Table of Contents

Summary of Contents for Sutter Instrument MPC-365 Series

- Page 1 MPC-365 Series Multi Motorized Narrow-Format Micromanipulator Control System Operation Manual Rev. 3.21k (20201120) One Digital Drive Novato, CA 94949 Voice: 415-883-0128 Web: www.sutter.com Fax: 415-883-0572 Email: info@sutter.com...

- Page 2 Copyright © 2020 Sutter Instrument Company. All Rights Reserved. MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120)

-

Page 5: Disclaimer

Do not allow unauthorized and/or untrained operative to use this device. Any misuse will be the sole responsibility of the user/owner and Sutter Instrument Company assumes no implied or inferred liability for direct or consequential damages from this instrument if it is operated or used in any way other than for which it is designed. -

Page 6: Operational

Always wear safety glasses when using sharp glass micropipettes with pressure microinjectors. Do not handle the manipulator mechanical while the power is on and take care to ensure no cables pass close to the mechanical manipulator. MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120) -

Page 7: Other

Failure to do this may result in damage to the motors. This instrument contains no user-serviceable components — do not open the instrument casing. This instrument should be serviced and repaired only by Sutter Instrument or an authorized Sutter Instrument servicing agent. ... - Page 8 (This page intentionally left blank.) MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120)

-

Page 9: Table Of Contents

Handling Micropipettes .......................... 5 1. INTRODUCTION ........................... 11 1.1 Structure of the MPC-365 Documentation Package ..............11 1.2 Components of the MPC-365 Series ..................... 11 2. MPC-200 MULTI-MANIPULATOR CONTROLLER AND ROE-200 INPUT DEVICE OPERATIONS ............................ 13 2.1 Electrical Connections and Initial Operating Instructions ............13 2.2 Initial Operating Instructions ....................... - Page 10 Figure 2-2. Top view of ROE-200......................15 Figure 2-3. Side view of ROE-200......................17 Figure 2-4. Configuration switches on rear of MPC-200 controller cabinet........19 Figure 2-5. Configuration switches (rear of MPC-200 controller)............21 MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120)

- Page 11 Table D-1. MPC-365 Controller cables and receptacles/connectors............ 58 Table E-1. ROE-200 configuration switches (rear)................59 Table E-2. MPC-200 rear-panel config. Switches 1 – 4 (angle setting) for Device, A or B....59 MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120)

- Page 12 Table E-6. Microns/microsteps conversion factors (multipliers)............61 Table E-7. Ranges and bounds........................ 61 Table E-8. Travel speeds.......................... 62 Table E-9. MPC-200 controller external-control commands............... 62 Table E-10. Straight-line move ‘S’ command speeds................66 MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120)

-

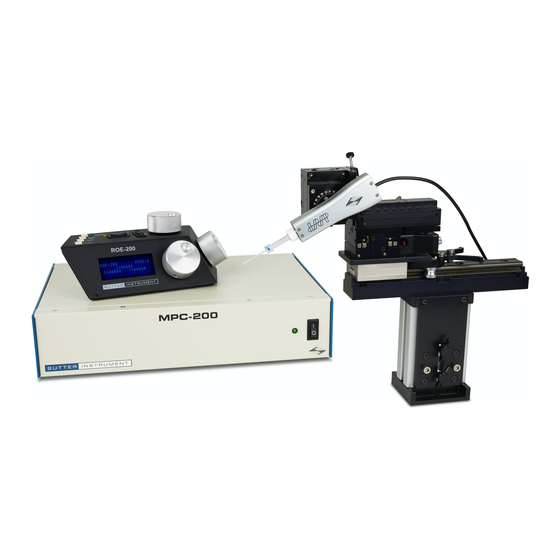

Page 13: Introduction

MPC-200-to-MP-856/M connecting cable (DB25 to compact DB 26 (25-pin) cable) • Power cable (for the MPC-200 controller) appropriate for your location • USB cable for computer control of the MPC-365 series system (connects to the ROE-200) • Primary to secondary MPC-200 daisy chain cable for future expansion (RJ-12 6-pin flat cable) 2. - Page 14 2 ROE-200 Rotary Optical Encoder manual control device 2 ROE-200-to-MPC-200 connecting cable (RJ-45 8-pin flat cable) 2 USB cable for computer control of the MPC-365 series system 6. MPC-365-6 (a six-manipulator system). Same as for the MPC-365, with the following changes: ...

