Subscribe to Our Youtube Channel

Summary of Contents for WEICHAI WP10NA

- Page 1 WEICHAI & PSI SERVICE MANUALS AVAILABLE ONLINE AT FLYPARTSGUY.COM WP10NA INSTALLATION AND APPLICATION MANUAL EMISSION-RELATED INSTALLATION INSTRUCTIONS FOR WP10GNA ENGINE NG, LPG & VPG 3100 GOLF ROAD, ROLLING MEADOWS, IL...

-

Page 2: Table Of Contents

WEICHAI & PSI SERVICE MANUALS AVAILABLE ONLINE AT FLYPARTSGUY.COM Contents INSTALLATION OF CERTIFIED ENGINES ..................1 NOTICE OF IMPORTANT REQUIREMENTS OF CERTIFIED ENGINES .......... 2 SYSTEM OVERVIEW ........................3 ENGINE MOUNTING SUSPENSION ................... 7 ELECTRICAL SYSTEM ......................... 9 INTAKE AIR SYSTEM ....................... 11 CLOSED CRANKCASE VENTILATION.................. -

Page 3: Installation Of Certified Engines

WEICHAI & PSI SERVICE MANUALS AVAILABLE ONLINE AT FLYPARTSGUY.COM INSTALLATION OF CERTIFIED ENGINES Thank you for your recent purchase of an EPA certified WEICHAI nonroad and Stationary Industrial Engine. These instructions are intended to give the installer of the engine all the information that is necessary to properly install the engine and related components into the equipment chassis. -

Page 4: Notice Of Important Requirements Of Certified Engines

Important Notice- The required Emission Control Information label has been placed on this certified engine during the WEICHAI assembly process. If you install the engine in a way that makes the engine's emission control information label hard to read during normal engine maintenance, you must place a duplicate label on the equipment, as described in 40 CFR 1068.105. -

Page 5: System Overview

Natural Gas (NG) to Propane (LPG/VPG) fuel is a software command from the operator console or a switch input into the 4G ECM. The Weichai WP10GNA engine is capable of operating in bi-fuel mode starting from VPG/LPG and switching to NG after the NG pressure develops from operation. With the... - Page 6 The input and output file structure and variable content need to be defined by the customer and implemented by WEICHAI. There will be an engineering change associated with setting up the file structures and debugging the communications with the telematics module.

- Page 7 WEICHAI & PSI SERVICE MANUALS AVAILABLE ONLINE AT FLYPARTSGUY.COM Figure 2: Direct Acting Electronic Pressure Regulator It is a continuous fuel flow device. This allows the most homogeneous mixture of air and fuel to the engine yielding optimum combustion with minimum emissions and maximum fuel economy.

- Page 8 WEICHAI & PSI SERVICE MANUALS AVAILABLE ONLINE AT FLYPARTSGUY.COM Figure 3: E480 Mixer MIXER: E480 A relatively constant pressure drop mixer is used to draw fuel when coupled with EPR. The basic principle of the product is to introduce air and fuel into engine. It also aids in introducing turbulence into the air and fuel assisting in making it a homogeneous mixture.

-

Page 9: Engine Mounting Suspension

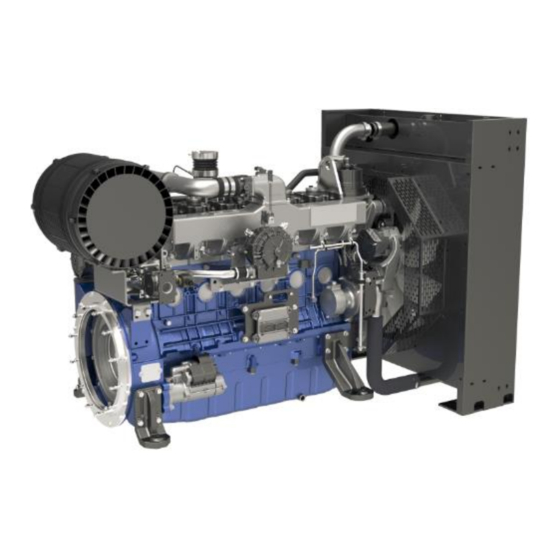

WEICHAI & PSI SERVICE MANUALS AVAILABLE ONLINE AT FLYPARTSGUY.COM HEAVY-DUTY DUAL STAGE REGULATOR (DSR) The heavy-duty dual stage regulator vaporizes liquid propane to gaseous form and also regulates the fuel pressure to meet the fuel pressure requirement. Figure 4: Heavy Duty Dual Stage Regulator The HD DSR is a two stage fully mechanical regulator that is available in LPG configurations. - Page 10 WEICHAI & PSI SERVICE MANUALS AVAILABLE ONLINE AT FLYPARTSGUY.COM Figure 5: Engine General Dimensions and layout...

-

Page 11: Electrical System

WEICHAI & PSI SERVICE MANUALS AVAILABLE ONLINE AT FLYPARTSGUY.COM ELECTRICAL SYSTEM WIRE HARNESS DIAGRAM Figure 6: Wire Harness Diagram... - Page 12 WEICHAI & PSI SERVICE MANUALS AVAILABLE ONLINE AT FLYPARTSGUY.COM CONTROL PANEL: Optional: PV380 AND REALATED HARNESS, Murphy MPC10, MPC20, and additional panel options are available. Contact Weichai for details. Figure 7: PV380 and Related Harness BATTERY SETUP The battery needs to be setup according to the steps below: Engine Electrical System is 24-volt DC Negative Ground Engine Battery should be 650CCA or Greater.

