Summary of Contents for BEFCO RS2-04R

- Page 1 BEFCO ® Operator’s Manual HAY EQUIPMENT Hay Rakes RS2-04R, RS2-05R, RS2-06R RS2-04L, RS2-05L, RS2-06L The operator’s manual is a technical service guide and must always accompany the machine. Manual 960-184B November 2014...

-

Page 2: Signal Words

SAFETY Take note! This safety alert symbol found throughout this manual is used to call your attention to instructions involving your personal safety and the safety of others. Failure to follow these instructions can result in injury or death. This symbol means: ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED! - Page 3 4 - MAINTENANCE 4.01 - Maintenance Safety 4.02 - Service 5 - REPAIR PROCEDURES 5.01 - Rake Teeth Replacement 5.02 - Suggested Spare Parts 5.03 - Storage 6 - TROUBLESHOOTING 7 - PRE-DELIVERY CHECKLIST 8 - WARRANTY PARTS MANUAL BEFCO NDEX...

-

Page 4: General Information

This limited warranty covers defective material and workmanship. The cost of normal maintenance or repairs for accidents or improper use and related labor will be borne by the owner. See Chapter 8 - Warranty. BEFCO ENERAL NFORMATION... -

Page 5: Model And Serial Number Id

Attached to the frame is an ID plate showing the model and the serial number. Record your implement model and serial number in the space provided below. Your dealer needs this information to give you prompt, efficient service when you order parts. BEFCO ENERAL NFORMATION... -

Page 6: Safety Precautions

7. Operate only in daylight or good artificial light. 8. Ensure implement is properly mounted, adjusted and in good operating condition. 9. Ensure that all safety decals are properly installed and in good condition. BEFCO AFETY RECAUTIONS... -

Page 7: Starting And Stopping

5. Allow no riders on tractor or implement. 6. Allow moving parts to stop before repair. 7. Securely support implement before working underneath. Additional warning and operating decals are available at no extra charge. Please specify model and serial number when ordering. BEFCO AFETY RECAUTIONS... - Page 8 ’ AKES PERATOR ANUAL Fig. 2 - Safety decals - implement; replace immediately if damaged. right side left side BEFCO AFETY RECAUTIONS...

-

Page 9: Operational Safety

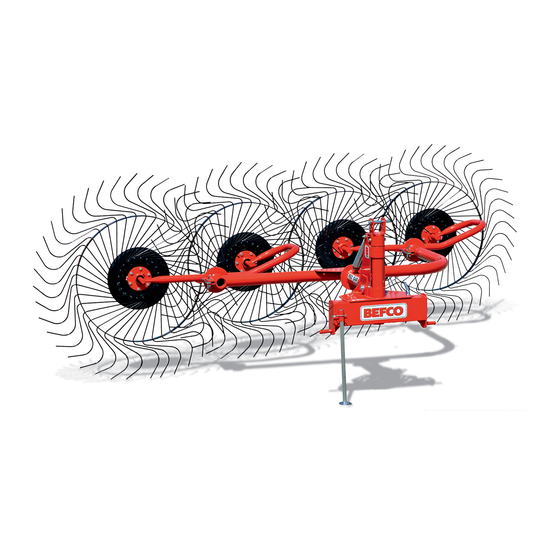

As the tractor moves forward, the wheels on BEFCO’s hay rakes gently turn the hay towards the back of the unit leaving all the hay raked in fluffy windrows suitable to form a compact and even bale. - Page 10 Slow down on sharp turns and slopes to prevent tipping and/or loss of control. 23. Comply with all federal, state and local laws during transport on roads. 24. Before parking the machine, lower the foot stand and secure it with the lock pins. See Chapter 4 - Maintenance. BEFCO PERATION...

- Page 11 5. To facilitate further assembly, use a hoist to attach the three point hitch of the hay rake to the three point hitch of the tractor. Secure the top link with the top hitch pin and the Ø4 hairpin cotter and the bottom hitches with lynch pins. See Chapter 7 - Pre-Delivery Checklist. BEFCO PERATION...

- Page 12 10. Assemble the foot stand on the base and secure it with the Ø4 hairpin cotter. 11. Tighten all hardware securely. Fig. 3 - Rake assembly rake wheel arm with hubs support arm top link support locking three point hitch base frame holder hitch BEFCO PERATION...

-

Page 13: Pre-Operational Check

1 three point hitch DANGER: Never allow anyone to stand between the hay rake and tractor during hookup operations. Refer to Table 1 - Torque Specifications, page 23. Refer to Table 2 - Technical Features, page 23. BEFCO PERATION... - Page 14 5. To have read and understood all safety decals on the implement. 6. To have contacted the local utility companies to make certain there are no bundled gas lines, electrical cables, etc., in the work area. 7. Checking the overall condition of the machine. BEFCO PERATION...

