WEICHAI WP13 Series Operation And Maintenance Manual

Hide thumbs

Also See for WP13 Series:

- Operation and maintenance manual (33 pages) ,

- Operation & maintenance manual (94 pages)

Table of Contents

Advertisement

Quick Links

- 1 Main Structural Characteristics of the Diesel Engine

- 2 Meanings of Wp13 Series Diesel Engine Models

- 3 Diesel Engine Power and Speed

- 4 Chapter I Product Technical Survey

- 5 Main Technical Parameters of Wp13 Series Diesel Engines

- 6 Engine Lubricating Oil

- 7 Common Faults and Troubleshooting

- Download this manual

Advertisement

Table of Contents

Summary of Contents for WEICHAI WP13 Series

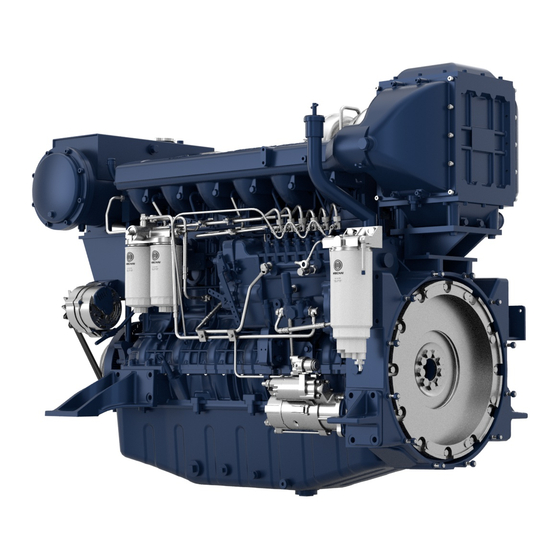

- Page 1 Operation and Maintenance Manual for WP13 Series Diesel Engines Operation and Maintenance Manual for WP13 Series Diesel Engines Weichai Power Co., Ltd.

- Page 2 Operation and Maintenance Manual for WP13 Series Diesel Engines Special Notes ◆ The fuel injection pump and injectors are precision components, so no adjustment or disassembly shall be available for any user. Otherwise, our company’s warranty will become invalid. ◆ The supercharger rotor shaft is a precision high-speed rotating part, so no dismantling or collision is permitted.

- Page 3 Operation and Maintenance Manual for WP13 Series Diesel Engines Precautions This diesel engine has been strictly tested in accordance with the test specifications before delivery, so never adjust the ECU data or increase the power of the diesel engine arbitrarily. Otherwise, our company will not implement the three guarantees.

- Page 4 Operation and Maintenance Manual for WP13 Series Diesel Engines Introduction The WP13 series diesel engines are of high-speed diesel engines developed on the basis of WP12 Landking diesel engines in accordance with National III / IV / V emission requirements and designed according to the relevant national standards. The...

-

Page 5: Table Of Contents

Meanings of WP13 Series Diesel Engine Models ..............1 Chapter II Technical and Performance Parameters of Diesel Engines ..........3 Main Technical Parameters of WP13 Series Diesel Engines ..........3 Chapter III Fuel, Lubricating Oil, Coolant and Auxiliary Materials for Diesel Engine ....4 Fuel............................ - Page 6 Operation and Maintenance Manual for WP13 Series Diesel Engines...

-

Page 7: Chapter I Product Technical Survey

Operation and Maintenance Manual for WP13 Series Diesel Engines Product implementation standards: Q/WCG134 WD10 Series Diesel Engines (for filing) Q/WCG131 WP10 Series Diesel Engines (for filing) GJBZ768A-1998 Guide for Fault Tree Analysis GJB/Z3-1988 After-sales Technical Services for Military Products GJB1443-1992 Quality Management Requirements for Product Packaging, Loading and Unloading, Transport and Storage A.1... -

Page 9: Chapter Ii Technical And Performance Parameters Of Diesel Engines

WP13 Diesel Engine Series Operating Manual Chapter II Technical and Performance Parameters of Diesel Engines 2.1 Main Technical Parameters of WP13 Series Diesel Engines Table 2-1 Main Technical Parameters of WP13 Series Diesel Engines Model WP13.480 WP13.500 WP13.530 WP13.550 Inline, water-cooling, four-stroke, direct-injection,... -

Page 10: Chapter Iii Fuel, Lubricating Oil, Coolant And Auxiliary Materials For Diesel Engine

Figure 3-1 Table for Grade Options of Lubricating Oil Attention: The WP13 series diesel engines shall never use any lubricating oil below level CF, and once the engine oil is replaced, you should replace the oil filter element at the same time! 3.3 Lubrication of Tension Gear... -

