29 Video Trigger Board

Unplug the coax video cable that connects the video board to the acquisition boards (see Figure 6 17). e. Slide back and lift up the Video Trigger circuit board (see Figure 6 18). 6 37 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 221: Figure 6 16: Circuit Board Installed

Removal and Installation Procedures Figure 6 16: Circuit Board Installed 6 38 Maintenance... -

Page 222: Figure 6 17: Proper Routing Of The Video Cable

Removal and Installation Procedures Figure 6 17: Proper Routing of the Video Cable 6 39 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 223: Figure 6 18: Circuit Board Removal

Removal and Installation Procedures Figure 6 18: Circuit Board Removal 6 40 Maintenance... - Page 224 SerPar Board (page 6 35) and Rear Cover and Cabinet (page 6 20) to complete reassembly of the oscilloscope. c. To ensure the Video Trigger is working correctly, perform the Diag nostics procedure on page 6 63. 6 41 TDS 520A, 524A, 540A, & 544A Service Manual...

-

Page 225: A11 Processor/Display Board

Removal and Installation Procedures A11 Processor/Display Board Additional modules Removed: D1 bus and analog and digital power cables. 1. Assemble equipment and locate modules to be removed a. Have handy a screwdriver with a size T 20 TorxR tip (Items 1 and 2). b. -

Page 226: Top Cover And Board Brackets

(Item 5). b. Locate the modules to be removed in the locator diagram Outer Chassis Modules, Figure 6 2, page 6 13. 6 43 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 227: Figure 6 20: Board Bracket Removal

Removal and Installation Procedures c. Do the procedures A14 D1 Bus and Power Cables (page 6 34), A23 SerPar Board (page 6 35), and A11 Processor/Display Board (page 6 42) to remove those modules. 2. Orient the oscilloscope: Set the oscilloscope so its bottom is down on the work surface and its front is facing you. -

Page 228: Rear Panel Cables

2. Orient the oscilloscope: Set the oscilloscope so its top is down on the work surface and its front is facing you. 3. Remove the Acquisition Board: Use Figure 6 21 as a guide. 6 45 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 229: Figure 6 21: A11 Processor/Display Removal

Removal and Installation Procedures a. Unplug each of the four interconnect cables that connect the at tenuators to the acquisition board from its jack on the Acquisition board. b. Unplug the ribbon interconnect cable that plugs in from the at tenuator at J1153. -

Page 230: Floppy Disk

To remove the disk drive, the shield, and the bracket together, re move the two T15 torque screws holding the bracket to the chassis. Then remove the disk, shield, and the bracket as a unit. 6 47 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 231: Figure 6 22: Floppy Disk Removal

Removal and Installation Procedures Figure 6 22: Floppy Disk Removal 4. Reinstallation: Do, in reverse order, substeps 3c then 3a or 3b then 3a to reinstall the floppy disk. Then see the following procedures, in the order listed, to complete reassembly of the oscilloscope: Front Cover, Trim Ring, Menu Buttons, and Attenuator Panel (page 6 23). -

Page 232: Rear Chassis

Then see the following procedures, in the order listed, to complete reassembly of the oscilloscope. A14 D1 Bus and Power Cables (page 6 34) Rear Cover and Cabinet (page 6 20) 6 49 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 233: Figure 6 23: Rear Chassis Removal

Removal and Installation Procedures DELAY TRIGGER TO J1001 MAIN TRIGGER TO J1000 AUXILIARY TRIGGER TO J1550 CH3 OUT TO J1201 EMI GASKET Figure 6 23: Rear Chassis Removal 6 50 Maintenance... -

Page 234: Procedures For Inner Chassis Modules

Top Cover and Board Brackets (page 6 44) A11 Processor/Display Board (page 6 42) A14 D1 Bus and Power Cables (page 6 34) Rear Cover and Cabinet (page 6 20) 6 51 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 235: Figure 6 24: A16 Low Voltage Power Supply Removal

Removal and Installation Procedures Rotate the edge of the board upward as indicated to clear the lip of the main chassis when lifting this board out. Figure 6 24: A16 Low Voltage Power Supply Removal 6 52 Maintenance... -

Page 236: A20 Or A30 Display Assembly And Supply Fuse

The display and the display driver board are a single module and must be removed and replaced as such. They are listed as a single module in the Replaceable Parts List. A20 refers to the TDS 520A and 540A monochrome module. A30 refers to the TDS 524A and 544A color module. - Page 237 Removal and Installation Procedures c. Remove the two screws that secure the band circling the front of display tube to the front subpanel. Carefully guide display tube forward to partially remove it from the front subpanel and to access the anode lead connected to the display tube. WARNING High voltage is present on the anode lead.