-

Page 15: Working Speed

RS2-04 rakes (see #1, fig. 5) and the second hole for RS2-05 and RS2-06 rakes (see #2, fig. 5). Setting the rake with the least amount of pressure will help to keep the finger wheels cleaner and therefore keep dirt off the forage. BEFCO PERATION... - Page 16 BEFCO’s RS2-04, RS2-05 and RS2-06 hay rakes offer six different angling positions that allow the operator to fine tune the unit to obtain the best raking results for his job (see fig. 6). The first hole on either side of the frame holder hitch is always the one to be used when transporting the hay rake (see #1, fig.

- Page 17 In the raking position, the rake wheels overlap front to back moving the crop to the center (see fig. 7). Proper raking is obtained by positioning the bends, on both the support arm and the arms with hubs, towards the back of the unit. Fig. 7 - Raking BEFCO PERATION...

- Page 18 Proper turning is obtained by positioning the bend on the support arm towards the tractor and bends on the arms with hubs towards the back of the unit (see fig. 9). Fig. 9 - Turning BEFCO PERATION...

-

Page 19: Uneven Terrain

CAUTION: Do not tow tractor and implement behind other vehicles. Use a properly equipped trailer with heavy tie-downs for towing operations. tighten turnbuckle to increase ground turn support clearance arm 90° Fig. 10 - Preparing hay rake for transport BEFCO PERATION... - Page 20 3. Reduce ground speed when turning and take care that the implement does not strike obstacles such as trees, fences or buildings. IMPORTANT: Always remember to engage the lock plate (see fig. 5) and reposition the locking pin in the transport position hole before transporting the hay rake (see fig. 6). BEFCO PERATION...

-

Page 21: Maintenance Safety

The Company will not claim responsibility for use of unapproved parts and/or accessories and other damages as a result of their use. Refer to Table 1 - Torque Specifications, page 23. BEFCO AINTENANCE... - Page 22 3. Remove any wrapping (stalks, weeds, trash, etc.) from implement. Every 8 hours: Grease fittings on wheel hubs (see fig. 12). Every 25 hours: Check hardware tightness; vibration can loosen bolts Fig. 12 - Grease points Refer to Table 1 - Torque Specifications, page 23. BEFCO AINTENANCE...

- Page 23 Working Weight lb. wheels diameter wheel diameter width width height speed RS2-04 30-80 56” 9/32” 8’6” 4’9” 12’10” 14 mph RS2-05 30-80 56” 9/32” 11’ 7’5” 14’6” 14 mph RS2-06 30-80 56” 9/32” 12’9” 7’5” 17’3” 14 mph BEFCO AINTENANCE...

-

Page 24: Repair Procedures

2. Slide the damaged tooth out of the wheel rake outer wheel frame and replace it with a new tooth. 3. Reassemble the tine clip using the M10x25 carriage bolts and secure it with the M10 nuts. Fig. 13 - Tooth replacement nut M10 tooth bolt M10x25 tine clip BEFCO EPAIR ROCEDURES... -

Page 25: Suggested Spare Parts

WARNING: Be sure to store the implement on a hard level surface and away from people especially children. Refer to Table 1 - Torque Specifications, page 23. See Chapter 4 - Maintenance. BEFCO EPAIR ROCEDURES... -

Page 26: Troubleshooting

Grease rake wheel. not turning. Bearing failure. Replace bearing. Excessive ground pressure. Ensure tractor SCV lever is in float position while working. Bolt lower spring clip to hole further away from springs to reduce ground pressure (see fig. 5). BEFCO ROUBLESHOOTING... - Page 27 Rake outer wheel Excessive ground speed. Reduce ground speed. breaking. Excessive ground pressure. Ensure tractor SCV lever is in float position while working. Bolt lower spring clip to hole further away from springs to reduce ground pressure (see fig. 5). BEFCO ROUBLESHOOTING...

-

Page 28: Pre-Delivery Checklist

IMPORTANT: Warranty is not valid unless Pre-Delivery Checklist and Warranty Registration form in Operator’s Manual is completed in detail and mailed to the Company. Model Number: __________ Serial Number: __________ Delivery Date: __________ Dealer’s Signature: __________ BEFCO ELIVERY HECKLIST... -

Page 29: Warranty

1. LIMITED WARRANTY BEFCO, Inc. herein referred to as the Company, warrants its machines and related accessories, hereafter referred to as the Machine, to be free from defects in material and workmanship, for a period of twelve (12) months from the date of invoice to the first registered owner;... - Page 30 6. WARRANTY SERVICE Warranty Service must be performed by a dealer authorized by BEFCO. If the warranty service requested is approved, the owner shall pay only for labor beyond the rate allowed, for overtime labor, and for any mileage charge for transporting the equipment to and from the dealer’s shop.