Page 11: Antifreeze Additive Of The Engine Cooling System

WP13 Diesel Engine Series Operating Manual 3.4 Antifreeze additive of the Engine Cooling System It adopts the antifreeze additive of ethylene glycol, with domestic long-acting antifreeze additive permitted for alternative, but the quality must be reliable, referring to the relevant instructions for its specific use. -

Page 12: Auxiliary Materials

WP13 Diesel Engine Series Operating Manual 3.5 Auxiliary Materials Table 3-2 Ser. No. Name Color Use and application Molykotte Pulver Coated on smooth metal surfaces to prevent occlusion Black (fine molybdenum For example: coated on the cylinder liner surface, etc. powder) Molykotte G.u.plus For lubrication before the lubricating oil has its pressure... -

Page 13: Chapter Iv Use And Operation Of Diesel Engine

WP13 Diesel Engine Series Operating Manual Table 3-3 References for Diesel Engine Sizing Brand Main uses List for sizing parts Additional remarks Bolts of the oil filter base Bolts of the oil cooler Plug screws of the oil cooler Coated on the thread regulating valve surface for fixing to As an option, DriLoc204... -

Page 14: Lifting Of The Diesel Engine

WP13 Diesel Engine Series Operating Manual ◆ According to the agreement between the manufacturer and the user, if the engine has been filled with coolant as the user requires, the coolant performance should be checked in time of unsealing; if the coolant antifreezing ability can satisfy the needs for -30℃ or -35℃, with its PH value and total hardness value of 7-8 (neutral) and 5-15°d [9-15°f (hardness)], then such coolant can be further used;... -

Page 15: Starting Of The Diesel Engine

WP13 Diesel Engine Series Operating Manual whether the starting system circuits are normally connected and whether the battery is sufficiently charged. Then open the fuel tank valve, loosen the vent screw on the fuel strainer, use the hand pump on the fuel strainer to exclude the air in the fuel system. 4.5 Starting of the Diesel Engine ◆... -

Page 16: Chapter V Regular Inspection And Maintenance Of The Diesel Engine

WP13 Diesel Engine Series Operating Manual ◆ The operating personnel should understand the following characteristics of the diesel engine: ① In time of the maximum torque, there will be lower fuel consumption; when the speed increases, the fuel consumption will rise. ②... - Page 17 WP13 Diesel Engine Series Operating Manual Figure 5-1 Expansion tank Figure 5-2 Check the engine oil level ● When the oil level is lower than the bottom scale line or higher than the top scale line of the oil dipstick, absolutely never start the diesel engine. Check the oil level after the diesel engine has been stopped for at least 5 minutes, so that the oil has sufficient time to flow back into the oil sump.

- Page 18 WP13 Diesel Engine Series Operating Manual Check whether the complete engine has water, gas or oil leakage Figure 5-4 Check the level of the urea solution. ● The level should be maintained at 30%-80% of the urea tank total volume. Check the fan.

-

Page 19: Maintenance Contents For Different Levels Of Maintenance

WP13 Diesel Engine Series Operating Manual Check whether the sound is normal. ● Check whether the speed and vibration is normal. ● 5.2 Maintenance Contents for Different Levels of Maintenance In addition to completion of the daily maintenance, the following contents should also be added: Replace the diesel engine oil. - Page 20 WP13 Diesel Engine Series Operating Manual Flywheel housing cover plate Pointer Flywheel groove Figure 5-11 Remove the valve rocker cover on the cylinder head to judge whether Cylinder 1 or Cylinder 6 is at its compression stroke (the cylinder in its compression stroke has clearances between its intake and exhaust valves and the rocker arm), as shown in Figure 5-12;...

- Page 21 WP13 Diesel Engine Series Operating Manual As shown in Table 3-1, use a feeler to check the clearance between the upper surface of the valve axle and the valve rocker arm. The WP13 diesel engine should have its intake and exhaust valve clearance of 0.4mm and 0.6mm respectively as required.

- Page 22 WP13 Diesel Engine Series Operating Manual Loosen nut 1; Adjust the adjusting bolt 1 until the contact clearance is 0 to the valve bridge; D. Loosen nut 2; Adjust the adjusting bolt 2 and insert a feeler gauge (0.6mm) between the adjusting bolt 2 and the valve bridge;...

- Page 23 WP13 Diesel Engine Series Operating Manual Figure 5-16 Exhaust the Air in the Strainer Drain the water in the water collector Attention! When the water collector is full or the spinning filter has been replaced, it is necessary to drain the water collected.

- Page 24 WP13 Diesel Engine Series Operating Manual Figure 5-18 Replace the Water Collector. Check the intake system, as shown in Figure 5-19. ● Check whether the air intake hose is aging or cracked and whether the hoop becomes loose. When necessary, tighten or replace relevant parts to ensure sealing performance of the intake system. Intake manifold Figure 5-19 Check the air filter element.