-

Page 238: Figure 6 25: Display Assembly Removal - Tds 524A And 544A

Removal and Installation Procedures J305 J350 J170 J570 Figure 6 25: Display Assembly Removal - TDS 524A and 544A 6 55 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 239: Figure 6 26: Display Assembly Removal - Tds 520A And 540A

Removal and Installation Procedures Figure 6 26: Display Assembly Removal - TDS 520A and 540A 5. Remove the Display Supply board: Use Figure 6 27 as a guide. a. Remove the six screws that mount the display driver board to the main chassis. -

Page 240: Figure 6 27: Display Driver Board Removal

Top Cover and Board Brackets (top cover only) on page 6 44 A11 Processor/Display Board (page 6 42) A14 D1 Bus and Power Cables (page 6 34) Display Frame Assembly 6 57 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 241: Front Subpanel

Removal and Installation Procedures Front Cover, Trim Ring, Menu Buttons, and Attenuator Panel (page 6 23) Rear Cover and Cabinet (page 6 20) (completes reassembly) Front Subpanel 1. Assemble equipment and locate modules to be removed: a. Have handy a screwdriver with a size T 15 TorxR tip (Items 1 and 2). b. -

Page 242: Main Chassis

Cleaning that follows. While doing Disassembly for Cleaning, you will remove the front panel assembly. Ignore the instructions to disassemble that assembly. 2. Reinstallation: See reinstallation instructions in Disassembly for Cleaning. 6 59 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 243: Disassembly For Cleaning

Removal and Installation Procedures Disassembly for This procedure is for disassembly of the TDS 520A, 524A, 540A, & 544A Digitizing Oscilloscopes into their individual modules so they can be Cleaning cleaned. For the cleaning instructions, see Inspection and Cleaning, which begins this section. - Page 244 Reinstall external modules: Do in the order listed the following proce dures. When doing these procedures, do the steps in reverse order. These procedures are found under Procedures for External Modules which starts on page 6 17. 6 61 TDS 520A, 524A, 540A, & 544A Service Manual...

- Page 245 Removal and Installation Procedures Front Subpanel (page 6 58) Display Frame Assembly (page 6 53) Front Cover, Trim Ring, Menu Buttons, and Attenuator Panel (page 6 23) Rear Cover and Cabinet (page 6 20) Line Fuse and Line Cord (page 6 18) 6 62 Maintenance...

-

Page 246: Troubleshooting

3. Wait: The internal diagnostics do an exhaustive verification of proper oscilloscope function. This verification will take about two minutes. When finished, the oscilloscope will display a report of any bad modules and/or interfaces. 6 63 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 247: Firmware Updates

Troubleshooting Firmware Updates The TDS 520A, 524A, 540A, & 544A firmware updates are easy to do. Simply install the firmware disks on your PC and follow the instructions in the READ ME file located on the first disk. NOTE You must set the Protection switch to the unprotected position before updating the firmware. -

Page 248: Figure 6 30: Primary Troubleshooting Procedure

Note: Set all the switches on S1001 back to the 6 64 for details on firmware updates. closed position and cycle power before performing another procedure. Figure 6 30: Primary Troubleshooting Procedure 6 65 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 249: Figure 6 31: Module Isolation Troubleshooting Procedure

Does the Are any (the discussion of the display report failures The oscilloscope is ok. TDS 520A, 524A, 540A, & 544A reported? any errors? Diagnostics on page 6 63 explains how to do this). Regardless of other failures,... -

Page 250: Figure 6 32: A16 Low Voltage Power Supply Module Isolation

J20? The Low Voltage Power Supply is ok. Perform the voltages the Primary troubleshooting procedure. Figure 6 32: A16 Low Voltage Power Supply Module Isolation Troubleshooting Procedure 6 67 TDS 520A, 524A, 540A, & 544A Service Manual... - Page 251 Troubleshooting Table 6 5: Normal Supply Voltages (Measured on J26 and J27 on the A11 DRAM Processor/Display Module) Supply Lower Limit Upper Limit Ground (J26 or J27 pin 15) +5.1 VA (J27 pin 5) +5.0 V +5.2 V +5.1 VB (J27 pin 17) +5.0 V +5.2 V +25 V (J27 pin 1)

-

Page 252: Figure 6 33: Power Supply Voltage Measurement Locations

Troubleshooting A17 Main LV Power Supply Module Figure 6 33: Power Supply Voltage Measurement Locations 6 69 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 253: Figure 6 34: Display Troubleshooting Procedure