-

Page 15: Mpc-200 Multi-Manipulator Controller And Roe-200 Input Device Operations

As it initializes, you will see a startup screen on the ROE-200 that briefly displays the name of the device and the version of the installed MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120) - Page 16 In MODE 0, when the ROE knob is turned slowly, a relatively slow movement is achieved that is useful for final moves to place a pipette near a cell. Conversely, when you make prolonged, rapid turns of the ROE knob, the controller/ROE automatically accelerates MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120)

-

Page 17: Main Controls On The Roe-200

When you return to Normal mode, the absolute coordinate system is recovered. The relative coordinate feature can be disabled via DIP switch 2 on back of the ROE-200. Figure 2-2. Top view of ROE-200. MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120) -

Page 18: Black Selector Switches

MODE 0 is Accelerated Mode. In MODE 0, slow turns of the ROE knob produce medium course moves for moving a pipette under a microscope near a cell. Prolonged, fast turns of the ROE knobs cause the controller to accelerate to top speed for long, imprecise movements MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120) -

Page 19: Other Controls On The Roe-200

ROE-200. This will cause a prolonged movement in each axis to the end of travel (EOT) sensors beyond the origin (0,0,0). Once the sensors are found, a short MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120) -

Page 20: Controls On The Mpc-200

"ON" next to Switch 1. For any new switch settings to take effect, the controller must be powered off and on. MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120) -

Page 21: Figure 2-4. Configuration Switches On Rear Of Mpc-200 Controller Cabinet

1, 2, 3 and 4. As indicated in the inset to the left of the table, the angles fall into two different quadrants according to whether the angles are more or less steep than 45 degrees. MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120) -

Page 22: Table 2-1. Configuration Switch Settings For Different Angles Of Steepness

1, a clockwise turn of the knob produces an increment in the display. An increment in the display coincides with movement downward in the Z axis, MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120) -

Page 23: Figure 2-5. Configuration Switches (Rear Of Mpc-200 Controller)

HOME or WORK position moves. In the MPC-365 system, the factory default for switch 8 is 1 (the Y axis is not moved (Y position ignored) during the HOME or WORK position moves). Figure 2-5. Configuration switches (rear of MPC-200 controller). MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120) - Page 24 (This page intentionally blank.) MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120)

-

Page 25: Mp-865/M (And Mp-265/M) Manipulator Mechanical Mounting Instructions

MP-865/M’s or MP-265/M’s X-axis slide using the supplied hex wrench. Mounting plate for the Extended X-axis slide MP-865/M or MP-265/M locking lever Extended X-axis slide Adjustable elevation Figure 3-2. MT-73 controls and adjustments. MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120) -

Page 26: Setting Headstage/Pipette Angle And Pipette Exchange

The stand can be any flat surface carrying ¼-20 or 10-32 holes on one-inch centers (such as a Sutter Instrument’s MT-series stands or MD series platforms). A good technique is to set the manipulator on top of the adapter plate and slide it around on your stand until it is in a good location. -

Page 27: Figure 3-4. Headstage Mounting

Rod mounted headstages and micro tools are accommodated by use of a rod clamp that fits into the dovetail (not shown). All the headstage adapters and mounting hardware are included with the manipulator and are shipped in a zip lock plastic bag. MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120) -

Page 28: Other Accessories

It is possible to change handedness of the MP-865 (or MP-265) mechanical. If you wish to do this, please contact Sutter Instrument for details. If you wish, Sutter can change the handedness for you. We will charge for shipping only. -

