Summary of Contents for CH Hanson Palmgren 9661615

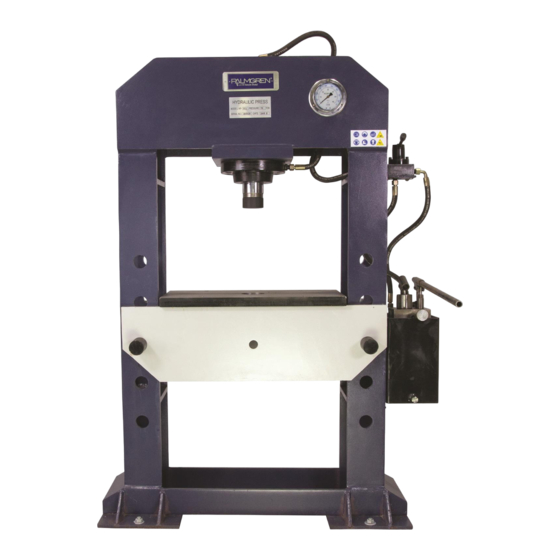

- Page 1 Operating Instructions & Parts Manual 75 Ton Manual Hydraulic Press Models 9661615 9643572.01...

- Page 2 PLEASE READ AND SAVE THESE INSTRUCTIONS. READ CAREFULLY BEFORE ATTEMPTING TO ASSEMBLE, INSTALL, OPERATE OR MAINTAIN THE PRODUCT DESCRIBED. PROTECT YOURSELF AND OTHERS BY OBSERVING ALL SAFETY INFORMATION. FAILURE TO COMPLY WITH INSTRUCTIONS COULD RESULT IN PERSONAL INJURY AND/OR PROPERTY DAMAGE! RETAIN INSTRUCTIONS FOR FUTURE REFERENCE.

-

Page 3: Getting Started

GETTING STARTED Package Contents: Pipe holder Save this manual Hydraulic pump assembly You will need this manual for the safety warnings and Frame with cylinder precautions, assembly instructions, operating and maintenance procedures, parts lists and diagrams. Keep your invoice with this Bag of replacement rubber manual. - Page 4 SAFETY RULES Preparing the work area for your job • Do not use this machine in dangerous environments. Do not Completely read and understand this use it in damp or wet locations. Do not expose it to rain. owner’s manual before assembly or tool operation.

-

Page 5: Specifications

Know how to use your tool SPECIFICATIONS The operation of any tool can result in Model 9661615 75 Ton Manual Hydraulic Presses foreign objects being thrown into the eyes, which can result in severe eye damage. Always wear Parameter Value safety goggles complying with United States ANSI Z87.1 before commencing power tool operation. - Page 6 ASSEMBLY/INSTALLATION Machine dimensions The following figure shows the approximate dimensions of the Lifting and setting up your machine hydraulic press and its parts. When determining a final location Make certain that slings, cables, chains, for your machine, ensure there is enough clearance for both forklifts or other load suspending gear or the operator and for technicians who will service the machine.

-

Page 7: Operation

OPERATION NOTE: The machine is adjusted to produce proper pressure at the factory. Always wear safety glasses complying Place the handle in the appropriate pump cylinder. with U.S. ANSI Z87.1 before beginning any power tool operation. Pump the hydraulic station, using the handle shown above. Do not operate this machine before Check the pressure using the gauge on top of the unit, properly lubricating the machine. -

Page 8: Troubleshooting Guide

TROUBLESHOOTING GUIDE Symptom Possible Cause(s) Corrective Action Ram does not move Low oil condition Fill oil Ram does not press Release valve not closed Close cylinder valve... -

Page 9: Maintenance/Repair

MAINTENANCE/REPAIR Before any maintenance is performed, ensure all pressure has been released. Daily: • General visual inspection-check for any visible damage or missing parts • Check that all labels are clearly visible and legible • Check for leaking hydraulic fluid Weekly: •... - Page 10 MAINTENANCE/REPAIR CROSS SECTION OF PISTON Item Description Item Description Oil Vat Pressurize Ring Stopcock Pressurize Ring Piston ring Pressurize Ring Pressurize Ring Vat Cover Piston Shaft Pressurize Ring Pressurize Ring Flange...

- Page 12 PALMGREN WARRANTY C.H. Hanson / Palmgren warrants their products to be free of defects in material or workmanship. This warranty does not cover defects due directly or indirectly to misuse, abuse, normal wear and tear, failure to properly maintain the product, heated, ground or otherwise altered, or used for a purpose other than that for which is was intended.