Troubleshooting This procedure helps you determine whether the display or the A11 DRAM Processor/Display module is bad. Power the oscilloscope off and disconnect the cable from J5 on the A11 DRAM Processor/Display module (see Figure 6 41) then power back on. Does J62 pin 1 J18 pins 1 and 2... -

Page 254: Figure 6 35: Horizontal And Vertical Sync Signals

Figure 6 35: Horizontal and Vertical Sync Signals White Level J62 pin 1 (Video) Black Levels Blanking Levels Figure 6 36: A Video Signal with White, Black, and Blanking Levels 6 71 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 255: Figure 6 37: Processor/Acquisition Troubleshooting Procedure

Select the extended diagnostics menu and run all the test suites (the discussion of the TDS 520A, 524A, 540A, & 544A Diagnostics on page 6 63 explains how to do this). Do the Processor/Acq tests Done. -

Page 256: Figure 6 38: Processor/Front Panel Troubleshooting Procedure

Panel module has most likely failed. Replace this module. Does the Front Panel work correctly now? Replace the A11 DRAM Processor/Display module. Done. Figure 6 38: Processor/Front Panel Troubleshooting Procedure 6 73 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 257: Figure 6 39: Attenuator/Acquisition Troubleshooting Procedure

Troubleshooting Attach a probe to the PROBE COMPENSATION signal located on the front of the oscilloscope. Connect the probe to a channel's BNC on the front, select the channel and view the output on the display. Do this for all the channels. Set all the channels to the same vertical For all scale and select a channel that works... -

Page 258: Figure 6 40: A11 Dram Processor/Display Module (View Of Right Side)

Probe only those points specified in the procedures. You can cause catastroph CAUTION ic damage if you attempt to probe other points. U1331 U2000 U2001 U1097 Figure 6 40: A11 DRAM Processor/Display Module (View of Right Side) 6 75 TDS 520A, 524A, 540A, & 544A Service Manual... -

Page 259: Figure 6 41: A11 Dram Processor/Display Module (View Of Lower Left Corner)

Troubleshooting U190 Figure 6 41: A11 DRAM Processor/Display Module (View of Lower Left Corner) 6 76 Maintenance... - Page 260 Options Replace this page with the Tab named Options...

-

Page 262: Table 7 1: International Power Cords

Options and Accessories This section describes the various options as well as the standard and option al accessories that are available for the TDS 520A, 524A, 540A, & 544A Digi tizing Oscilloscopes. Options The following options are available: Options A1-A5: International Power Cords... - Page 263 Option 1P: HC100 4 Pen Plotter With this option, Tektronix ships a four color plotter designed to make wave form plots directly from the digitizing oscilloscope without requiring an exter nal controller. It handles A4 and US letter size media.

-

Page 264: Table 7 2: Standard Accessories

Options and Accessories Option 23: Active Probes With this option, Tektronix ships two active high speed voltage probes (the P6205 10X FET). Option 9C: Certificate of Calibration and Test Data Report Tektronix ships a Certificate of Calibration which states this instrument meets... -

Page 265: Table 7 4: Optional Accessories

016-0708-00 Optional Accessories You can also order the following optional accessories: Table 7 4: Optional Accessories Accessory Part Number TDS 520A, 524A, 540A, & 544A Service Manual 070-8713-03 Plotter (GPIB and Centronics Standard) HC100 Oscilloscope Cart K218 Rack Mount Kit (for field conversion) - Page 266 P6703A Opto Electronic Converter, 1100 to 1700 nm, DC to 1 GHz 1 V/mW. P6711 Opto Electronic Converter, 500 to 950 nm, DC to 250 MHz 5 V/mW. P6713 Opto Electronic Converter, 1100 to 1700 nm, DC to 300 MHz. 5 V/mW. TDS 520A, 524A, 540A, & 544A Service Manual...

-

Page 267: Table 7 3: Probe Accessories

Options and Accessories TVC 501 Time to voltage converter. Time delay, pulse width and period measurements. Probe Accessories The following optional accessories are recommended for use with the stan dard probe listed under Standard Accessories. Table 7 5: Probe Accessories Accessory Part Number 013-0226-00... -

Page 268: Table 7 6: Accessory Software

Options and Accessories Accessory Software The following optional accessories are Tektronix software products recom mended for use with your digitizing oscilloscope: Table 7 6: Accessory Software Software Part Number EZ Test Program Generator S45F030 Wavewriter: AWG and waveform creation S3FT400... - Page 269 Options and Accessories Options...

- Page 270 Electrical Parts Replace this page with the Tab named Electrical Parts List...

- Page 272 The modules that make up this instrument are often a combination of me chanical and electrical subparts. Therefore, all replaceable modules are listed in Section 10, Mechanical Parts List. Refer to that section for part numbers when using this manual. TDS 520A, 524A, 540A, & 544A Service Manual...