Page 29: Operations

4.2 Make It Go 1. Turn on the power using the ON/OFF switch on the front panel of the MPC-200 controller cabinet… MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120) -

Page 30: Basic Operation

4.3.1 Standard Screen ROE-200 MODE:0 Z=00000 X=00000 Y=00000 4.3.2 No Manipulator Connected Screen NO MANIPULATOR DETECTED, PLEASE TURN OFF CONTROLLER ATTACH MANIPULATOR 4.3.3 Diagonal-Mode Screen (DIAGONAL) ROE-200 MODE:0 Z=00000 X=00000 Y=00000 D=00000 MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120) -

Page 31: Move In Progress Screen

4.3.4 Move in progress screen: PLEASE WAIT MOVE IN PROGRESS 4.3.5 Setting Work Position (WORK POS) ROE-200 DEVICE LOCKED (HOLD WORK POS. FOR 2s TO UNLOCK DEVICE) MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120) - Page 32 (This page intentionally blank.) MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120)

-

Page 33: External Control

MPC-200 controller over the USB interface between the computer and the USB connector on the rear of the ROE-200 that’s connected to the MPC-200 controller. The USB device driver for Windows is downloadable from Sutter Instrument’s web site (www.sutter.com). The MPC-365 (MPC-200) requires USB CDM (Combined Driver Model) Version 2.10.00 or higher. -

Page 34: Command Sequence Formatting

Little- Endian enforcement may be needed if running on a Big-Endian system. Some processors (e.g., ARM) can be configured for specific endianess. MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120) -

Page 35: Microsteps And Microns (Micrometers)

MOM objective mover (firmware v3.13 or 3.16, and device Port A only): 21.5mm in all three axes. 5.7 Travel Speed The following table shows the travel speeds for single-, double-, and triple-axis movements for supported devices using orthogonal move commands. MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120) -

Page 36: Commands

2: No 0000 0001 <SOH> 2: Yes 0000 0000 <NUL> 3: No 0000 0001 <SOH> 3: Yes 0000 0000 <NUL> 4: No 0000 0001 <SOH> 4: Yes 0000 1101 <CR> Completion indicator MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120) -

Page 37: Get Active Device & Firmware Version ('K') Command

= (verbyte & 0x0F) + ((verbyte >>4 & 0x0F) * 10); Major version number as an integer (e.g., 3): verbyte = ret[2]; /* get major ver. digits */ majver = (verbyte & 0x0F) + MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120) -

Page 38: Get Current Position ('C') Command

(1 byte). Table 5-8. Change Active Device (‘I’) command. Value Description Command Tx/- Ver. Total Byte Alt- Ctrl- ASCII Delay/- Bytes Offset key- char def./- Dec. Hex. Binary (Len.) pad # char. MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120) -

Page 39: Move To Controller-Defined Home Position ('H') Command

This command moves to the center position (midpoint between beginning of travel and end of travel positions). Movement is equivalent to pressing the CENTER key. The “Home Position” is defined manually on the ROE-200. The “Work Position” is defined manually on the ROE-200. MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120) -

Page 40: Move To Specified Position Orthogonally At Full Speed ('M') Command

Move to Specified Position in a Straight Line at Specified Speed (‘S’)CommandThis command instructs the controller to move all three axes to the position specified, in straight line at the specified speed (Speed Level 0 – 15). The command sequence consists of fourteen bytes. MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120) -

Page 41: Table 5-13. Move To Specified Position In A Straight Line At Specified Speed ('S') Command

0.65000 650.00 650000 50.00% 0.56875 568.75 568750 43.75% 0.48750 487.50 487500 37.50% 0.40625 406.25 406250 31.25% 0.32500 325.00 325000 25.00% 0.24375 243.75 243750 18.75% 0.16250 162.50 162500 12.50% 0.08125 81.25 81250 6.25% MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120) -

