Summary of Contents for FISNAR VDP100

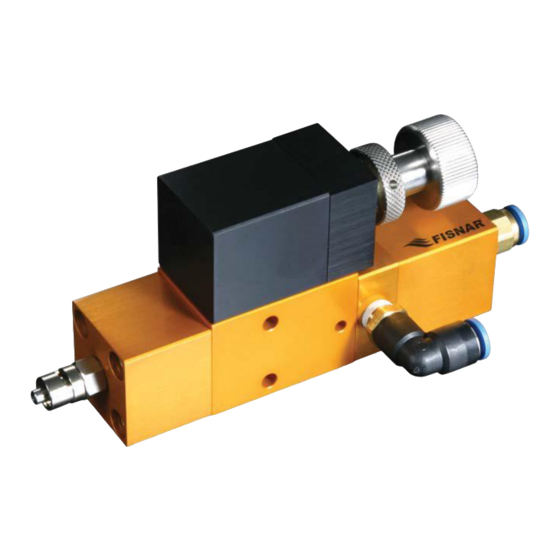

- Page 1 Rev. A - October, 2013 VDP100 INSTRUCTION MANUAL DISPENSING VALVE MODEL VDP100 ◀INSTRUCTION MANUAL▶...

-

Page 2: Table Of Contents

Rev. A - October, 2013 VDP100 INSTRUCTION MANUAL CONTENTS 1. Safety - - - - - - - - - - - - - - - - - - - - - - - - - 3 2. Introduction - - - - - - - - - - - - - - - - - - - - - - - - - 5 3. - Page 3 Rev. A - October, 2013 VDP100 INSTRUCTION MANUAL SECTION 1 GENERAL SAFETY WARNINGS 1. Equipment Misuse Hazards Any misuse of the dispensing equipment or accessories such as over- pressurizing, modifying parts, using incompatible chemicals and fluids, or using worn or damaged parts, can cause item to rupture and result in fluid splashing in the eyes or on to the skin.

-

Page 4: Safety

Rev. A - October, 2013 VDP100 INSTRUCTION MANUAL 2. Hose Safety High pressure fluid in the hoses can be very dangerous. If the hose develops a leak, split or rupture due to any kind of wear, damage or misuse, the high pressure spray emitted from it can cause material to splash in the eyes or on the skin. -

Page 5: Introduction

1%, such as oil and grease. The VDP100 valve has a range up to 0.9cc. The model VC1195N is a suitable 4-way valve controller for the VDP100 double acting metering valve. -

Page 6: Specification

Rev. A - October, 2013 VDP100 INSTRUCTION MANUAL SECTION 3 SPECIFICATION 4 - 5 kgf/cm² (56psi – 71psi) Operating Air Pressure Material Delivery Pressure MAX 80kgf/cm (1137psi) Metering Type (0.1cc – 0.9cc) Valve Structure Material Body : AL(hard coating) Driving part material... -

Page 7: Operation

Rev. A - October, 2013 VDP100 INSTRUCTION MANUAL SECTION 4 OPERATION 1. Commissioning the Valve a. Open the air line (A) and fluid line (B) of the dispensing valve. b. Keep cycling the machine until all air in the line is removed. -

Page 8: Disassembly / Reassembly

Rev. A - October, 2013 VDP100 INSTRUCTION MANUAL SECTION 5 DISASSEMBLY / REASSEMBLY ISOLATE ALL AIR AND MATERIAL FEEDS FROM THE VALVE PRIOR TO SERVICING. 1. Disassembly a. Remove the four Bolts (16) from the Change Body (17). b. Remove the bolts (7), disassembling the Metering Body (1) and Metering Cap (6). -

Page 9: Exploded View / Parts List

Rev. A - October, 2013 VDP100 INSTRUCTION MANUAL SECTION 6 EXPLODED VIEW AND PARTS LIST 1. Metering Body (Aluminum) 2. O-ring 3. Piston(Bronze) 4. O-ring 5. O-ring 6. Metering Cap(Aluminum) 7. Bolt 8. Stopper Washer 9. Stopper Lock Nut(Stainless Steel) 10. -

Page 10: Troubleshooting

Rev. A - October, 2013 VDP100 INSTRUCTION MANUAL SECTION 7 TROUBLESHOOTING Shaft does not move o Check power of the air supply line and other equipment. o Check for cured material at the valve outlet. Material leaks o If it leaks from the Needle (12), unfasten the Metering Cap (6) and clean the O-ring (2) on the Piston (3). -

Page 11: Dimensions

Rev. A - October, 2013 VDP100 INSTRUCTION MANUAL SECTION 8 DIMENSIONS 11 | P a g e...

Need help?

Do you have a question about the VDP100 and is the answer not in the manual?

Questions and answers