- Page 273 Replaceable Electrical Parts List Electrical Parts List...

- Page 274 Diagrams Replace this page with the Tab named Diagrams...

- Page 276 The tilde (~) preceding a signal name indicates that the signal performs its intended function when in the low state. Other standards used in the preparation of diagrams by Tektronix. Inc are: Tektronix Standard 062-2476 Symbols and Practices for Schematic Drafting ANSI Y14.159-1971 Interconnection Diagrams...

-

Page 277: Figure 9 1: Interconnections

Diagrams FRONT PANEL 26 PINS SWITCHES ACQUISITION BOARD J1201 FRONT PANEL CH3OUT KNOBS J1550 AUXTRIG SIGNAL J1000 MENU SWITCHES 10 PINS J1001 FLEX FRONT PANEL BOARD CALOUT J920 9 PINS P1400 CH 1 CH1OUT INPUT1 J1400 9 PINS P1351 P1300 9 PINS 9 PINS J501... - Page 278 2 PINS 2 PINS 100 PINS J560 12 PINS 4 PINS 4 PINS (OPTION 05) DRAM PROCESSOR/ DISPLAY DRIVER SHUTTER DRIVER CONNECTOR BOARD DISPLAY BOARD BOARD BOARD Figure 9 1: Interconnections (Cont.) TDS 520A, 524A, 540A, & 544A Service Manual...

- Page 279 Diagrams A20 CRT Driver for Monochrome Models only (TDS 520A and TDS 540A) CRT DRIVER BOARD (TDS 520A & 540A) J574 TUBE ASSEMBLY 16 PINS 16 PINS CRT DRIVER DRAM PROCESSOR/ (TDS 520A & 540A DISPLAY BOARD Figure 9 1: Interconnections (Cont.)

-

Page 280: Figure 9 2: Block Diagram

SIGNAL PROBE COMPENSATION FRONT PANEL LOW VOLTAGE POWER SUPPLY SERPAR POWER BOARD TO ALL CIRCUITS MAIN LV POWER SUPPLY MAIN CONVERTER CONTROL FLOPPY DRIVER POWER FACTOR CONTROL Figure 9 2: Block Diagram TDS 520A, 524A, 540A, & 544A Service Manual... - Page 281 Diagrams CHANNEL 3 SIGNAL OUT AUX TRIGGER INPUT MAIN TRIGGER OUTPUT DELAYED TRIGGER OUTPUT OPTION 05 CONNECTOR BOARD GPIB IEEE STD 488 PORT PROCESSOR SYSTEM REAR PANEL CRT_ANODE VERT_YOKE ~FSYNC VIDEO /VIDEO GRID1,2 V1000 ~VSYNC FOCUS DISPLAY VIDEO SYSTEM BOARD ~HSYNC HORIZ_YOKE ~FSYNC...

- Page 282 Mechanical Replace this page with the Tab named Mechanical Parts Parts List...

- Page 284 Replaceable Parts This section contains a list of the replaceable modules for the TDS 520A, 524A, 540A, & 544A. Use this list to identify and order replacement parts. Parts Ordering Information Replacement parts are available through your local Tektronix field office or representative.

- Page 285 Using the Replaceable Parts List This section contains a list of the mechanical and/or electrical components that are replaceable for the TDS 520A, 524A, 540A, & 544A. Use this list to identify and order replacement parts. The following table describes each column in the parts list.

- Page 286 SUB OF COOPER INDUSTRIES INC 75915 LITTELFUSE INC 800 E NORTHWEST HWY DES PLAINES IL 60016-3049 SUB TRACOR INC 80009 TEKTRONIX INC 14150 SW KARL BRAUN DR PO BOX 500 BEAVERTON OR 97077-0001 10 3 TDS 520A, 524A, 540A, & 544A Service Manual...

- Page 287 KNOB:SMALL,FLUTED TK1163 ORDER BY DESC 650-2927-XX REPLACEABLE AS:DISPLAY FRAME WITH FLEX 80009 6502927XX 378-0366-XX FILTER,LT,CRT:6.75 X 5.50,DARK GRAY 80009 3780366XX (TDS 520A/540A ONLY) 386-6211-XX RETAINER,FILTER:DUST SEAL ASSY,LEXAN TK1163 3866211XX (TDS 520A/540A ONLY) 386-5954-XX PANEL,INPUT:PLASTIC,ATTENUATOR 80009 3865954XX 614-0914-XX FRONT PNL ASSY:FRONT PANEL...

-

Page 288: Figure 10 1: Cabinet And Front Panel