-

Page 13: Intake Air System

WEICHAI & PSI SERVICE MANUALS AVAILABLE ONLINE AT FLYPARTSGUY.COM CANBUS J1939 INTERFACE CONNECTING WITH ZTR TELEMATICS Figure 8: CANBUS J1939 Interface Connection with ZTR Telematics INTAKE AIR SYSTEM The intake system should be sealed between the mixer inlet and the filter. Proper clamps should be used to ensure unfiltered air is not drawn into the system. -

Page 14: Closed Crankcase Ventilation

Figure 9: Intake Air System CLOSED CRANKCASE VENTILATION Weichai engine uses a closed crankcase system as shown in Figure 10. The breather separates the crankcase oil/gas mixture and lets the oil return to the sump and sends the gas into the intake system. -

Page 15: Natural Gas Fuel System

WEICHAI & PSI SERVICE MANUALS AVAILABLE ONLINE AT FLYPARTSGUY.COM Figure 10: Closed Crankcase Ventilation System NATURAL GAS FUEL SYSTEM The fuel first passes the fuel shut off when the engine starts cranking. Then it goes through the DEPRs and comes into the mixers to be mixed with the air from the air filter as shown in Figure 11. -

Page 16: Lpg & Ng Bi-Fuel System

WEICHAI & PSI SERVICE MANUALS AVAILABLE ONLINE AT FLYPARTSGUY.COM LPG & NG BI-FUEL SYSTEM When the engine operates with LPG, the NG shutoff valve will be closed. The LPG first enters the LPG shutoff valve and then goes to LPG evaporator to turn the LPG to vapor and later enters the DEPR and further mixes with the air in the mixer as shown in Figure 12. -

Page 17: Pre-Catalyst Oxygen Sensor

WEICHAI & PSI SERVICE MANUALS AVAILABLE ONLINE AT FLYPARTSGUY.COM Figure 13: Cooling System PRE-CATALYST OXYGEN SENSOR Apply an adequate amount of anti-seize compound to the threads of the oxygen sensor and install the sensor in the O2 sensor port located on the exhaust manifold elbow pipe. Tighten the sensor to the... -

Page 18: Post-Catalyst Oxygen Sensor

WEICHAI & PSI SERVICE MANUALS AVAILABLE ONLINE AT FLYPARTSGUY.COM Figure 14: UEGO Sensor Installation POST-CATALYST OXYGEN SENSOR The sensor installation point must be sufficiently tested by the customer for functionality and durability. There shall be no possibility of exhaust leaks upstream of the sensor as exhaust pulsations can draw in ambient air leading to erroneous measurements. - Page 19 WEICHAI & PSI SERVICE MANUALS AVAILABLE ONLINE AT FLYPARTSGUY.COM System measures: Never switch on sensor heating before engine starting. Delayed switch-on or power control of the sensor heater (e.g. as a function of engine and ambient temperature), so that the max. allowed ceramic temperature is not exceeded when there is condensation water present.

-

Page 20: Catalytic Converter

Minimum distance between sensor and exhaust outlet should be 15.7 inches (400 mm). CATALYTIC CONVERTER A very important component in a low emission engine is the catalytic converter. Weichai engines use a TWC converter. For this type of catalytic converter to work properly, the following two criterion must be met: The air-to-fuel ratio must oscillate between rich and lean. - Page 21 WEICHAI & PSI SERVICE MANUALS AVAILABLE ONLINE AT FLYPARTSGUY.COM Vibration Vibration isolation must be provided between the engine and the TWC. Vibration isolation must be provided between the product and the chassis. Vibration acceleration loads shall not exceed 10g. Installation Product shall not support mounting loads from adjacent components.

-

Page 22: Flywheel

Figure 17: Catalytic Convertor Mounting Options FLYWHEEL The Weichai engines come with SAE 1 standard flywheel housing and flywheel SAE 3 adapter. The flywheel adapter will be used depending on the customer requirement and as shown in Figure 18. Contact Weichai representative for assistance of the connector/adaptor installation. -

Page 23: Adjustable Parameters

WEICHAI & PSI SERVICE MANUALS AVAILABLE ONLINE AT FLYPARTSGUY.COM ADJUSTABLE PARAMETERS This engine has been certified by the US EPA to operate on pipeline quality commercial Natural Gas fuel as well as commercial LPG/propane. The Fuel System is non-adjustable and it can compensate for changes within commercial fuels at different locations in the US. -

Page 24: Oil Level Gauge Installation

If a gauge was purchased through Weichai America Corporation, the connector on the wiring harness and the connector on the gauge should be a match. If the gauge was not supplied by Weichai America Corporation, please contact our service department and the right connector can be purchased. - Page 25 WEICHAI & PSI SERVICE MANUALS AVAILABLE ONLINE AT FLYPARTSGUY.COM hose at the desired length. Remove the oil cap, sandwich the Oil Balance Line Block with provided gaskets, place the oil fill neck assembly on top of the gasket and thread provided bolts into the four holes.

-

Page 26: Acronym Definition

WEICHAI & PSI SERVICE MANUALS AVAILABLE ONLINE AT FLYPARTSGUY.COM 4x M6x1.0x35 Gasket Oil Filler Neck Assembly Oil Balance Line Block Gasket 1/8” NPT to 3/8” Barbed Figure 11: Balance Line ACRONYM DEFINITION ABBREVIATION DEFINITION DEPR Direct acting Electronic Pressure Regulator...

Need help?

Do you have a question about the WP10NA and is the answer not in the manual?

Questions and answers