-

Page 31: Warranty Registration

Operator’s Manual and literature published by the Company. Inspected by: Date: Date: Dealer’s Signature: Customer’s Signature: This registration along with a copy of the invoice must be sent to BEFCO, Inc. within 14 days of date of purchase. - Page 32 Place stamp here BEFCO, Inc. Warranty Department P.O. Box 6036 Rocky Mount, NC 27802-6036...

-

Page 33: Parts Manual

BEFCO ® Parts Manual HAY EQUIPMENT Hay Rakes RS2-04R, RS2-05R, RS2-06R RS2-04L, RS2-05L, RS2-06L BEFCO RS2-04, RS2-05, RS2-06 (US).lwp Parts Manual 12/2013 November 13, 2014 RS2-04R, 05R, 06R Ver. A RS2-04L, 05L, 06L Ver. A... - Page 34 ’ AKES HREE POINT HITCH PERATOR ANUAL RS2-04, RS2-05, RS2-06 BEFCO ARTS ANUAL 08/2013...

- Page 35 Washer, flat Ø21x37x3 Z 502-928B Pin, locking Ø16x178 Z 503-929B Locking lever, pivot housing 000-7716 Bolt HH M12-1.75x45 C8.8 Z F 009-4139 Nut ES M12-1.75 Z TN 004-1291 Hairpin cotter Ø5 003-2366 Hairpin cotter double loop Ø4 BEFCO ARTS ANUAL 08/2013...

- Page 36 ’ AKES RAME PERATOR ANUAL RS2-04 BEFCO ARTS ANUAL 08/2013...

- Page 37 RS2-04 Ref. Part # Description Qty. 502-943B Support arm, 4 wheel; RS2-04 502-947B Arm w/hub right, 2 wheel; RS2-04R 502-948B Arm w/hub left, 2 wheel; RS2-04L 502-938B Pin, locking Ø12x56 Z 001-5240 Hairpin cotter Ø3 000-7716 Bolt HH M12-1.75x45 C8.8 Z F 003-0064 Nut PT M12-1.75 C6 Z TK...

- Page 38 ’ AKES RAME PERATOR ANUAL RS2-05 BEFCO ARTS ANUAL 08/2013...

- Page 39 000-1020 Washer, lock Ø14 Z 000-1019 Nut HH M14-2.00 C6 Z TK 502-938B Pin, locking Ø12x56 Z 000-7716 Bolt HH M12-1.75x45 C8.8 Z F 003-0064 Nut PT M12-1.75 C6 Z TK 503-929B Locking lever, pivot housing BEFCO ARTS ANUAL 08/2013...

- Page 40 ’ AKES RAME PERATOR ANUAL RS2-06 BEFCO ARTS ANUAL 12/2013...

- Page 41 Nut PT M12-1.75 C6 Z TK 503-929B Locking lever, pivot housing Part no longer available. Must order #18031074 (Qty. 1), #18031075 (Qty. 1), #003-8614 (Qty. 3), #000-1279 (Qty. 3), #000-1280 (Qty. 3) and #000-2034 (Qty. 3). BEFCO ARTS ANUAL 12/2013...

- Page 42 & ’ AKES AKE WHEEL PERATOR ANUAL RS2-02, RS2-03, RS2-04, RS2-05, RS2-06 BEFCO ARTS ANUAL 08/2013...

- Page 43 Dust cover 003-3176 Bolt HH M10-1.50x25 C8.8 Z F 306-002F Grease fitting M08-1.25 STR Z 006-7217 Pin cotter Ø3x35 N 003-0156 Nut PT M10-1.50 C6 Z 502-949B Wheel complete right 502-950B Wheel complete left (not shown) BEFCO ARTS ANUAL 08/2013...

- Page 44 ’ AKES ECALS PERATOR ANUAL RS2-04, RS2-05, RS2-06 BEFCO ARTS ANUAL 08/2013...

- Page 45 950-493B Decal “WARNING - Crushing hazard” 950-417B Decal “CAUTION - To avoid serious injury” 950-477B Decal “RS2” 950-480B Decal “04R” 950-481B Decal “05R” 950-482B Decal “06R” 960-184B Manual hay rakes RS2-04R, 04L, 05R, 05L, 06R, 06L BEFCO ARTS ANUAL 08/2013...

- Page 47 Use only original spare parts All rights reserved. It is unlawful to copy, reprint or use any of the information or details in this manual without the expressed written permission of the Company. Technical information provided in this manual is approximate, the Company reserves the right to modify or improve the models shown for technical or commercial purposes.

- Page 48 ® P.O. Box 6036 Rocky Mount, NC 27802-6036 Tel.: 252.977.9920 - Fax: 252.977.9718 www.befco.com ®...

Need help?

Do you have a question about the RS2-04R and is the answer not in the manual?

Questions and answers