-

Page 25: Maintenance Of The Diesel Engine Kept In Storage For Long

WP13 Diesel Engine Series Operating Manual The diesel engine allows the maximum intake resistance of 7kPa, which shall be checked when the diesel engine is working at the rated speed and full load, and when the intake resistance reaches the maximum allowable limit, the filter element should be cleaned or replaced according to the provisions of the manufacturer. -

Page 26: Complete Regular Maintenance And Keep Detailed Records

30000km(400h) Routine maintenance Therein, for WG Class-II, contact Weichai Power Maintenance Service Center for National-III Landking Engines once every 10000 kilometers’ (200 hours’) working. A- First mandatory maintenance: replace the engine oil and oil filter, but do not replace the fuel strainer and fine filter elements. -

Page 27: Chapter Vi Analysis And Troubleshooting Of The Common Troubles

Chapter VI Analysis and Troubleshooting of the Common Troubles The WP13 series diesel engines are designed and manufactured in a strict quality assurance system, and each diesel engine has been tested as specified. At the same time, the diesel engine is a kind of precision machinery, with its long-term effect closely related to normal maintenance and services. -

Page 28: Common Faults And Troubleshooting

(1) The starter does not work The WP13 series diesel engines have their starters controlled by ECU, in time of normal work, the ECU will output a current to drive the starting relay, and after the relay is connected, the battery will drive the starter to start the engine. - Page 29 WP13 Diesel Engine Series Operating Manual Turn the ignition key to the “Start” position and check whether the starter acts (if other reasons have been eliminated). Starter (2) The rail pressure cannot be established (The starter can work normally, but it cannot start the engine) Vent bolt Oil return hollow bolt...

- Page 30 WP13 Diesel Engine Series Operating Manual ◆ Check whether the rail pressure sensor has its initial voltage of about 500mV, or check whether the set rail pressure is 30-50 MPa. It can be measured as follows: Enter the operation interface of the fault diagnosis instrument, select the “real values” and click “Next”.

- Page 31 WP13 Diesel Engine Series Operating Manual Select required function Press >> to continue Identification Fault memory Delete the faults in the fault memory Real values Implementation element “Next” Function test Enter the sub-interface for function test, select “Test of proportioning unit”, and click “Next”; Function test Starting fault information Compression test...

- Page 32 WP13 Diesel Engine Series Operating Manual Circuit tester Water Oil pressure sensor Camshaft speed temperature sensor sensor Crankshaft speed sensor Rail pressure sensor Fuel injector wiring Flow measurement unit connector...

- Page 33 WP13 Diesel Engine Series Operating Manual (4) The crankshaft and camshaft signals are missing On the diesel engine, there are two speed sensors mounted respectively outside the flywheel housing and the high-pressure fuel pump. The functions are respectively shown as follows: the crankshaft position sensor and cylinder identification sensor will decide the fuel injection timing of electronic control engine, and if a diesel engine cannot be started, such two signals have been missing.

- Page 34 WP13 Diesel Engine Series Operating Manual 6.2.3 Insufficient Engine Power Limp home: a mode of the engine operating with faults. The ECU detects the engine fault, but the engine will not stop immediately, but the engine power will be limited and the engine speed can only be increased to 1500 rpm for the driver to drive to the nearest repair station for troubleshooting.

- Page 35 WP13 Diesel Engine Series Operating Manual ③ The water tank is blocked: check the water tank and clean or repair it. ④ The water pump belt is loose: adjust the tension as provided ⑤ The water pump has its gaskets and impellers damaged or worn: check and repair or replace the faulty parts.

- Page 36 WP13 Diesel Engine Series Operating Manual First cut off the power supply and start the engine again in a minute. If the problem is still kept as usual, check the fuel pipeline air tightness and troubleshoot it. (6) Sensor fault The intake pressure sensor (installed on the intake manifold) is used by the ECU to estimate the air intake, the water temperature sensor (installed on the water pump) is used to judge the thermal load of the engine, and the rail pressure sensor (installed on the common rail pipe) is used to detect the...

- Page 37 WP13 Diesel Engine Series Operating Manual Use a tool to dry the connectors and then start again. Note: an accelerator of the same type should be needed in time of replacement. 6.2.5 Engine hunting during Idling ◆ Reason and troubleshooting of engine hunting: ①...

- Page 38 Appendix: Table for Power Correction Coefficients Temperature ℃ Air pressure kPa Note: the temperature and air pressure indicated in this correction table refers to the intake temperature and the pressure of the dry intake air (not equal to ℃ the atmospheric pressure) respectively; this correction table is only applicable to the temperature of 10-40 and the pressure of 80 -110 Pa.

Need help?

Do you have a question about the WP13 Series and is the answer not in the manual?

Questions and answers