Page 42: Interrupt Move ('^C') Command

(after sending a command sequence and before sending the next command). Clearing Send/Receive Buffers: Clearing (purging) the transmit and receive buffers of the I/O port immediately before sending any command is recommended. MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120) - Page 43 /* initialize all minimum positions in microns*/ min_x_um = 0; min_y_um = 0; min_z_um = 0; /* initialize all maximum positions in microns */ /* MP-865/M */ max_x_um = 50000; max_y_um = 12500; MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120)

- Page 44 = cp_x_um + rp_x_um; /* add relative pos. to current pos. */ /* convert new absolute X position in microns to microsteps */ sp_x_us = sp_x_um * um2usCF; Repeat for each of the remaining axes as required before issuing a move command. MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120)

- Page 45 MP-265/M and MP-285/M (and based devices) – see table. Straight-Line Move Speeds: Actual speed for the “Straight-Line Move ‘S’“ command can be determined with the following formula: (1300 / 16) * (sp +1), where 1300 is the MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120)

-

Page 46: Table 5-17. Straight-Line Move 'S' Command Speeds

= ret[1]; /* get minor ver. digits */ /* get 1’s digit & then get & add 10’s digit */ minver = (verbyte & 0x0F) + ((verbyte >>4 & 0x0F) * 10); MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120) - Page 47 FF FF FF xx xx xx yy yy yy zz zz zz 0 1 2 3 cpxus 00 xx xx xx 0 1 2 3 cpyus 00 yy yy yy 0 1 2 3 cpzus 00 zz zz zz MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120)

- Page 48 Convert microsteps to microns. Use double-precision variables for current position in microns; initialize each to 0. double cpxum, cpyum, cpzum; cpxum = cpyum = cpzum = 0; Microsteps-to-microns conversion factor (see “Microns / microsteps conversion” table for appropriate factor) MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120)

- Page 49 (e.g., U16, U32, I32) are always in Big-Endian bit/byte order, while MPC-200 multibyte values are always transcieved in Little-Endian bit/byte order. A single completion indicator byte (ASCII CR) is returned when streaming ends and target position has been reached. MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120)

- Page 50 (This page intentionally left blank.) MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120)

-

Page 51: Maintenance

As such, it DOES NOT REQUIRE LUBRICATION. Attempting to lubricate any part of the electromechanical assembly will void the warranty and may harm one or more of the motors. MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120) - Page 52 (This page intentionally left blank.) MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120)

-

Page 53: Appendix A. Limited Warranty

Warranty work will be performed only at the factory. The cost of shipment both ways is paid for by Sutter Instrument during the first three months this warranty is in effect, after which the cost is the responsibility of the customer. - Page 54 (This page intentionally left blank.) MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120)

-

Page 55: Appendix B. Accessories

½-inch riser (MP-RISER-0.5) and 1-inch riser (MP-RISER-1.0) Suitable for upright microscopes. Useful with MD-series stand and large platform stages such as the MT-78-FS, MP-78, and MPC-78. Risers can be combined to achieve desired height. MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120) - Page 56 (This page intentionally left blank.) MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120)

-

Page 57: Appendix C. Fuse Replacement

(Examples: Bussmann GDC-2A. GMC-2A or S506-2-R (RoHS); or Littelfuse 218 200 or 218 200P (RoHS)) Figure C-1. Rear view of the MPC-200 controller cabinet showing the power entry module and fuse location. MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120) - Page 58 (This page intentionally left blank.) MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120)

-

Page 59: Appendix D. Technical Specifications

6.65 lb. (6 lb., 10.4 oz.; 3.02 kg) Electrical: Input voltage (Mains) 100 - 240 V , 50/60 Hz Power consumption 170 Watts maximum per MPC-200 controller (340W max. for an MPC-365-3 or MPC-365-4 system) MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120) -

Page 60: Roe-200

(approx. circuits. Foil B connector receptacle (full-sized) sized) 10 feet) shielding. D.4. ROE-200: Dimensions: 10 x 6 x 4 in (25.4 x 15.24 x 10.16 cm) Weight: 3.5 lbs. (1.6 kg) MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120) -

Page 61: Appendix E. Quick Reference

Table E-2. MPC-200 rear-panel config. Switches 1 – 4 (angle setting) for Device, A or B. Switch Steepness Relative Angle (Value) to 45° More None Less 0 = OFF (Up); 1 = ON (Down) MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120) -

Page 62: External Control

Y-Axis lockout during HOME & WORK position moves Y not moved ** * Normal operation (factory default). ** Normal operation (factory default) in MPC-365 series systems. RIGHT Table E-4. MPC-200 rear-panel RIGHT TRAN config. switches for Device A or B. TRANS... -

Page 63: Table E-6. Microns/Microsteps Conversion Factors (Multipliers)

Little- move commands. Endian enforcement may be needed if running on a Big-Endian system. Some processors (e.g., ARM) can be configured for specific endianess. MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120) -

Page 64: Table E-8. Travel Speeds

2: Yes 0000 0000 ^@ <NUL> 3: No 0000 0001 ^A <SOH> 3: Yes 0000 0000 ^@ <NUL> 4: No 0000 0001 ^A <SOH> 4: Yes 0D 0000 1101 <CR> Completion indicator MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120) - Page 65 Command: Calibrates the active 1.03 (FW >1.03) device. 0D 0000 1101 <CR> Completion indicator The “Home Position” is defined manually on the ROE-200. The “Work Position” is defined manually on the ROE-200. MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120)

- Page 66 0D 0000 1101 <CR> Completion indicator (‘F’) 4F 0100 1111 Turn ON Command (see ‘S’ Command’s Streaming Return Data for Current S-Move Position note) command streaming data 0D 0000 1101 <CR> Completion indicator (‘O’) MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120)

- Page 67 However, care should be taken to ensure that all relative cp_x_um = cp_x_us * us2umCF; /* microsteps to position calculations always result in correct positive absolute microns */ positions before initiating a move command. MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120)

-

Page 68: Table E-10. Straight-Line Move 'S' Command Speeds

One exception is the “Interrupt Move” (^C) before/after conversion to/from a multibyte type value (I32, command, which can be issued while a command-initiated U32, etc.). MATLAB automatically adjusts the endianess of move is still in progress. MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120) - Page 69 = cpyum = cpzum = 0; Microsteps-to-microns conversion factor (see “Microns / microsteps conversion” table for appropriate factor) double us2umCF = 0.0625; Get microns from microsteps for each axis cpxum = cpxus * us2umCF; MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120)

- Page 70 A single completion indicator byte (ASCII CR) is returned transferred into a byte array, and then into a U32 data type when streaming ends and target position has been reached. via a byte-swap function to ensure 24-bit to 32-bit NOTES: MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120)

-

Page 71: Index

..............57 microsteps and microns (micrometers) ..33, 61 maintenance ............49 move interruption ........44, 66 manual operation..........59 multi axis movement speed increase ..44, 66 Minimizing Electrical Noise ........ 26 MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120) - Page 72 Setting Headstage/Pipette Angle ......24 Special installations Instructions for changing handedness ... 26 warranty ..............51 weight .............. 57, 58 MPC-200 controller .......... 57 technical specifications ROE-200 ............58 MPC-200 controller dimensions ............. 57 NOTES MPC-365 SERIES OPERATION MANUAL – REV. 3.21K (20201120)

- Page 73 Addendum All Operation Manuals of MPC-200/ROE-200-Based MPC-Series Systems Rev. 1.00 – November 28, 2007 As of Version 3.11 (November 12, 2007) of the firmware for the MPC-200 micromanipulator controller and ROE-200 input device, the CENTER routine associated with the white button on the rear of the ROE-200 has been replaced with a CALIBRATE routine that is less likely to break a pipette.

Need help?

Do you have a question about the MPC-365 Series and is the answer not in the manual?

Questions and answers